This website is for the course How to Make Almost Anything (Fall 2022) You can reach me at

Contact me

alexiaasgari

@gsd.harvard.edu

Group Project 1: Laser Cutting

To exercise the using the tool of laser cutting, we were challenged to first characterize the laser as a group, and then use the laser cutter to create a parametric design.

Characterizing the Machine

Alexia Asgari, Selin Dursun, & Treyden Chiaravalloti

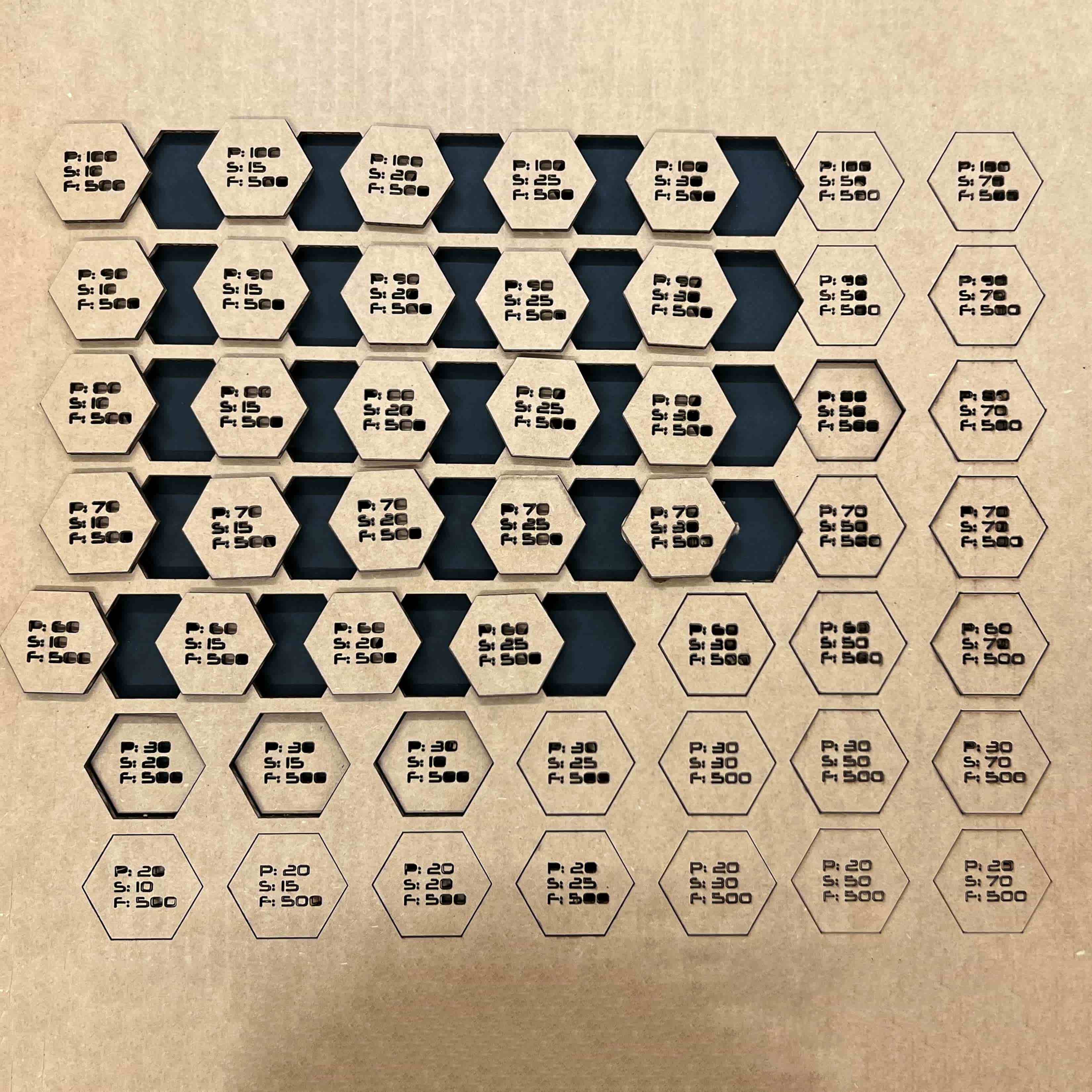

In order to characterize the machine, we preformed a series of tests. We started by varying the speed and power of the laser to find parameters that could cut through the provided cardboard and engrave the provided cardboard. In the photos to the left, the pieces that cut through are offset from their original locations. We drew the hexagons in Rhino and exported them as an XPS into Lightburn. Each hexagon was placed in a seperate layer to be given different parameters. There was some inaccuracy as a parameter of cutting several times was set on certain layers. However, by comparing patterns of the surrounding tiles, we were able to assume their likley characteristics. We chose ideal parameters based on cut depth, lack of burn marks, and speed of process.

