10: Group Machine

For the group machine, we made a Barduino, a machine that can dispense and mix drinks. I did 2 things in particular:

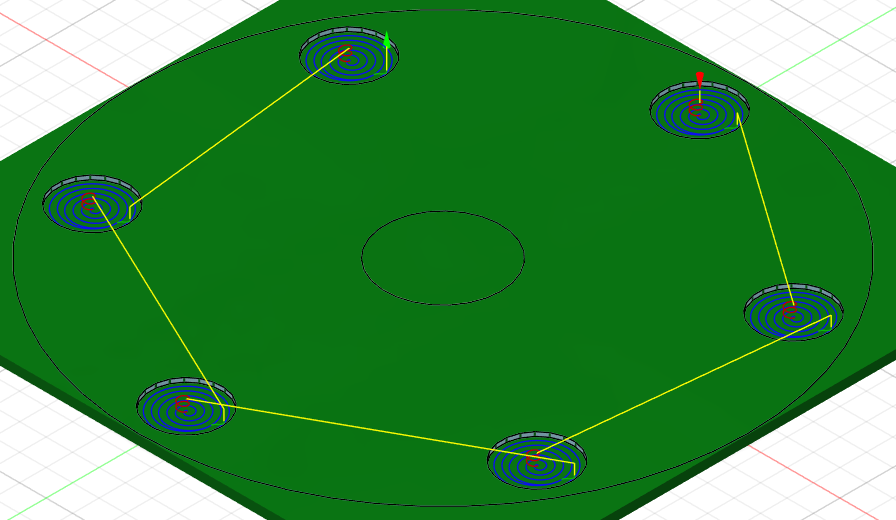

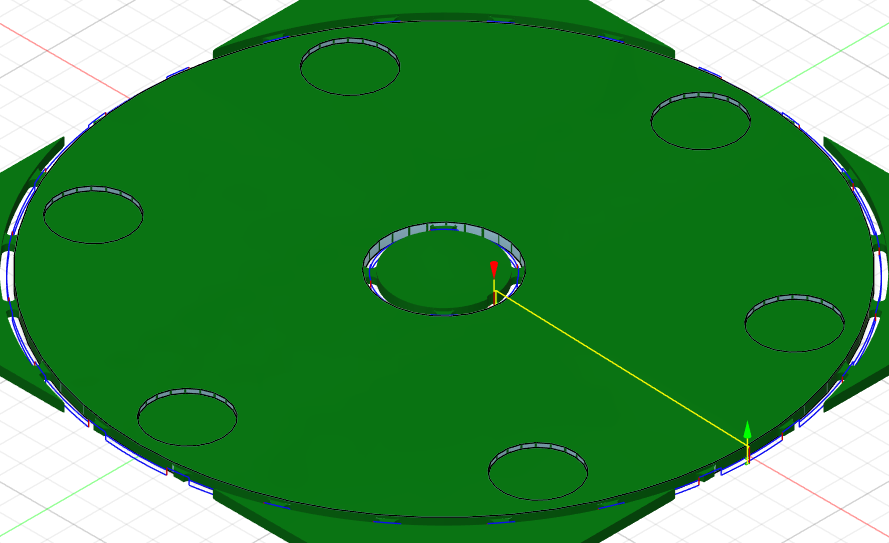

Turntable CAM

I did the CAM for the turntable. This uses a 3/8” flat end mill with spindle speed 12000rpm, cutting feedrate 120”/min, and ramp and plunge feedrate 60”/min

The Fusion file is here.

