14

WILDCARD WEEK

This week I worked on computer controlled cutting using a waterjet.

| Tools: | OMAX waterjet, OMAX software, Rhino, Metak Rasps |

| Files: | Frame Model, Frame Parts Layout |

| Date: | 12.14.2022 |

Design

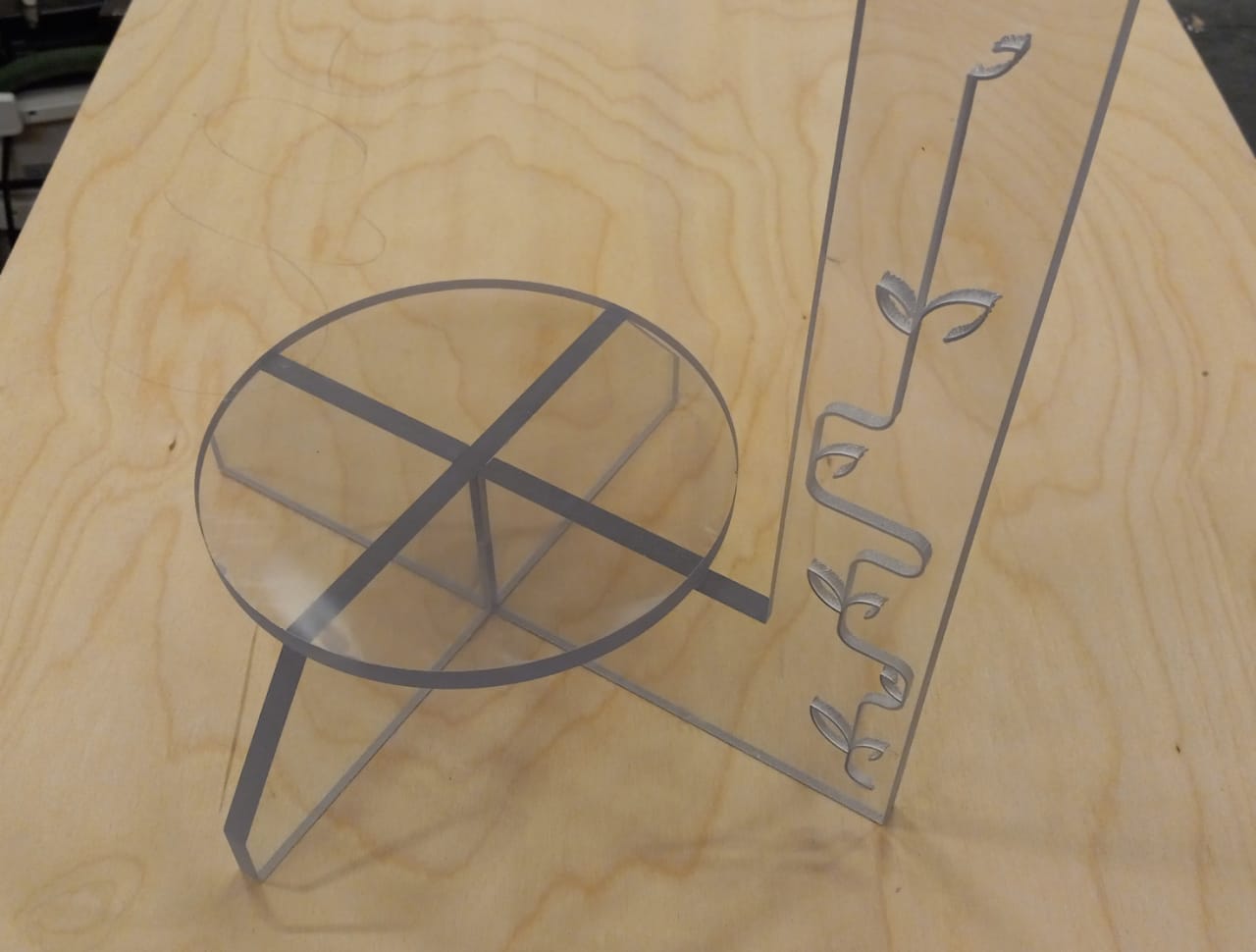

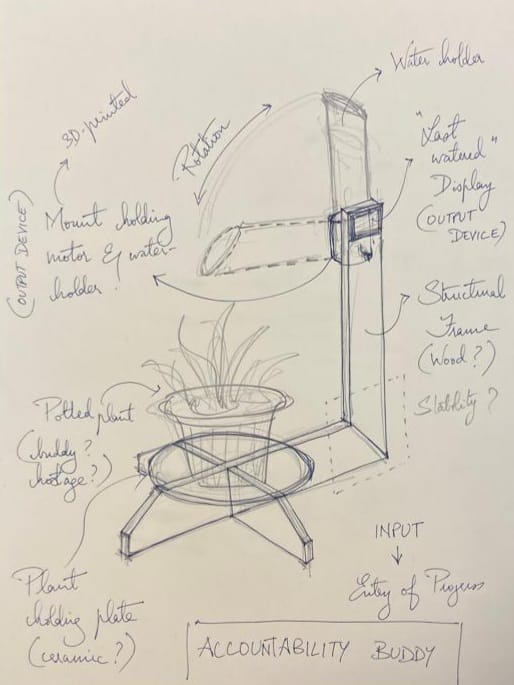

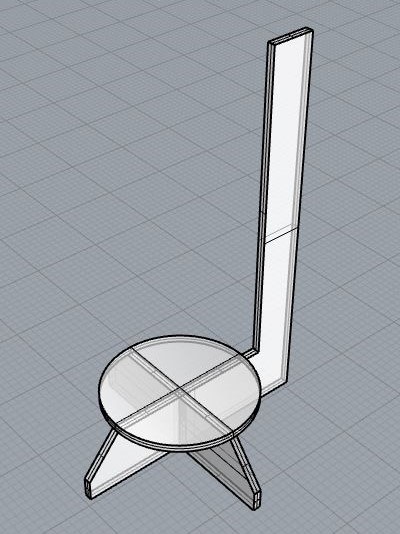

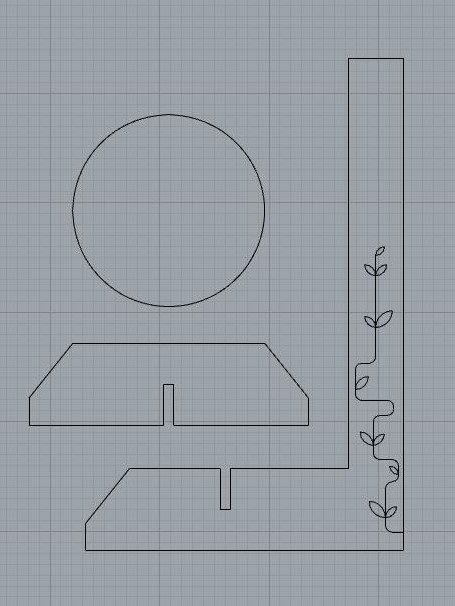

I decided to make something that would be useful for my final project--a frame to hold the plant and the watering mechanism. I ended up modelling this frame after that of our pancake bot from last week. I wanted the frame to have a relatively light aesthetic, so I decided to use a transparent polycarbonate sheet. Thankfully, I found a scrap 3/8" polycarbonate sheet in the archshop. I had to edit the design to fit the parts in the sheet, but it all worked out (mostly).