Cardboard Cut Parameters :

- Power: 90%

- Speed: 20 mm/s

- Force: 500

Cardboard Engrave Parameters :

- Power: 20%

- Speed: 30 mm/s

- Force: 500

Testing Joints

Alexia Asgari, Selin Dursun, & Treyden Chiaravalloti

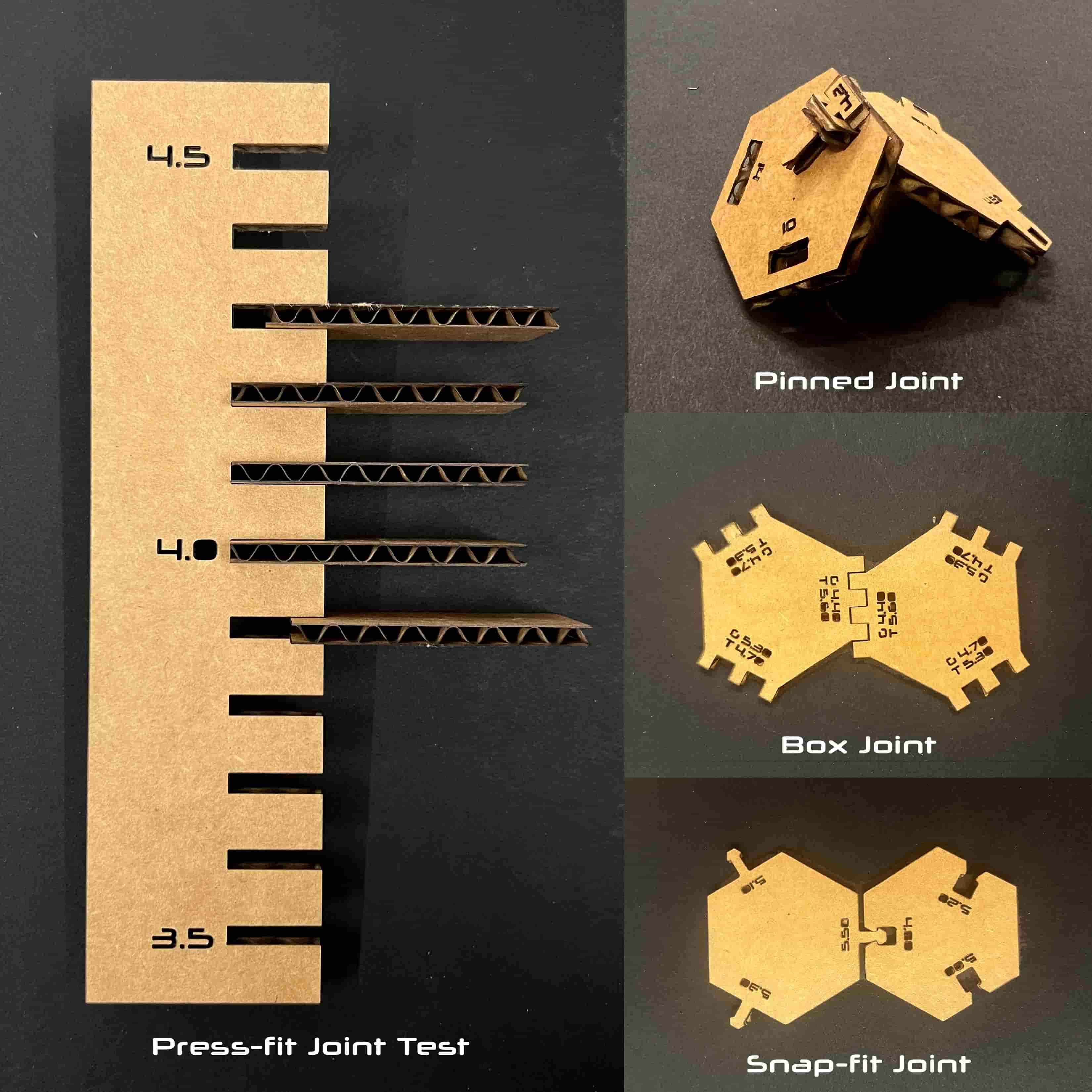

For this exercise, we chose several joint types the group was interested in utilizing. We tested several sizes using the different sides of the hexagon, ultimatley detemining the ideal combinations, as pictured. We also noticed that certain joint types like press-fit and box joints, benifited by the flexibility and compression of the cardboard, while others were weakened like the snap fit.

