Week 9: Test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine (group assignment)

We covered several things:

- The OSB is around 0.5 but changes depending on the batch and the weather

- The onion skin! Chris said he would set it depending on the thickness - my onion skin came out nice and was easy to cut my parts out with a box cutter

- Limit small parts to 6"x12" or larger

- OSB dimensions were 96 x 48 with two inch protected. 94 x 46 in

The OSB was 0.466 inches and fit well without any additional kerf added. (See test below!)

Week 9: Make something big

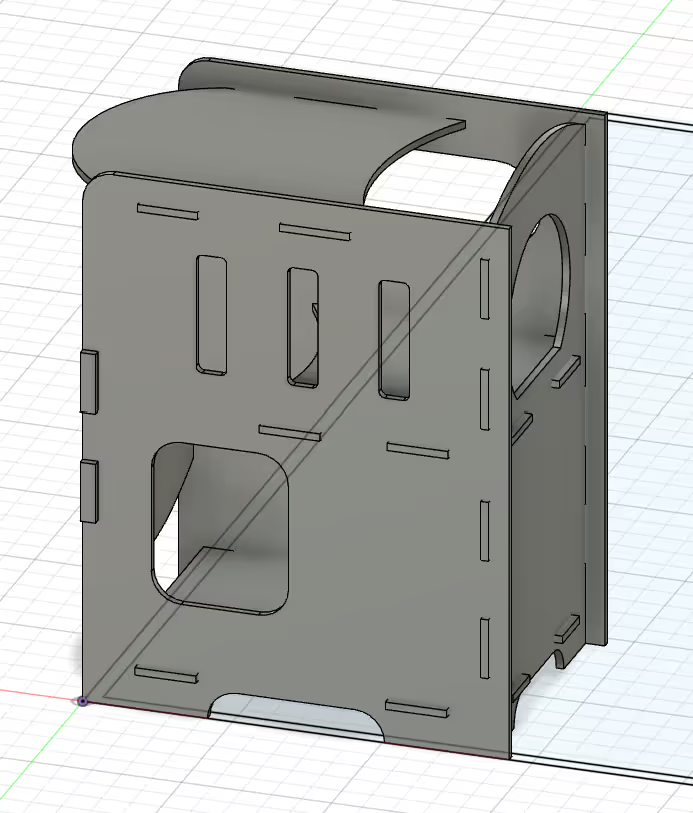

This week was more intuitive for me than the others. This was basically a giant version the a lasercutter. My goal this week was to designs a cat tree for my cat that would fit next to my couch. The overall dimensions I used at first was 40 x 26 x 50 in. I wanted the bottom part to fit my cat's litter box. The litter box enclosure at the bottom drove most of the first design.

