- wk8

- ∨ design node for diamond cubic lattice

- ∨ create toolpaths with mastercam

- ∨ mill master model on intelitek

- ∨ pour reoflex 30 urethane mold

- ∨ cast parts

- ∨ assembly

this week i'm gonna explore the geometry of the tetrahedral skeleton further

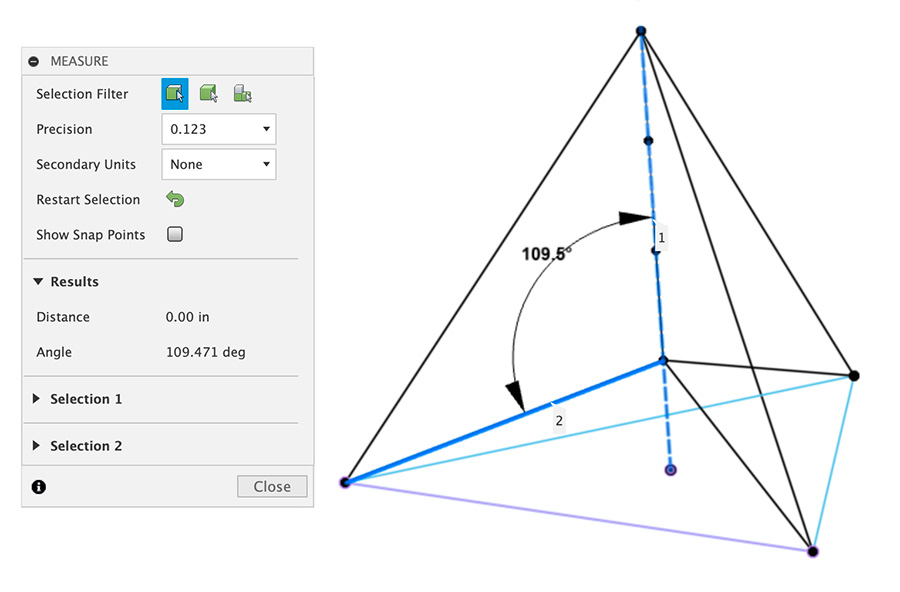

looking back at CAD from wk4 and wk6 the skeletal (voronoi?) has an internal angle of 109.471 degrees between members, not 120 degrees like i previously thought.

three members are always 120 degrees to the other normal member.

i have a bunch of sch 40, 1" pvc pipe

for which the parts will tenon into.

• ID: 1"

• OD: 1.315"

