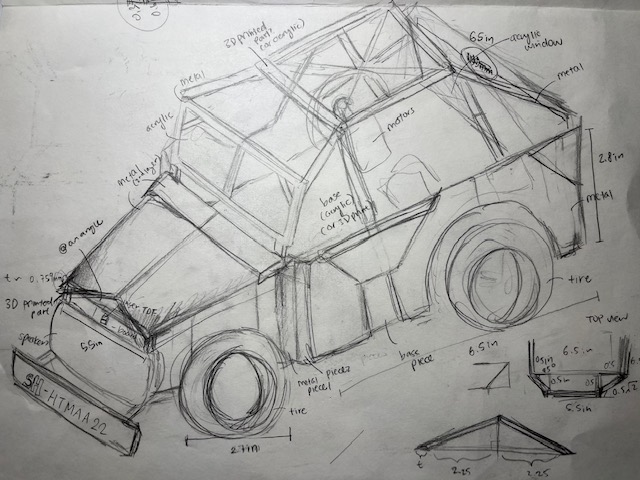

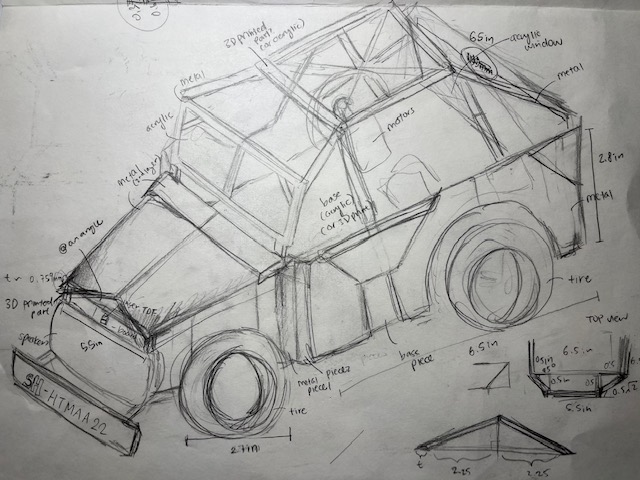

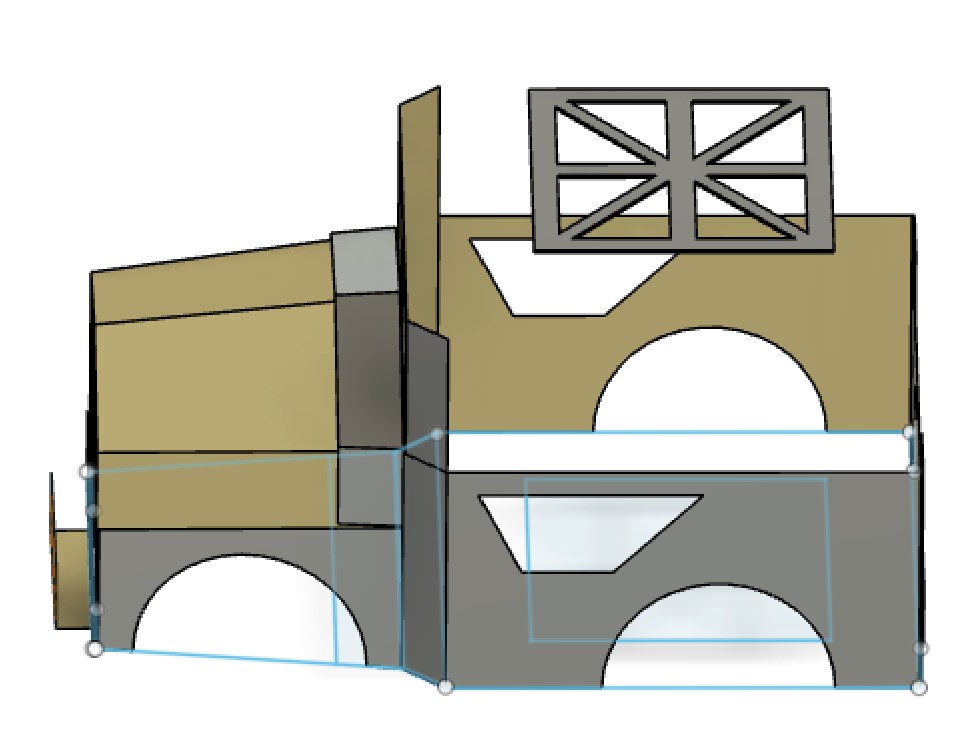

For this week, I decided to try using metal for my car's backbone structure. It was my first time trying sheet metal (0.03" or 22 gauge steel) fabrication, so I was excited to use the Fablight metal cutter and spot welder. I started by sketching my car's structure as shown below. I was limited by the motor's length (~2.3in) so I decided to make the width of the car to be 6.5in. After measuring