Week 05 - Make Something Big!

1.1 Group Assignment

1.2 Individual Assignment

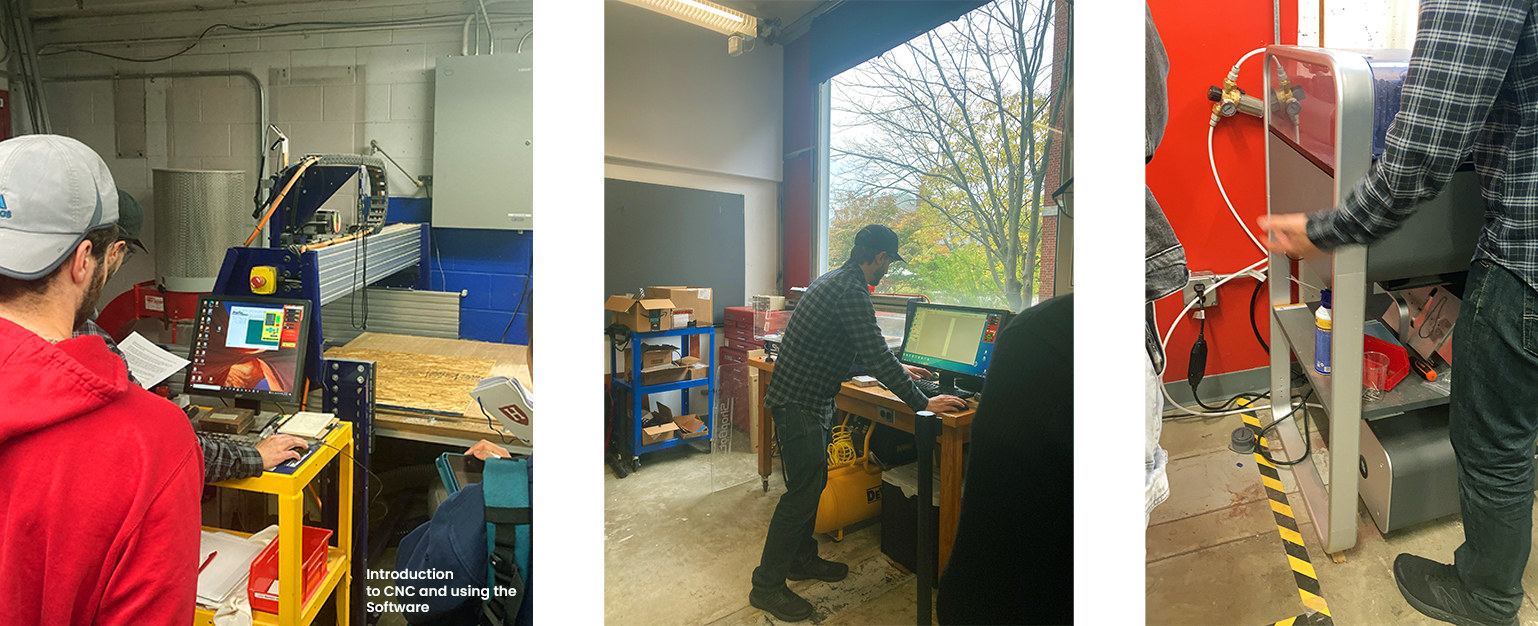

This week's group assignment was to test runout, alignment, speeds, materials, and toolpaths for our CNC machine. Documentation can be found on the Harvard Section's website.

1.2 Individual Assignment

The individual assignment of the week was to make something big out of any wood of our preference.

There has been only 2 months since I moved here, so, some of my storage furniture is missing. I decided to design a functional piece this week, such as a shoe storage unit or multi-use storage furniture of any kind.