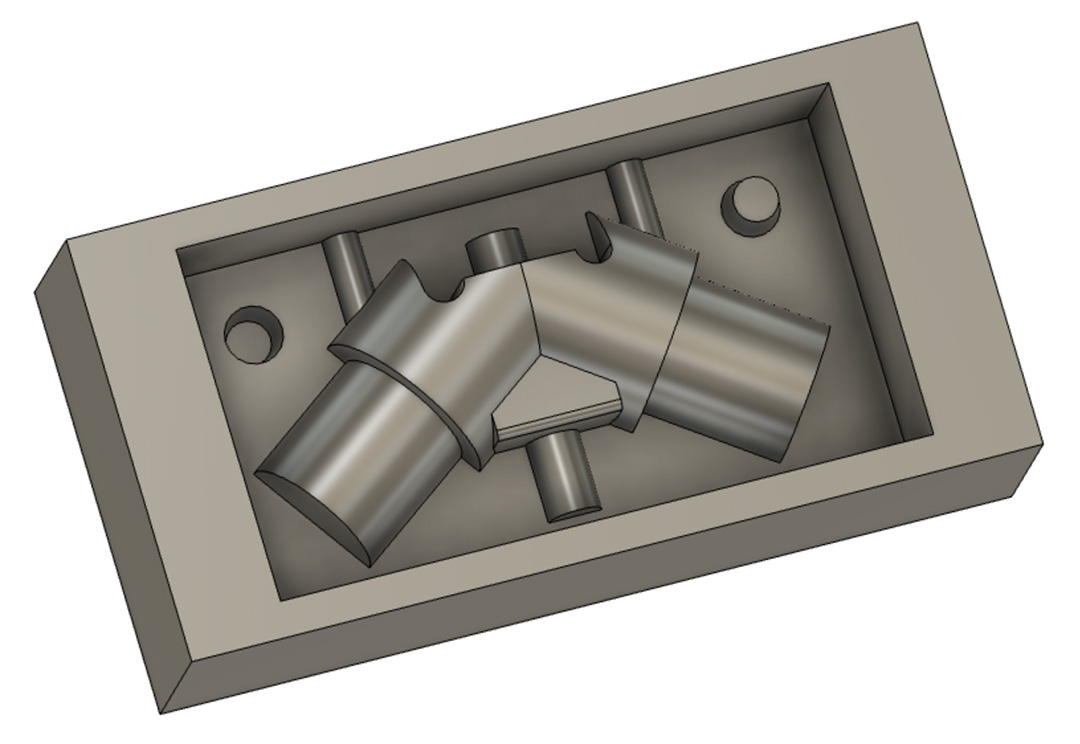

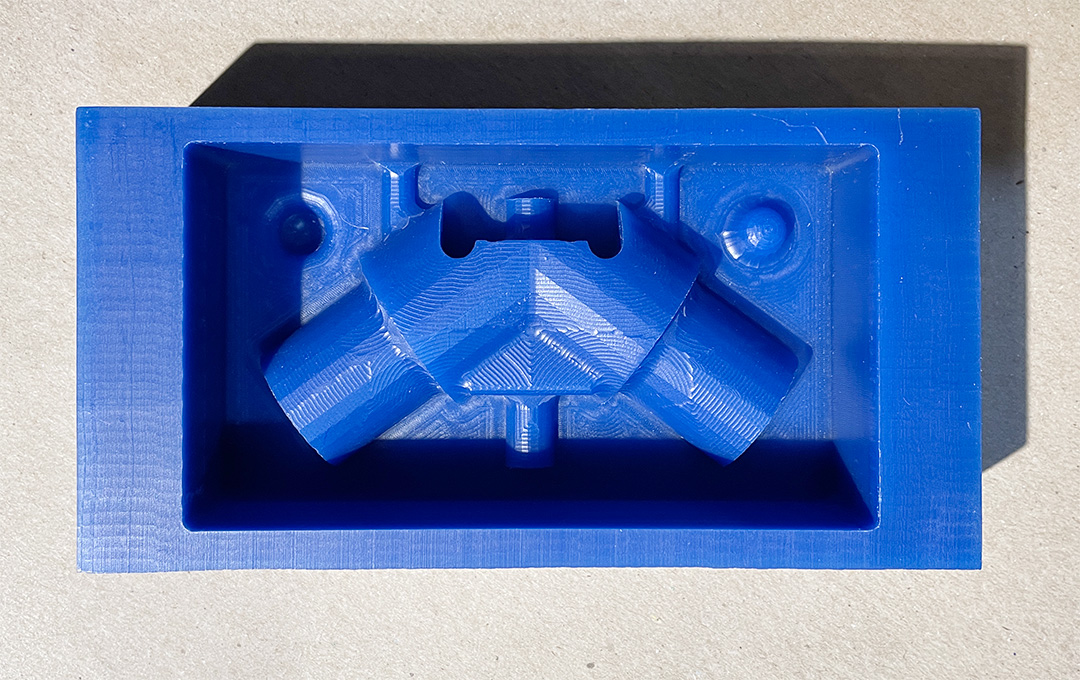

• master constrained by 3x6x1.5" machinable wax stock

• master-mold (wax) wall thkness: min 1/4"