each dimension, I specified the car's overall dimension and determined design choices.

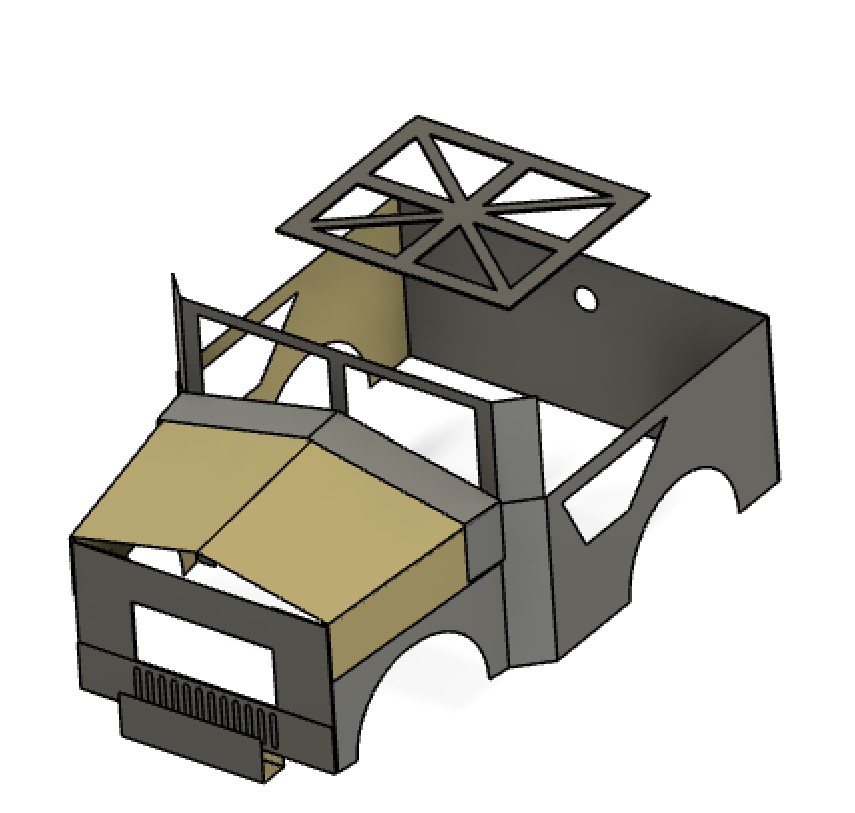

I requested OH with Alfonso to receive guidance on CADing my car's complicated structure. He directed me to 3D CADing and the surface tool to replicate the 3D structure of sheet metal. Since I needed to join the metal sheets with spot welding, I included lap joints (extra surfaces that bend to interface the surface of the other surface). Overall, the 3D design was satisfyingly done.

