Week of Dec 4, 2024

Design and produce something with a digital process not covered in another assignment

This week was like being at a seafood buffet, and it was challenging to pick one wildcard process out of all the fun option available. I went with the Zund, though I was also interested in trying the UR-10 robotic arm and metal laser-cutting with the Fablight.

The Zund is a 2.5 axis large format machine primarily for industrial use. Some cool applications include cutting really big things (only limited by bed width of 1.8m, as the length can be rolled), cutting materials that cannot be cut on a laser cutter (e.g. polycarbonate plastic aluminum, and maybe even pasta sheets?!), creasing both sides of a material with high levels of precision, and using custom end effectors (ultrasonic welder for inflatables, pizza cutter, pen - possibilities are endless).

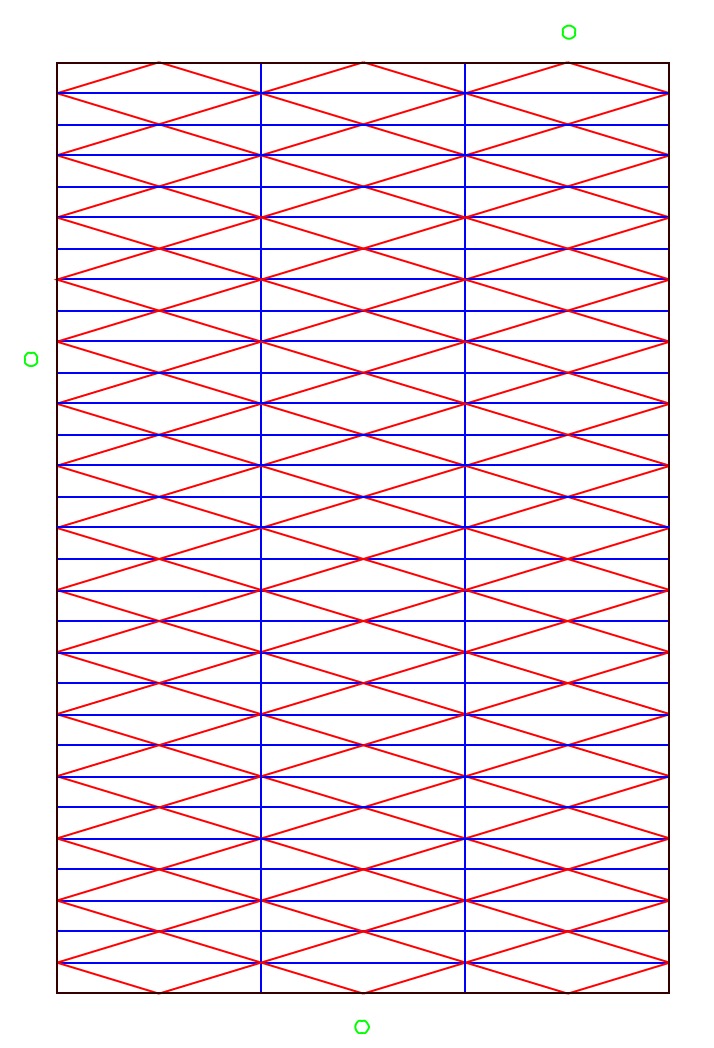

I wanted to make a rigid version of my folded patterns so far, using plastic. Thus the goal for this week was to pre-crease polycarbonate plastic and to fold it. Prior to cutting, TA Alfonso guided us on file setup, which was via layers in .dxf. In my case, I prepared 4 layers each for mountain folds, valley folds, boundary, and registration holes (8mm diameter circles). DXF file here.

Started off with TA Alfonso showing how to change the tool modules - there are 3 modules, the rightmost being a cutting tool which we will keep, and the middle and leftmost being a router that we are replacing with a crease tool in the middle module. To install, ensure that the orange dots are lined up before twisting it until one of the dots disappears:

We then cut the polycarbonate material in 2 passes: 1st pass was mountain fold + registration marks, 2nd pass was valley fold + boundary cut (after flipping the material over). What's cool about the Zund is that once you flip the material over, it reads the registration holes and automatically calibrates, such that the material can be slanted like so. The tension and warp created by the creases were also a non-concern since the Zund has a vacuum under the bed which ensures flat adhesion for the flipped pass.

