- wk6

- ∨ make something big

- ∨ cutting the file

- ∨ assembling the parts

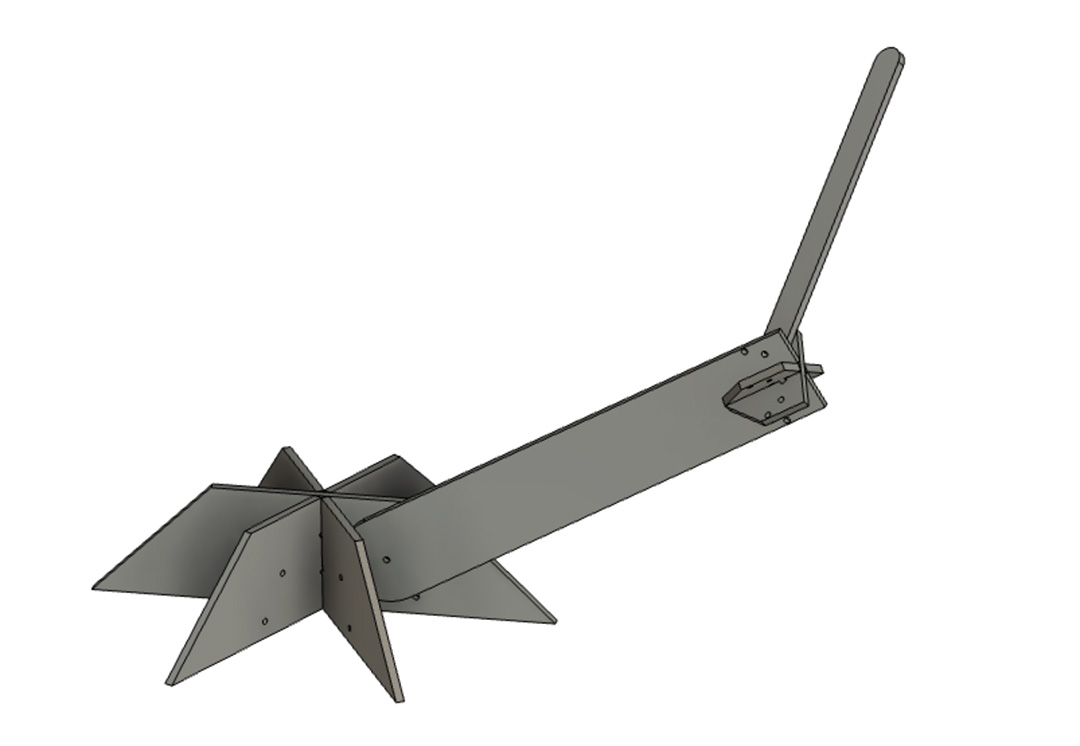

this week i'm gonna use the assignment to prototype and figure out geometry for my "grow a tetrahedron" final

i need the skeleton of the tetrahedron ( 120 degrees? )

