Week 2: Electronics Production

Group Assignment

Group assignment answers can be found here: Group Assignments

In-Circuit Programmer

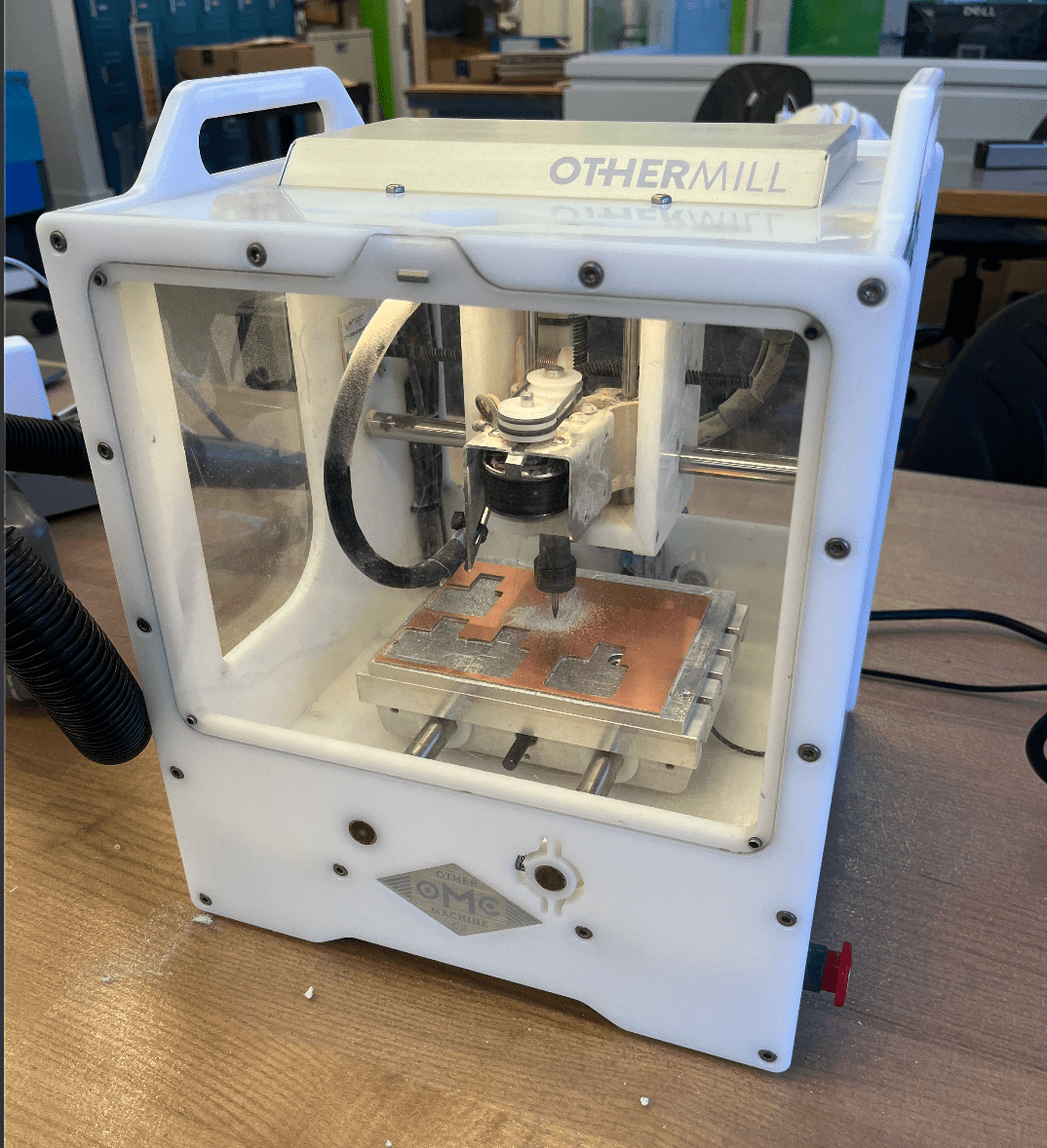

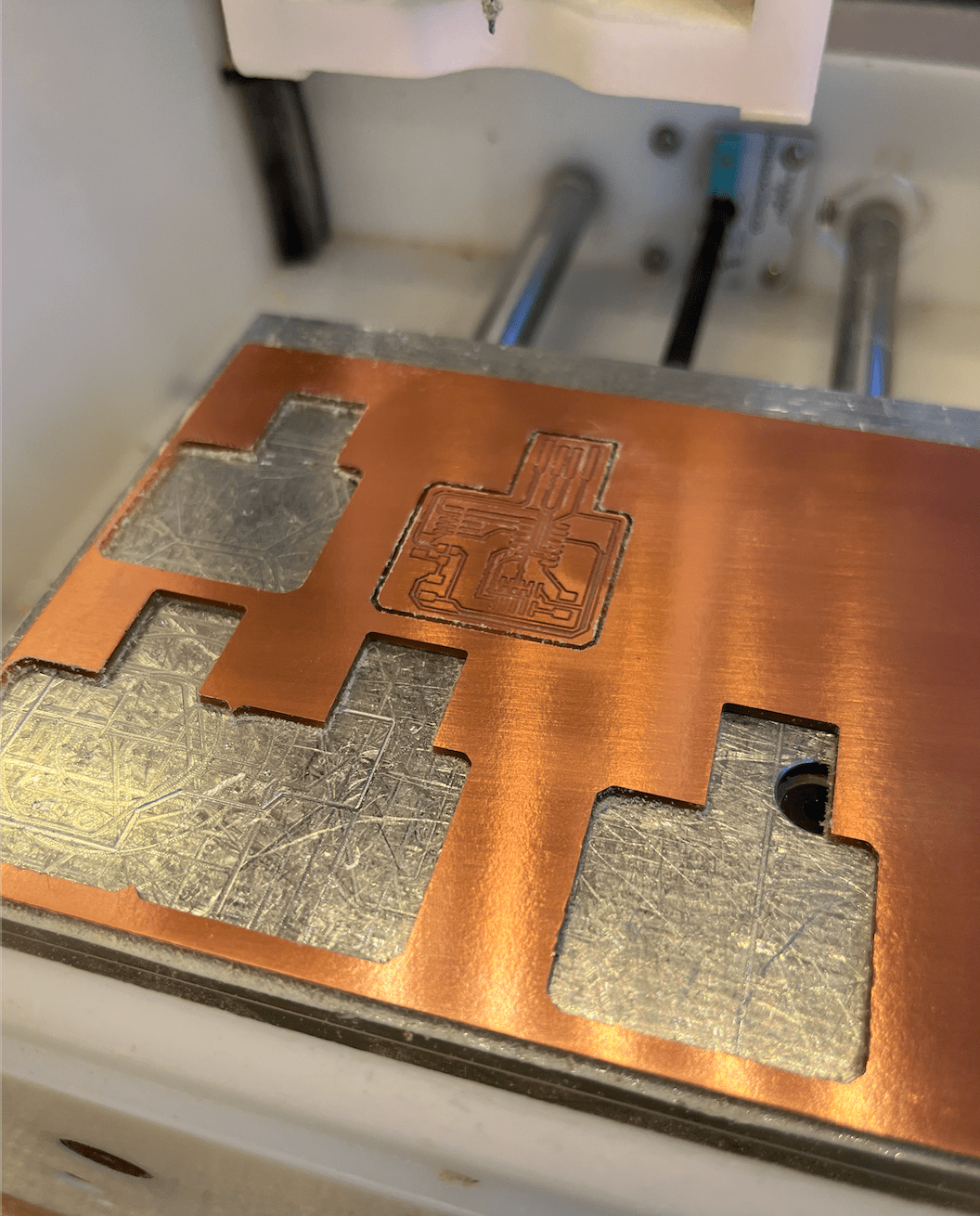

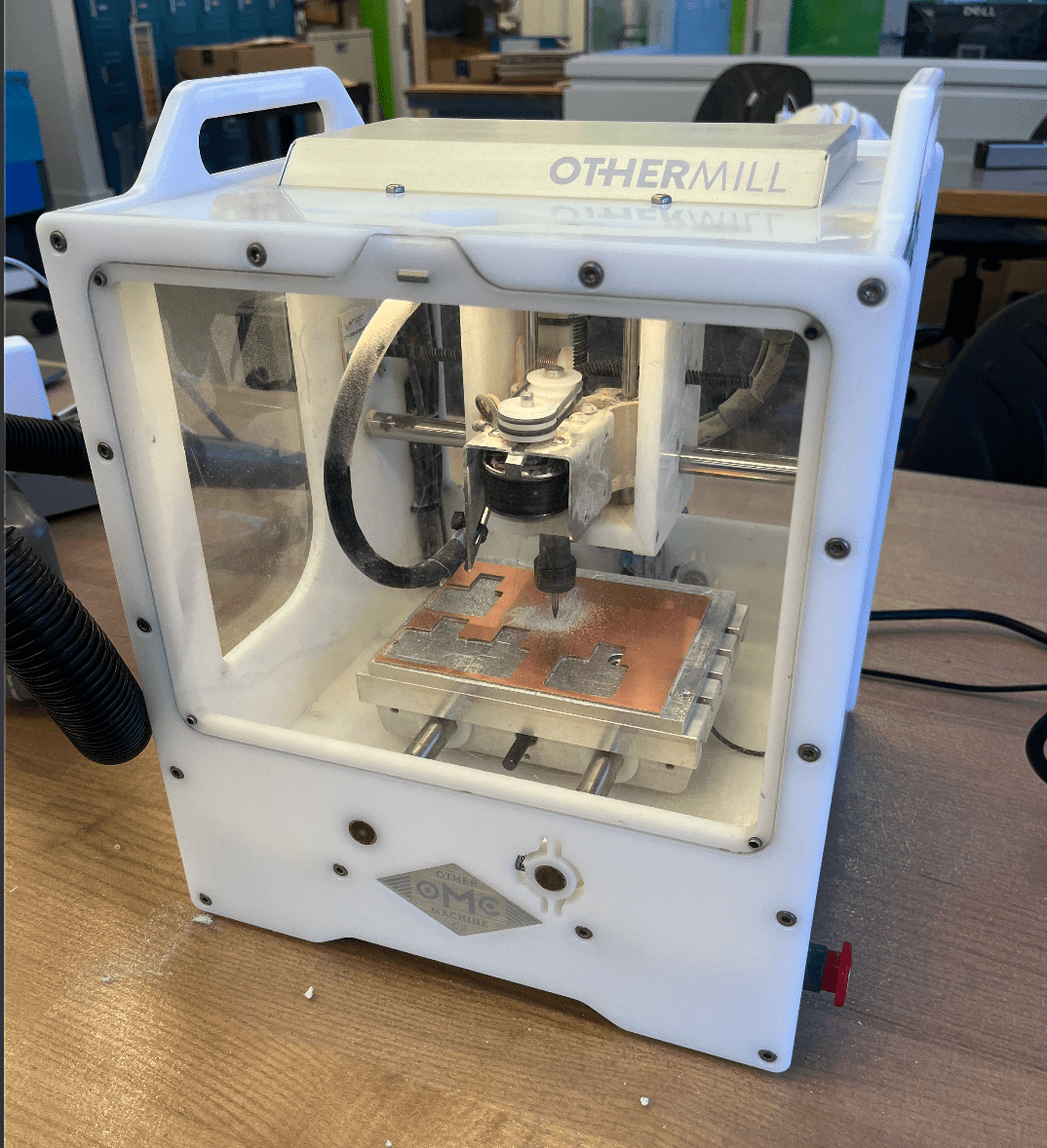

