Week 07 - Molding and Casting

Group Assignment

Loading!

Individual Assignment

Where to start...

This week was the week that I felt the most tired but still eager to keep going.

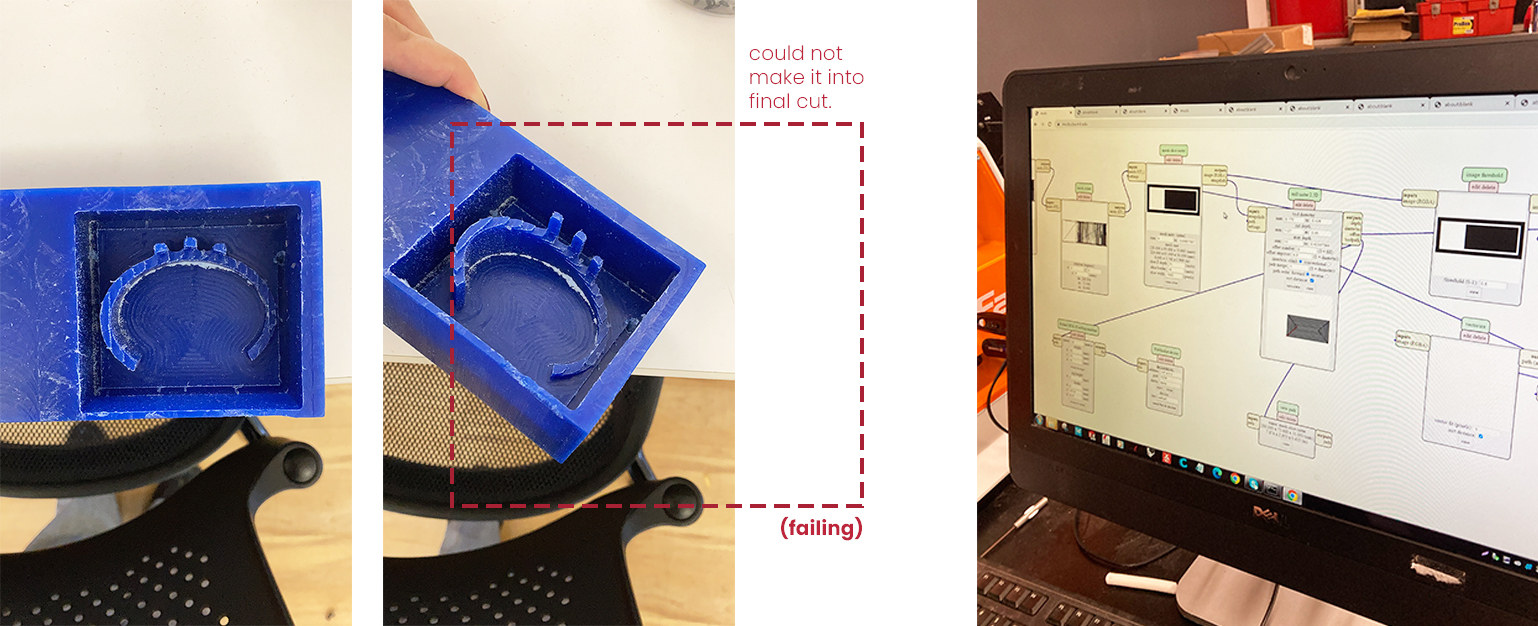

I wanted to create a PCB holder for a potential wearable synthesizer product for my final project, and realized to late that I should have started from something way smaller.

During the design process, for the first time in years, I just did not feel like anything I have designed spoke to me. However, I wanted to give it a try and not loose more time than I should AFTER 3 DAYS OF CONFUSEMENT. This is the model that I wanted to give a try:

After this process, there came the milling part. I left it overnight and found it taken out of the machine. I suppose it was too deep for the machine to cut, and when I saw the model in the physical dimension, I felt very distant to it. So, I took a trip to Reynolds Materials to mold and cast my hand instead of making a hand tool.