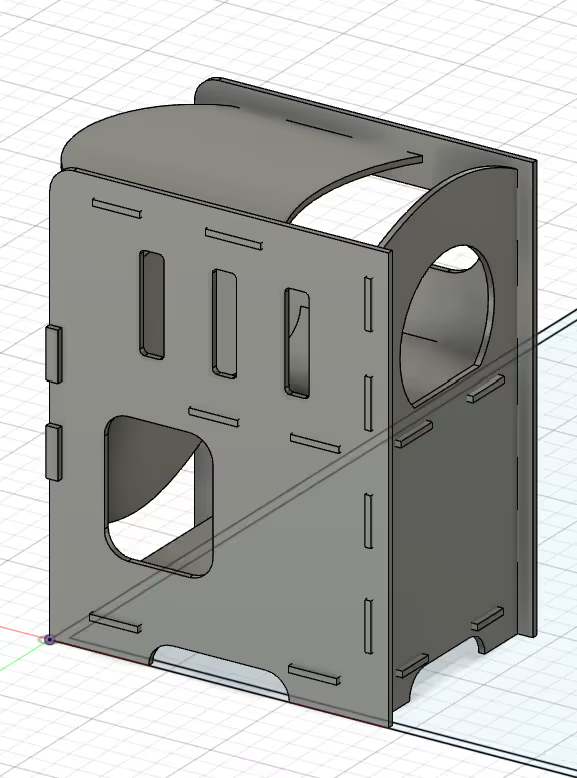

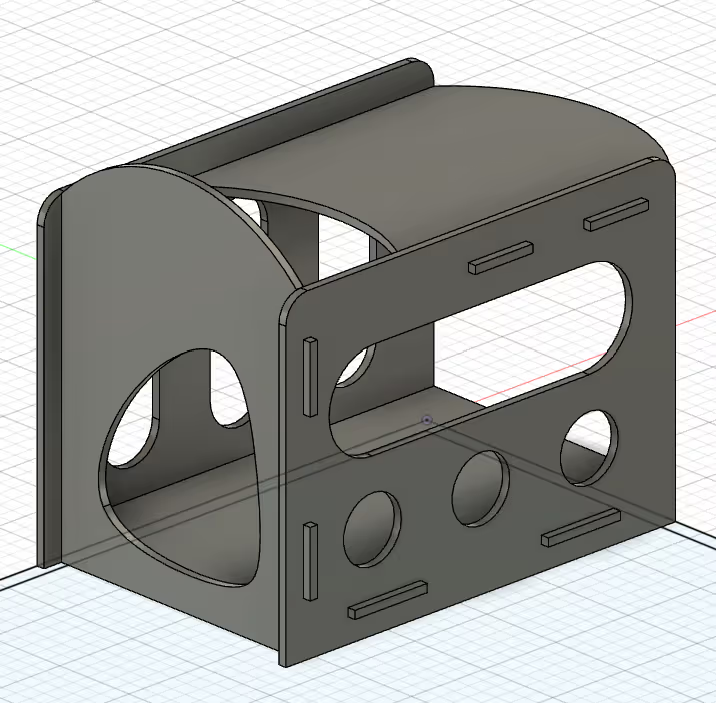

You can see in the front profile has a window for the litter box which I measured specifically to fit there.