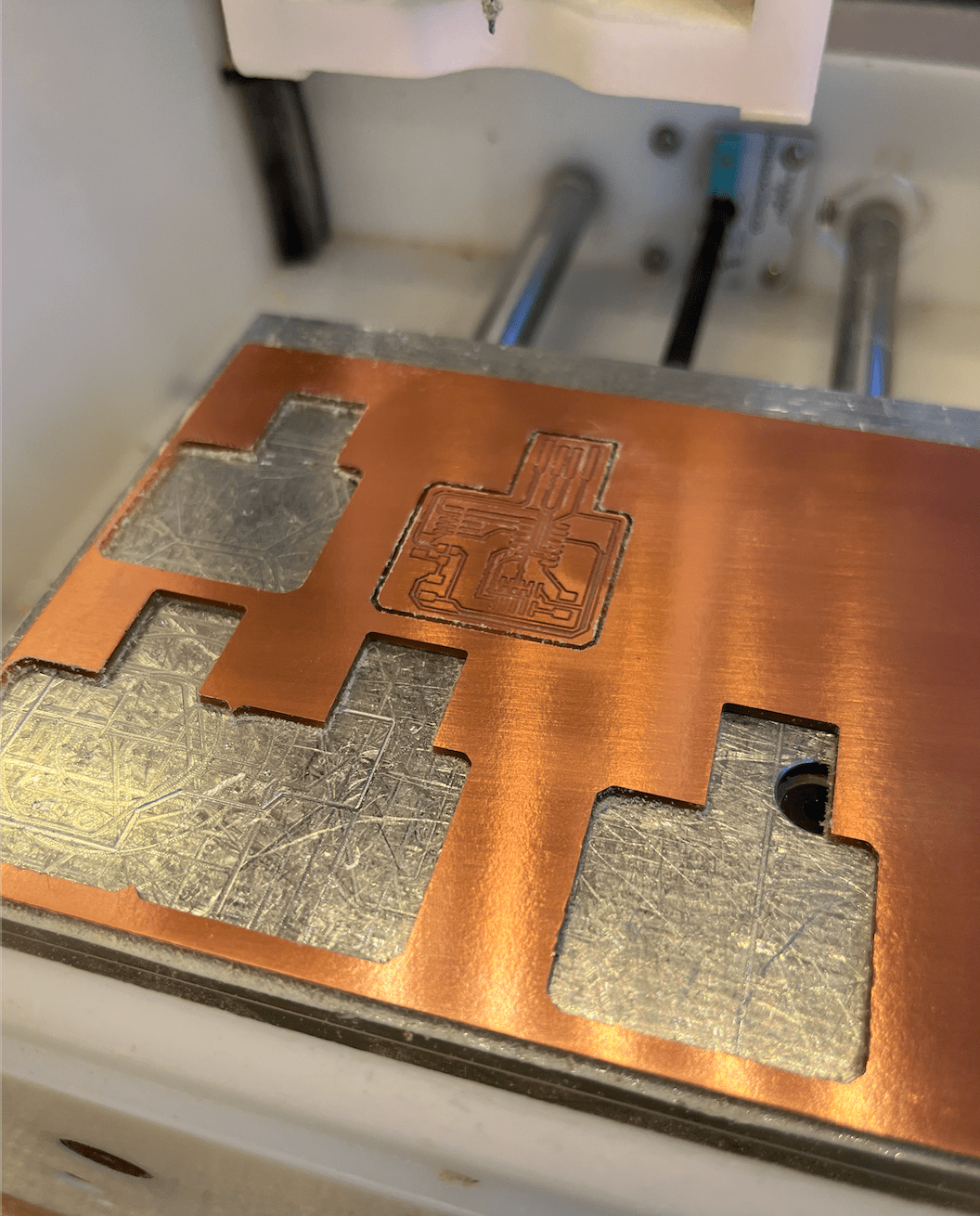

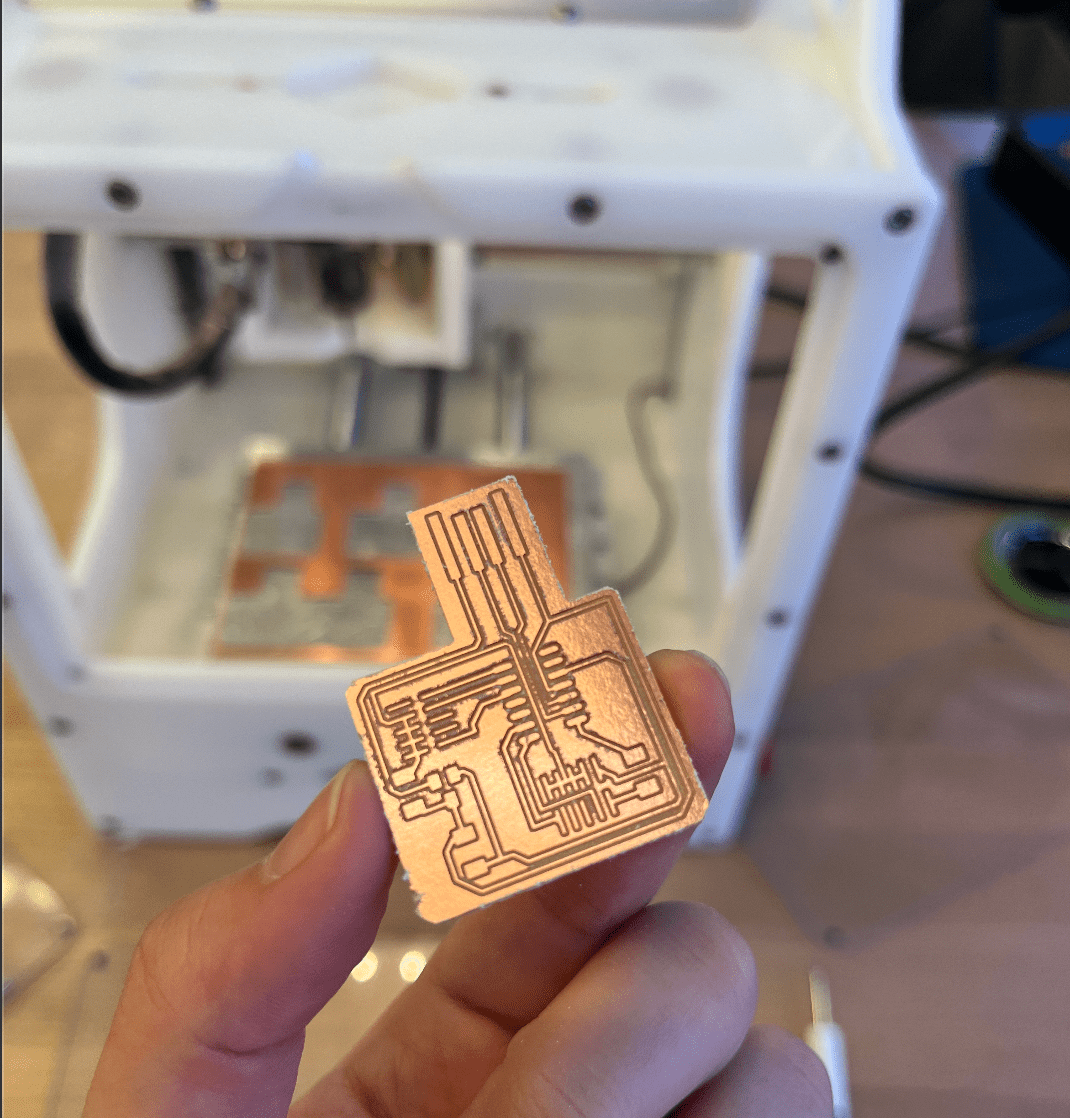

This week we made an in-circuit programmer that includes a microcontroller, following a board design provided to us. After importing the file into the software and changing the milling tip to the appropriate one, I started milling. I first milled the traces with a 1/64in tip, and then milled the outline with a 1/32in tip.

