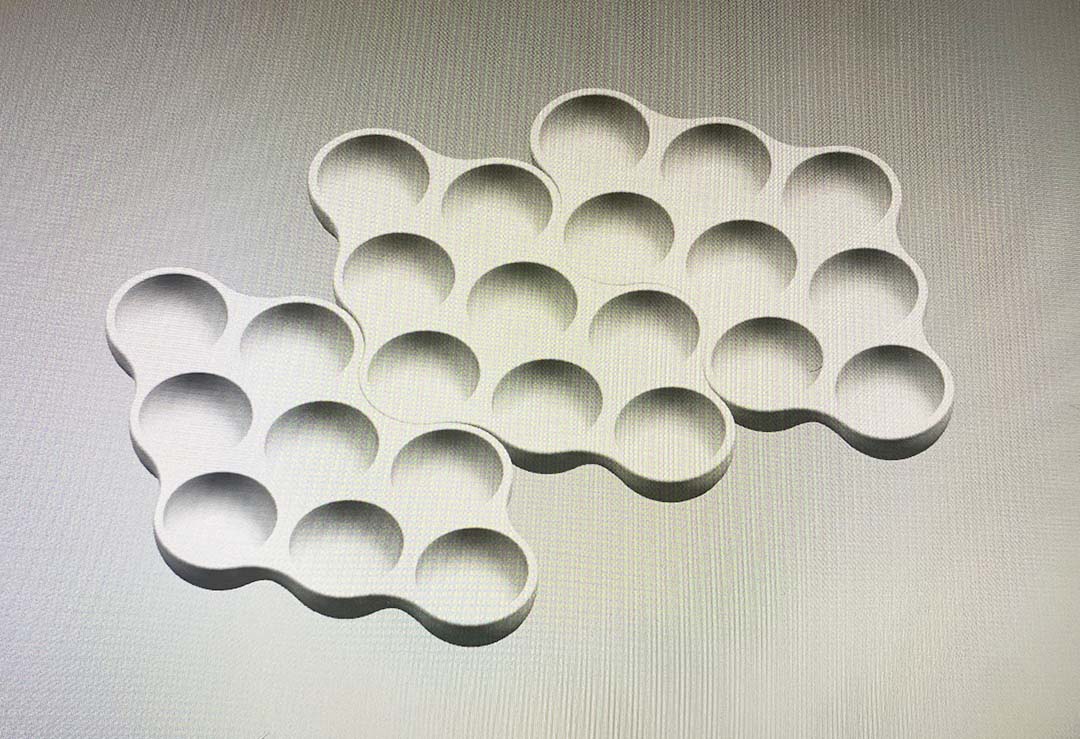

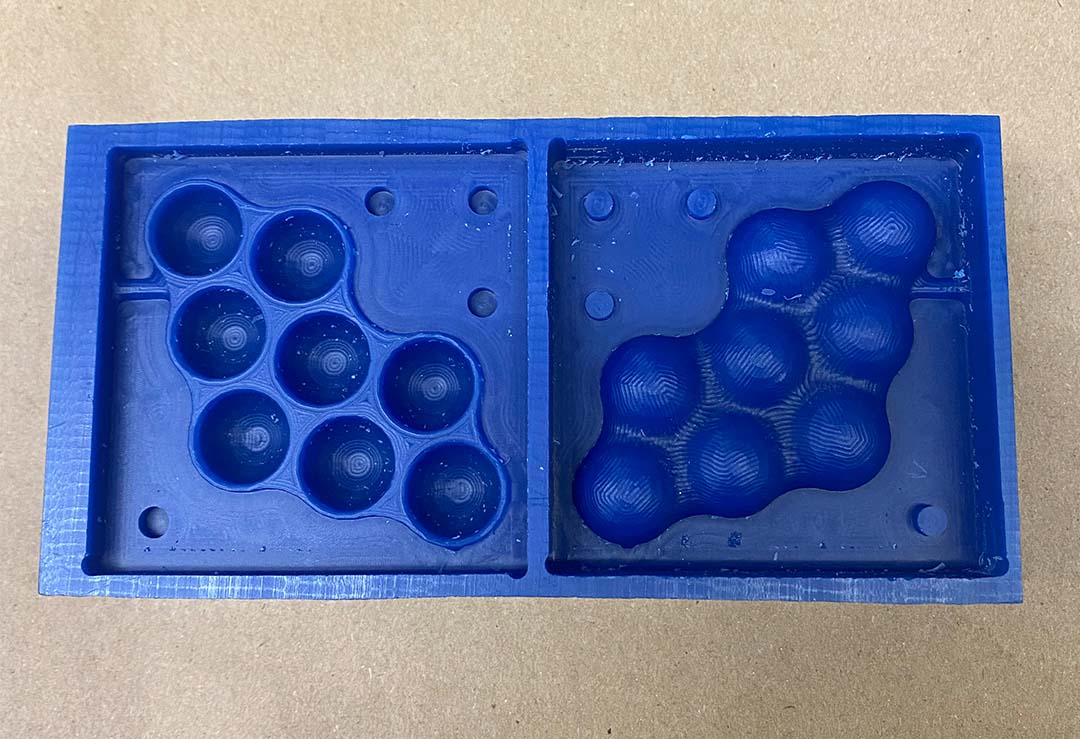

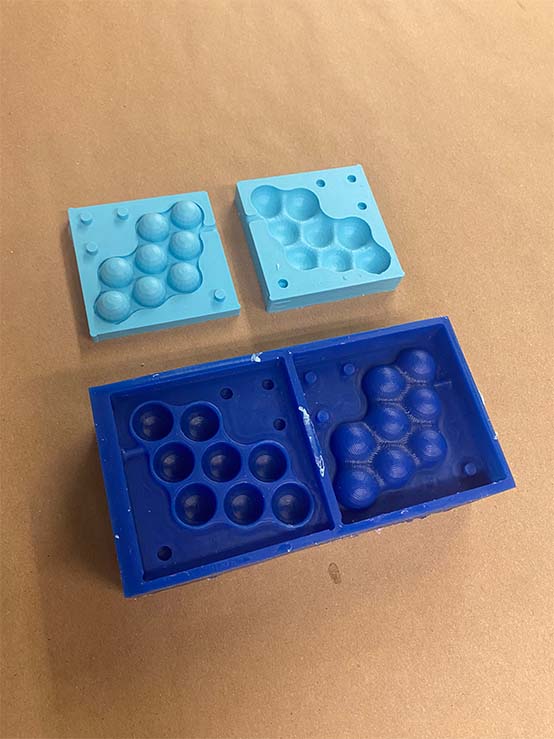

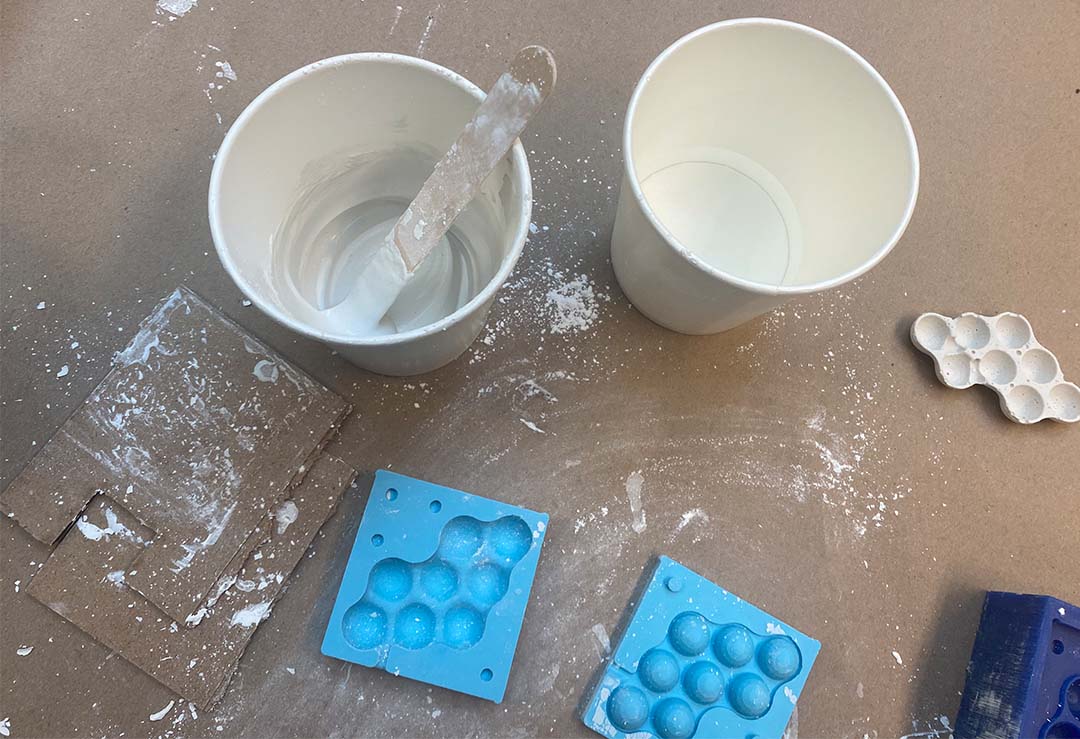