• mold (urethane) wall thkness: min 0.26"

halves connected by 5/16th bolts

109.471 degrees internal angle

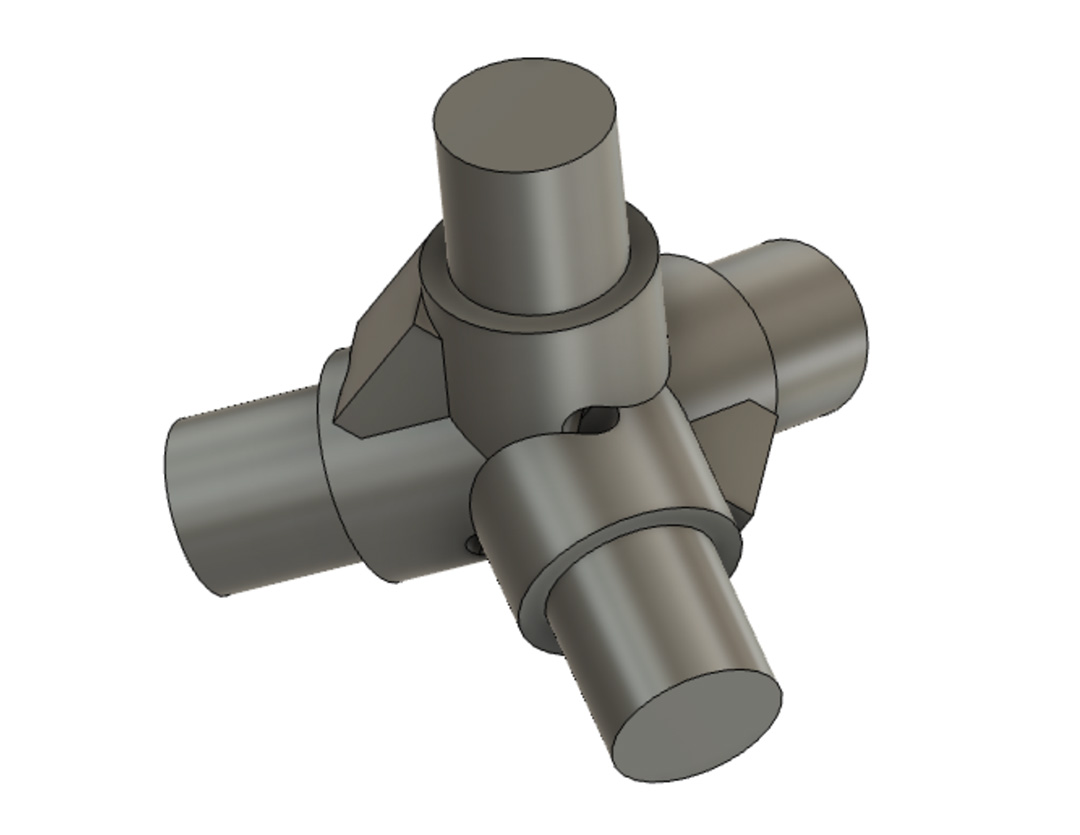

assembly of diamond cubic connector

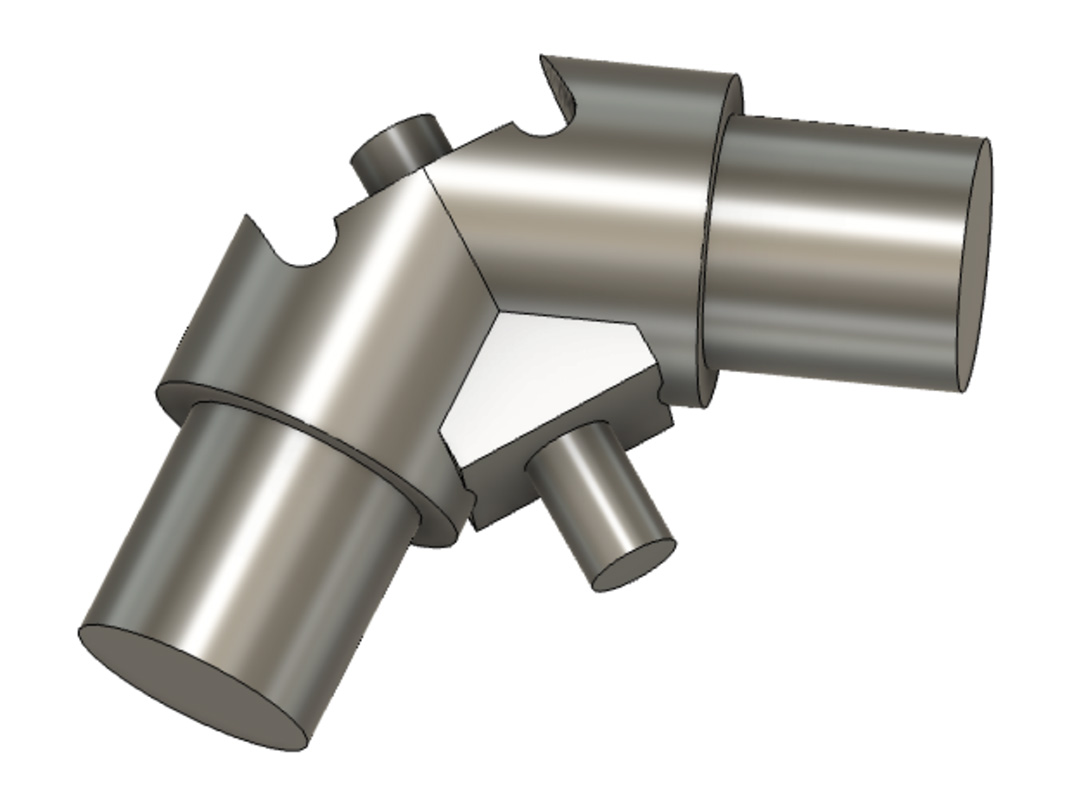

half component with removable core

quarter component with sprue and registration

half of half the component

for a two-sided mold

• add sprue(s)

• add registration bumps

• no taper added..

