Week1

A Tale of Flames, Failure, and Modular Redemption <3#

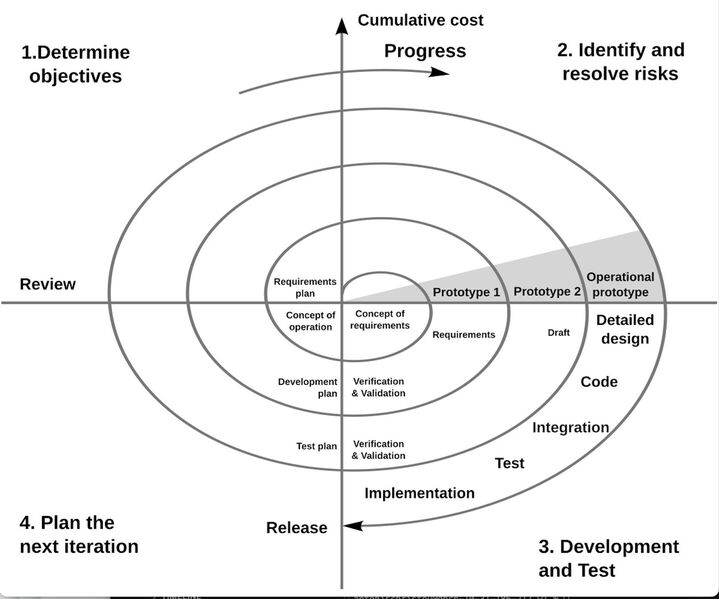

I was pretty interested in the concept talked about in class known as spiral design. It was the first time I had heard of it in a formal way like this, but it very much aligned with my own intuitions for how design should happen - iterative, constructive, and frequently testable. This week, however, I learned a great deal, perhaps most importantly what happens when one does not follow this system :(