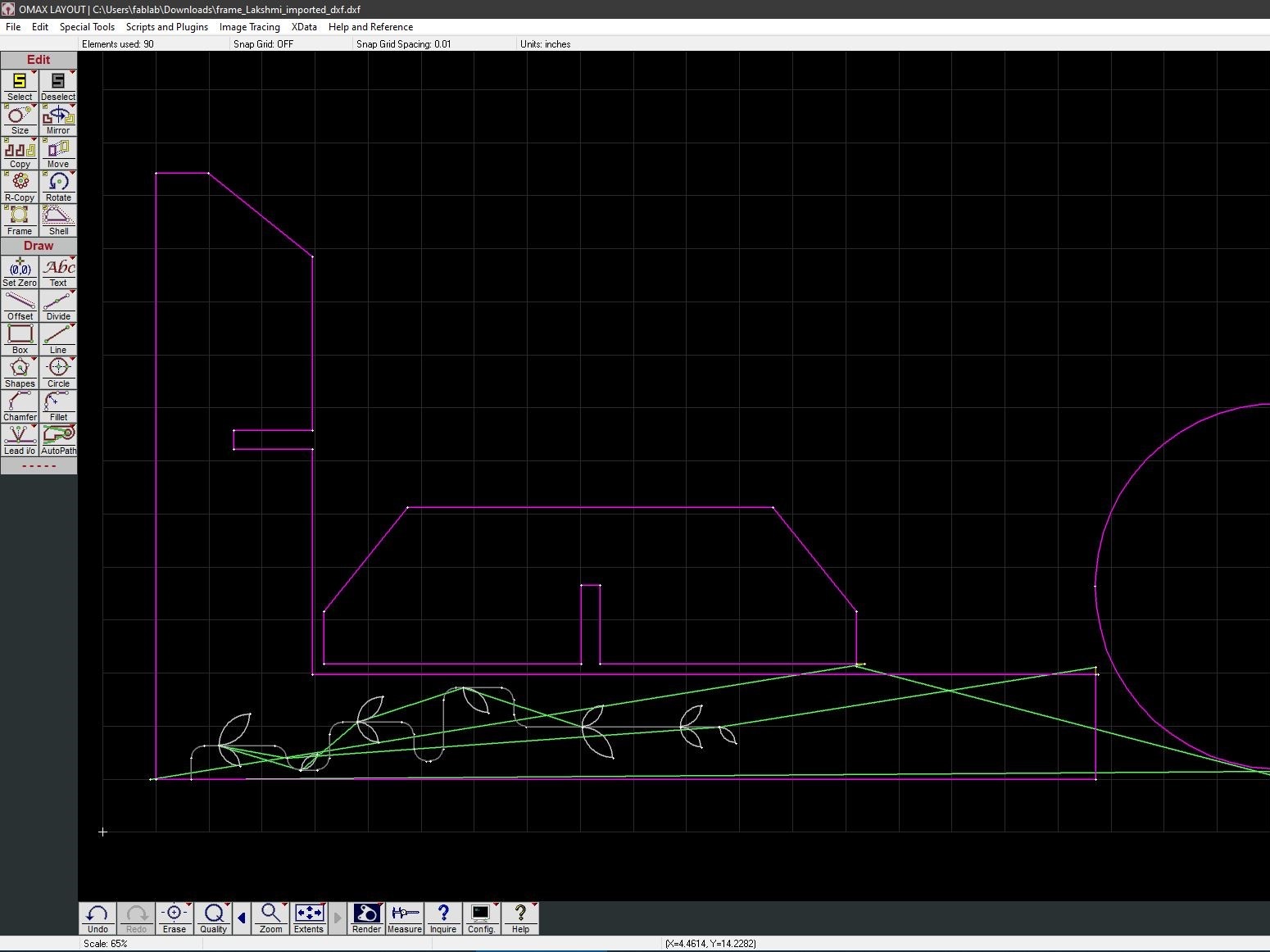

Setting Up

The appeal of the waterjet is that it can cut through anything. However, it is one of the messiest computer controlled cutting processes I've tried so far. The setup too is longer than with other machines:

1. The material needs to held down properly (the archshop uses scrap lead ballast blocks) to avoid the water from displacing it, so there needs to be room on the material to allow for this OR you need to pause the job at various points to move the weights out of the nozzle's path.

2. Because the nozzle of the jet has to be very close to the surface to be cut, we need to jog the nozzle to various points in the cutting path to check for clearance.

3. Added to this, the software has a mind of its own. The path the nozzle takes seems kind of unpredictable and may need minor adjustments in the dxf to result in the intended changes to the path.