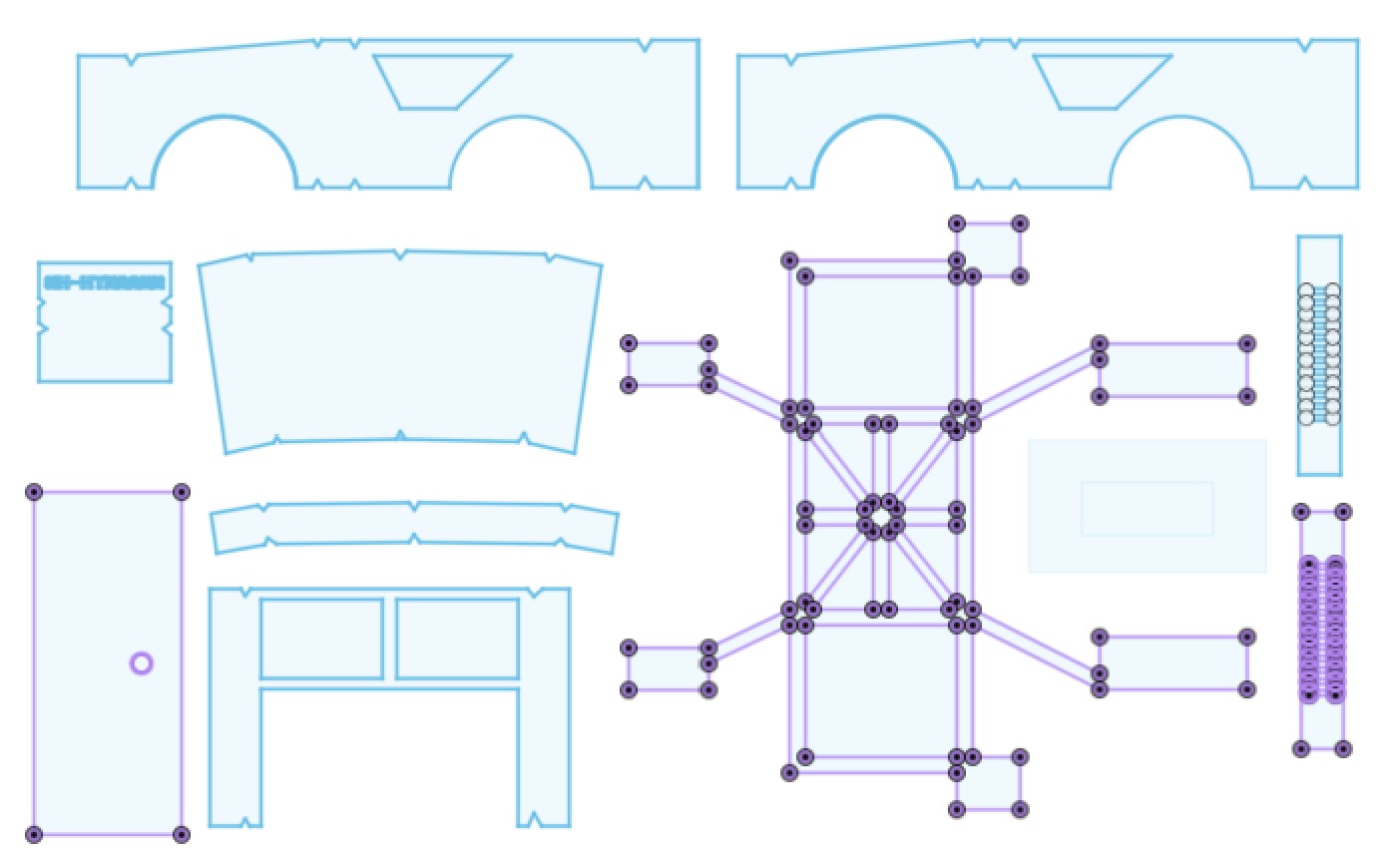

After completing my 3D cad design, I needed the .dxf file to laser cut sheet metal. In fusion, I unstitched the connected surface so I should independently move/rotate them to flatten them out. It was a tedious process, so Alfonso helped me through the Rhino software for bent surfaces. Importantly, before cutting the metal, I included bending marks (triangles) so I could easily find where I needed to fold later.