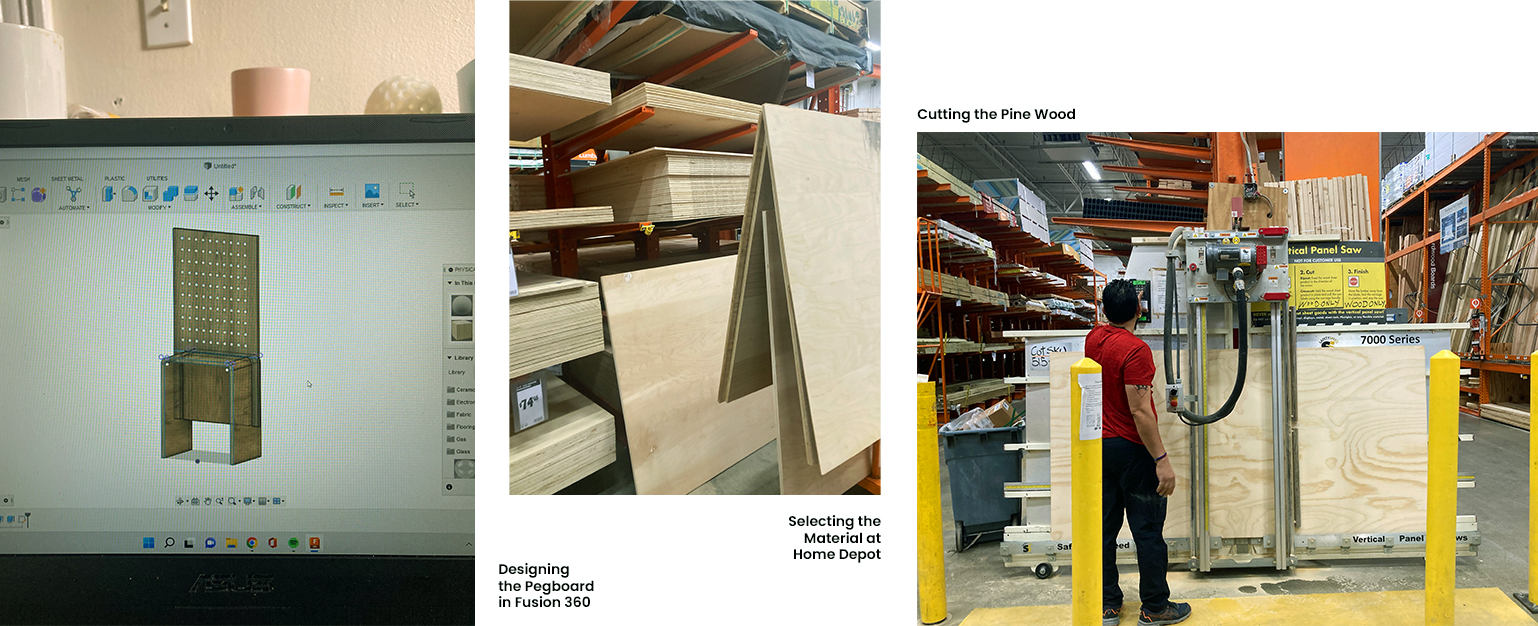

My idea resulted in creating a pegboard that has a shoe storage unit below. Modularity and simplicity of it felt tempting to at least start my journey for the week.

I designed my model in Fusion, and than booked a reservation for using the CNC machine.