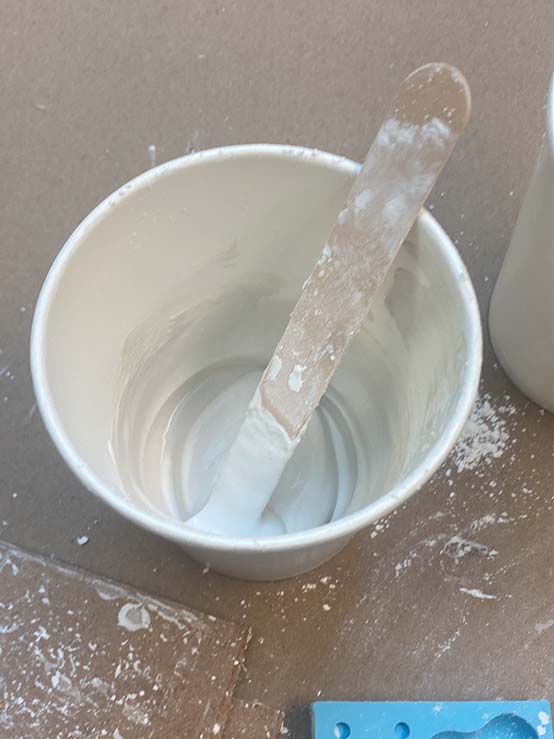

I figured out a few problems. First, The thickness of the product is

too narrow, only 2mm. It was