• 3/8" ⌀ removable core

• 0.26" tool clearance between part and wall

• 0.26" t-bone for mating face

• export as .step

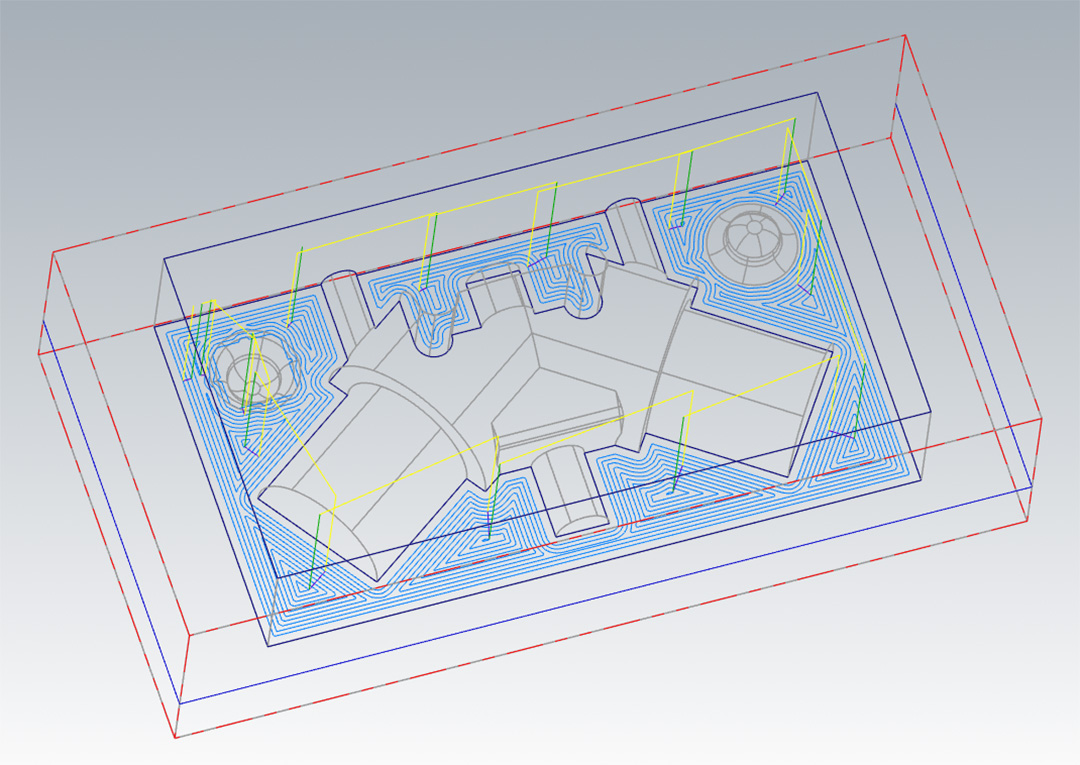

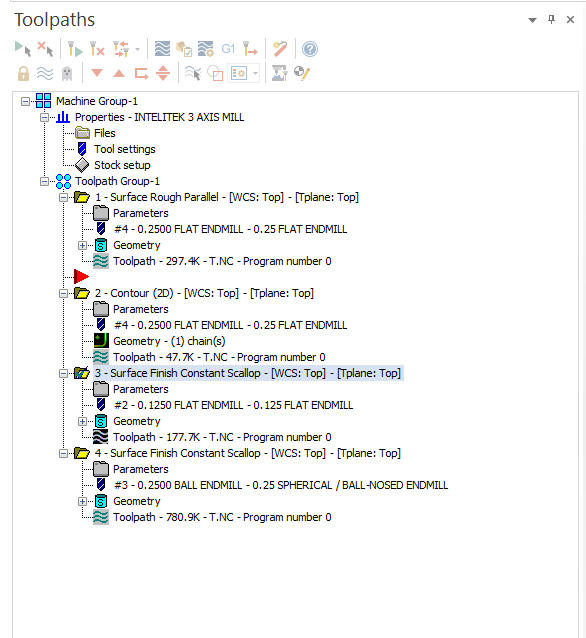

mastercam

1/8" flat, bottom and internal corners

1/4" ball, finishing pass

thurs

mastercam ain't easy (thnks jen!)

• check surfaces = avoid surface

• containment lines = tool boundary sketch

• parallel (1/4" flat) for roughing

• contour (1/4" flat) to clean wall

• scallop (1/8" flat) for bottom, internal corners

• scallop (1/4" ball) for finish surfaces

• simulate with "verify"

• "G1 icon" is post

• check post-processor

• tool library (offsets) is checked by jen

feeds and speeds:

• SFM for wax = 270

• S4000 F76 (for 1/4")