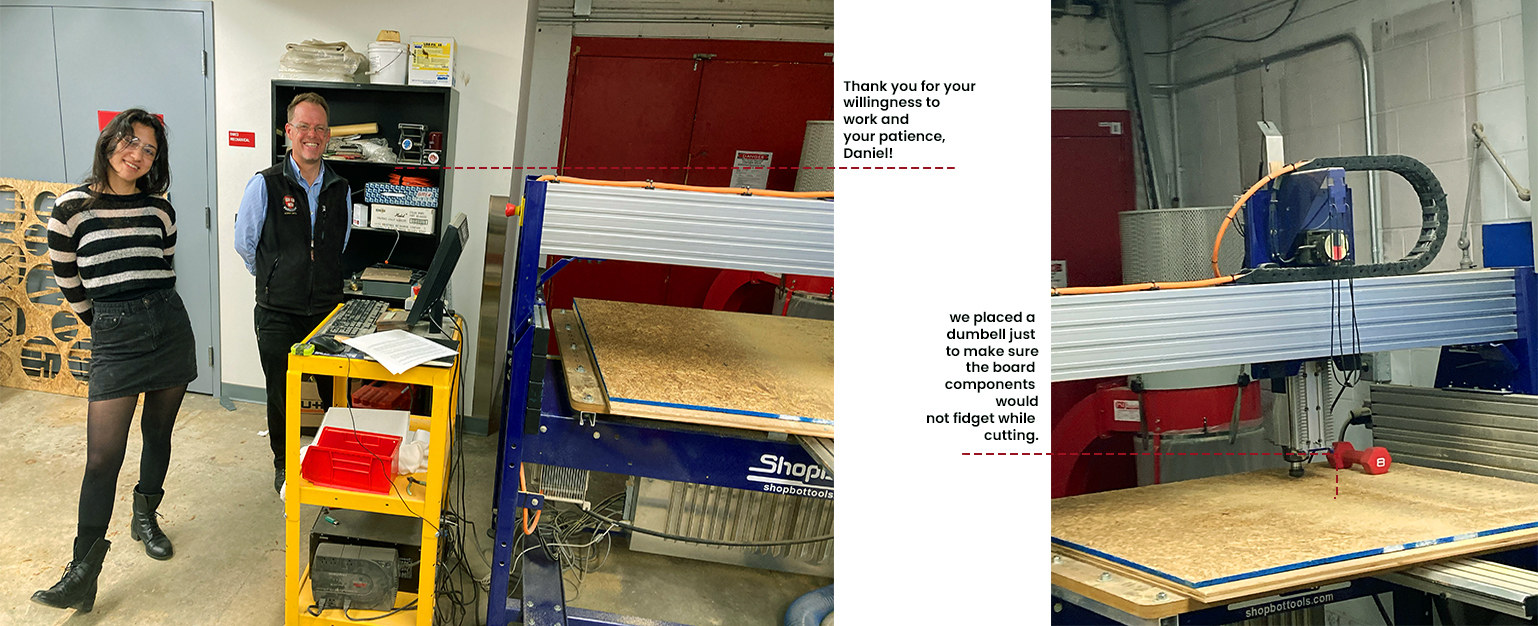

Daniel was very helpful and attentive. This was the first time I have used ShopBot but it was very handy to use and no problems occurred during the cutting process. We were a bit afraid that the pegholes and the mdoular dowels would not be able to fit since I have not designed any dog-bones, but it worked out perfectly for the OCB.

Daniel was very helpful and attentive. This was the first time I have used ShopBot but it was very handy to use and no problems occurred during the cutting process. We were a bit afraid that the pegholes and the mdoular dowels would not be able to fit since I have not designed any dog-bones, but it worked out perfectly for the OCB.

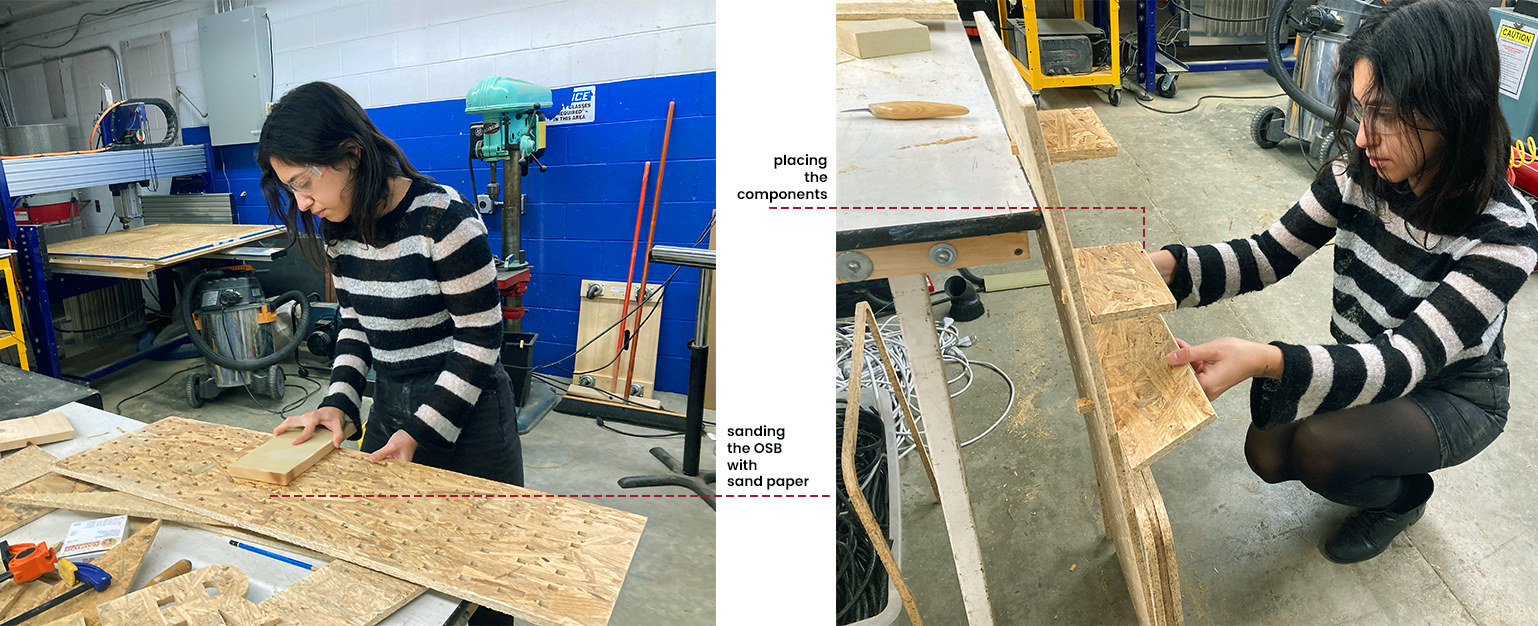

I have spent quite a long time perfecting the surface with a sandpaper.

The second phase was with Plywood. After 3 hours of cutting and 5 hours of smoothing the surface, my begboard was ready. Due to the time limitation, I was not able to add the shoe storage part, and did legs for the pegboard while my board was being cut.

The second phase was with Plywood. After 3 hours of cutting and 5 hours of smoothing the surface, my begboard was ready. Due to the time limitation, I was not able to add the shoe storage part, and did legs for the pegboard while my board was being cut.

Overall, it was again a week full of experimenting-failing-learning.

Overall, it was again a week full of experimenting-failing-learning.