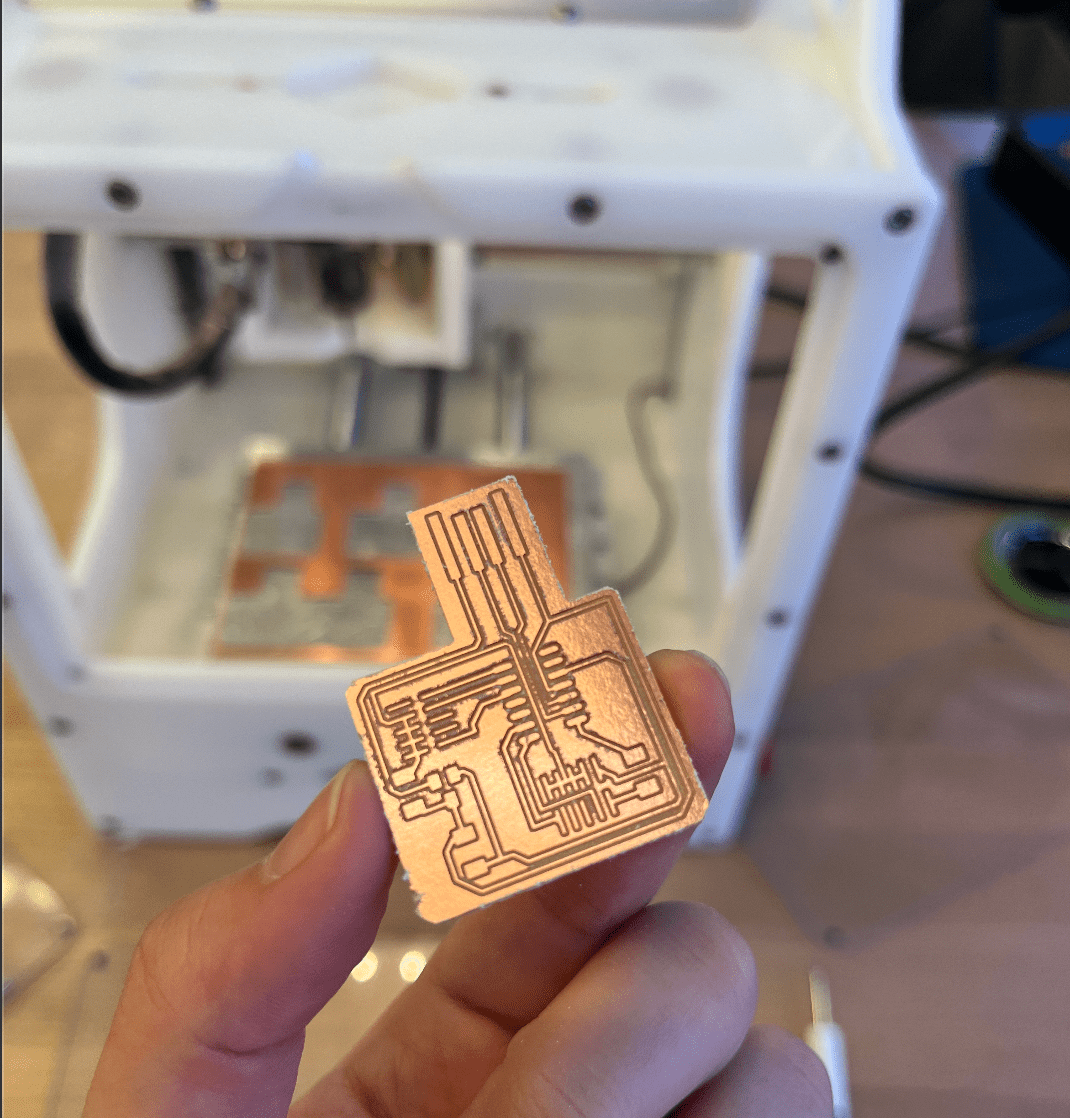

After vacuuming up the dust, I took the cut board out from the machine.