Group Assignment#

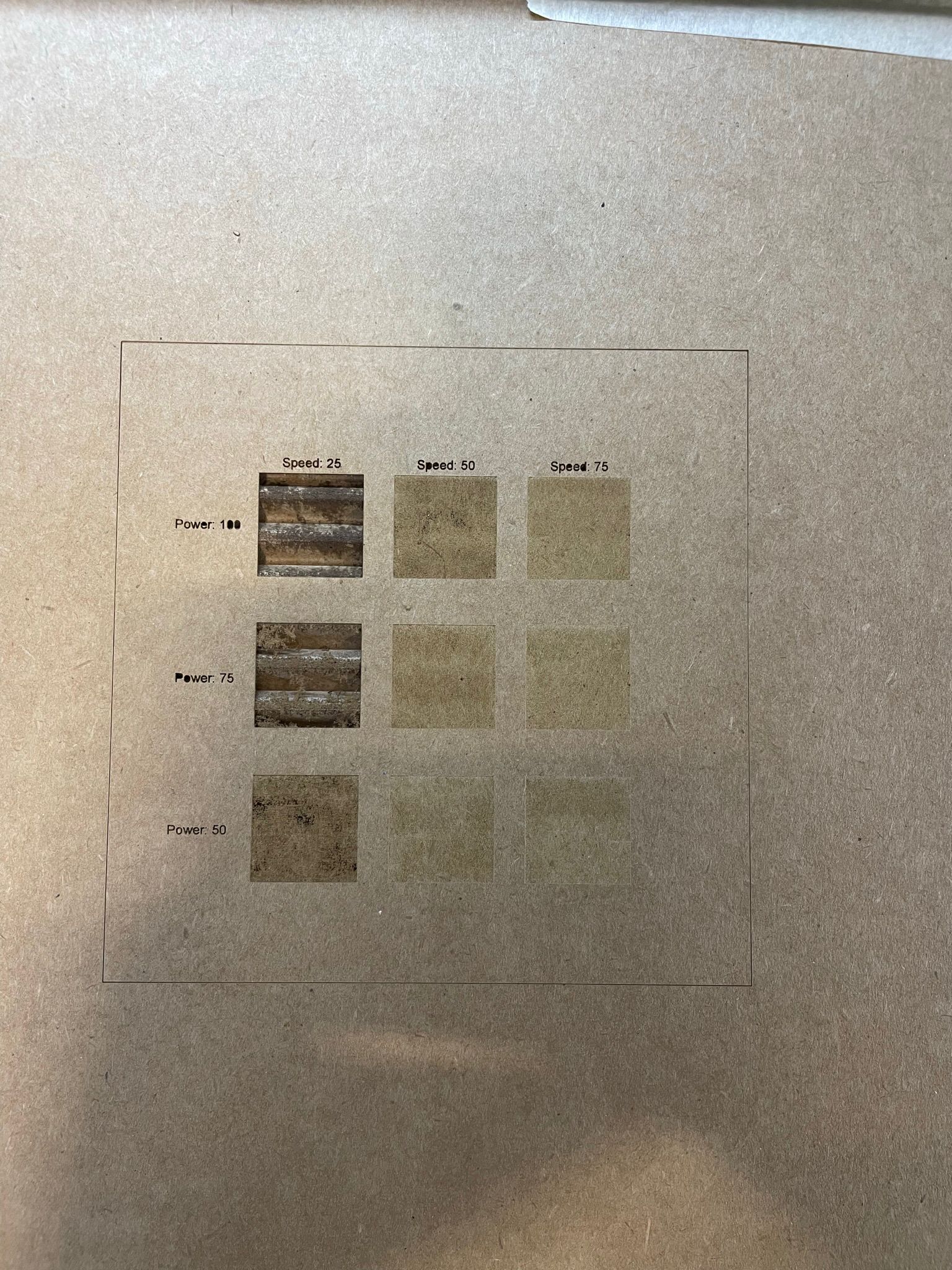

A bunch of us MAS people met on Saturday morning to hash out the group part of the assignment, which was to test out the various powers, speeds, and other settings for the laser cutter, as well as figure out the kerf of the laser cutter. After some iterating, and some intense group wisdom invoked by the collective brainpower of a cohort of graduate students, we settled on a value 0.2 mm for the “full tool width” - sometimes it seems that kerf is either the full or half tool width, depending on who you ask, which is confusing to me even now. I had some past experience with laser cutters, but in the past I was mostly expected to simply follow the steps that were established in terms of what power, speed, etc to use and so hadn’t really developed much of an intuition for how the settings of the laser actually effect its output past the very basics. Also, I had never made a cut precise enough to warrant accounting for kerf.

We also made a little kerf comb, and came up with a repeated series of bad puns about kers, such as saying there was a steep “learning kerf” many, many times.

Vinyl Cutting#

I had never used (or honestly seen) a vinyl cutter before, but honestly it was lowkey my favorite tool of the week. I was really impressed by some of the artistic and creative output people were able to coax out of it. While I did not attempt anything nearly as intricate, I made a few things for my friends that they really enjoyed, making the experience fun for me as well. In particular, I wanted to pay homage to my best friend in the whole world’s beloved doggy, Maisy:

Using the cutter was actually pretty easy once I was shown how, and pretty soon I had a neat sticker version, which will now live forever on my notebook. In the future, I’d like to experiment with even crazier stickers, even if they heavily test my patience to tweeze them out.

Laser Cutter#

Sigh. I had such hopes of making a cool musical instrument this week, somewhat inspiried by a previous student’s work, but destiny did not agree with me.

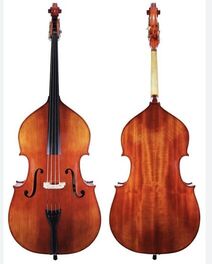

Basically, my concept was that I wanted to make a double bass out of cardboard to fix the fundamental issue that plagues all double basses - they’re extremely not portable! Clearly, luthiers from across time and space had never thought of making a bass out of cardboard, and I’m sure there would be no negative acoustic consequences of doing this.

My first mistake was spending way too long CADing my model. Again, I have very little CAD expeirence, so I wasted a lot of time just figuring out how it would be possible to model what I thought would be a very simple shape. It started easy enough, with me tracing the outline of an actual bass:

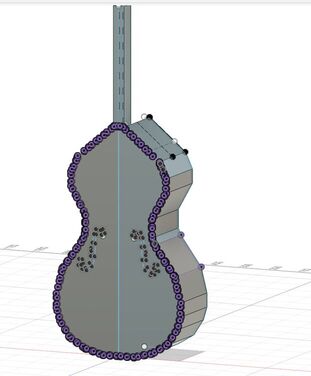

Then, I extruded it and added some other important details like the thickness of the neck and things, using parameters as I went.