very breakable and fragile. And also, I

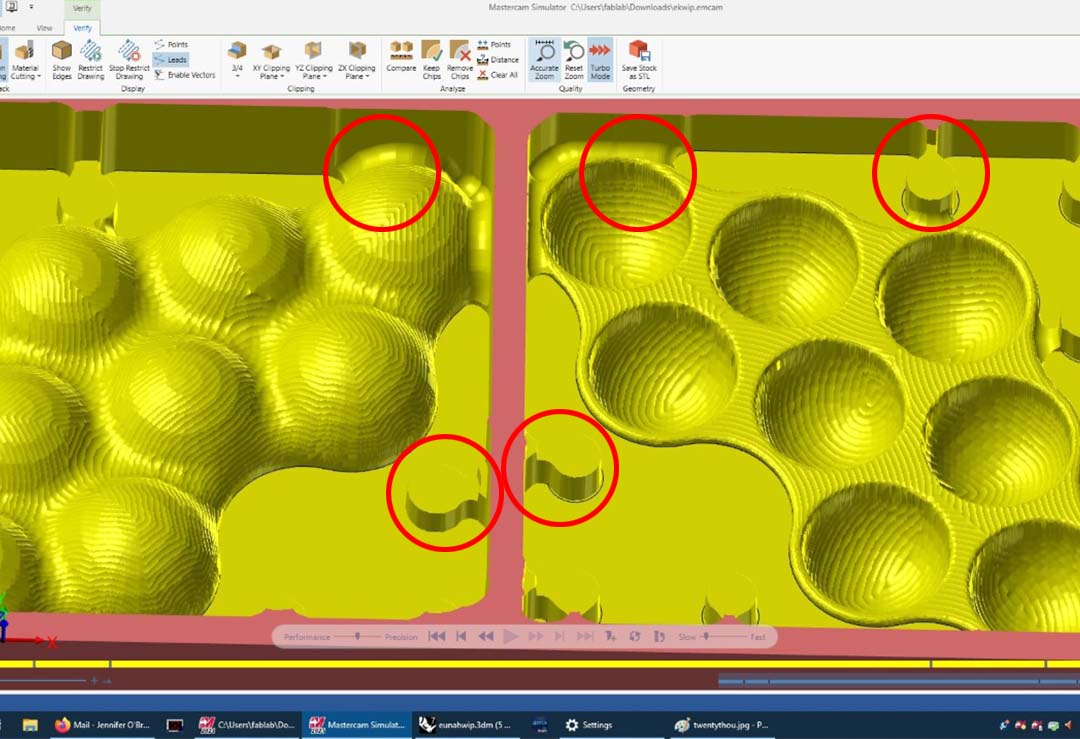

didn’t properly pop out the bubble makes a lot of holes. And Most

