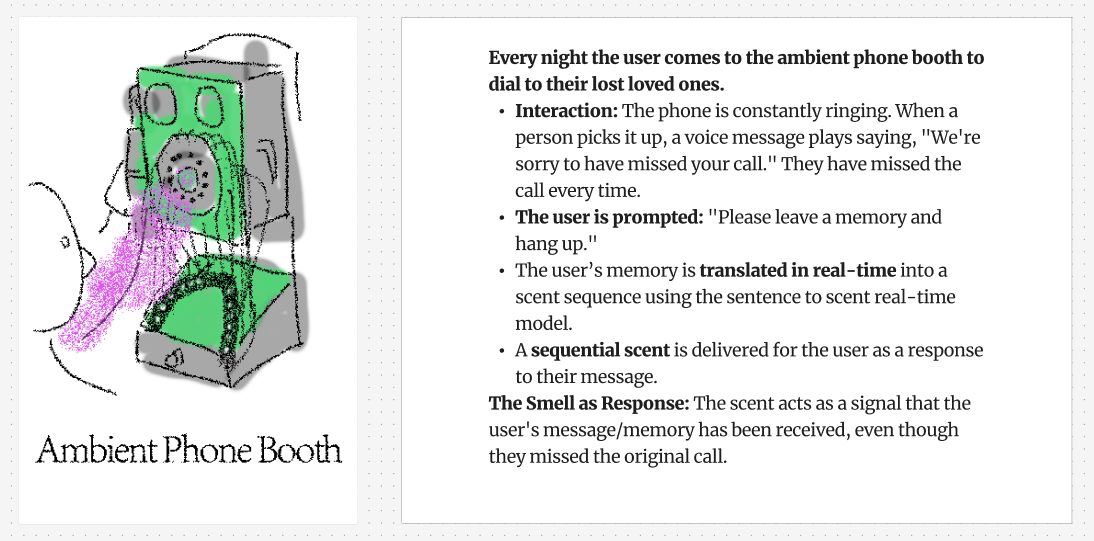

Scent Dial - Into The Past

Initial Concept

Initial sketch by Awu Chen inspired by Gigi Minsky's personal story

Project Overview

The Scent Dial combines a vintage rotary telephone interface with a modular Bluetooth-controlled ultrasonic scent diffuser system. Instead of dialing phone numbers, users dial scent sequences - each number on the rotary dial corresponds to a different scent (e.g., 12 = smell of home, 6 = smell of dinner). The project integrates the scent diffuser technology developed in Week 12 (networking and communications) with the interface design from Week 13 (interfaces and applications), creating a tangible scent interface.

The initial concept of the Scent Dial originated from a phone call between myself and Gigi Minsky where a personal and potent experience of TeleAbsence Moment was captured and recounted around the telephone. By the end of this call, Gigi and I decided that it is worth developing this idea further and inviting JB Labrune in our following conversation.

The initial concept of the Scent Dial originated from a phone call between myself and Gigi Minsky where a personal and potent experience of TeleAbsence Moment was captured and recounted around the telephone. By the end of this call, Gigi and I decided that it is worth developing this idea further and inviting JB Labrune in our following conversation.

Project Vision

• Nostalgic Interface Design: Using a vintage rotary telephone to create an intuitive, tactile interface for scent control

• Scent-Number Mapping: Creating meaningful associations between dialed numbers and scents (12 = home, 6 = dinner, etc.)

• Networked Scent Technology: Integrating Bluetooth-controlled ultrasonic scent diffusers for wireless scent emission

• Tactile Interaction: Transforming scent selection from digital menus into physical, ritualistic dialing actions

• Accessible Technology: Making sophisticated scent technology approachable through familiar, nostalgic interfaces

• Complete System Integration: Combining hardware fabrication, networking, and interface design into a cohesive final project

• Scent-Number Mapping: Creating meaningful associations between dialed numbers and scents (12 = home, 6 = dinner, etc.)

• Networked Scent Technology: Integrating Bluetooth-controlled ultrasonic scent diffusers for wireless scent emission

• Tactile Interaction: Transforming scent selection from digital menus into physical, ritualistic dialing actions

• Accessible Technology: Making sophisticated scent technology approachable through familiar, nostalgic interfaces

• Complete System Integration: Combining hardware fabrication, networking, and interface design into a cohesive final project

The Scent Dial System

The Scent Dial consists of several integrated components:

Rotary Telephone Interface: A vintage rotary telephone serves as the primary input device. The rotary dial mechanism is modified to detect which number is being dialed, converting the physical rotation into digital signals that control scent emission.

Ultrasonic Scent Diffuser: The output device from Week 12 uses ultrasonic piezo disk vibration at 108kHz to convert water (soaked with essential oils) into scented water vapor. The diffuser is controlled via Bluetooth networking.

Microcontroller System: The custom PCB integrates an ESP32C3 microcontroller that processes the rotary dial input, maps numbers to scents, and communicates with multiple scent diffusers via Bluetooth Low Energy to activate the appropriate scents.

Scent-Number Mapping: Each number on the dial corresponds to a different scent profile. Users can dial specific numbers to activate corresponding scents, creating a personal "phone book" of scents.

3D Printed Scent Speaker: A custom 3D-printed housing (the "scent speaker") contains the ultrasonic mist maker and integrates with the rotary phone design, creating a cohesive physical form.

Hardware Fabrication and Assembly

The Scent Dial hardware fabrication involved several key steps:

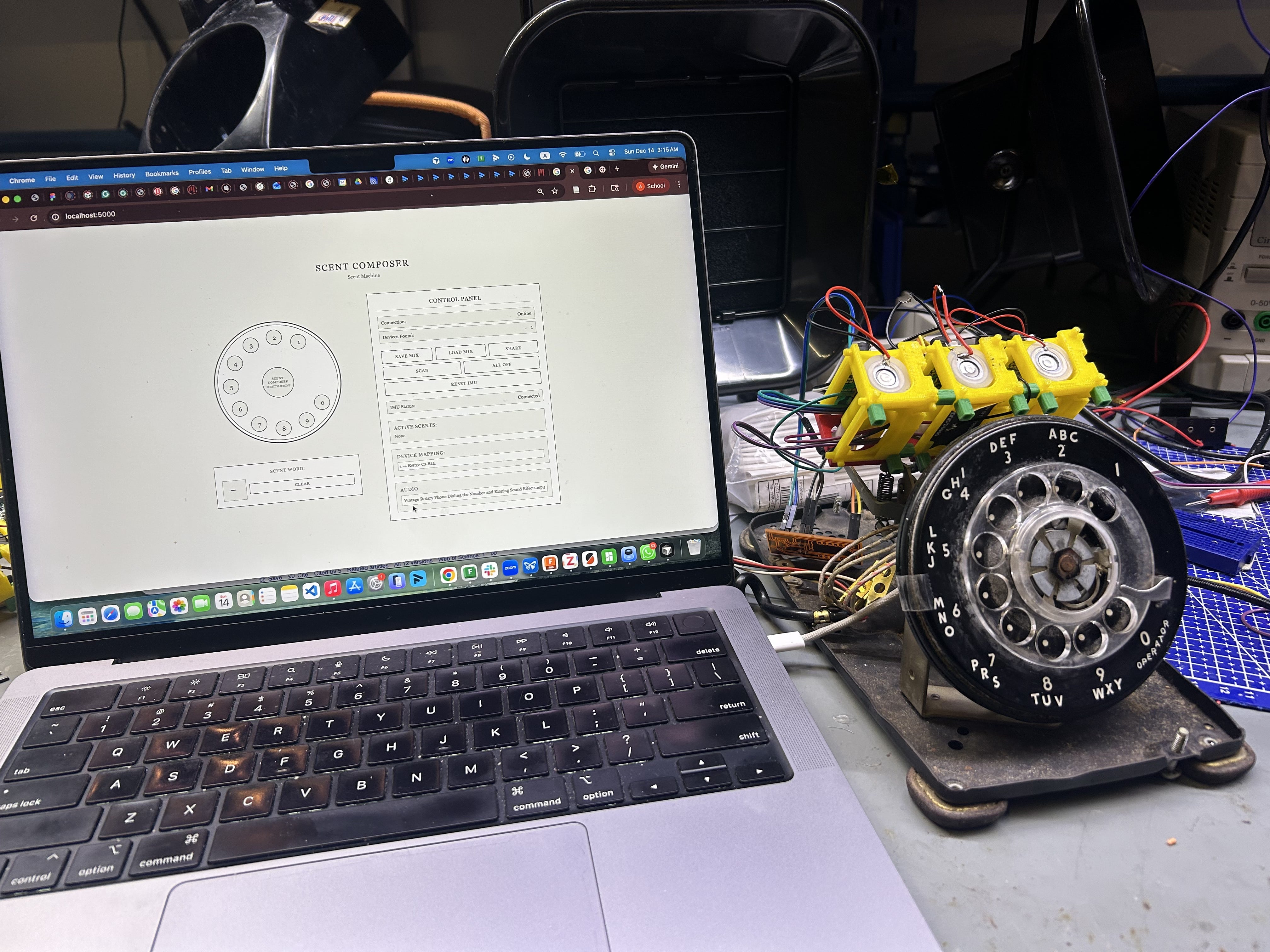

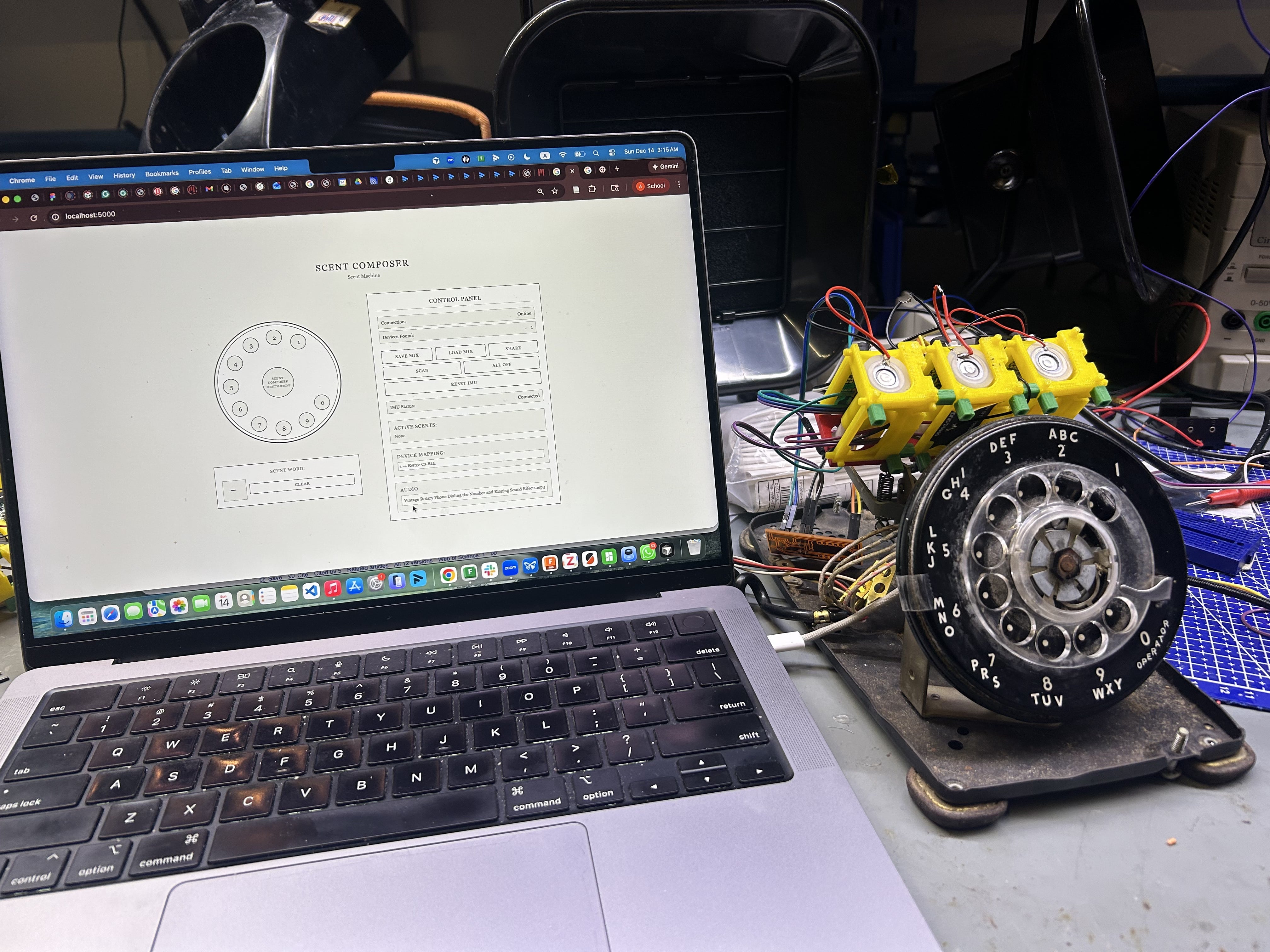

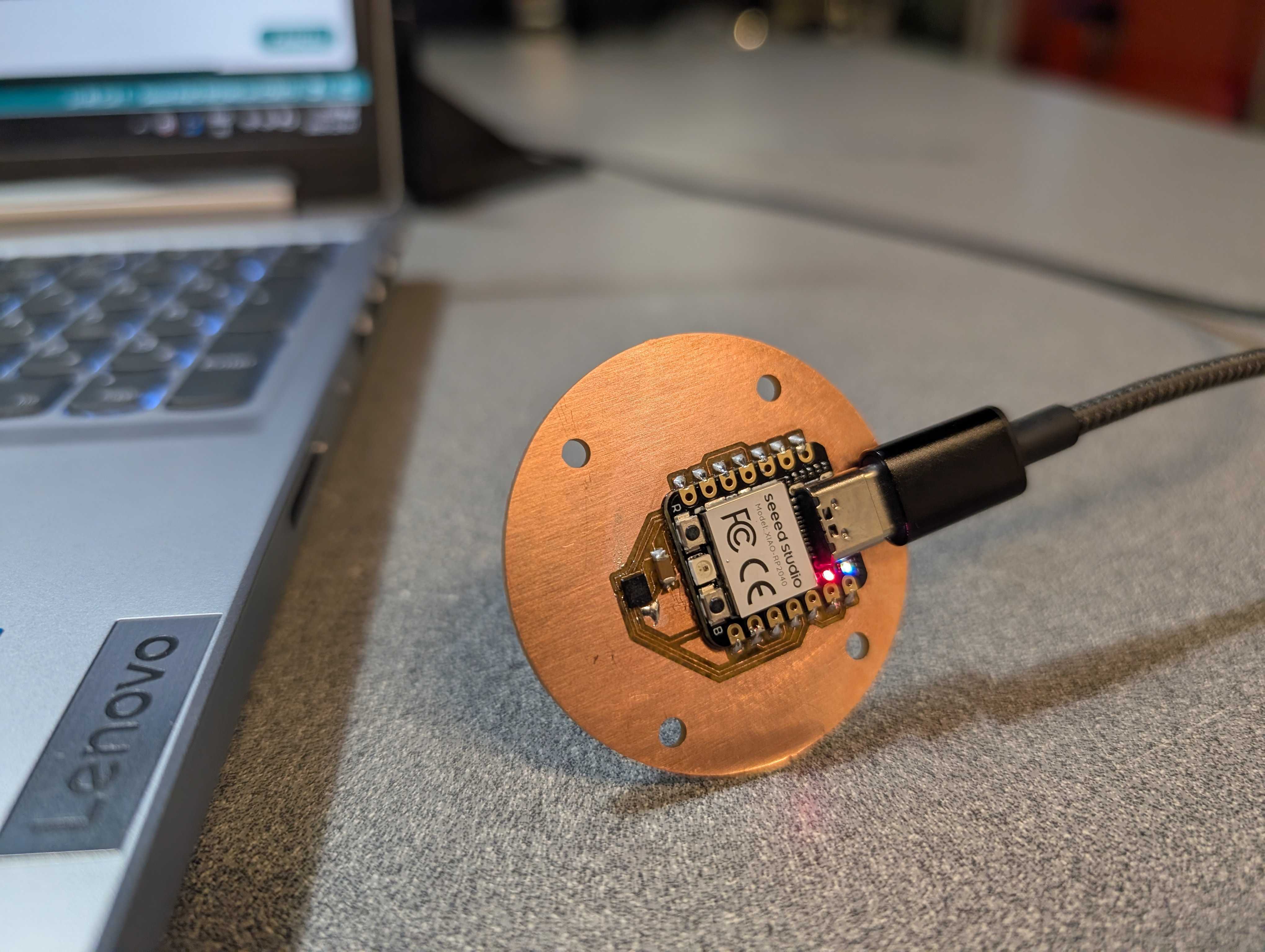

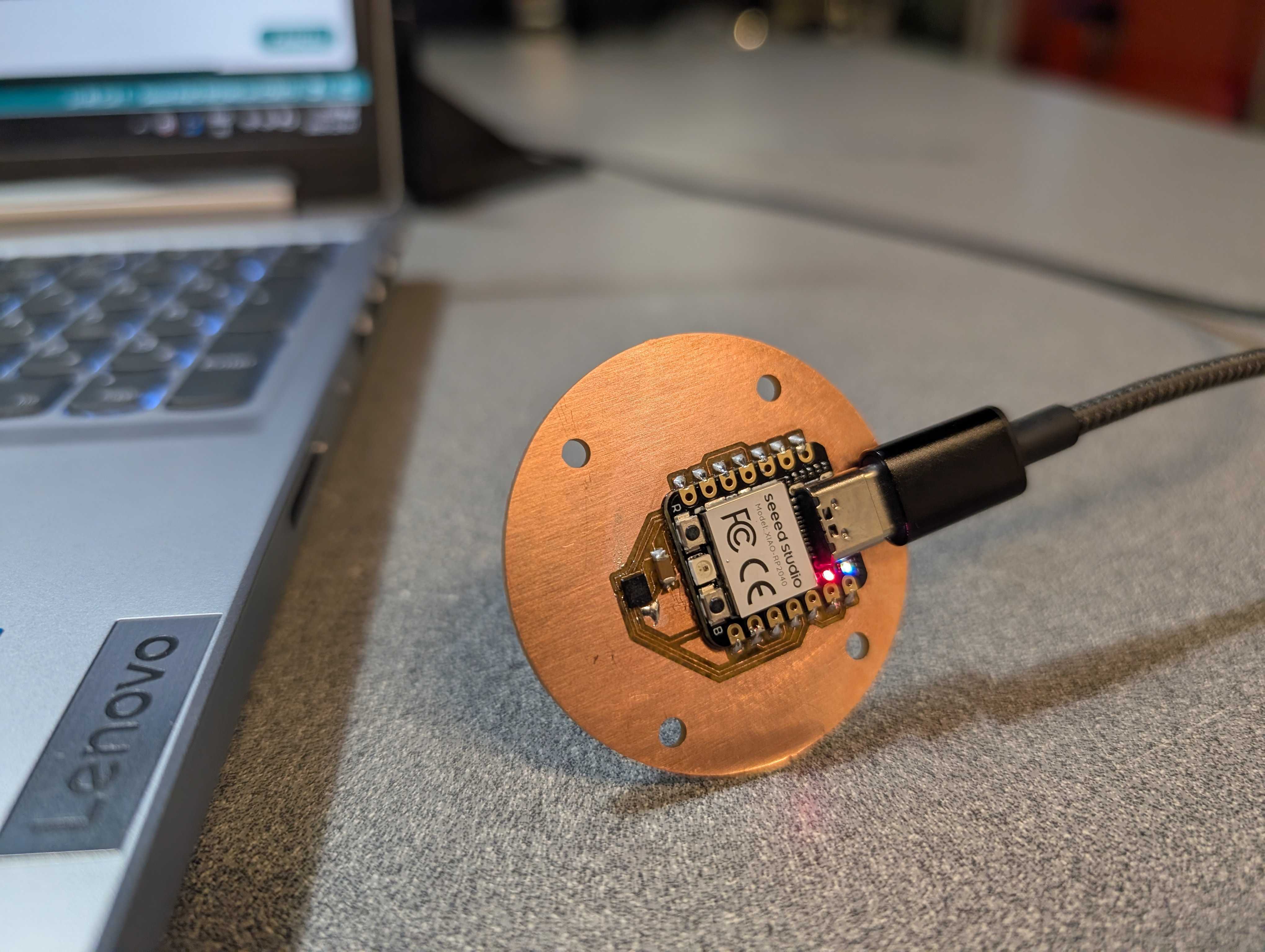

Modular scent diffuser setup featuring ultrasonic piezo atomizer disks integrated with Xiao ESP32C3 controllers. Each individual atomizer can be used to diffuse scent into the air and controlled separately. The modular design was developed in collaboration with Richard Zhang for the DJ Scent Mixer created as part of the wild card week.

Barebone assembly showing the rotary dial web interface integrated with the core electronics before final housing

Assembly process video of the Scent Dial

Four views of the assembled Scent Dial showing the complete integration of the rotary phone interface and scent speaker from different angleswo