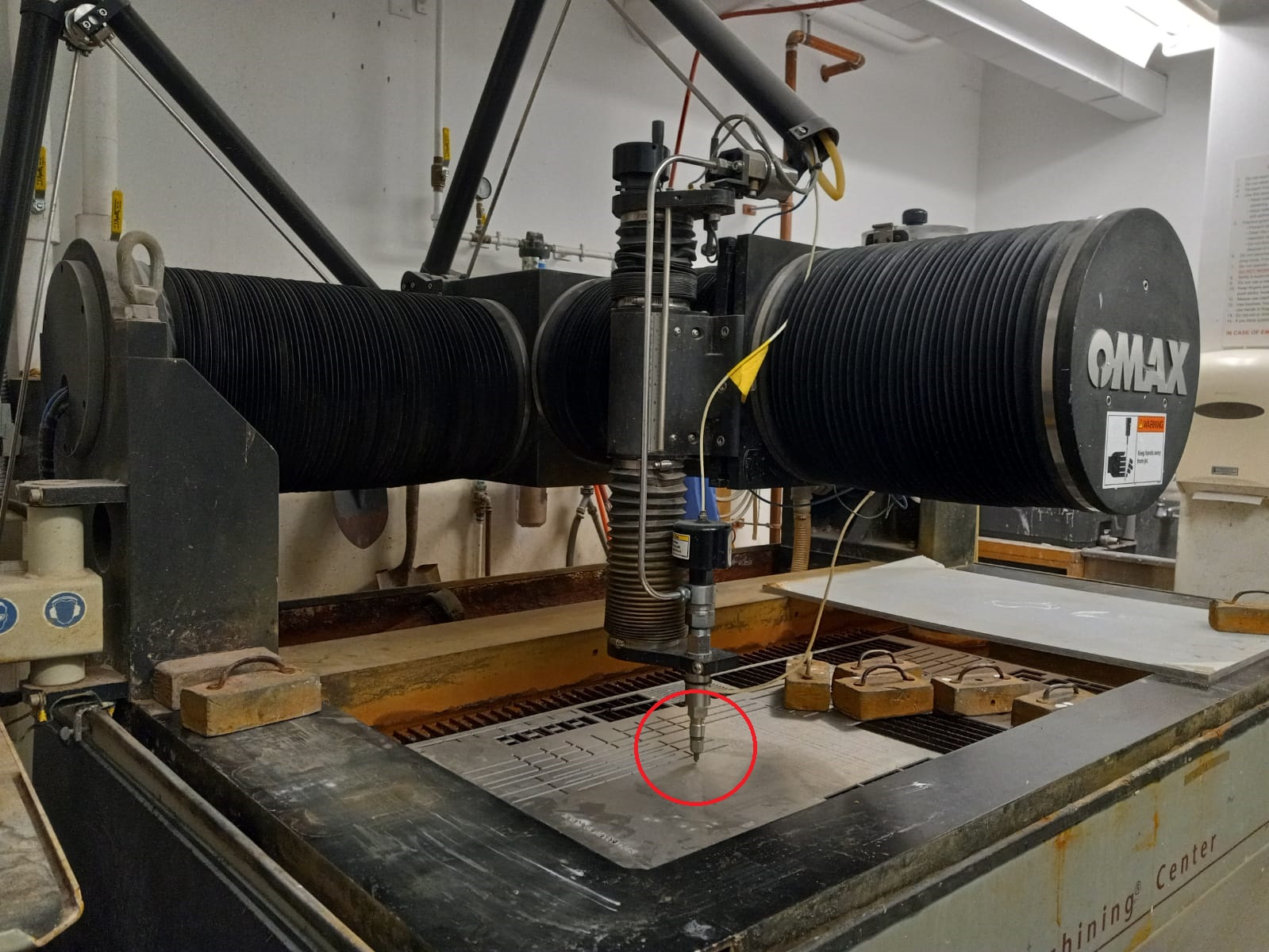

Cutting

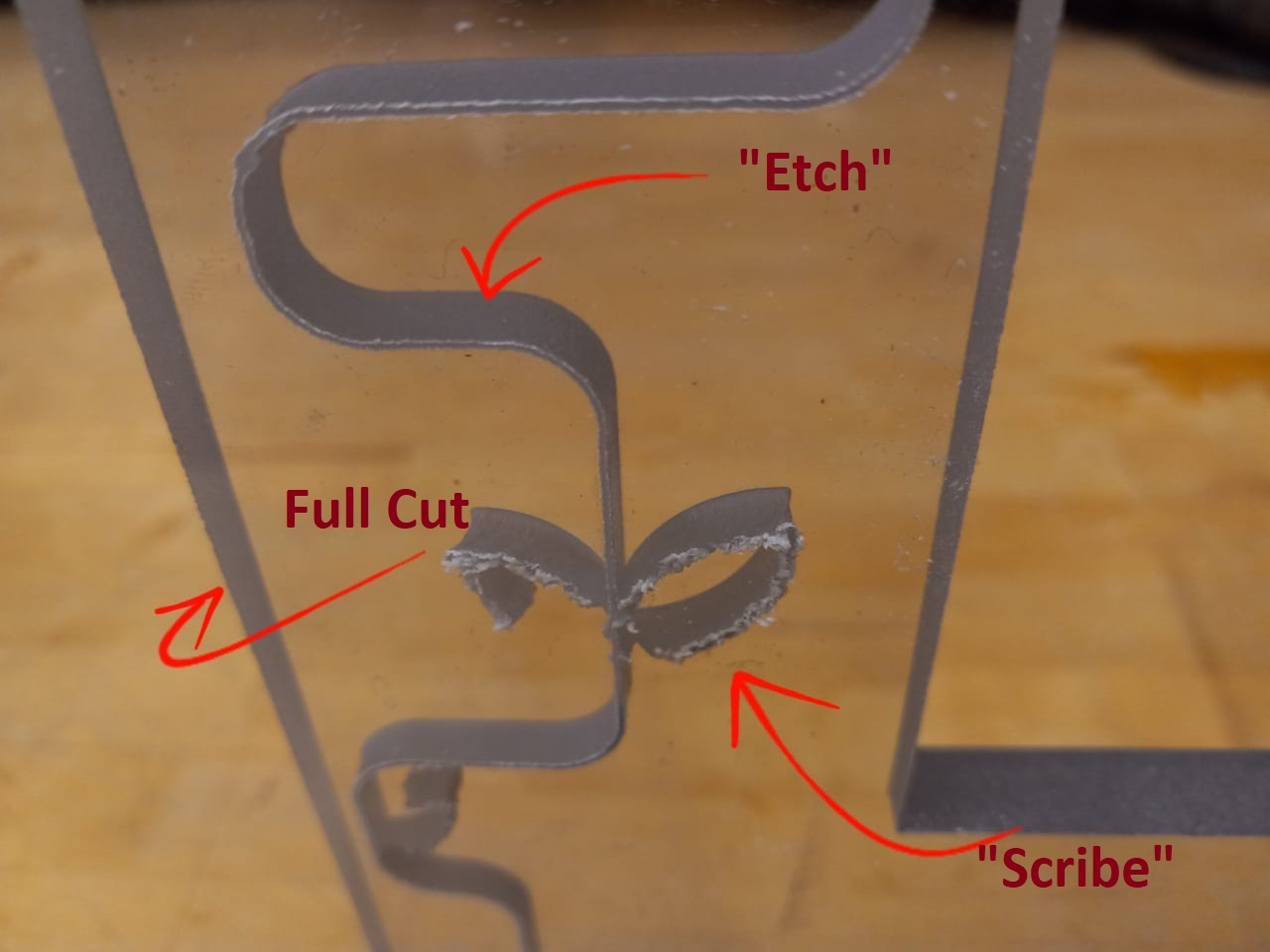

The cutting itself was quite fast. Waterjet cutting is not really recommended for anything besides full cuts, but I decided to try etching anyway. The result was not great. The biggest problem was that the "etch" and "scribe" settings on the separate layers ended up cutting through the entire thickness of the material! The machine also left out "etching" some parts altogther (seemingly arbitrarily).

The assembly of the frame was straightforward, but needed some filing and nudging. I could've increased the thinkness of the press-fit joint, especially since polycarbonate does not have much give, like wood.