13: Laser Cutting a Metal Sign

For wildcard week, I did metal laser cutting with the FabLight laser cutter at the CBA shop.

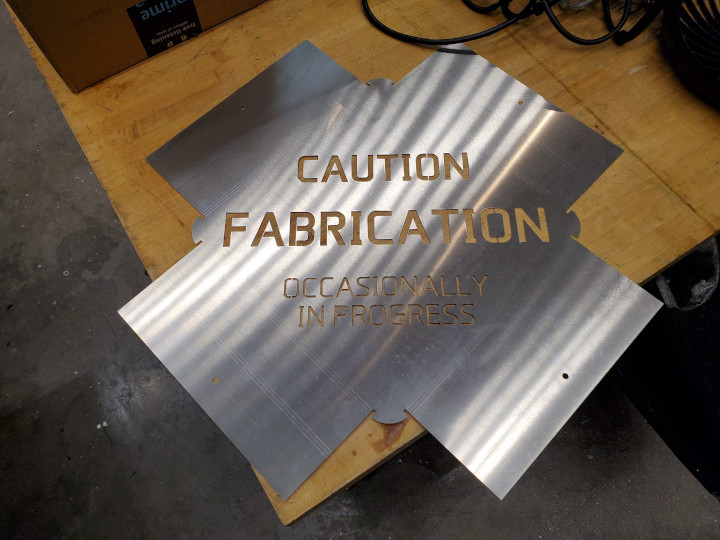

There’s a sign on the door to my room that says “Caution: Fabrication occasionally in progress” because I occasionally make some stuff in there. I decided to cut a metal version of this sign.

I pulled the design I had from the while ago, changed the font, added 0.5mm lines to break up holes in letters, and designed flanges that would make the sign stick out 2 inches.

This was exported as a .dxf, imported into FabCreator (I think that’s the program’s name?), set the settings to 0.04” 6061 aluminum (despite the fact that I was cutting steel, probably), and exported a .fab file for the laser cutter.

The laser cutter settings were

- Engrave: 5 in/s feed rate, 10% power, 2000 Hz frequency, 10 PSI cut pressure

- Cut: 0.15 in/s feed rate, 100% power, 1800 Hz frequency, 130 PSI cut pressure

And now for action! I used steel (probably) that was probably 1mm thick.

The laser cutter was slower than I expected, so I had to wait a while. When cutting out the letters, sometimes they would get stuck in the frame, which was worrying. In particular, the second A in FABRICATION stuck out so much it interrupted the laser cutter’s rapid movement. Thankfully, the laser cutter tried again and gave it a nice ramming and it got out of the way. Also, sometimes it would complain that the gas pressure is low. Resuming the job fixed the issue whenever it happened. And the cut came out amazing! (except for welded particles on the bottom)

Then came folding. For the mountain folds, I used the finger brake at the CBA shop. However, the geometry makes it impossible to do the valley folds there. The ends were too short for the finger brake to get a handle on them. So, I faked a finger brake.

Not as good as the real thing, but it did the job. The result:

And now people will really know to beware, because fabrication is occasionally in progress.