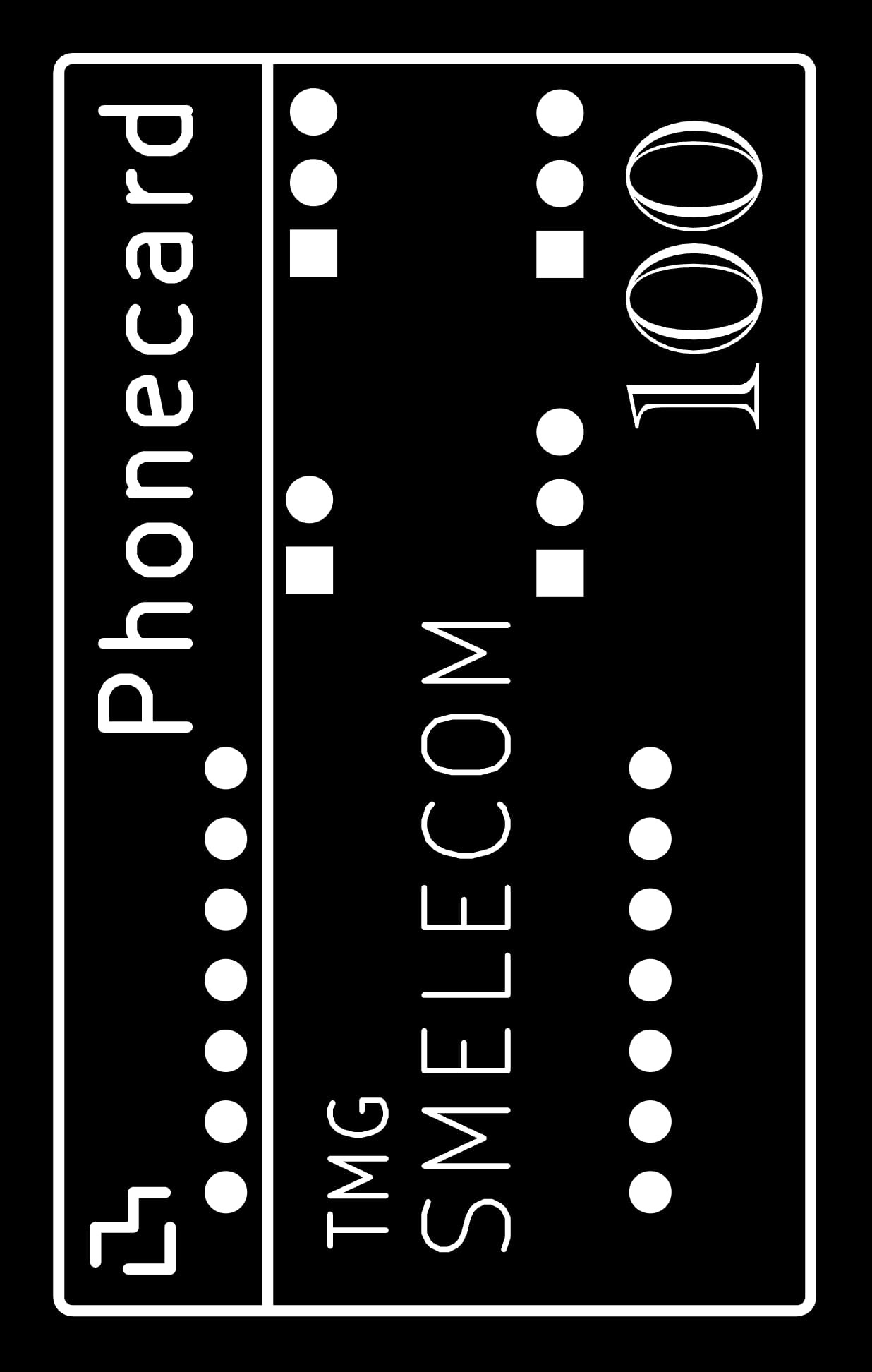

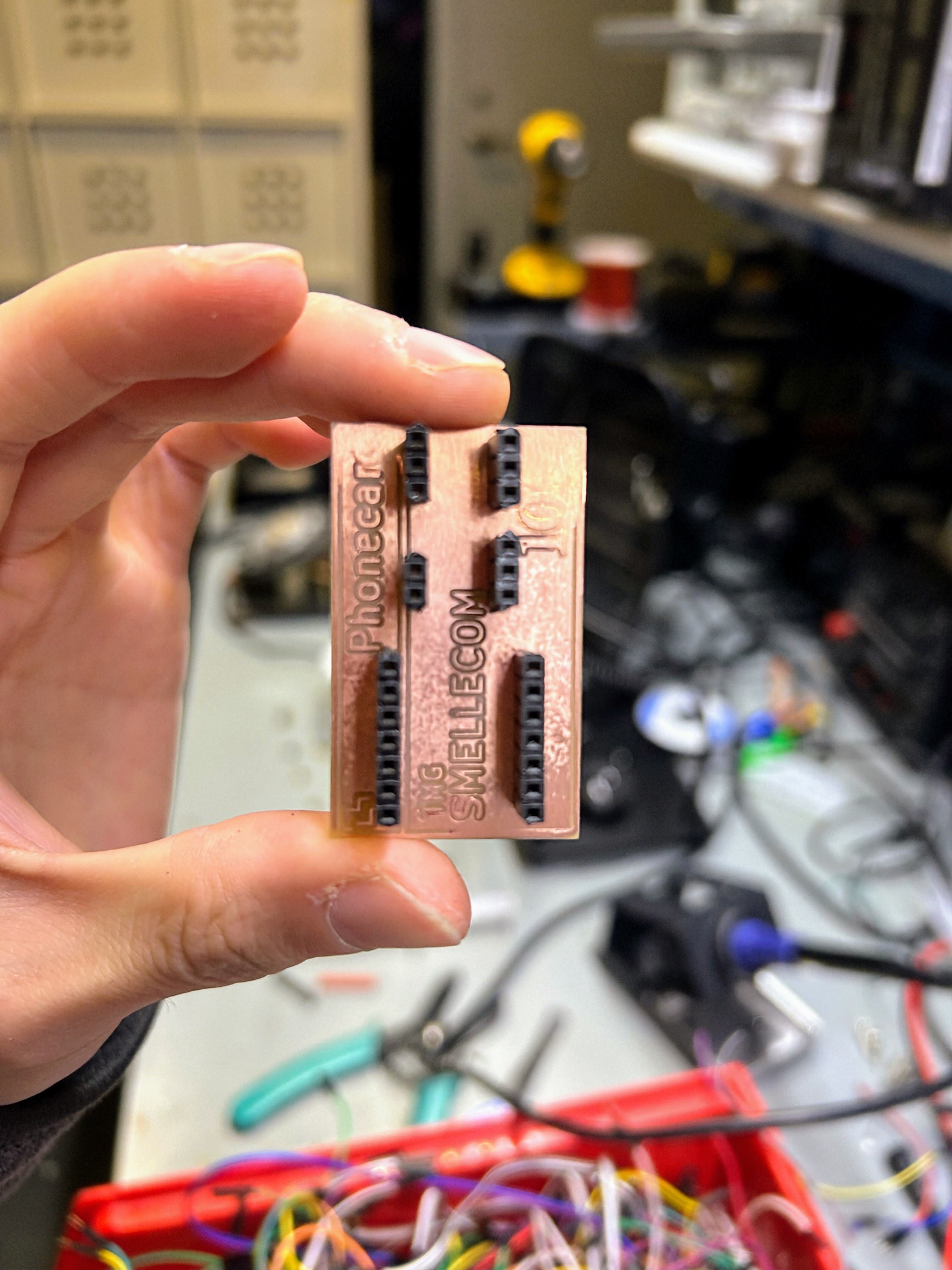

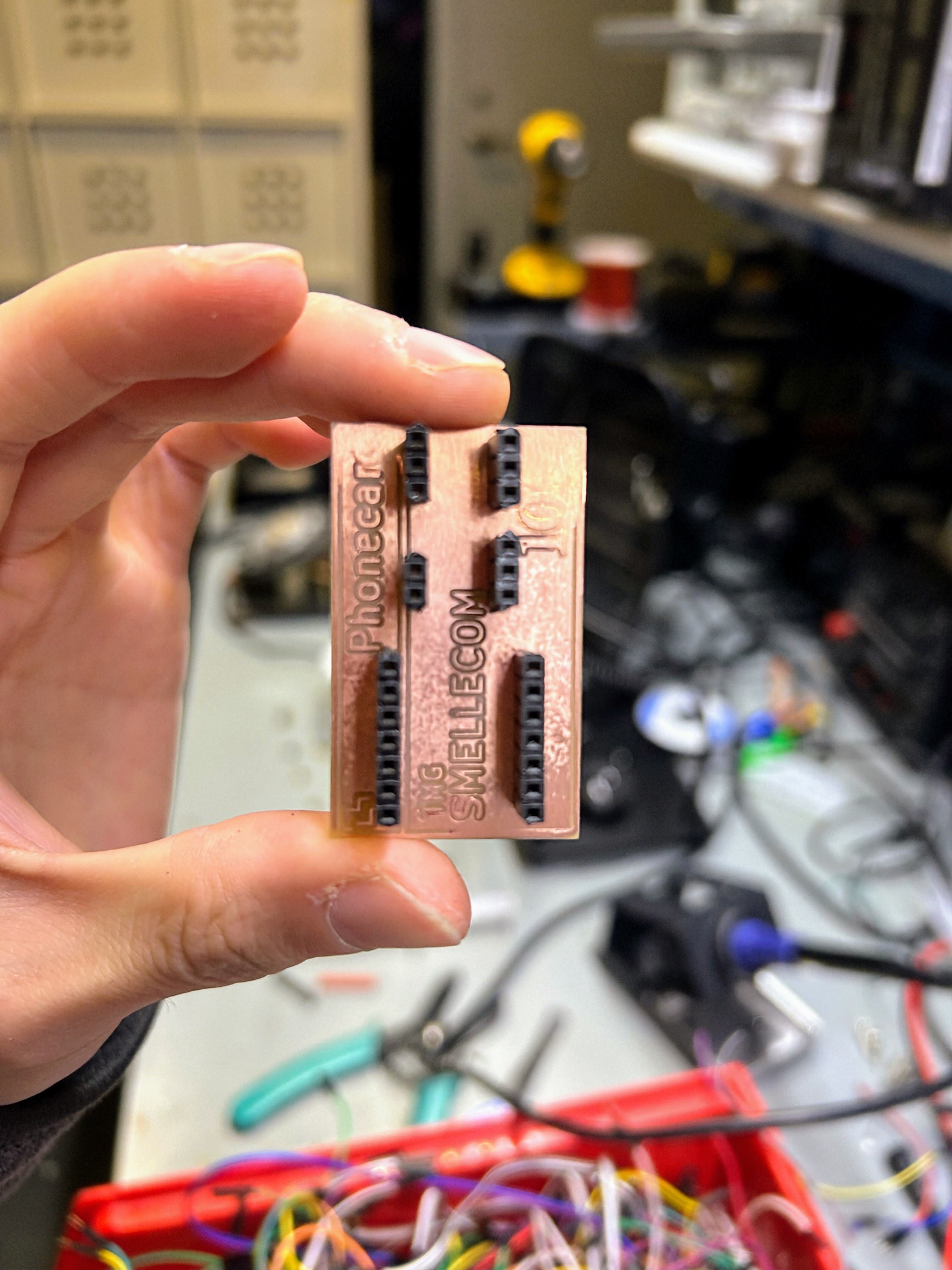

Hero shot of the Scent Dial with the SMELLECOM custom PCB

Final HTMAA showcase shot and edited by Hye Jun Youn

Custom Scent Dial PCB Development

Soldering of the old rotary phone with the scent electronics

Testing of the IMU sensor with the web UI

Modular Scent Diffuser Setup

Modular scent diffuser setup featuring ultrasonic piezo atomizer disks integrated with Xiao ESP32C3 controllers. Each individual atomizer can be used to diffuse scent into the air and controlled separately. The modular design was developed in collaboration with Richard Zhang for the DJ Scent Mixer created as part of the wild card week.

Final Assembly and Testing

Barebone assembly showing the rotary dial web interface integrated with the core electronics before final housing

Assembly process video of the Scent Dial

Four views of the assembled Scent Dial showing the complete integration of the rotary phone interface and scent speaker from different angleswo

Final Showcase and Presentation

Hero shot of the Scent Dial with the SMELLECOM custom PCB

Final HTMAA showcase shot and edited by Hye Jun Youn

The Scent Dial features a custom-designed PCB that integrates all control electronics into a single, compact board. This custom PCB enables the system to control all scent diffusers using one ESP32C3 microcontroller via Bluetooth, creating a unified control system for multiple scent emission devices.