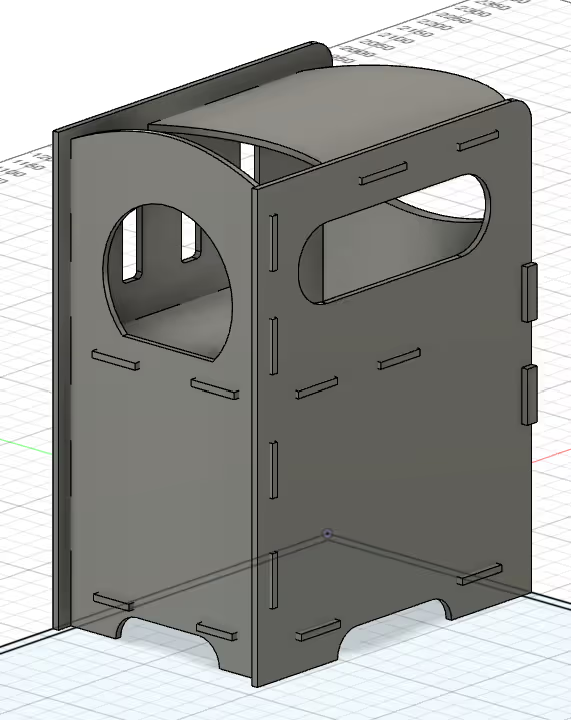

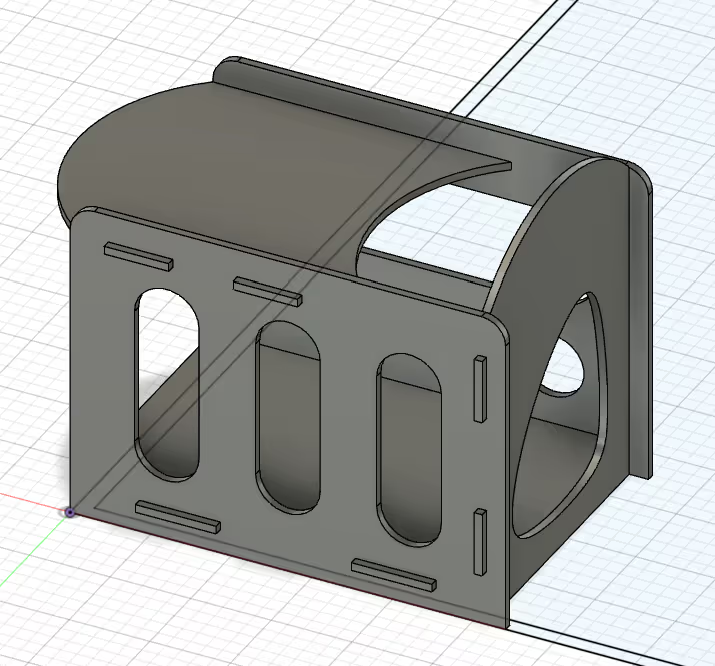

The back didn't have many windows because I was trying to enclose the litter box for smell control.

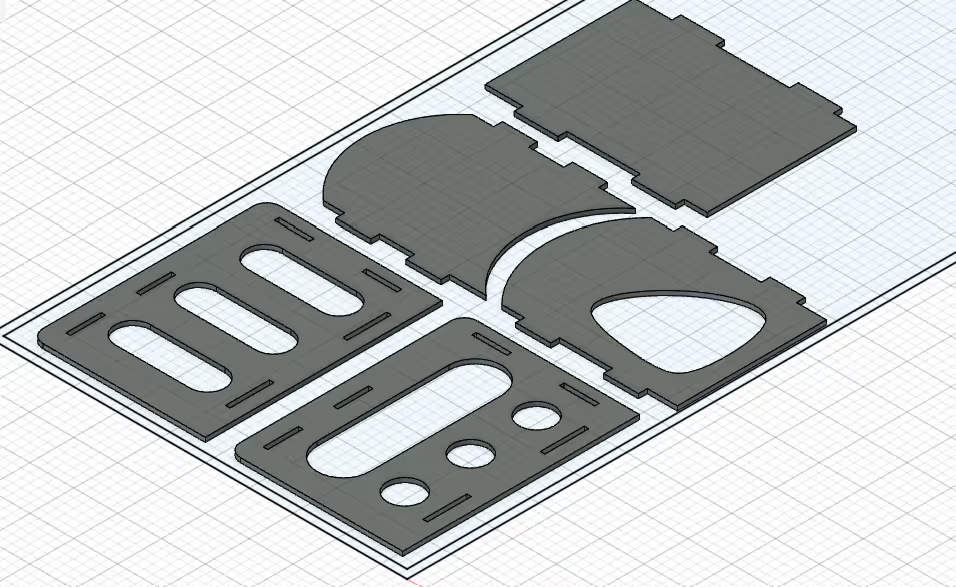

After designing - it didn't fit on the 96 x 48 sheet of OSB that was to be provided. Well, it fit - but it would have caused some problems on the Onsrud without having 2-3 inch gaps between pieces.

I redesigned the cat jungle gym to go on top of the litterbox instead of the litterbox fitting inside it to reduce the size.

I left a lot of windows in it since my cat is more likely to hang out inside if there are a lot of openings to play through.

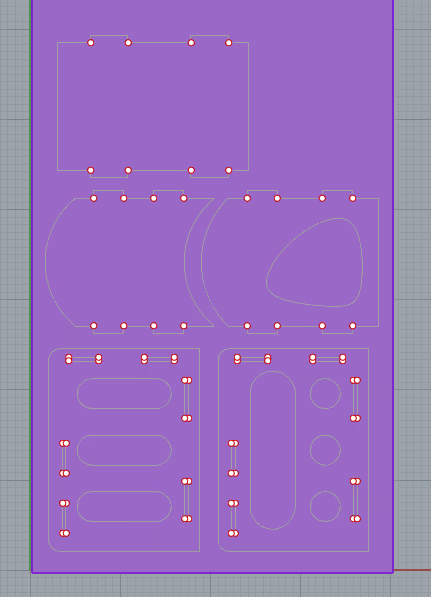

This is the pieces disassembled within the 96 x 48 box.