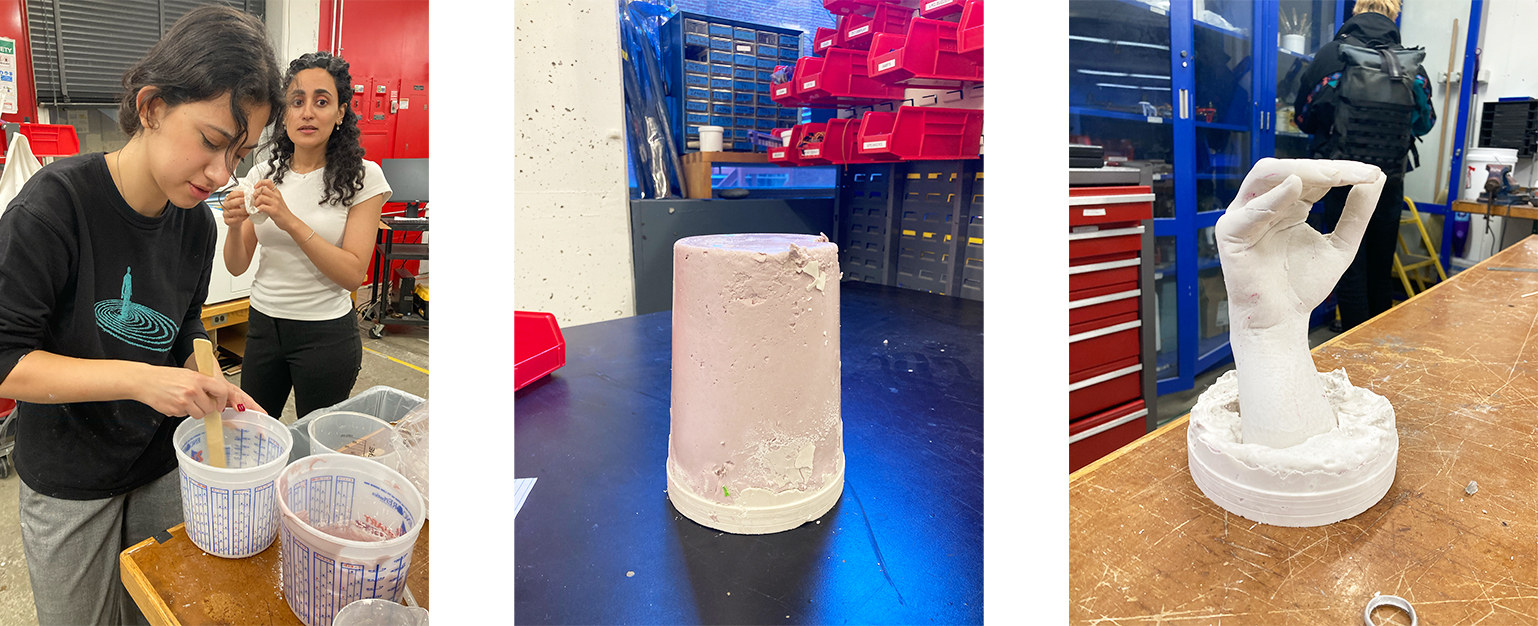

Sweet Sondos and Her Helping Hands

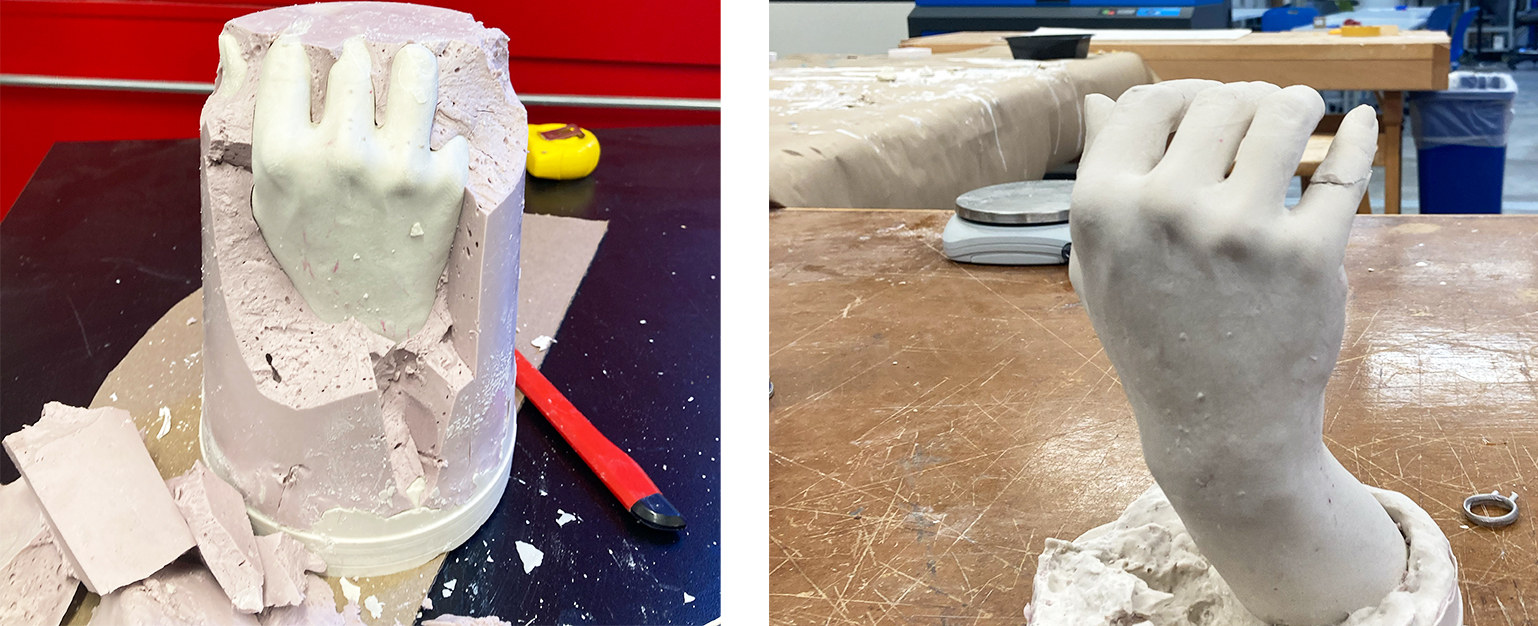

Working with algenite was easy thanks to our lovely dentist Sondos, who was there every step of the way, from mixing the water and algenite in the ratio of 1:1 to casting it with gypsum with the same ratio. Thank you infinitely for all your help, Sondos!

I left my hand inside the cap for almost 20 minutes to make sure that the shape was detailedly refined.

We first layed a thin layer for the surface of the hand after taking my hand out, for the gypsum to reach every corner that it can reach.