to unfurl

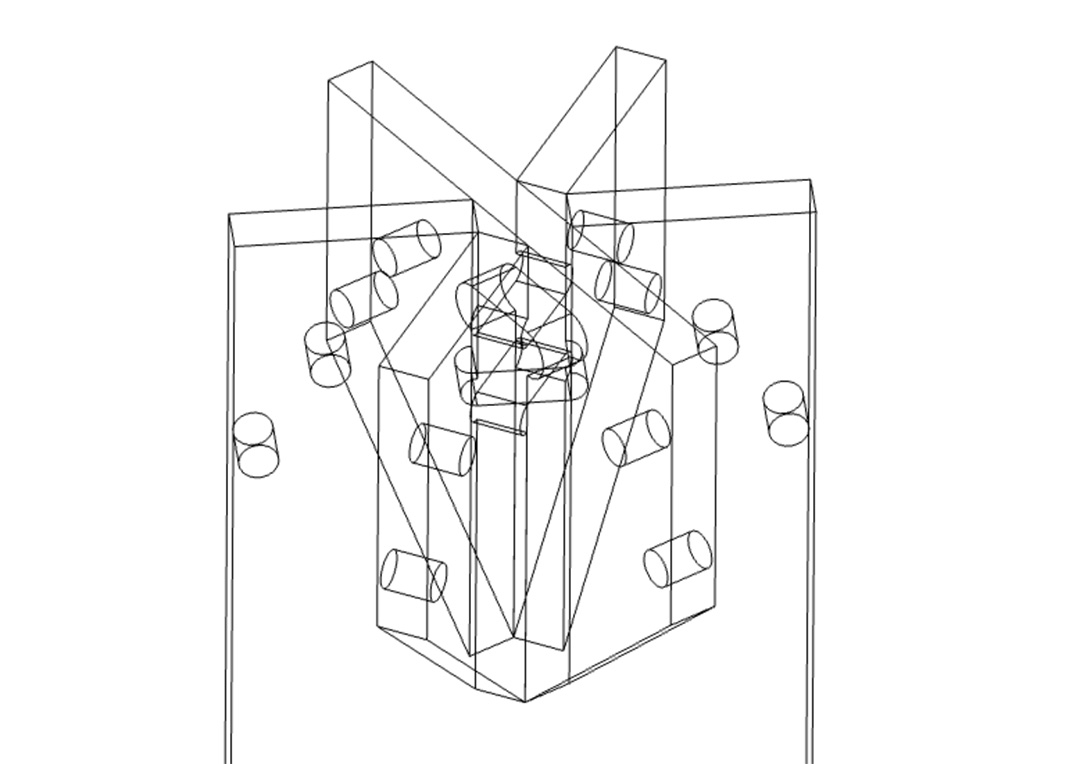

I only modeled one of each part

osb is short grain

doesn't have grain direction

orientation of parts on the sheet doesn't matter

i have a bucket of 5/16ths bolts

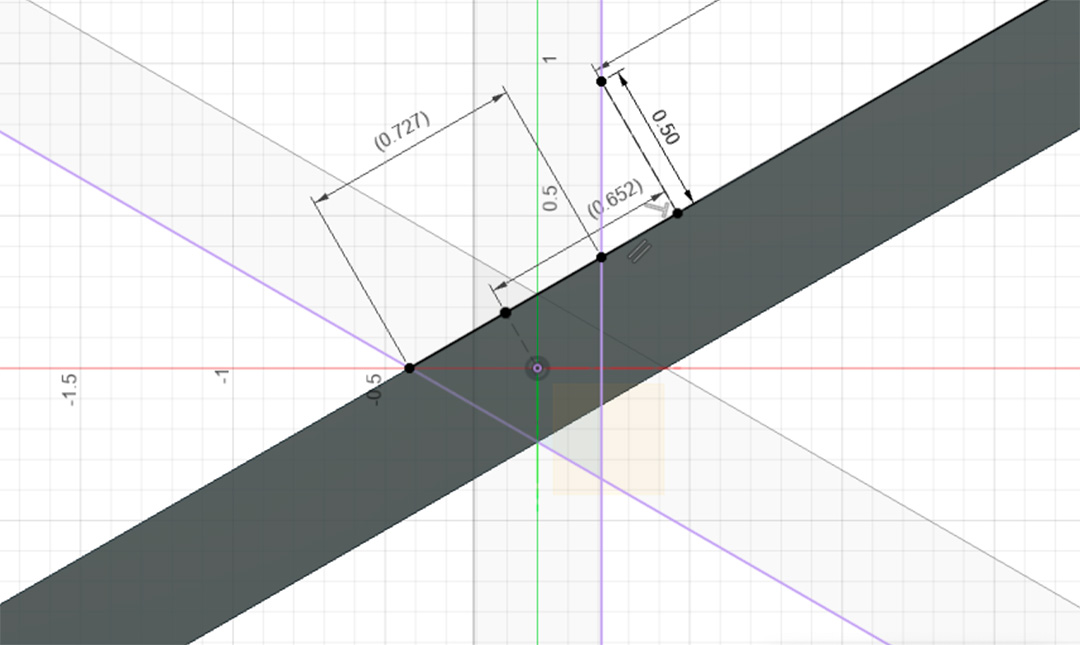

cad in fusion

0.727" hexagonal intersection

the triple lap joint

• 0.26" dia t-bone holes

• allows 1/4" bit contour

• lap has 0.13" clearance on middle section

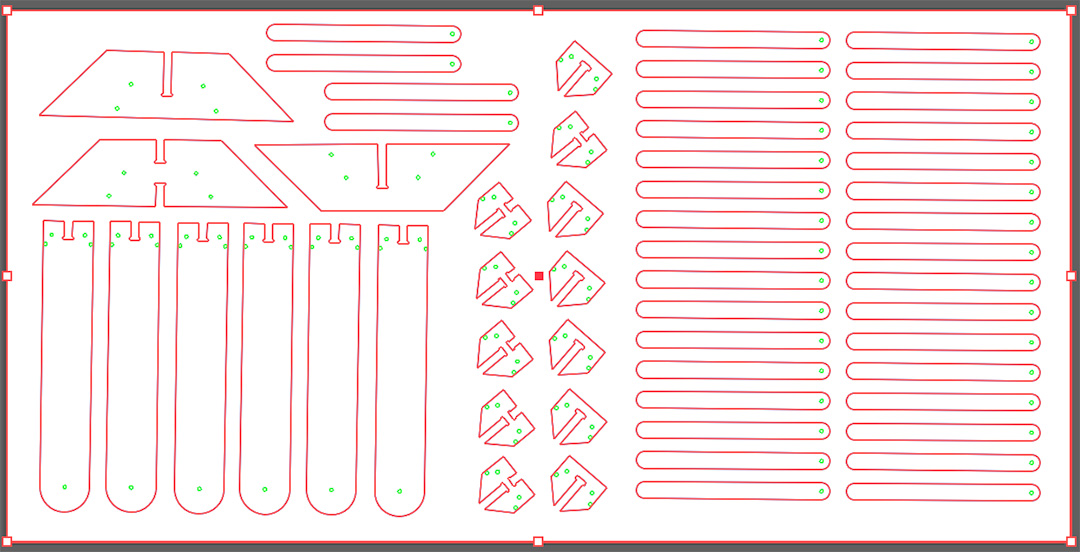

layout in illustrator

• make sure Scale Units 1 = 1 Inch

• make your artboard in Illustrator 48x96in, and layout lineart there.

• repeat: open up more .dxf's > scale 1=1 > and copy+paste the lineart to the first .dxf opened.

• lay out your work as you will. grain direction doesn't matter with OSB.

• put holes (tool inside of line) on one layer, and outlines (tool outside of lines) on another layer.

• or different kinds of tools onto their own layer.

• exporting the file as one .dxf will bring all the layers with it to mastercam.

holes and contours on separate layers

test cut

test cut - 0.42" for press fit

N51 archshops/chris will generate toolpaths in mastercam

email drawings (.dxf) in advance

• 4x8" board, nominal thickess 7/16"

• 3 tools. corners were remachined with 1/8" drill, and 1/8" sq endmill.

• 1/4in sq endmill for contours.

• 0.015in onion skin.

• 0.008in onion skin for regular plywood

• 0.005in bottom for thru-holes

dust collection system was down, clean after cut

vacuum table couldnt hold down osb, it was cupped.

turn vacuum on, shoot screws away from toolpaths.

(take measurements from drawing/cam)

the onsrud

vacuum (clean) by hand

• feed: 250ipm

• speed: 18000rpm

thnks benjamin for help

and cam

vacuum workholding is weak near origin, theres acrylic? sheet to seal that corner

vacuum sensors can be overridden on each quadrant, if P1 error comes on.

utility knife for onion skins

rasp to clean edges

dispose of skeleton

assembly

tri-lap joint

garage workspace

i took the parts home to assemble in my garage.

initially thought the holes were too small, and tried drilling them out.

turns out bolts could be just driven in.

maybe a couple thou bigger would be fine.

voila

unfurl a tetrahedron

geometry seems to work.

notice how each branch can tuck into the triangular region of the preceding branch.

hexagons inside hexagons

tetra pods