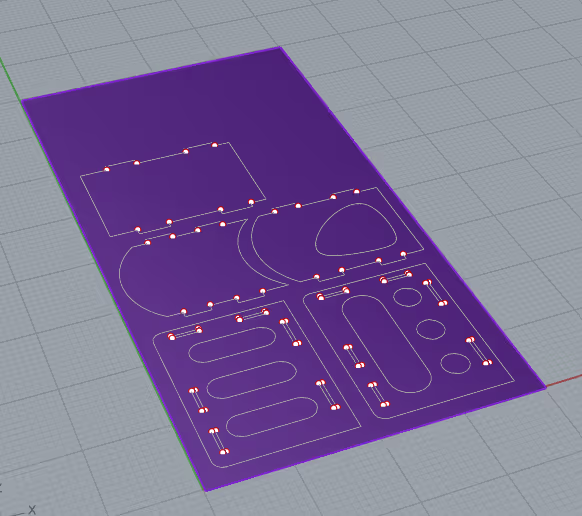

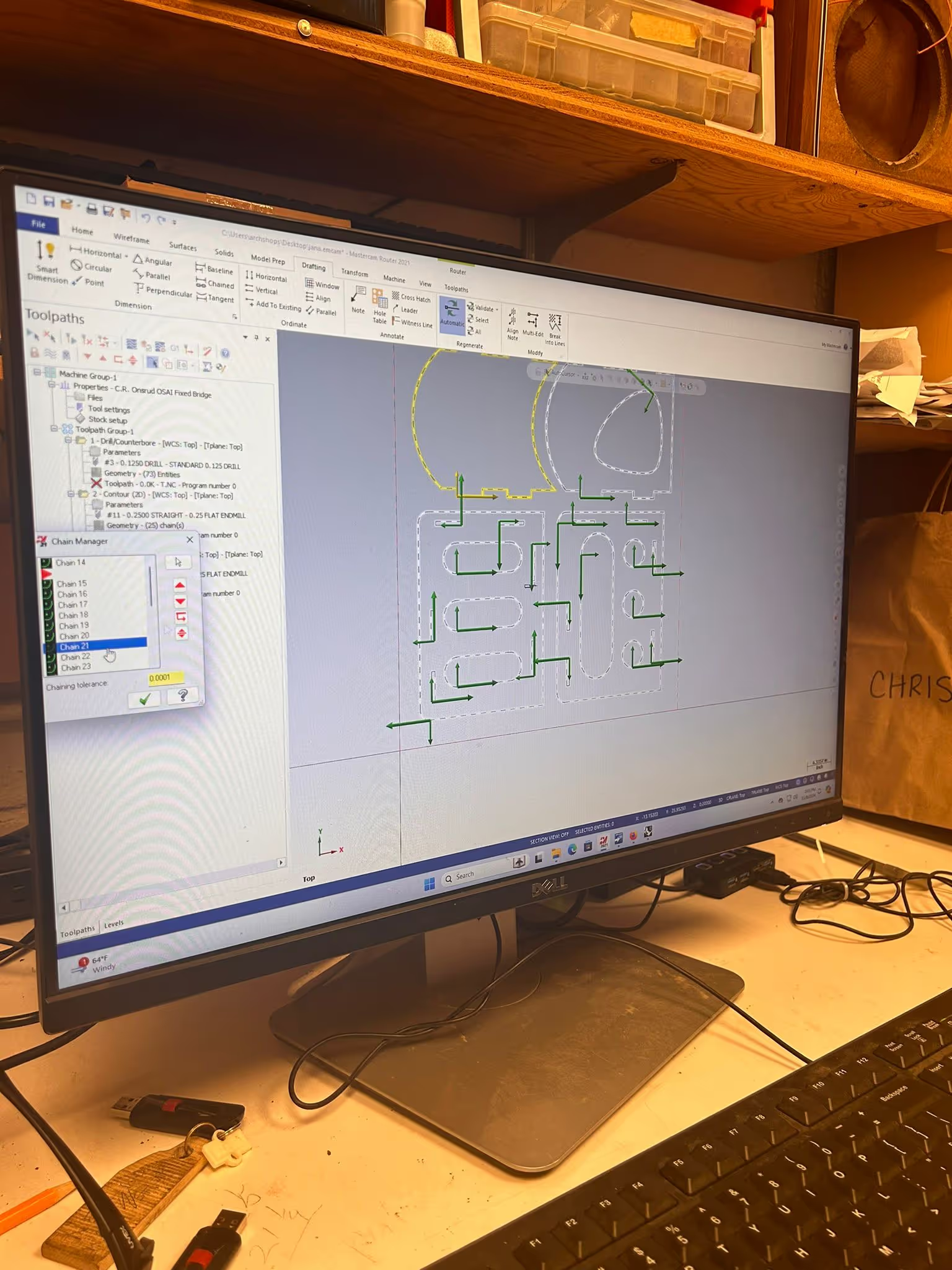

To print on the Onsrud, they prefer a Rhino file, so imported my geometry and projected my lines on to the surface. Also, since you will notice the points at each of the drill points. We learned that the drill points are where the router goes in to cover the corners that a circular part can't reach. This is important because the parts interlock. If the corners aren't fully cut out then the pieces won't fit together properly.