and here’s the file link

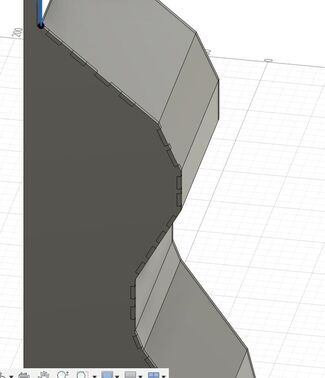

However, when it came time to slice up my 3D shape into finger or box joints, Fusion was very much not cooperating. I had so many issues with vanishing faces, and the software refusing to select the lines I wanted, plus just generally making it almost impossible to achieve to the point that I got a bit sloppy. Alfonso at his office hours provided monumental support by telling me that rather than extrude a big shape then trying and doing things like hollow it out, it would be better to loft between two faces, thus creating a hollow shape from the beginning. He then pointed out that I could do things like draw rectangles, extrude them, then use tools like combine and split to get them to be only apart of the relevant piece. This was generally effective, but I still was having difficulties doing things that should have been easy, like mirroring certain faces to get the slots for the joints on both sides. This result in a sloppy design - in the future I should be 1) practice more with Fusion so that I am sure I can achieve what I want 2) consult people better at the software for the best way of designing what I want from a conceptual point of view and 3) use even more parameters - I used some, but honestly, not enough to prevent me from having to redo work at several junctions, costing me valuable time.

At this point after many hours of pain and frusteration, I thought I was ready to laser cut….

FIRE AND FAILURE TIME#

I spent the next morning iterating on a bunch of cuts, but I failed repeatedly to get a sturdy joint in my work. This was due to a number of factors that I need to do better at in the future - 1) My kerf settings were off, and I iterated too slowly in figuring out the correct value, wasting time. What I needed to do was to make several test cuts all in one go, experimenting with different values and shapes and parameters rather than doing put cardboard in, make changes in model + export, make cut, remove cardboard, fail, repeat. All of these things took too much time and made it difficult to work in a spiral pattern. 2) I suspect I should have used thicker cardboard for what I had in mind - this was very thin and quite flimsly and 3) most importantly I (drum roll please)….set the laser cutter on fire :)

Basically what happened was the following - I and another student were working as we should have been, in pairs, working to help each other on our cuts. However, on one fateful go, we missed the fact that a piece of tape had come loose, and as soon as the laser started operated it instantly got caught on the arm and burst into flames. We then followed safety procedure, cutting the air supply - the fire continued. We then took the fire blanket out of the container and hurled it onto the what was at this point relatively large fire. The fire continued. At this point, I ran and called for help, while the other student I was with pushed down on the blanket, smothering the fire and ending the crisis.

Sad times, but pretty good documentation material, no?

So the laser cutter was now broken, thus killing any dreams I had of finishing the design I had intended. Disappointing, but I almost feel like I learned more from the collection of failures this week - as a result of all my foolish iteration, I feel quite comfortable using the laser cutter and playing with its settings, as well as have in mind better ways to design in the future.

Oh and yeah. I also am now quite skilled in fablab safety procedures and putting out fires….