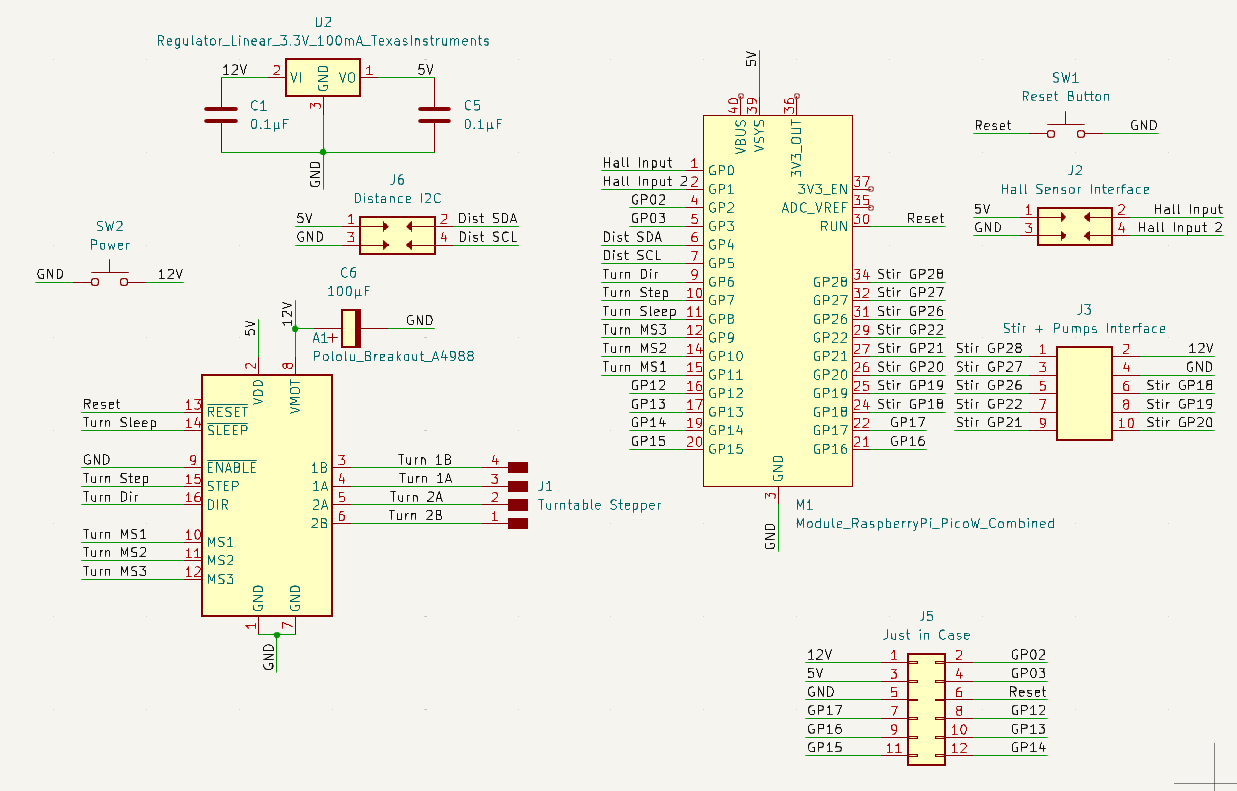

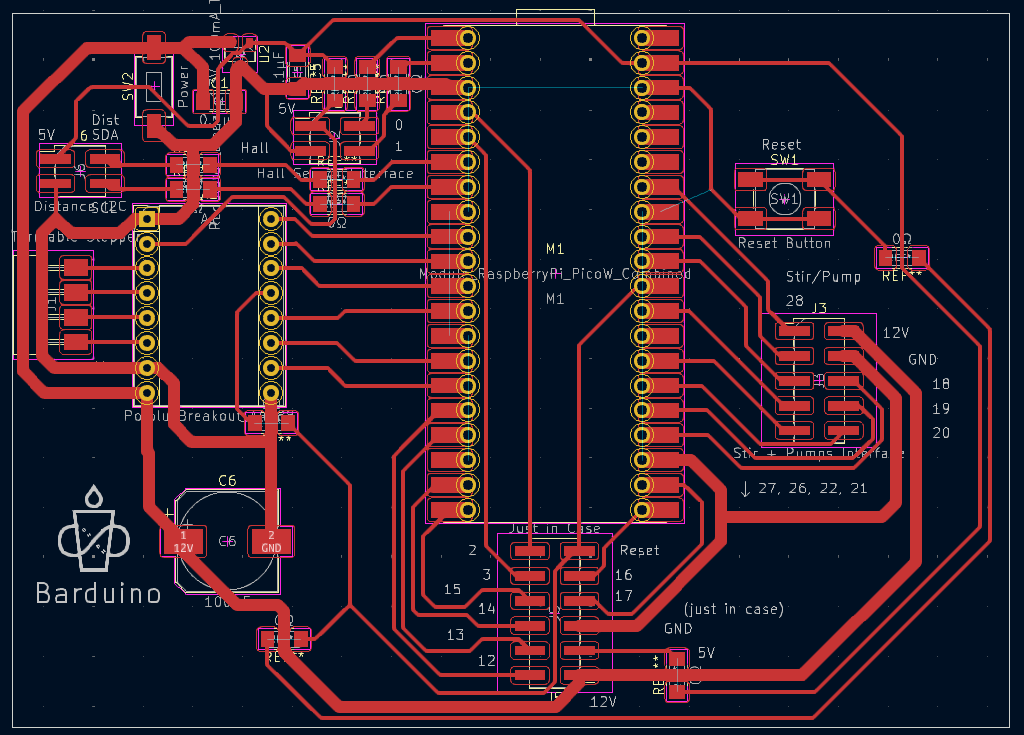

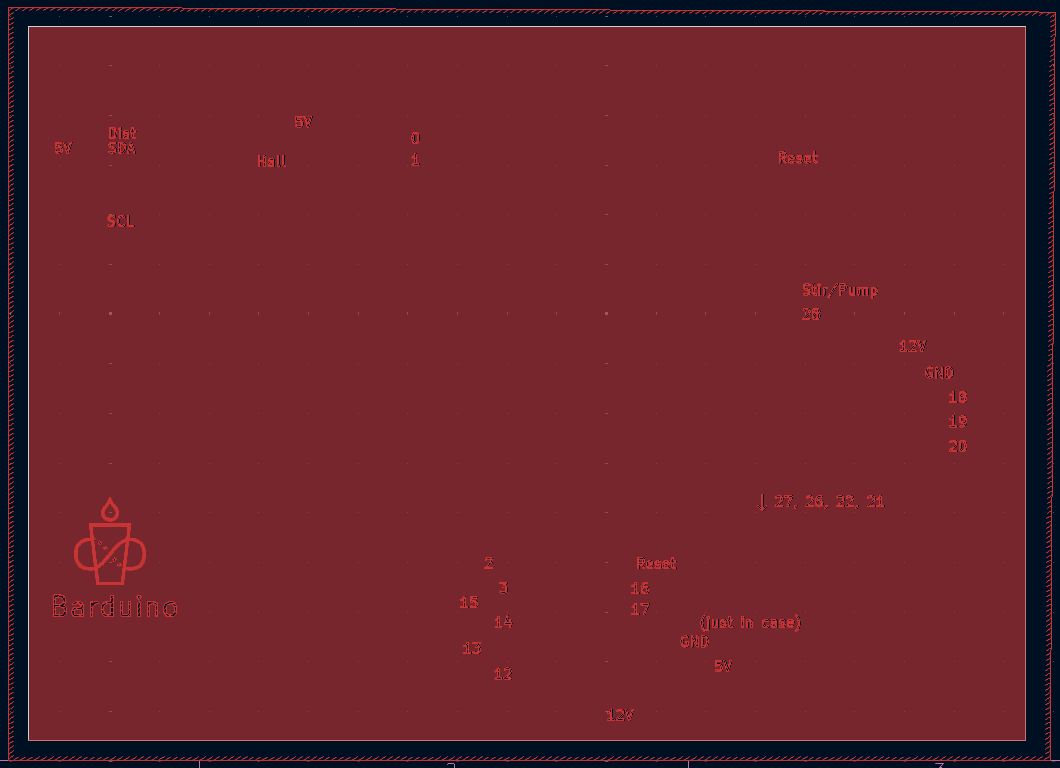

Main board

I also designed the main board. This needed to communicate with an external Hall sensor, a distance sensor (for cup sensing), the stirring interface, and a stepper motor (for spinning the turntable). I also exposed the extra pins along with a copy of GND, which proved useful for debugging stepper motor problems.

The KiCad files are here.

For the text, I needed to use a trick to get it to register properly in Bantam Tools. I copied all the text and the edge outline (for alignment) onto a separate board, added a fill-in zone, turned the text into rules that banned filling in, and plotted that board separately.

This was imported into Bantam Tools and only the traces were milled. And they were milled with an engraving tool. Unfortunately, I set the trace depth too low, so the engraving came out subpar, but whatever.

One reason why this job can’t be combined with the regular trace milling is that Bantam Tools has a bug that if you add a bigger tool in addition to the engraving tool, the letters that don’t have holes get lost. This is probably because Bantam Tools sees that the letters aren’t really separating traces, and it won’t just rest machine every single area it can rest machine because that would then lead to unnecessarily rest machining sharp corners in traces.

I also did the soldering for the board, except power.