No glue or fasteners used in assembly!

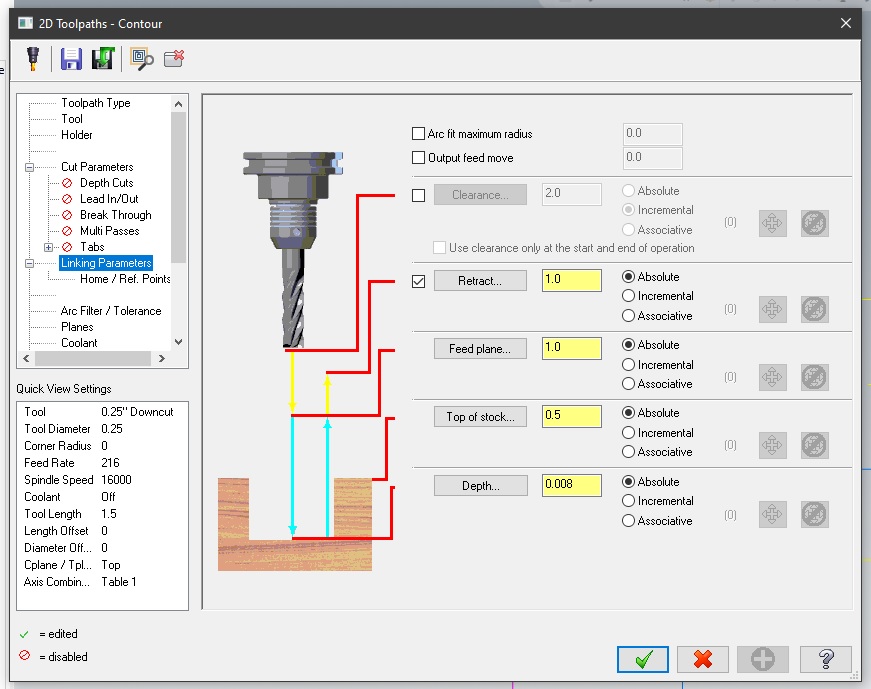

I worked with Chris and N51. He helped set up my file. The drilled corners were first, then the outlier lines, and finally the inner lines.

I used the OSB on the Onrud. We nailed down the corners because the vaccum wasn't consistently holding it down in one place.

Putting the cat jungle gym together required some elbow grease. I routed the edges to make assembly smoother.