(Tiny) Redemption?#

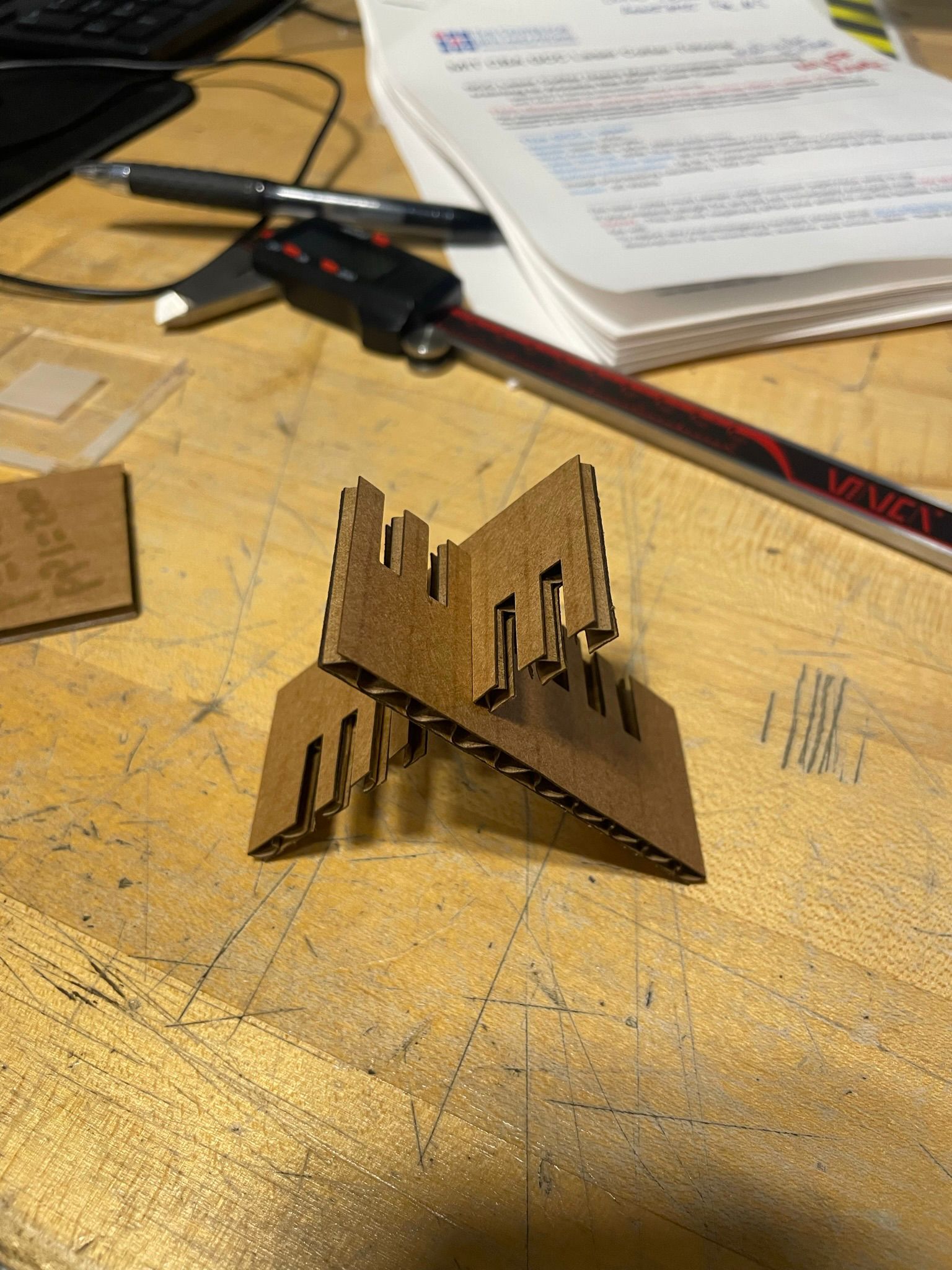

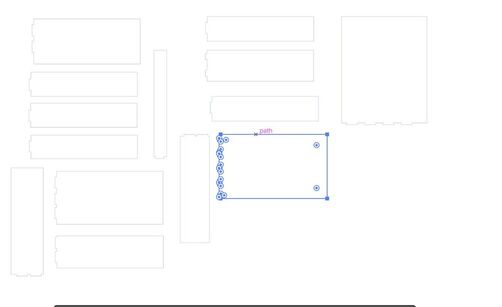

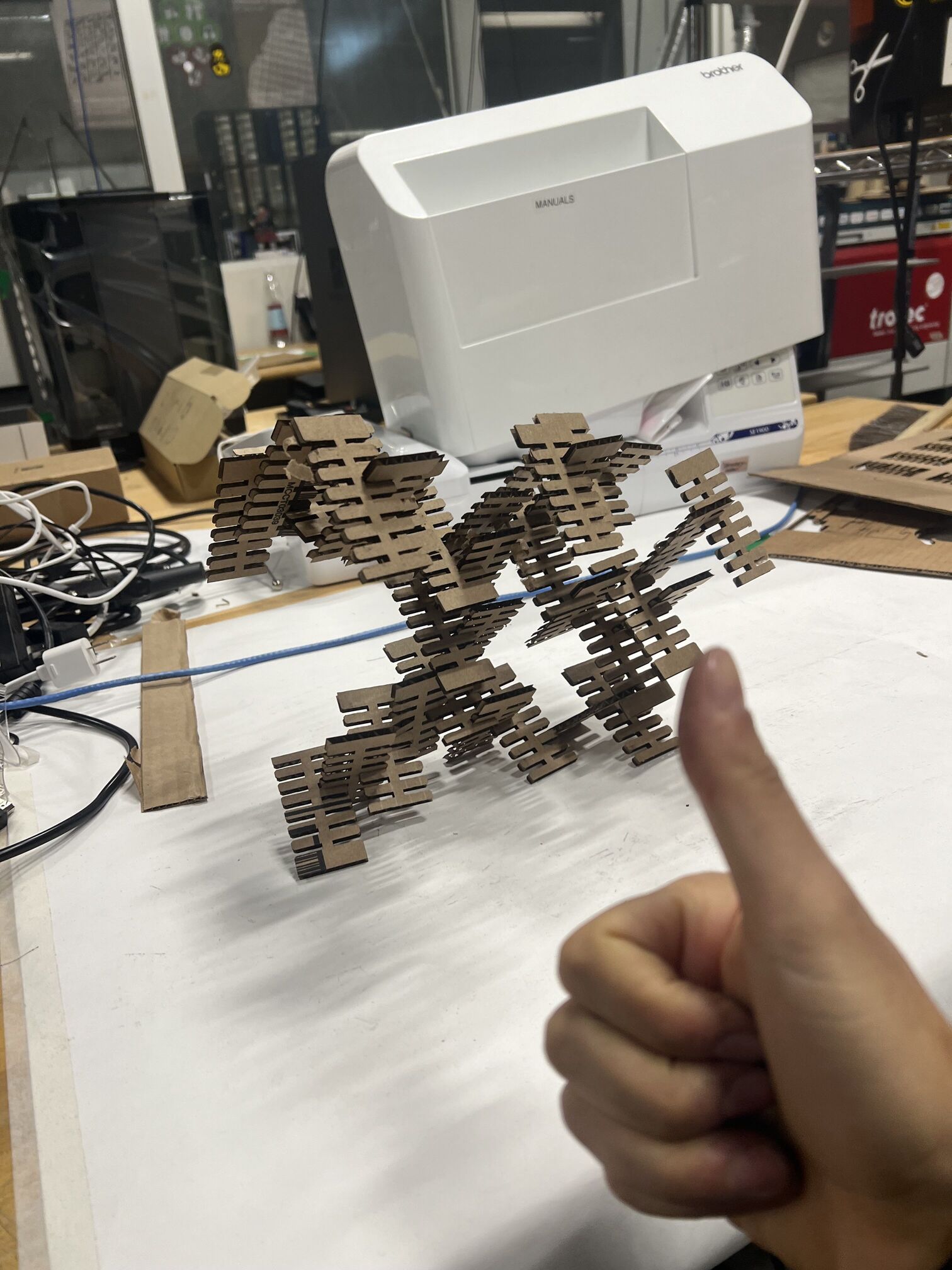

So with all that failure in mind, I thought to reverse my paradigm. Rather than make one huge thing and cut it down, what if I made many small things and build them up?