PCB Design and Architecture

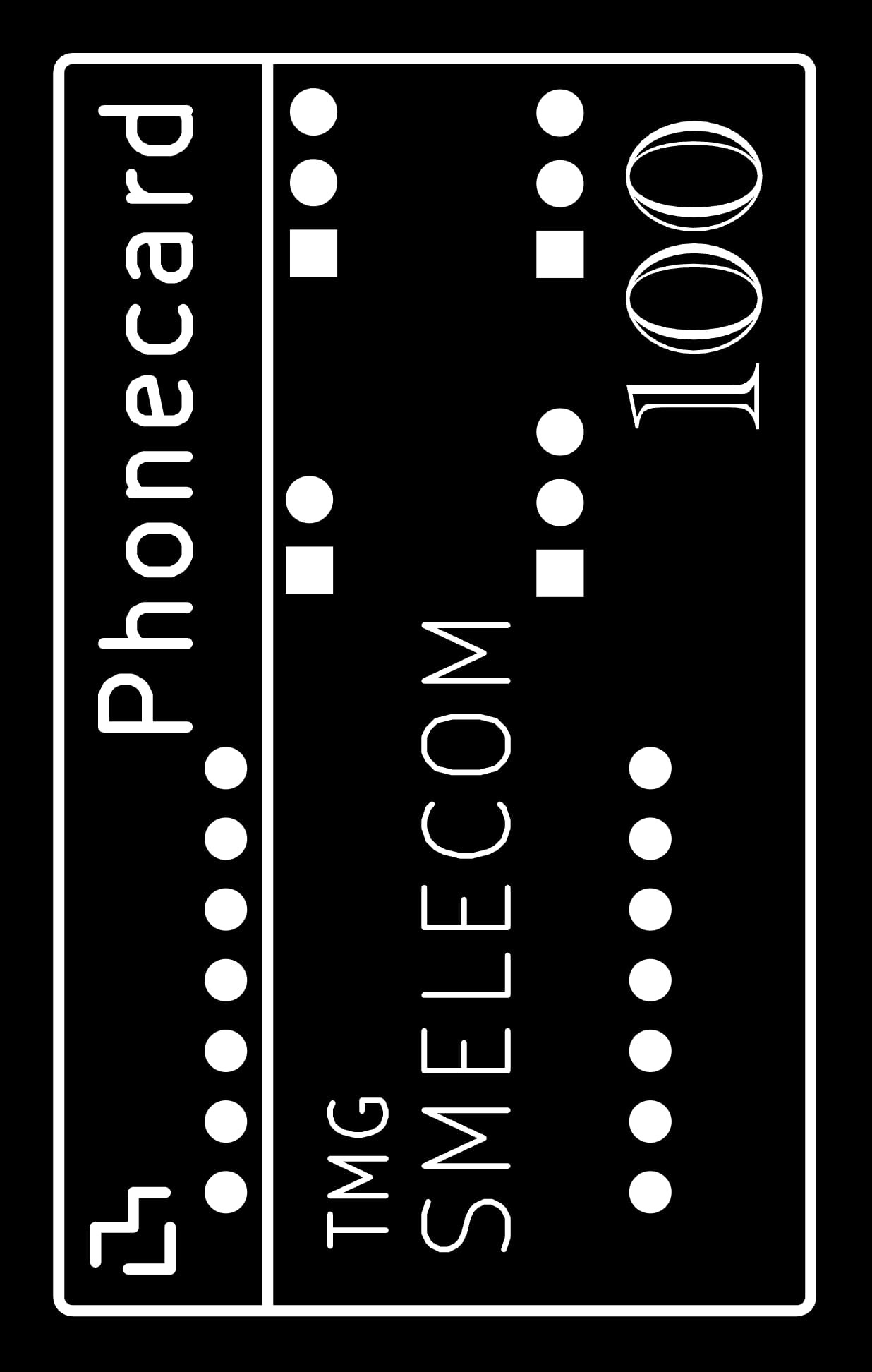

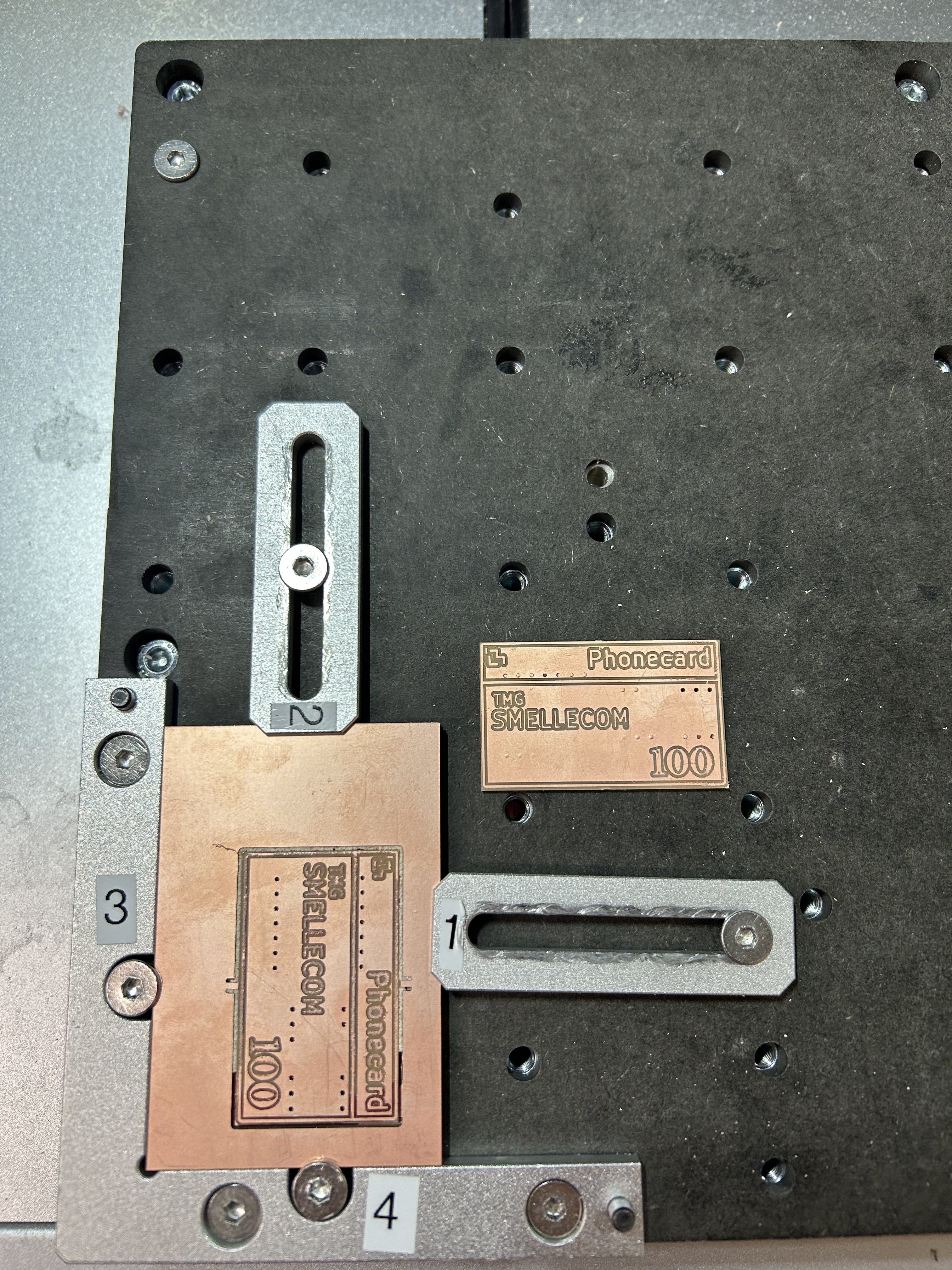

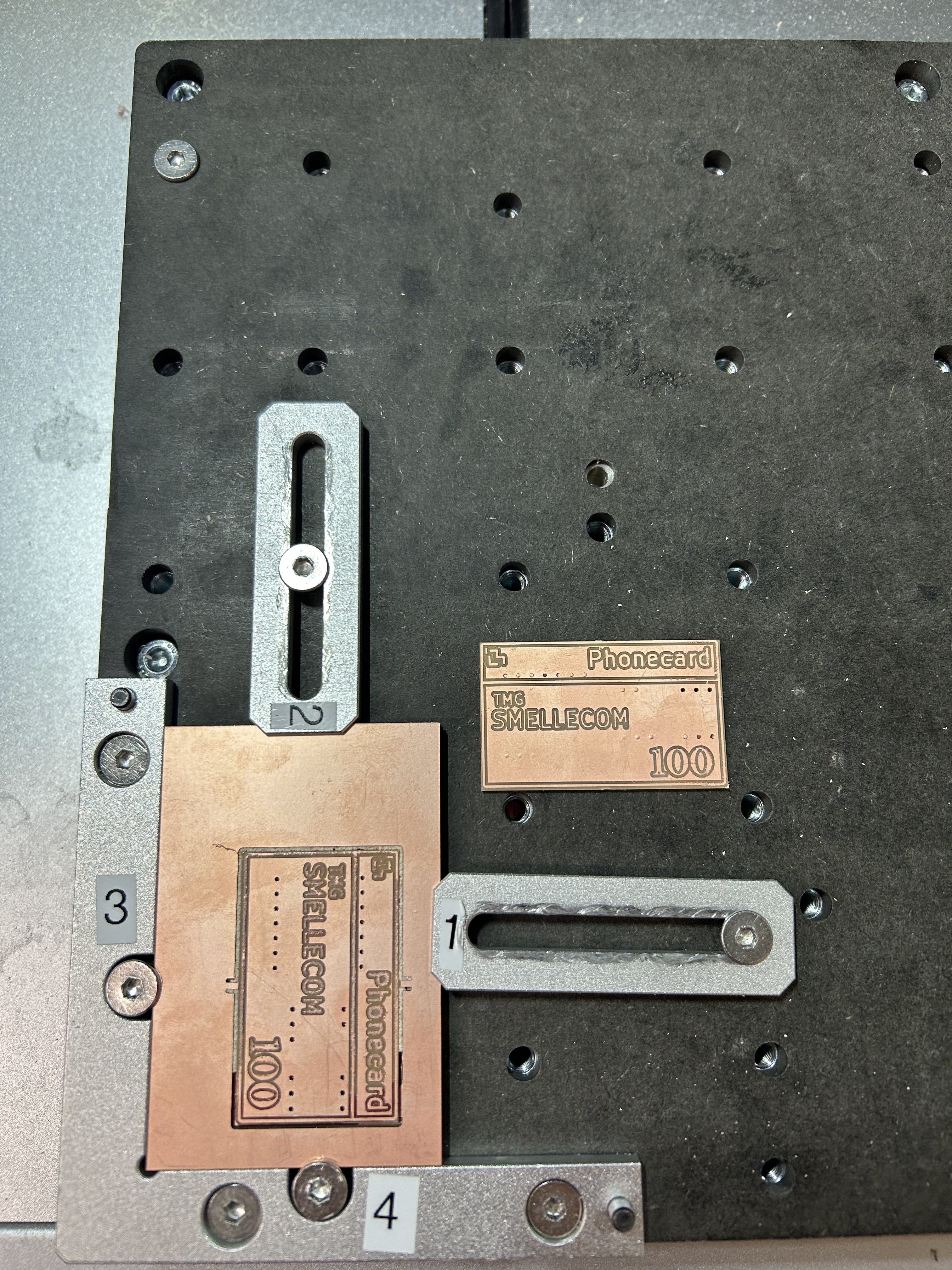

SmellPhone PCB design featuring custom engraving

Completed SmellPhone PCB with all components soldered and ready for integration

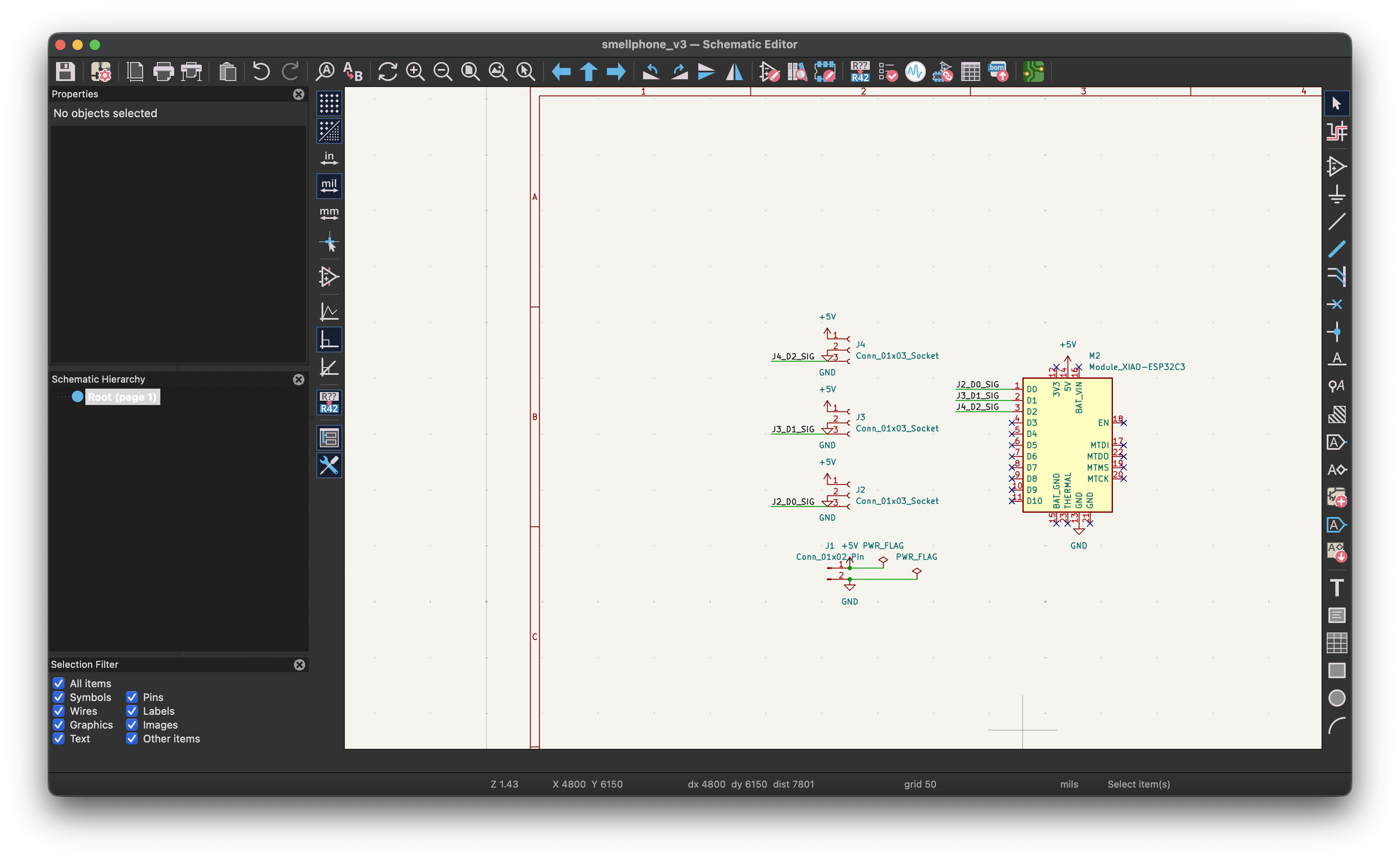

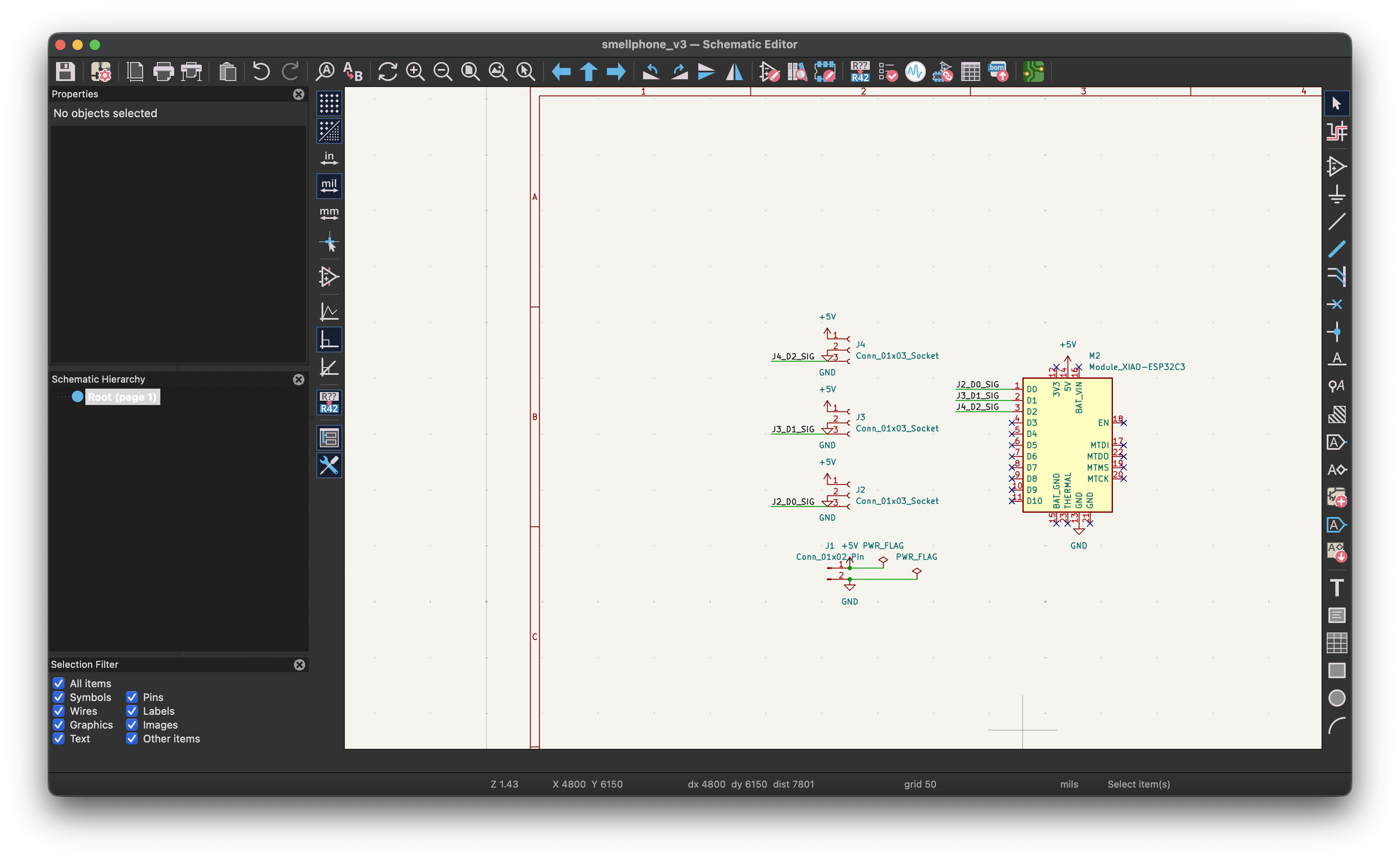

Schematic design of the custom scent dial PCB showing the circuit connections and component relationships. The design integrates the ESP32C3 microcontroller with rotary dial sensing and Bluetooth communication circuitry.