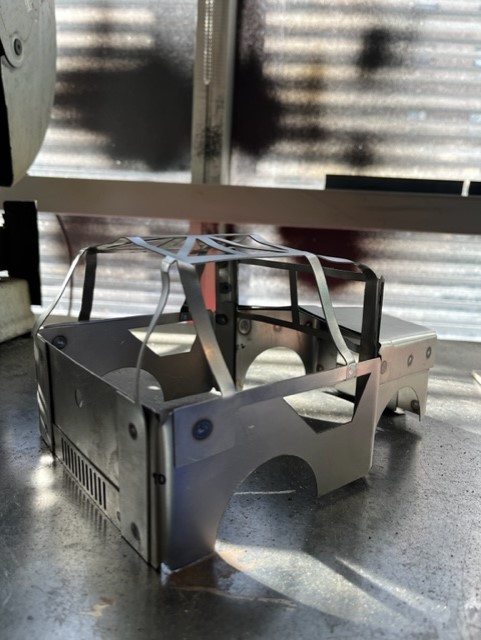

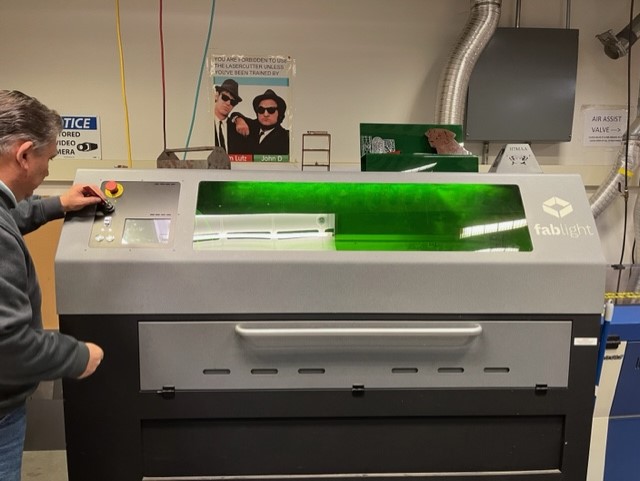

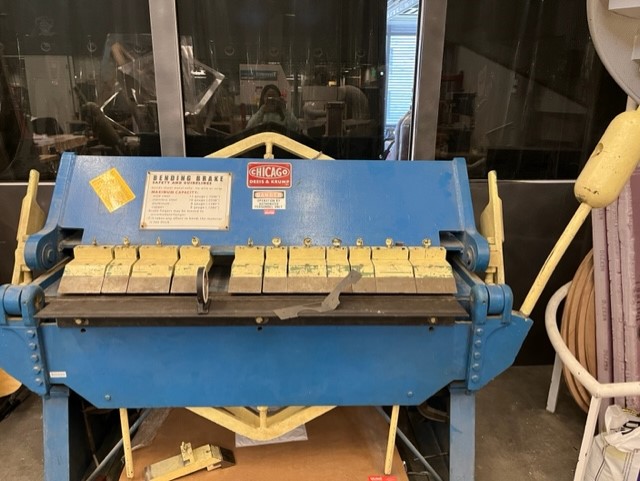

Together with John, I used Fablight machine to laser cut my surfaces. However, it malfunctioned during the process so I instead used water jet for some components. After the parts were cutted, I filed the rough edges and bend surfaces using the bending brake. The protractor device helped me specify angles, and this process was generally simple.

To assemble the car's parts together, I used a spot welder, which was fast and effective. Some geometry was more difficult to reach, but the car looked similar to my CAD model. I first disliked its distorted roof, but I'm starting to like it more. I will probably flatten it with a hammer (Quentin's suggestion), decorate it with leaves (Anthony's suggestion), or cover it with a clear vinyl sheet (John's suggestion). I haven't decided what I'm planning to do yet. I'm planning to spray the car with antioxidants to prevent the steel from rusting.