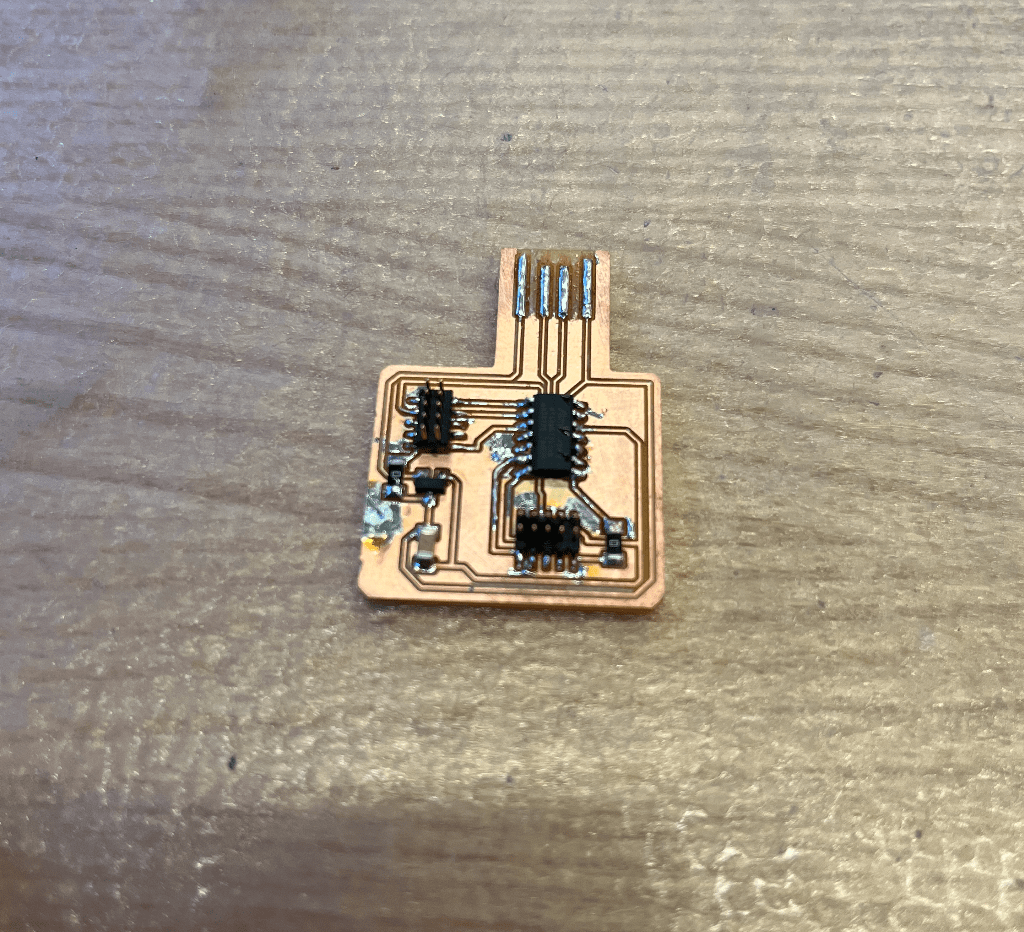

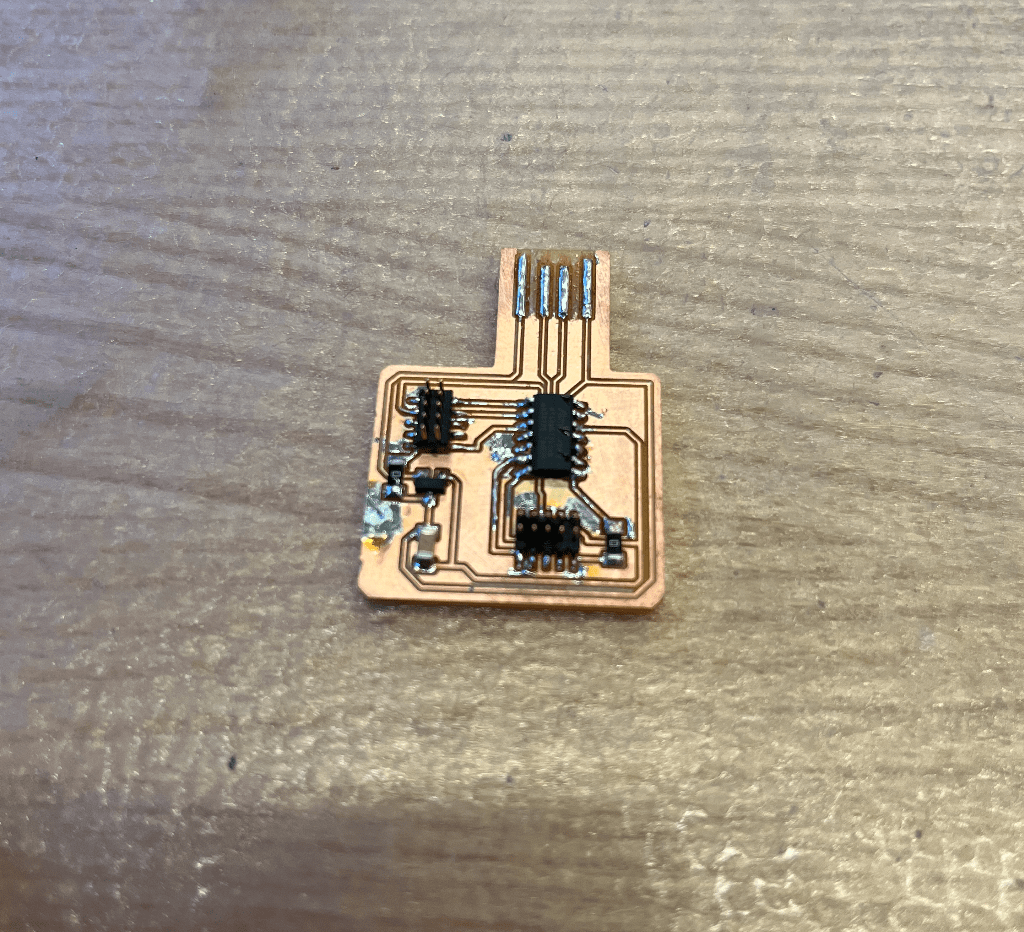

I then learned to solder and began to stuff the board with the pieces: a microcontroller, two 0 ohm resisters, one 1 uF capacitor, 2 [insert part name], and 1 [insert part name]. I struggled quite a lot because the traces were so thin, and learned from Anthony that if you select both tools at once on the computer, the machine will automatically select what tool to use to mill the different parts and I would end up with thicker traces that would make soldering easier. Throughout the process, I had shorts that I needed to fix, and I think I consistently used too much solder. I knew the best thing to do was make sure everything was hot (the temperature was set to 750C), but it was hard sometimes to have the soldering iron tip touch both the part metal and the copper and leave room for the solder to touch everything as well. I also discovered the usefulness of the solder wick in this process. Regardless, I managed to finish stuffing the board, as seen below.

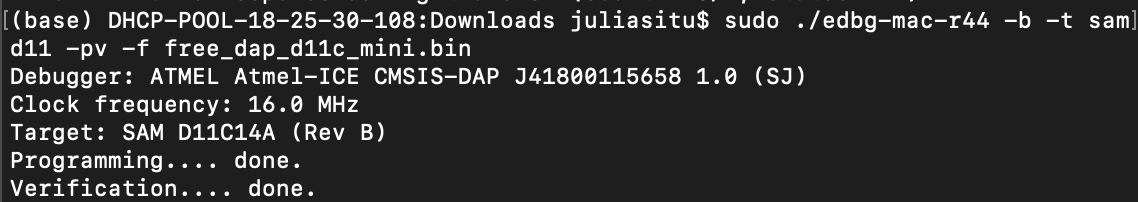

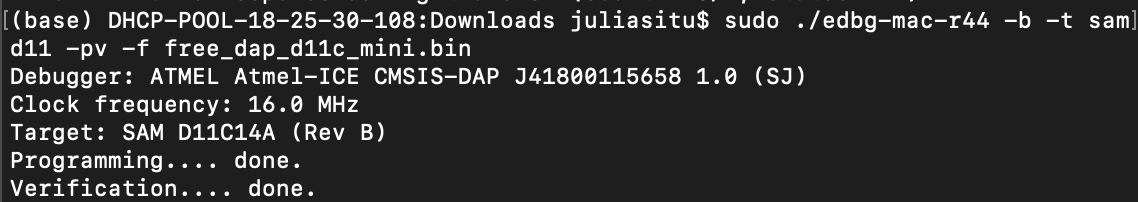