3 tools, exported separately

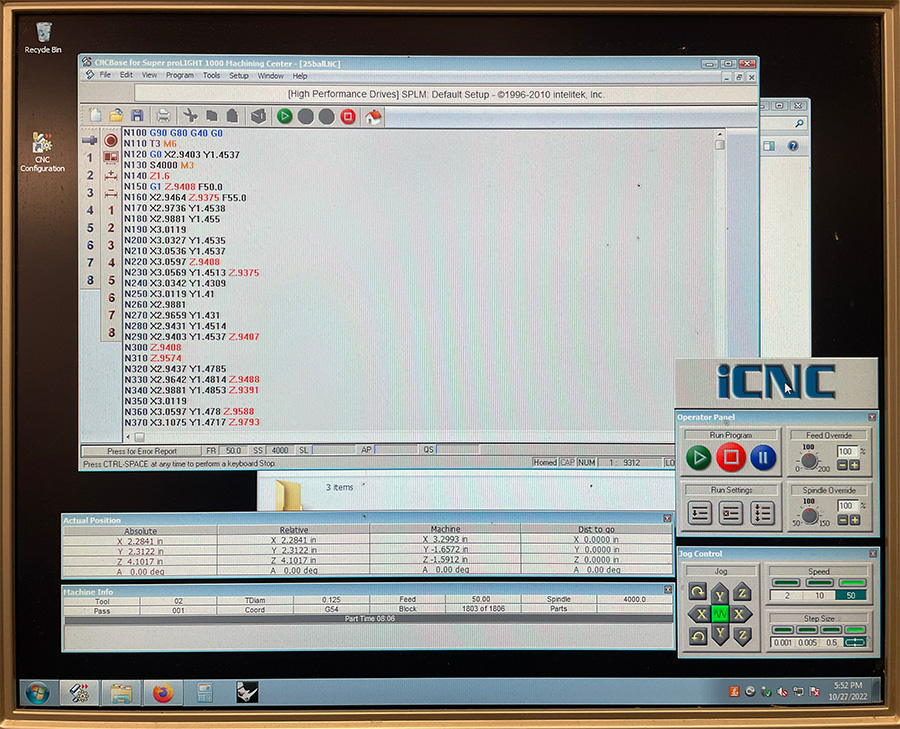

cnc controller - zero XY under "setup"

intelitek is locked out. get permission.

home machine

• open gcode file

• double check tool #

• insert tool into spindle

• jog to XY (eyeball)

• zero XY under "setup"

• Z0 is spoilboard.

• square stock to bed (eyeball)

• hot glue to spoilboard

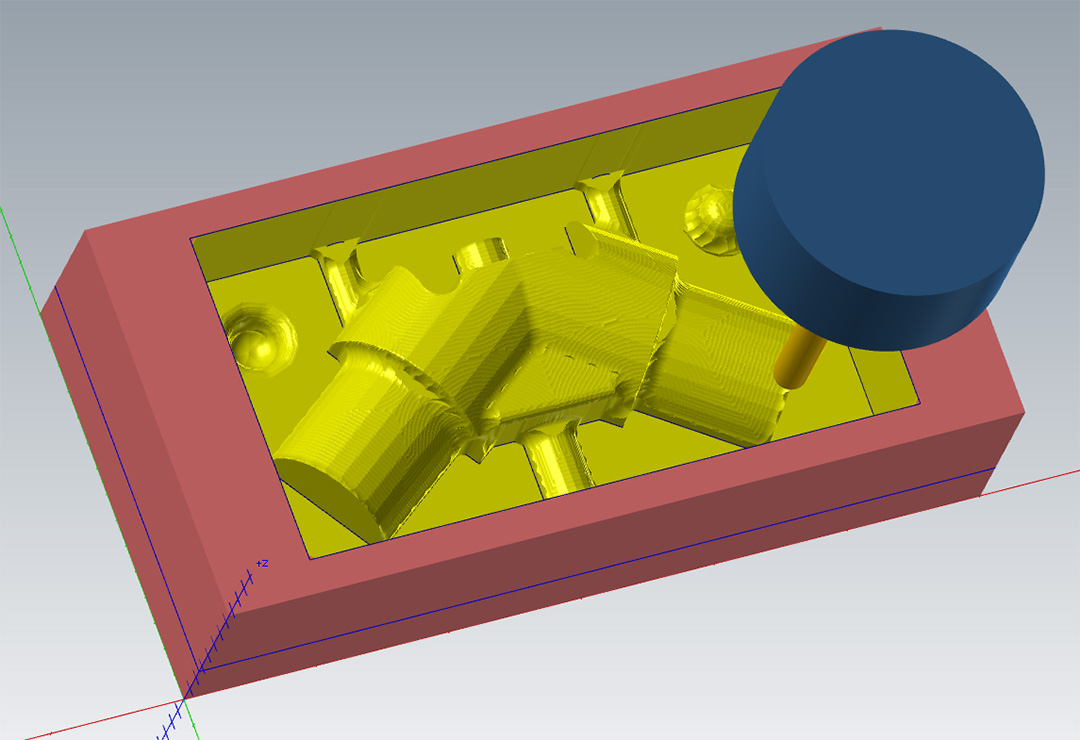

rough mill (1/4" flat)

vacuum between toolchange

finishing pass (1/4" ball)