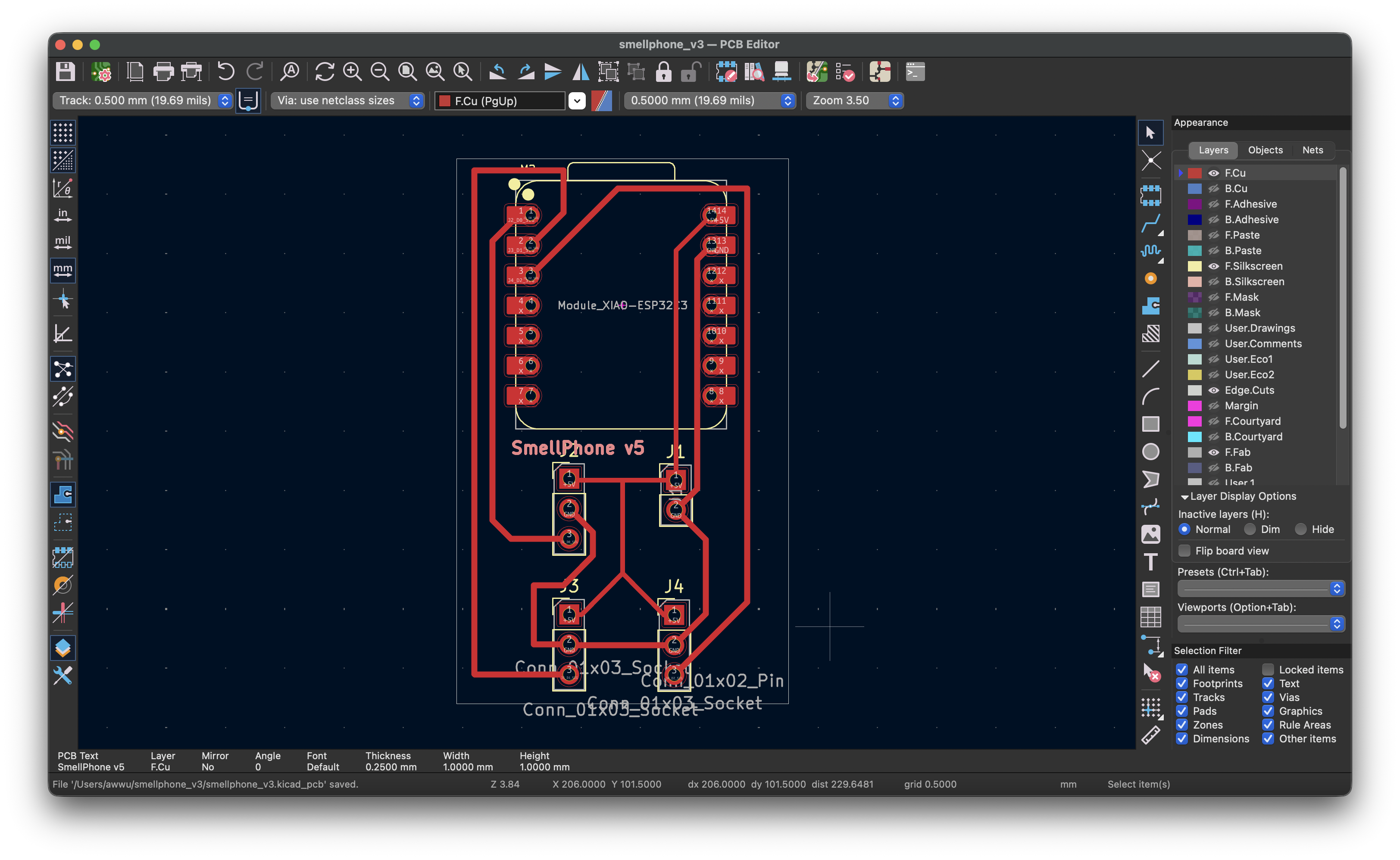

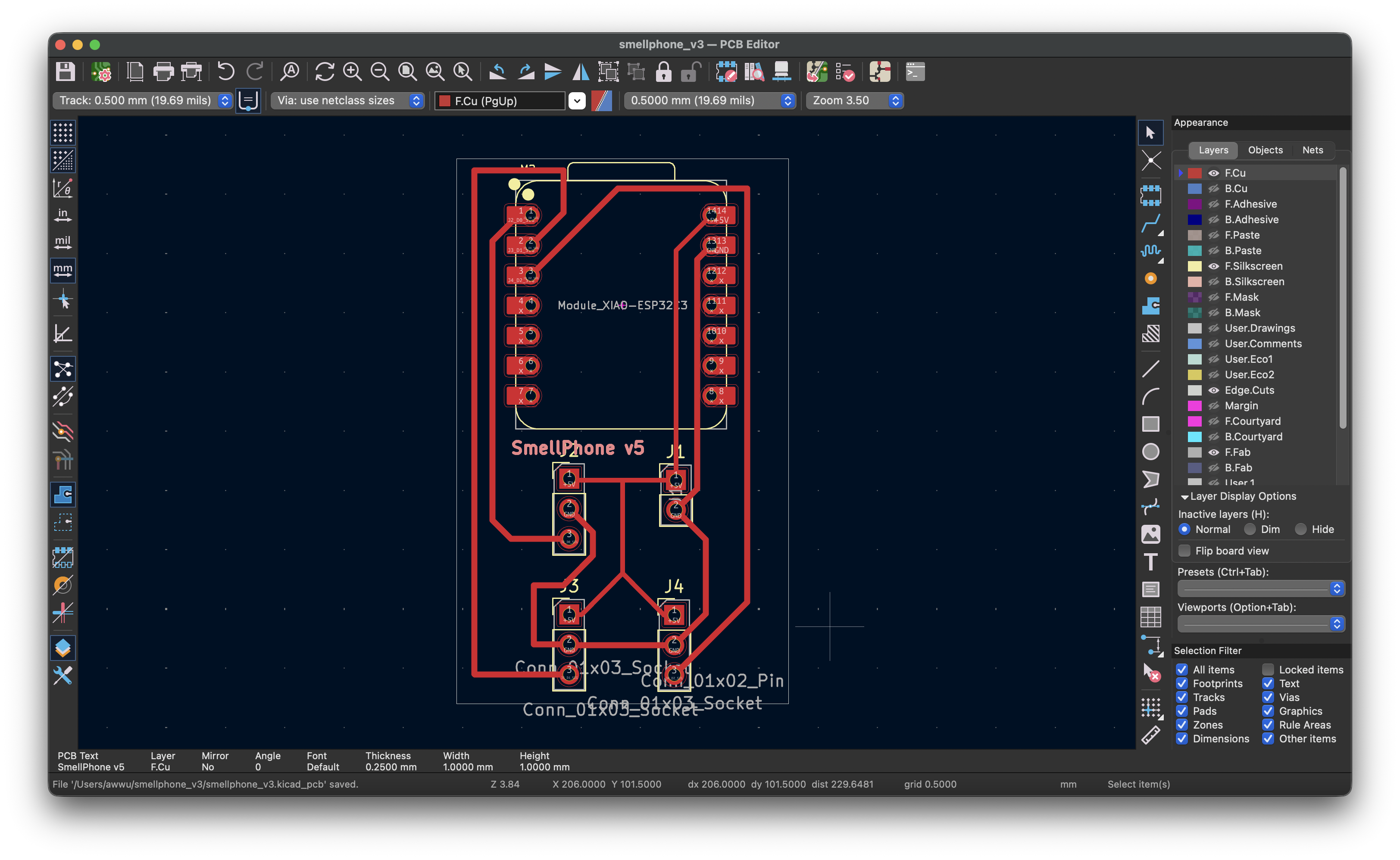

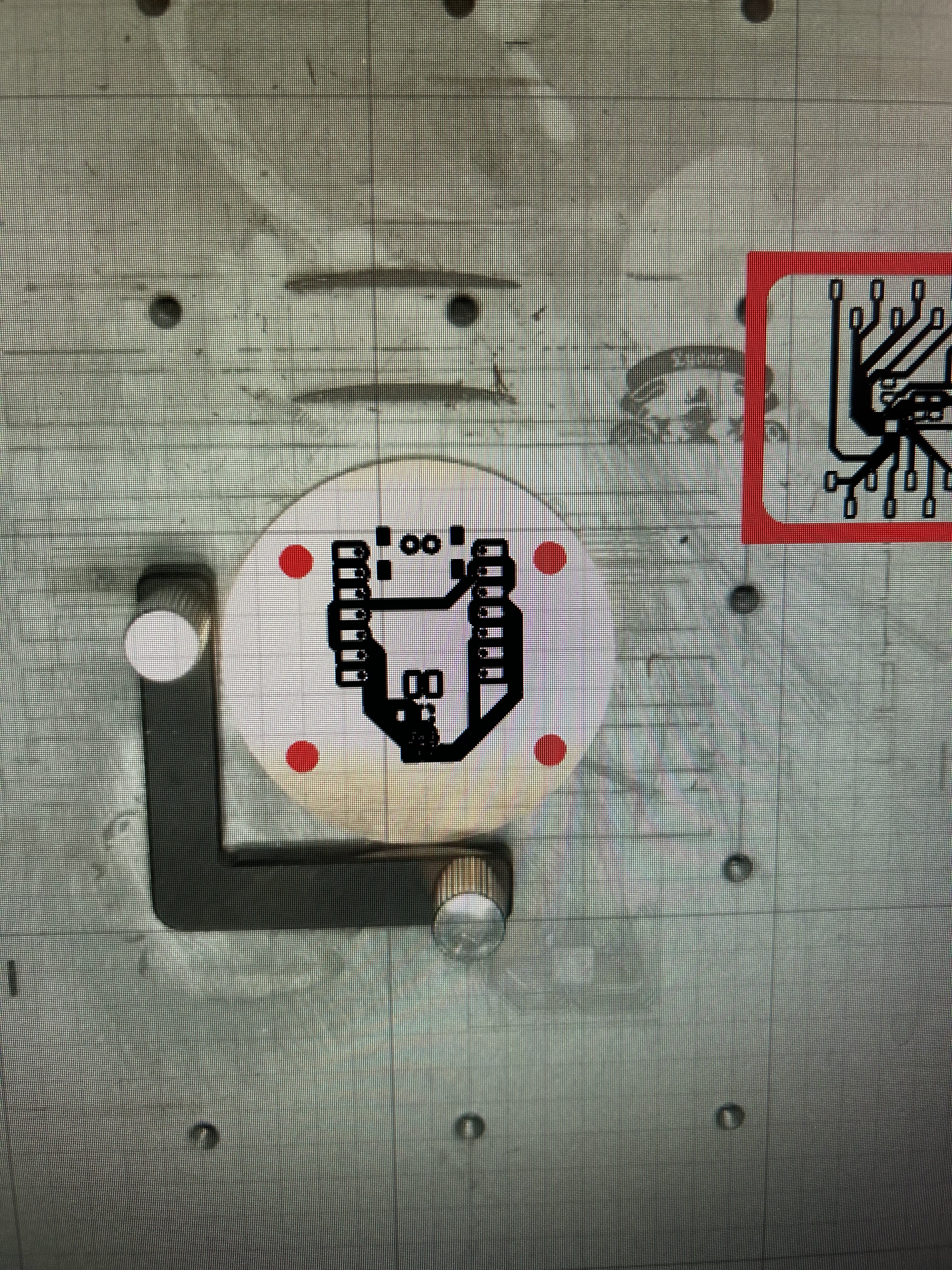

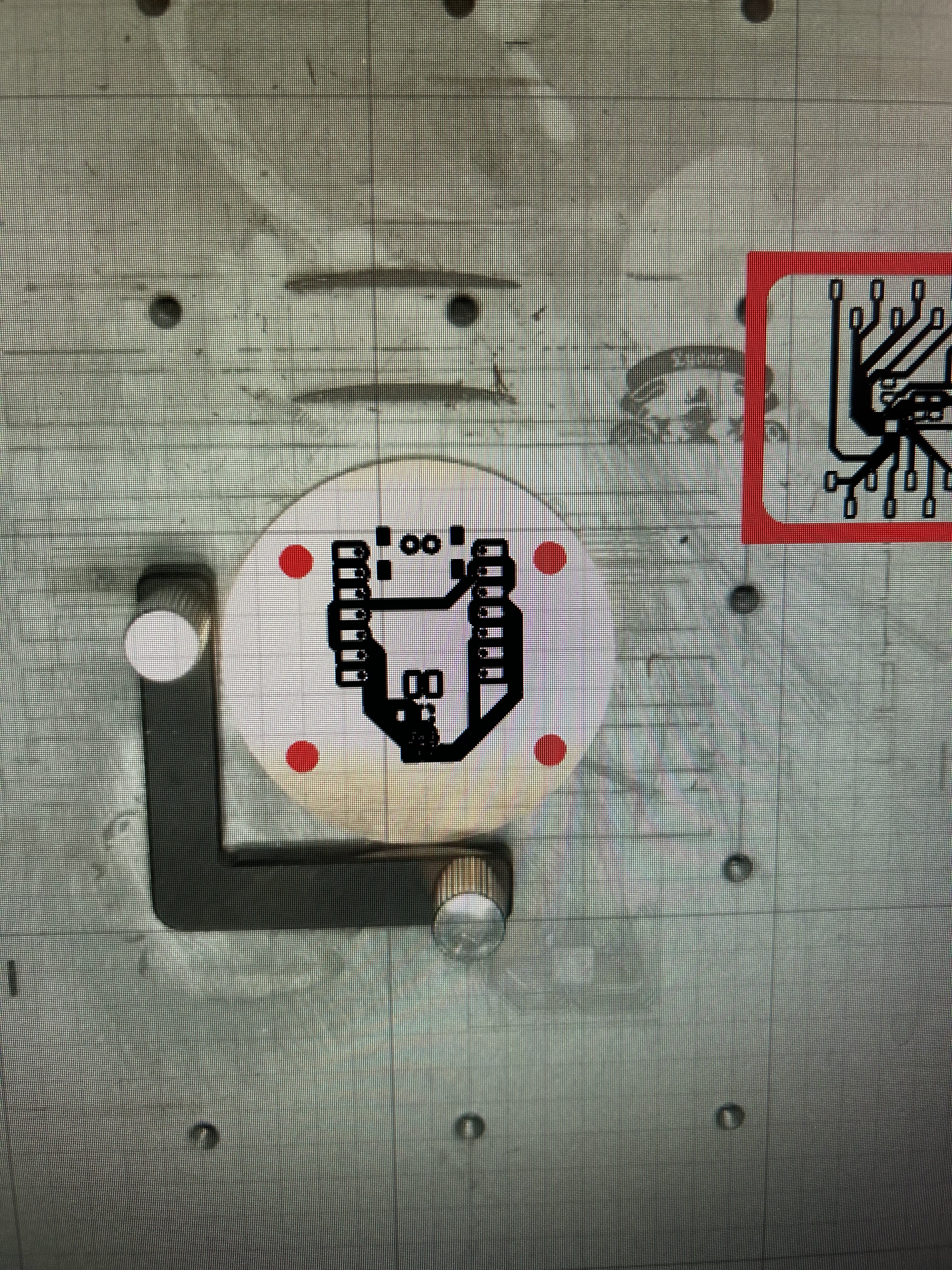

PCB layout editor view showing the component placement and trace routing for the custom scent dial PCB. The layout optimizes signal integrity and power distribution for reliable operation.