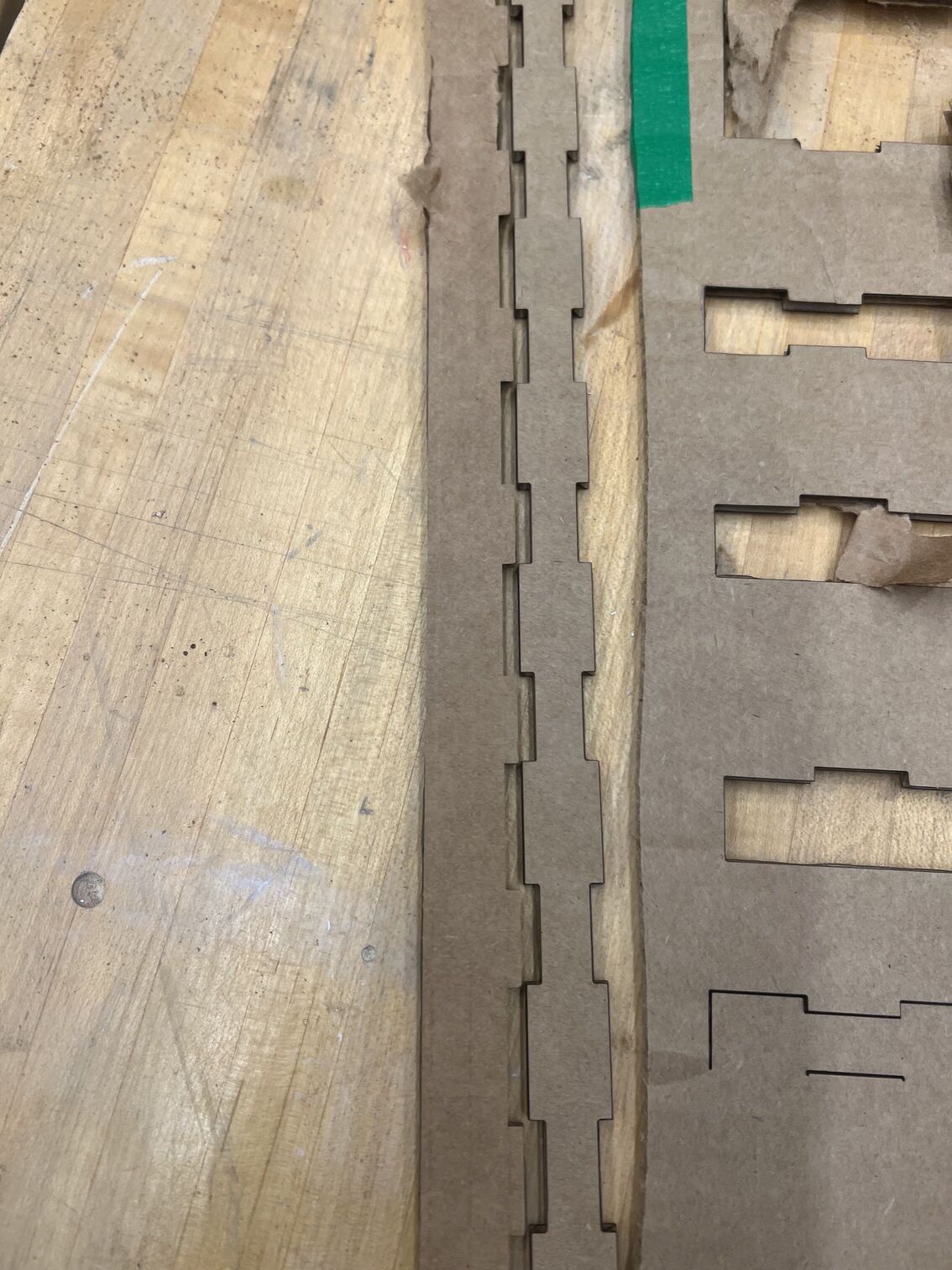

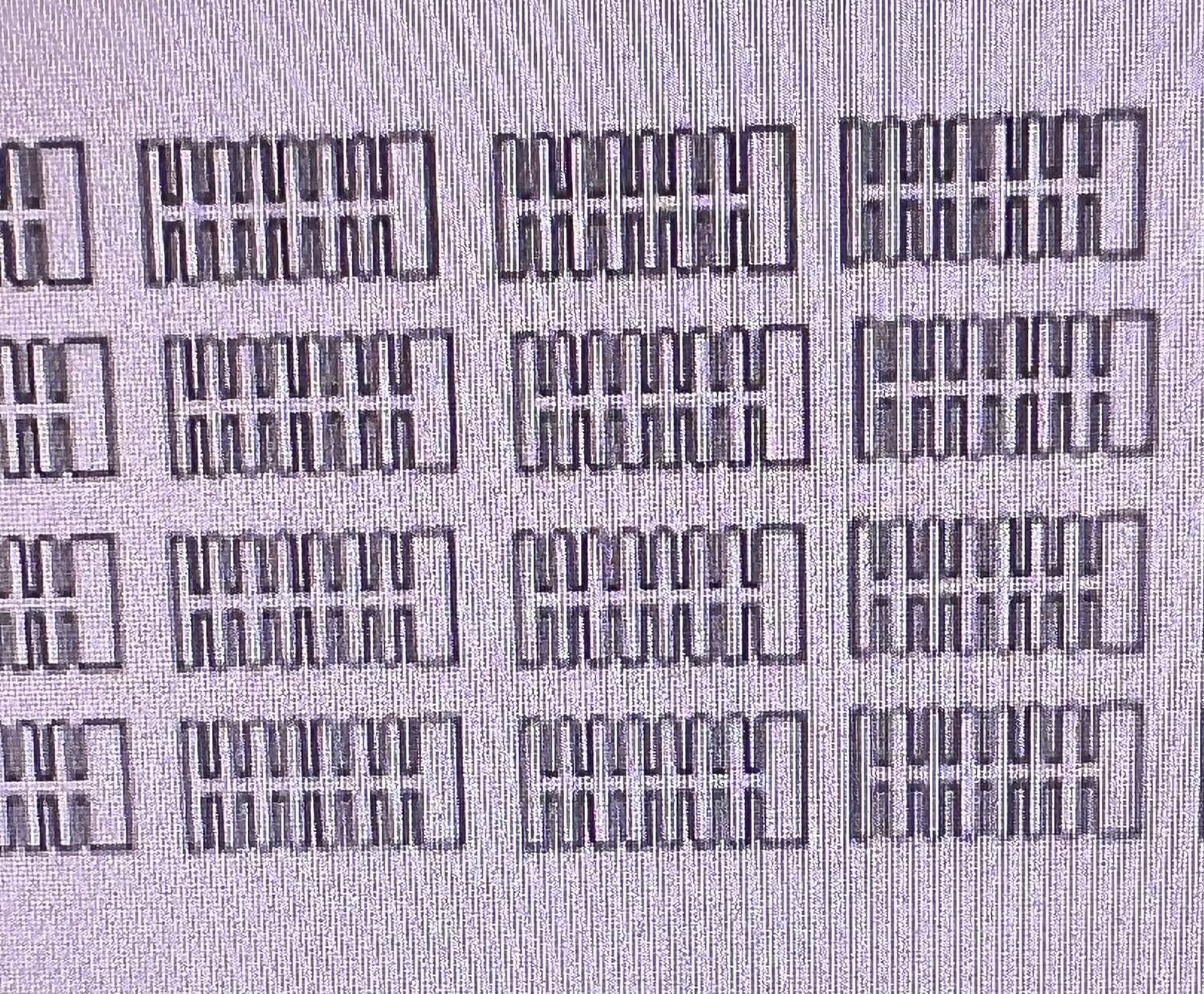

So I designed these simple joints with the idea of making them as modular as possible.