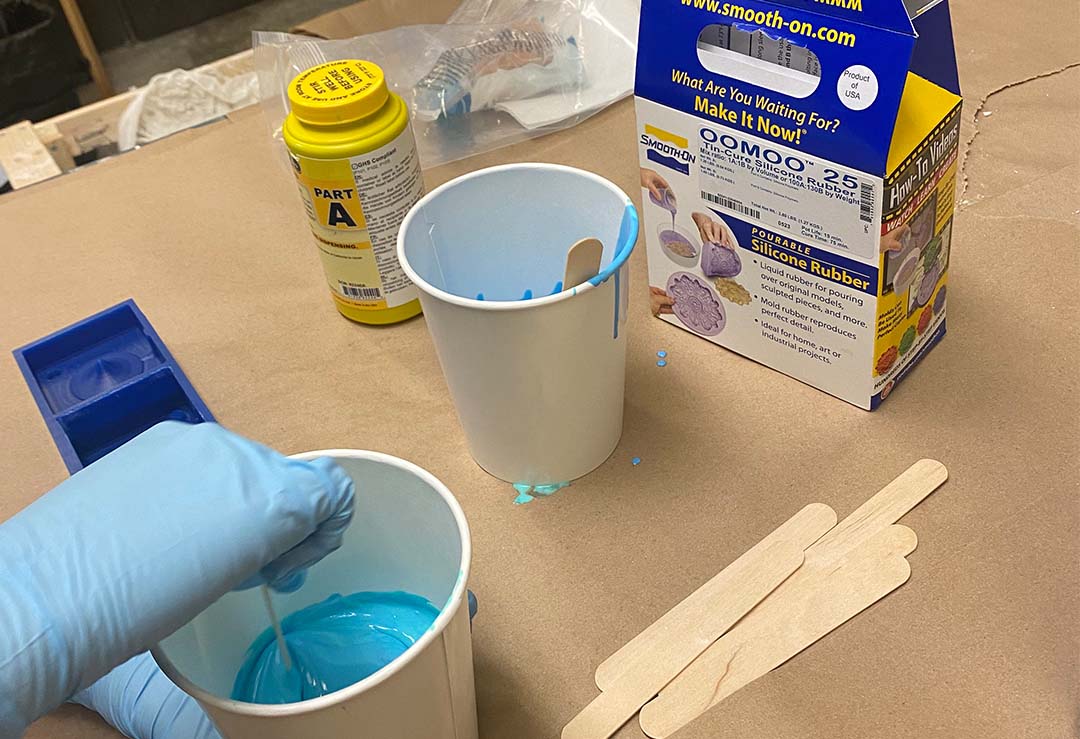

importantly, the ratio was wrong. It should be less water. so the

mixture should be more creamy rather than watery.