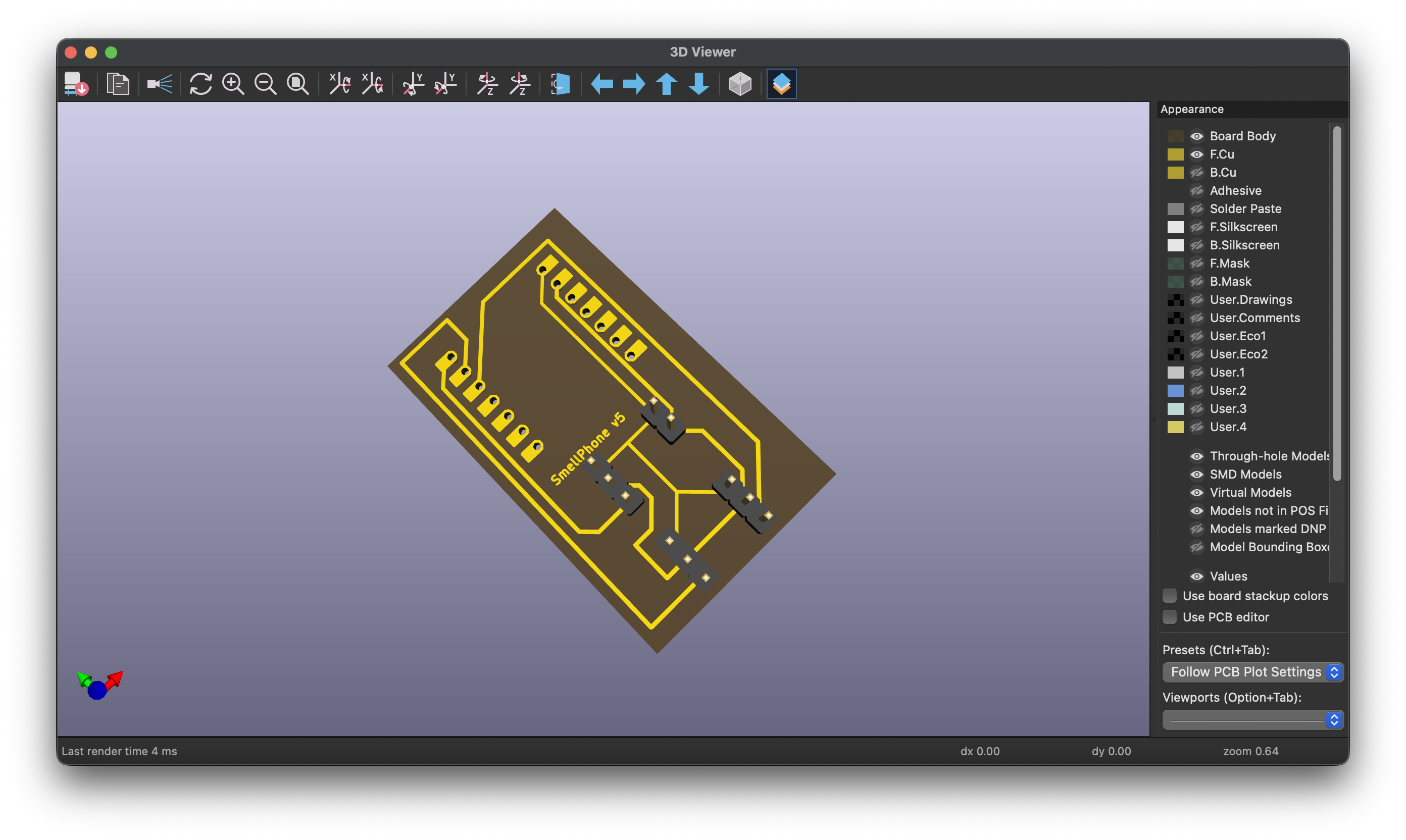

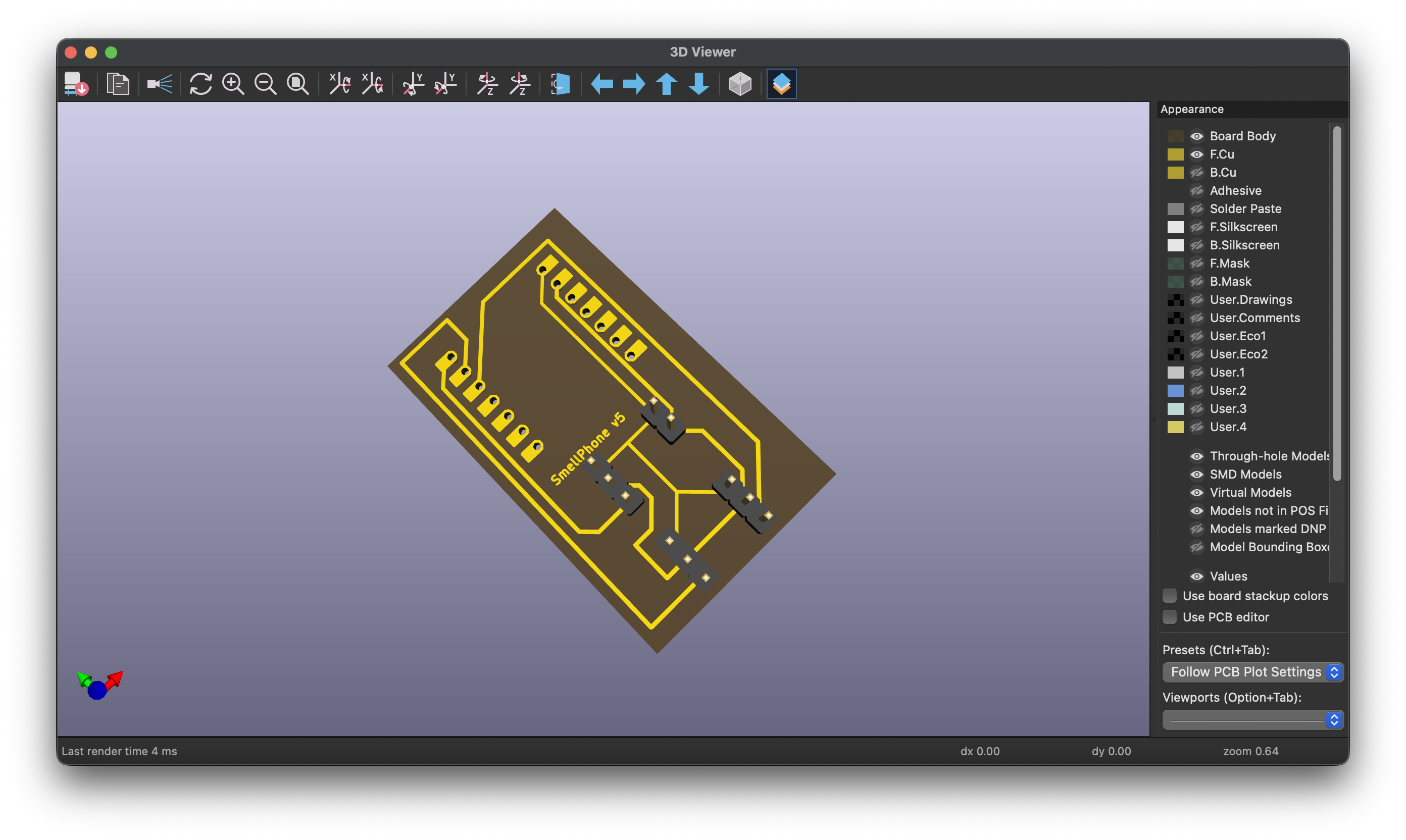

3D visualization of the custom PCB design showing the component placement and board structure. This visualization helps verify component clearances and assembly feasibility before fabrication.