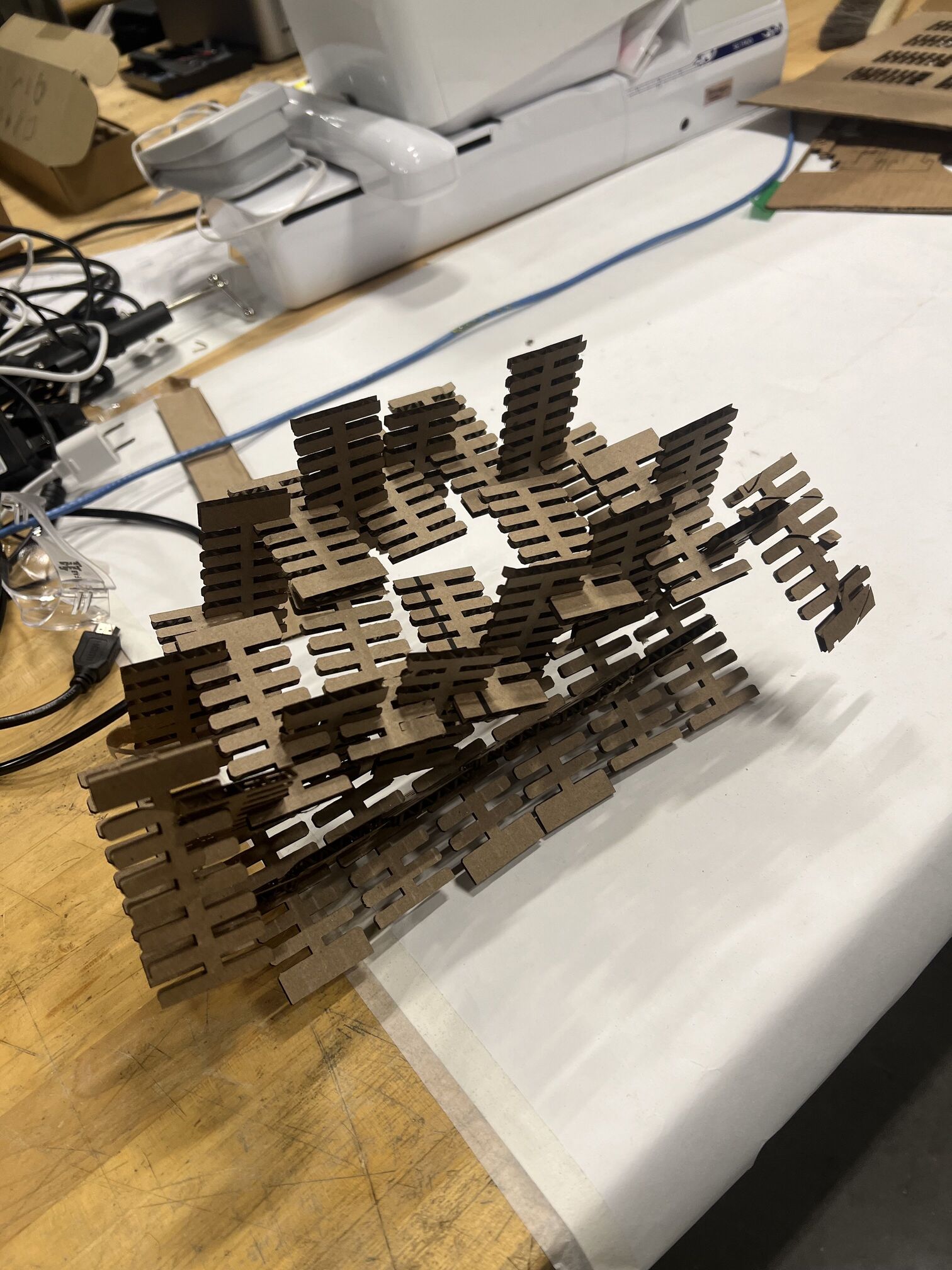

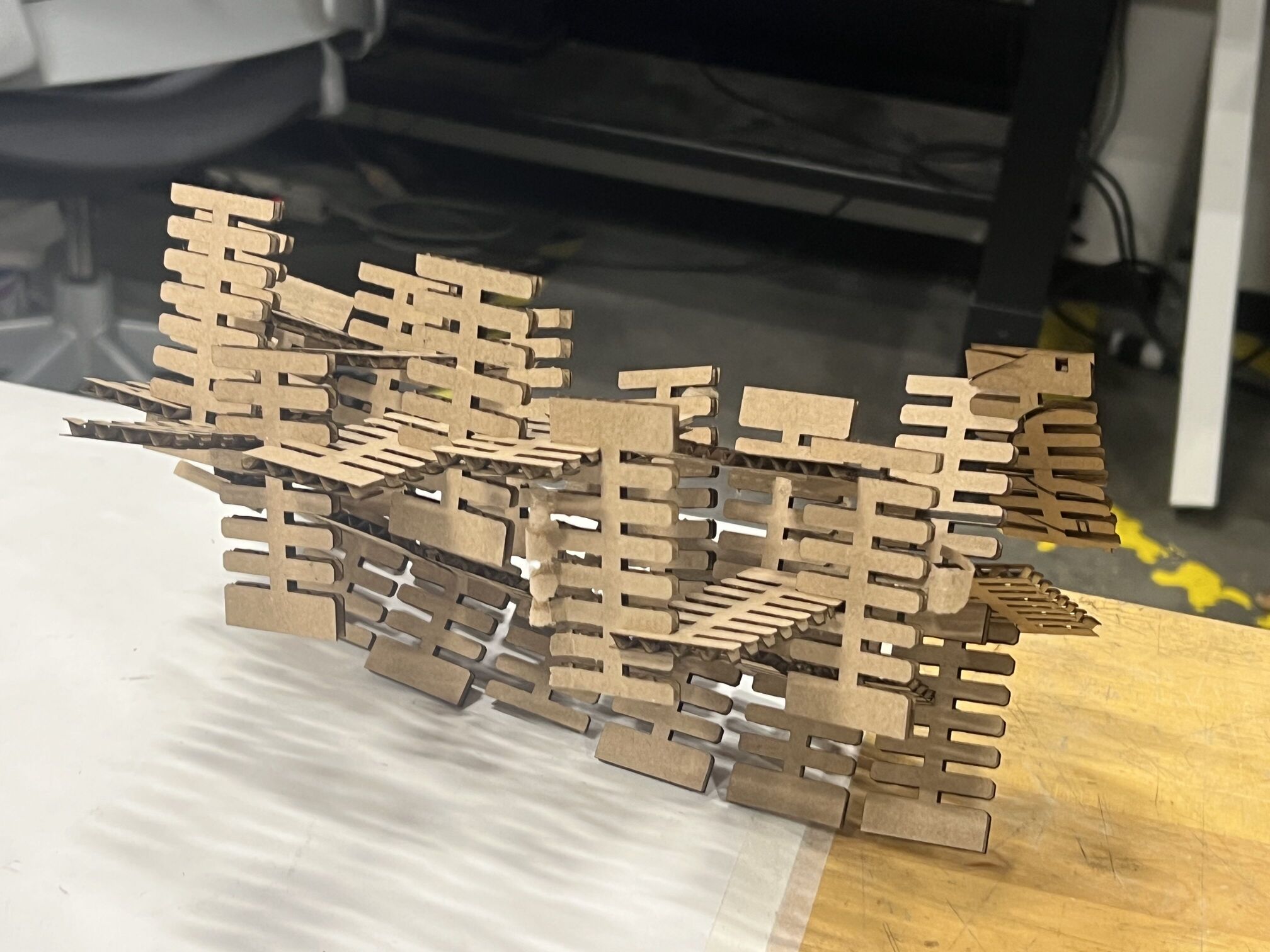

I initially tried to make a giant mega tower to solve the question of “how high can we build?” (with cardboard and no knowledge of structural integrity whatsover), and learned that the answer is not very. I then moved to making abstract installation type structures, full of wierd geometries and vaguely anthropometric like shapes.

Lessons for progeny:

-SPIRAL DESIGN

-come up with a scheme to iterate as fast as possible

-failure is far more enlightening than success :)