master model

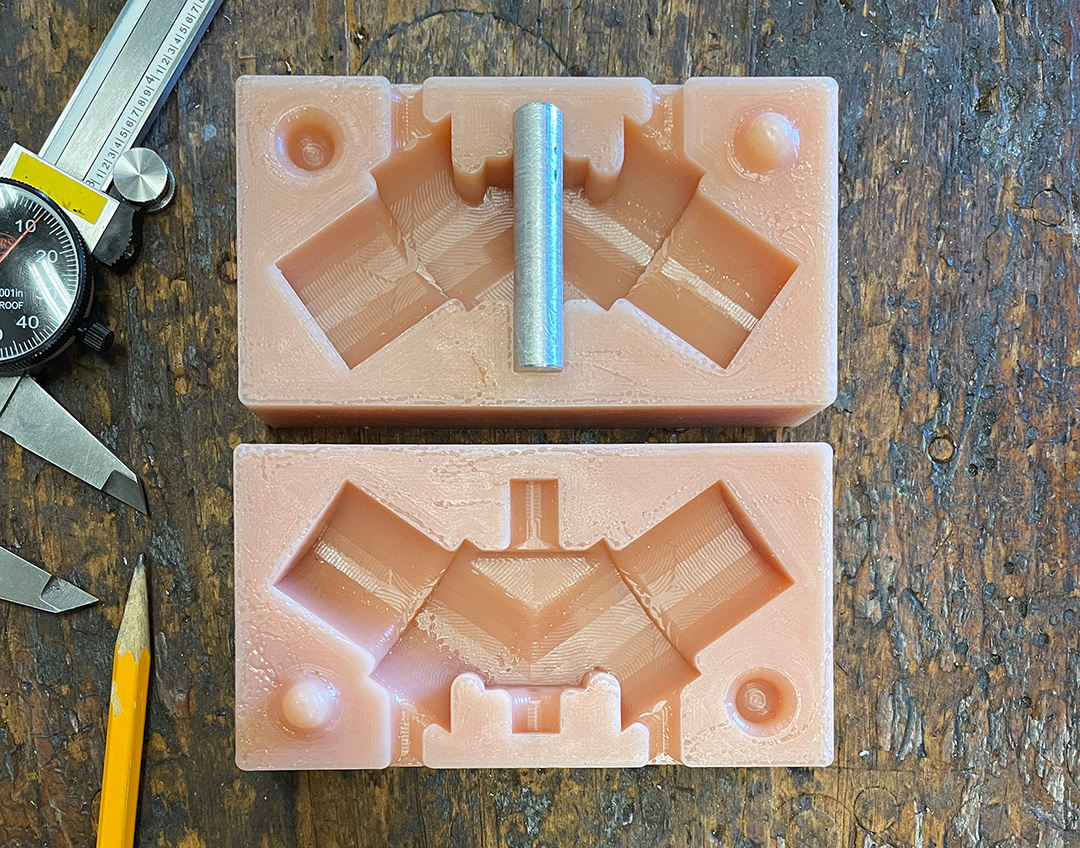

pour the mold

fri noon

1st half

using reoflex 30, urethane

pam for mold release, brush in corners

1:1 ratio

pour A or B into the other more viscous liquid

stir well, try not to fold air into it

• chip brushes

• gloves

• plastic cups

• tongue depressors

• fan+hepa for ventilation

• n95

should de-gas

basement shop

sat noon

2nd half

potlife: 30mins

cure: 16hrs

sun 10AM

demold 2nd half, looks good

go to shop to make core

• find 3/8th round stock in scrap bin

• cut close to length

• face

• break edges

facing 3/8" core

core

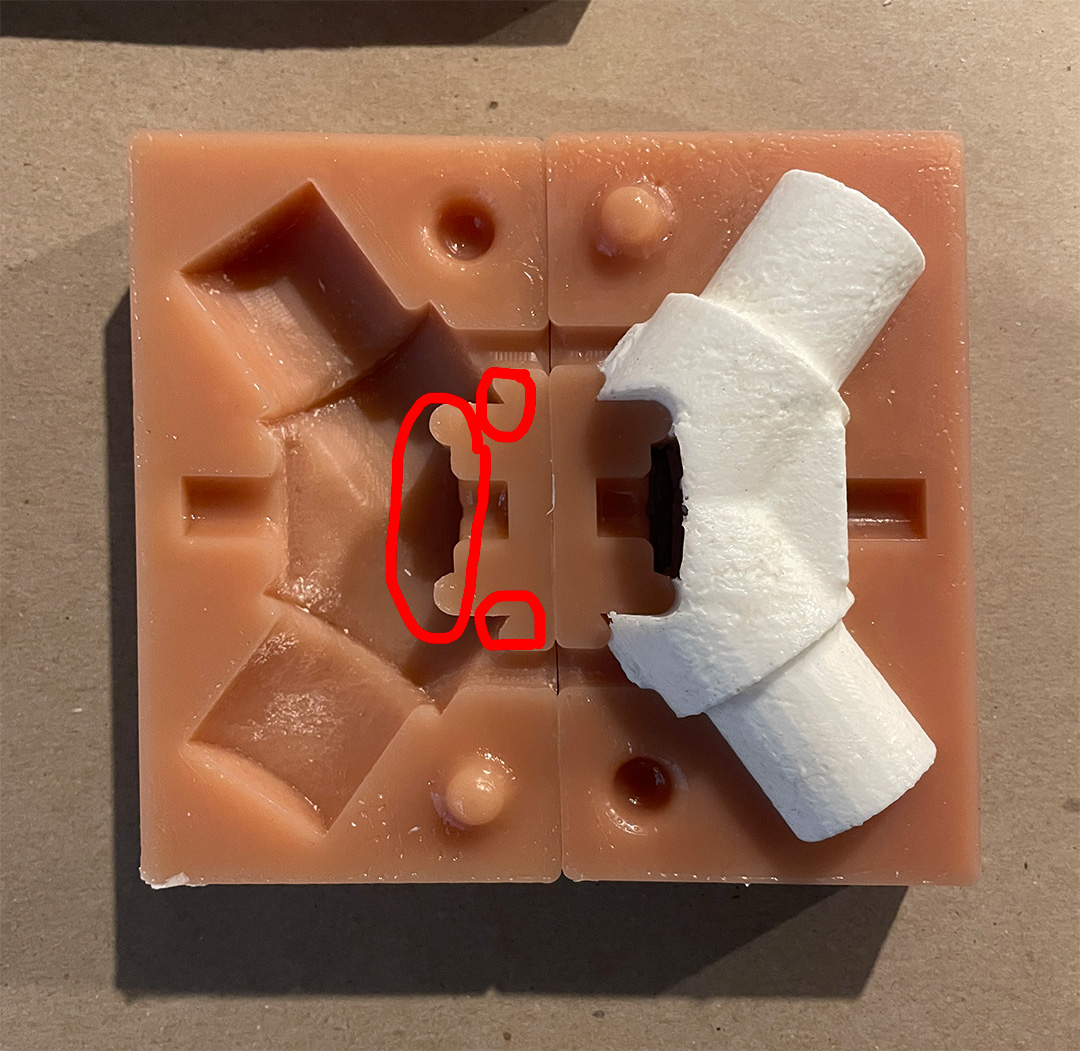

cast parts

dry run, make paper cone

turn on hepa fan, don't spill

2 pours on sunday

2 pours on monday

smooth-cast 310 - hard white plastic

1:1 ratio

potlife: 7mins

cure: 4hrs

air was getting trapped at the top of the mold

at two different locations.

i cut some relief into the urethane.

mold needs surgery

2x tetra / diamond cubic connectors

the kit

connected to 1" pvc

debrief

need better hepa fan

i should build this one.

• 2 spills - need to calculate mold volume

• restock: gloves, stirrers

mold started failing after 3rd cast

• got sticky. i didn't demold soon enough?

• is it because i used pam and not real mold release?