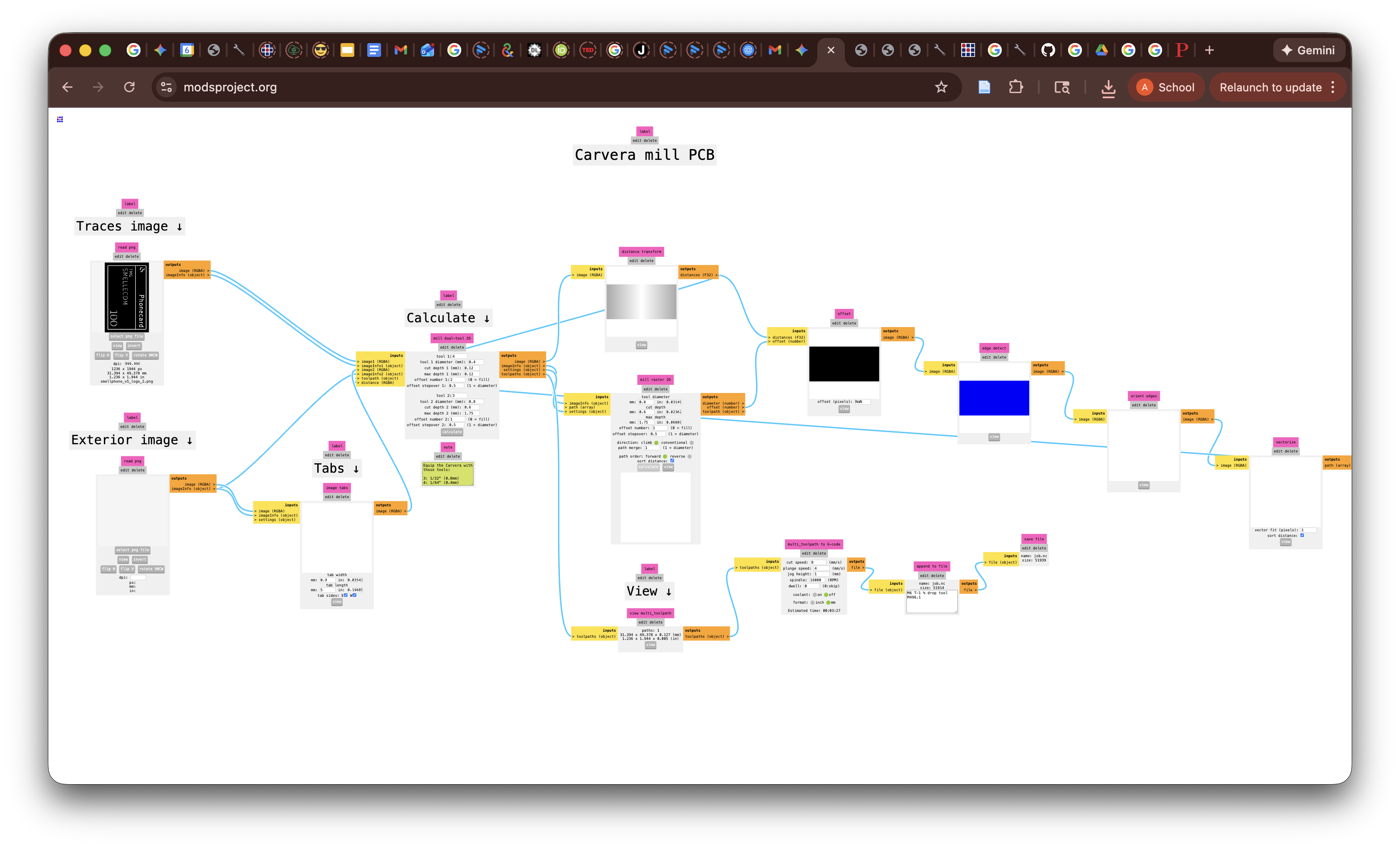

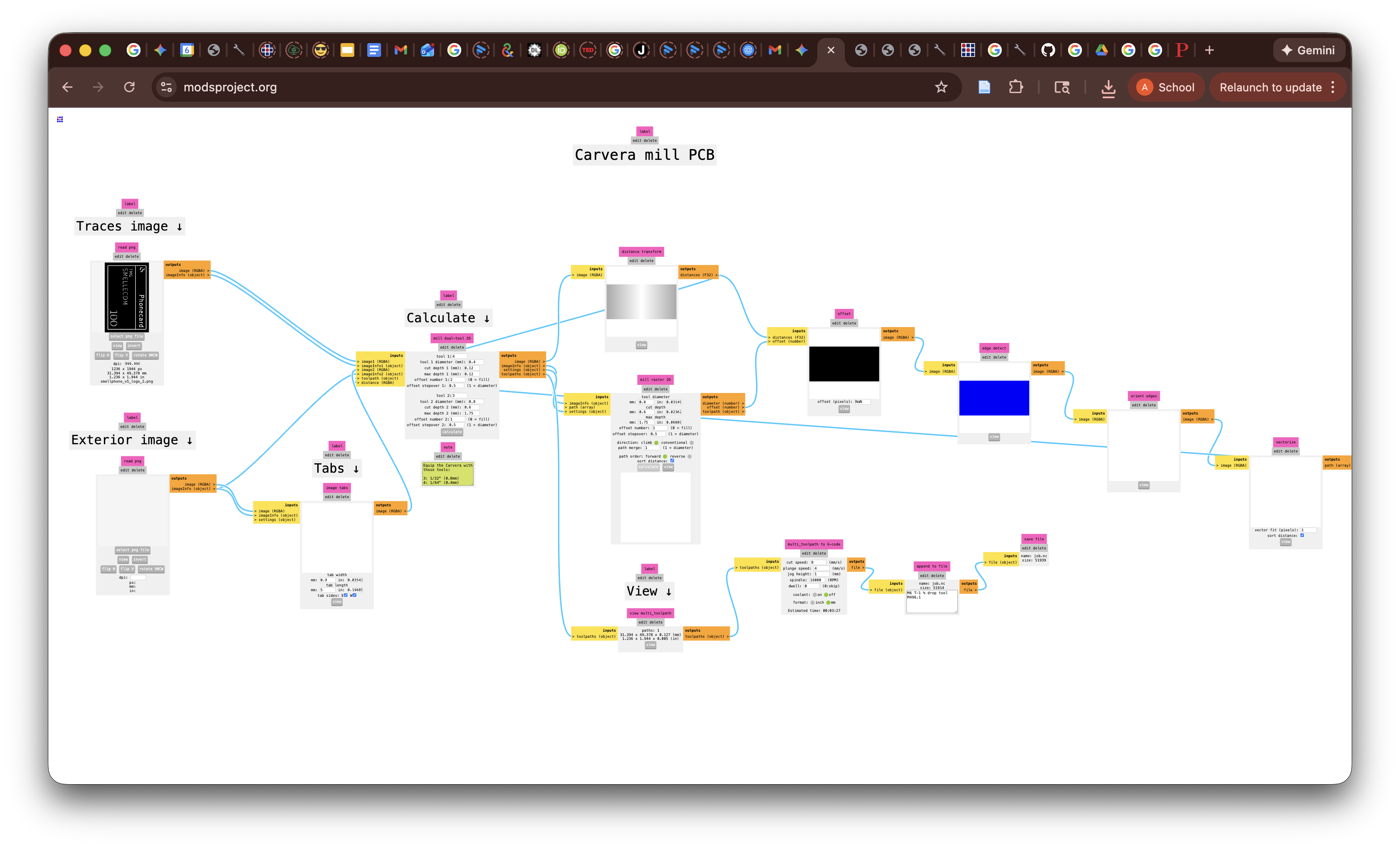

G-code generation for the Carvera milling machine to fabricate the custom PCB. The toolpaths are optimized for precise trace cutting and component pad creation.