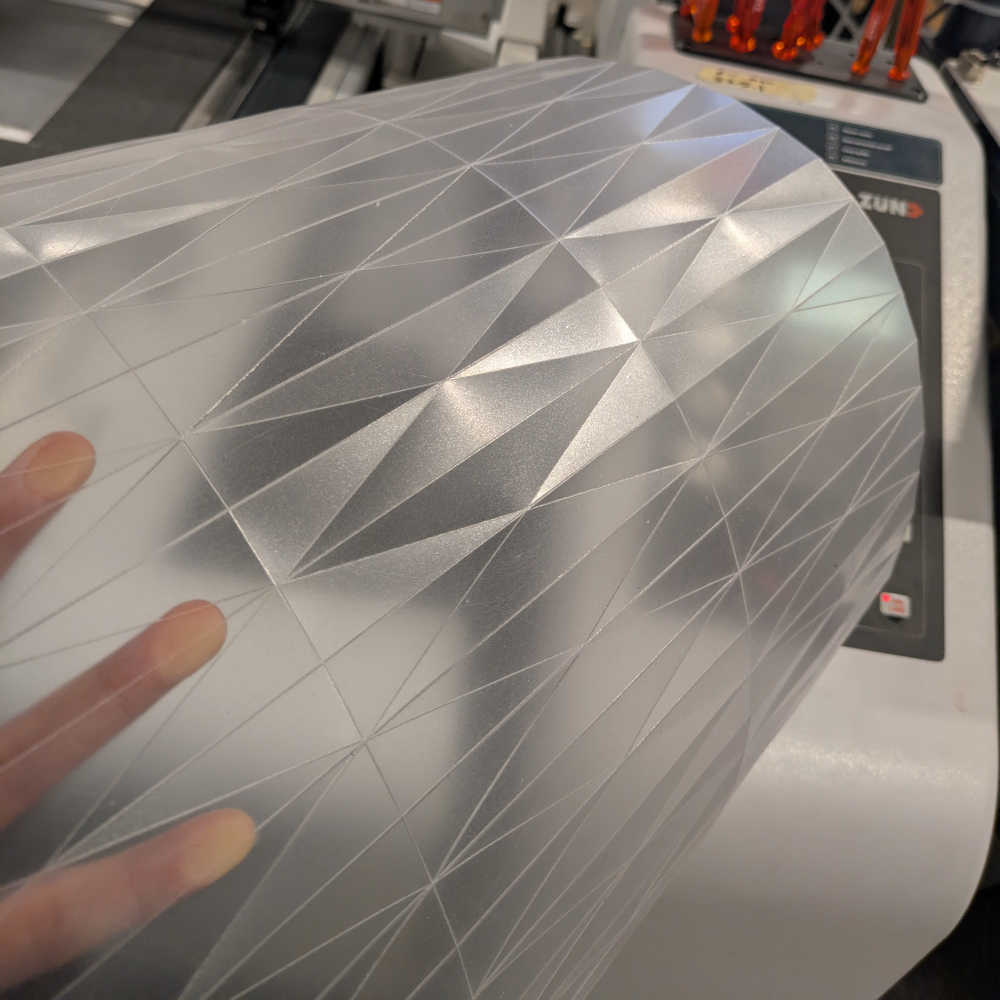

And the end result is still extremely precise! Pictured here are the completed creases:

We moved on to trying to cut a harder polycarbonate for a file that takes up almost the whole bed - trying to make a large scale Yoshimura folding version of my helmet, perhaps as a little cocoon for my desk. Alas, we broke not one, but 3 tool tips when trying to test cut the registration circles. Apparently this has never happened before so now we know that harder polycarbonate really stresses the limits of the Zund tools.

The pre-creased polycarbonate sheet can then be folded. The Zund did not really save me time from folding though, as I still had to manually fold and polycarbonate was significantly more difficult to fold than fabric.

After much time grappling with the folds, I decided to try making fun shapes with the folds, to also show the folding at different stages. I shall call this series "Unfolding Folds".

As a bonus, the clear material makes for really nice shadows. I would be interested to further explore making art with this! Adding to the list...