Press-fit Joint :

- Cardboard Width : 4.5 mm nominal (4.4 mm actual)

- Slot width (snug fit): 4.0 mm

- Slot width (adjustable fit): 4.1 mm

Pinned Joint :

- Cardboard Width : 4.5 mm nominal (4.4 mm actual)

- Pin Width: 4.8 mm

- Pin Hole Width/Height: 4.3 mm

- Slot Width: 12 mm

Box Joint :

- Cardboard Width : 4.5 mm nominal (4.4 mm actual)

- Gap Width: 4.4 mm

- Tooth Width: 5.6 mm

Snap-fit Joint :

- Cardboard Width : 4.5 mm nominal (4.4 mm actual)

- Snap Hole Width: 4.8 mm

- Snap Insert Width: 5.5 mm

Kerf

Alexia Asgari, Selin Dursun, & Treyden Chiaravalloti

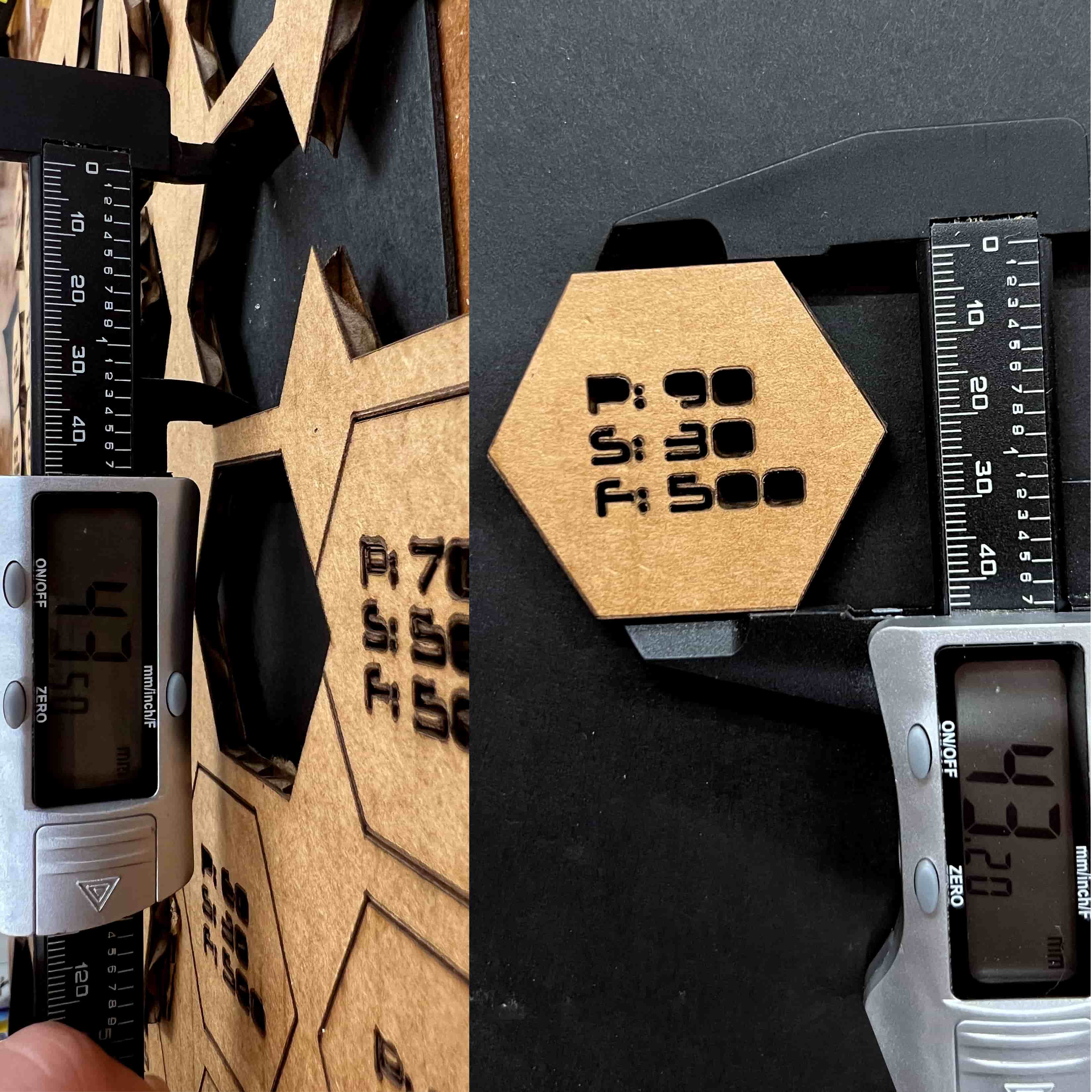

To determine the kerf, we measured the inside and outside of the cut.

Kerf Finding :

- CAD Dimension: 43.3

- Inner Dimension: 43.2

- Outer Dimension: 43.5

- Kerf: 0.3 mm