After stuffing, the next step was to program the board. I followed the instructions to set up my computer, and successfully programmed my board to be a programmer.

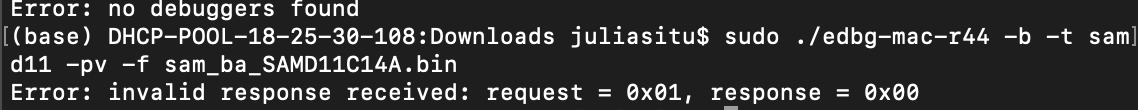

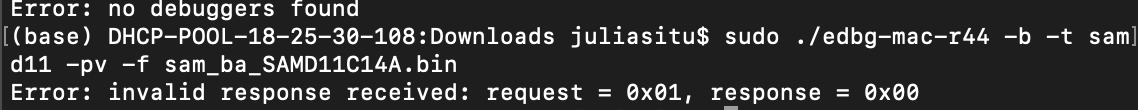

However, when trying to use my board to program another board, I ran into some problems. At first, we noticed that my board had a short. After removing the short, my board successfully programmed another board on Anthony's laptop. However, on my Mac, it failed to program, as seen below. This seems to be a Mac issue, as I think someone else also ran into this problem with their Mac. Anthony did mention that the solder on the board's USB end was not level and slightly uneven, so I went back and added more solder and smoothed the solder out, to improve connectivity stability. However, this was not the issue that had prevented my board from programming another.

Lessons learned from this week: select all tools to be used when milling and make the machine do all of the work to make stuffing easier, make sure everything is hot when soldering, don't use too much solder, the solder wick is very useful but also gets very hot so don't touch it.