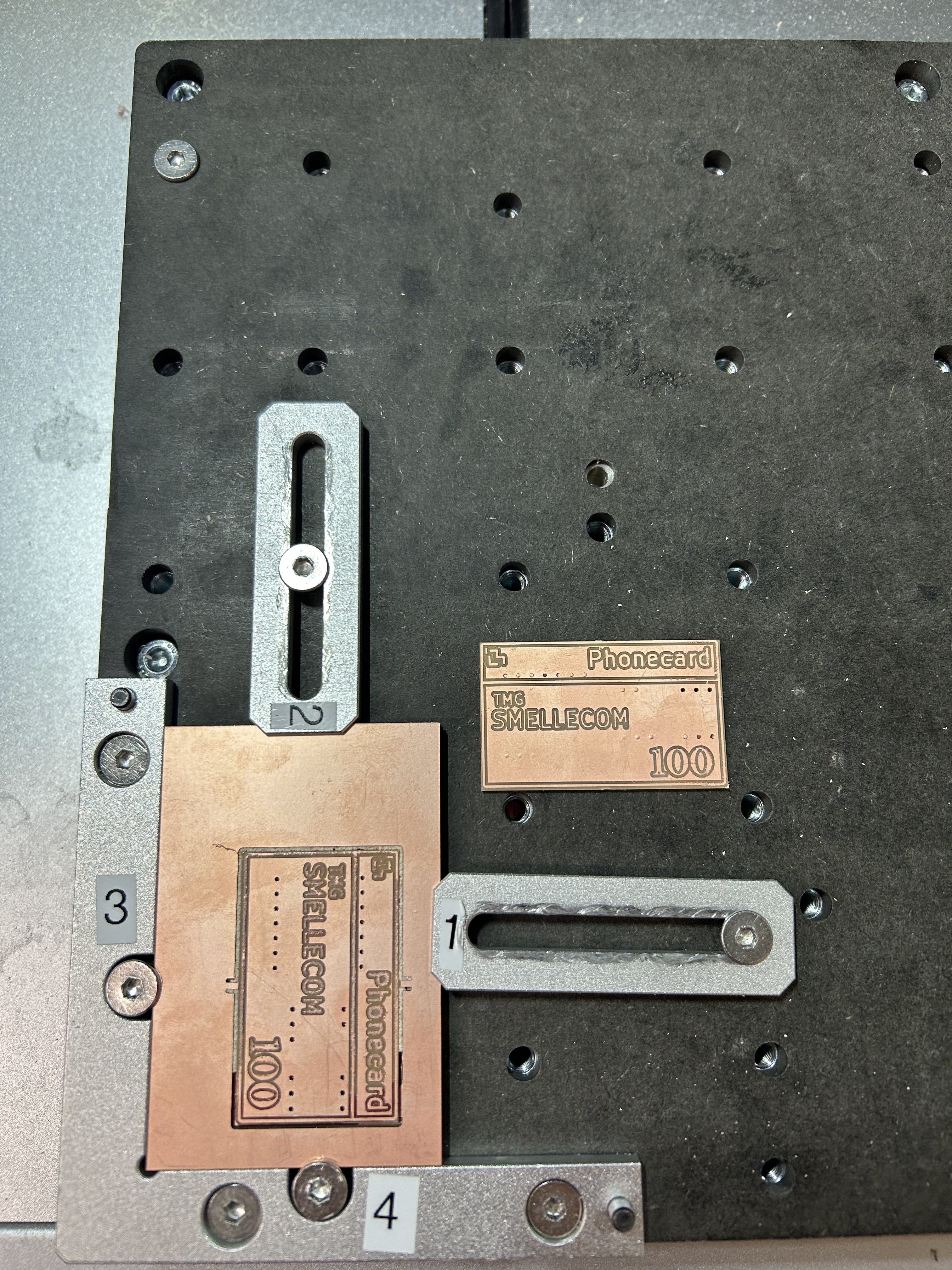

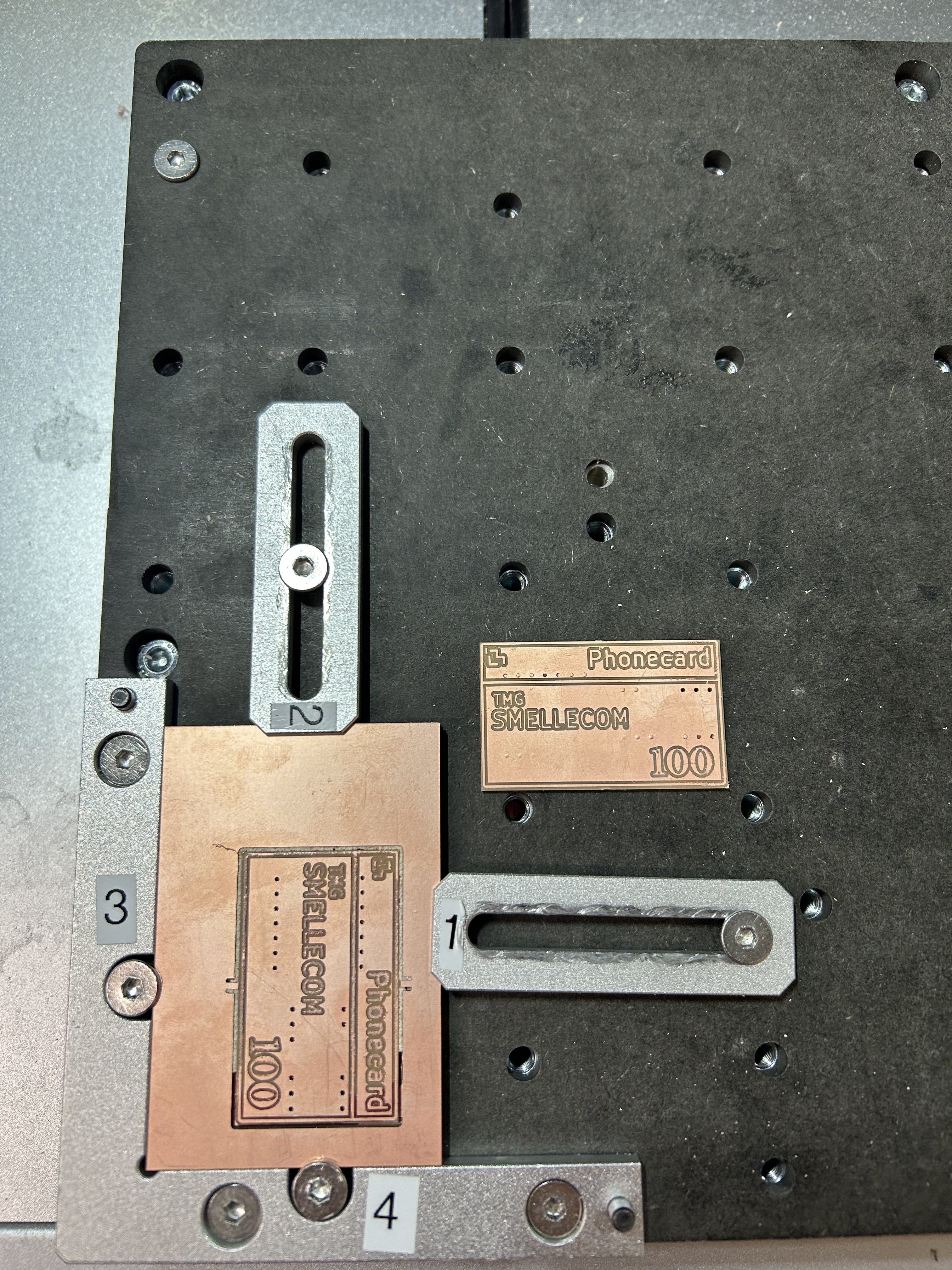

Completed milled backside of the custom PCB showing the precision-cut traces and component pads. The milling process creates the circuit pathways for the bottom layer connections.

System Integration

The custom PCB was designed to consolidate the rotary dial sensing, microcontroller processing, and Bluetooth communication into a single integrated circuit board. The ESP32C3 serves as the central processing unit, handling both the rotary dial input detection and Bluetooth Low Energy (BLE) communication to control multiple scent diffusers simultaneously.

Key Features:

• Unified Control System: Single ESP32C3 microcontroller manages all scent diffuser communication

• Bluetooth Low Energy: BLE protocol enables wireless control of multiple diffusers

• Rotary Dial Interface: Integrated sensing circuitry for detecting dial rotations

• Compact Design: All electronics consolidated into one PCB for simplified assembly

• Scalable Architecture: Can control multiple scent diffusers from a single interface

• Bluetooth Low Energy: BLE protocol enables wireless control of multiple diffusers

• Rotary Dial Interface: Integrated sensing circuitry for detecting dial rotations

• Compact Design: All electronics consolidated into one PCB for simplified assembly

• Scalable Architecture: Can control multiple scent diffusers from a single interface

Scent Dial PCB Fabrication

SmellPhone PCB design featuring custom engraving

Completed SmellPhone PCB with all components soldered and ready for integration

PCB Design Process

Schematic design of the custom scent dial PCB showing the circuit connections and component relationships. The design integrates the ESP32C3 microcontroller with rotary dial sensing and Bluetooth communication circuitry.

PCB layout editor view showing the component placement and trace routing for the custom scent dial PCB. The layout optimizes signal integrity and power distribution for reliable operation.

3D visualization of the custom PCB design showing the component placement and board structure. This visualization helps verify component clearances and assembly feasibility before fabrication.

PCB Fabrication

G-code generation for the Carvera milling machine to fabricate the custom PCB. The toolpaths are optimized for precise trace cutting and component pad creation.

Completed milled backside of the custom PCB showing the precision-cut traces and component pads. The milling process creates the circuit pathways for the bottom layer connections.

The custom PCB serves as the central control hub for the entire Scent Dial system:

Rotary Dial Input Processing: The PCB receives signals from the rotary dial mechanism, processes the pulse patterns to determine which number was dialed, and maps that number to a corresponding scent profile.

Bluetooth Communication Hub: The ESP32C3 on the PCB acts as a Bluetooth Low Energy central device, capable of connecting to and controlling multiple scent diffusers simultaneously. This allows a single rotary phone interface to control an entire network of scent emission devices.

Unified Control Architecture: By consolidating all control electronics onto one PCB, the system becomes more reliable, easier to assemble, and more scalable. The single ESP32C3 can manage connections to multiple diffusers, enabling complex scent sequences and coordinated multi-diffuser operations.

Power Management: The PCB includes power regulation and distribution circuitry to ensure stable operation of all components, including the ESP32C3, rotary dial sensors, and any additional interface electronics.

IMU Sensor PCB Development

The Scent Dial incorporates an IMU (Inertial Measurement Unit) sensor PCB for detecting rotary dial movement and rotation. The PCB was designed with the help of Quentin (built on top of Quentin's PCB design) and fabricated using laser engraving and milling workshop hosted by Quentin during the wild card week.

Laser trace alignment process for creating precise circuit traces on the IMU sensor PCB

Quentin's expert support at soldering the IMU sensor onto the PCB

Fully assembled and completed IMU sensor PCB ready for integration into the Scent Dial [Photo Courtesy of Quentin]

IMU Laser Engraving

Laser trace alignment process for creating precise circuit traces on the IMU sensor PCB

Quentin's expert support at soldering the IMU sensor onto the PCB

Completed IMU Sensor PCB

Fully assembled and completed IMU sensor PCB ready for integration into the Scent Dial [Photo Courtesy of Quentin]

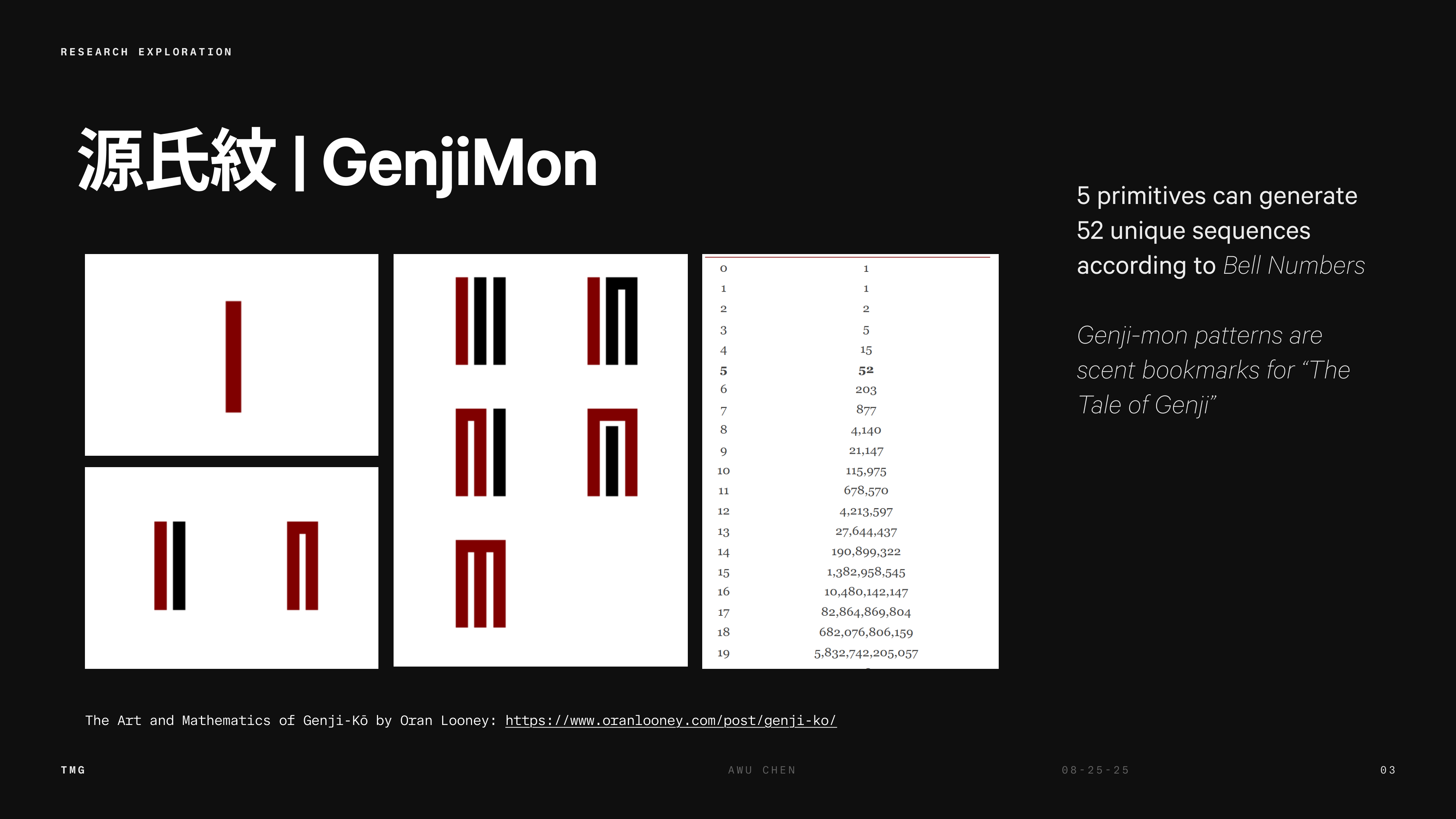

Sequential Scent Research: Genji Mon Tradition

Cultural Significance

The Genji Mon (源氏紋) is a traditional Japanese family crest pattern with deep historical significance. The pattern represents the Genji clan, one of the most influential families in Japanese history, particularly during the Heian period (794-1185). Historical Context: • Origins: The Genji Mon pattern dates back to the Heian period and is associated with the Minamoto clan (源氏)• Cultural Impact: Featured prominently in "The Tale of Genji" (源氏物語), considered the world's first novel

• Design Elements: The pattern typically features geometric arrangements representing different aspects of court life

• Modern Usage: Still used in traditional Japanese arts, textiles, and ceremonial contexts

Historical Images

Historical Genji Mon pattern showing traditional geometric design elements and cultural significance

Variations of Genji Mon patterns demonstrating the geometric complexity and artistic tradition

Mathematical analysis of Genji Mon pattern showing the underlying geometric principles and bell number relationships

Significance of the Sequential Scent Research

RQ: The effectiveness of a scent sequence as a memory trigger is directly correlated with the uniqueness of its temporal pattern, as measured by the accuracy and speed of memory recall.

H1: The temporal pattern of a scent sequence is more effective as a memory trigger when it is more unique.

H2: The temporal pattern of a scent sequence is more effective as a memory trigger when it is more predictable.

H3: The temporal pattern of a scent sequence is more effective as a memory trigger when it is more consistent.

H1: The temporal pattern of a scent sequence is more effective as a memory trigger when it is more unique.

H2: The temporal pattern of a scent sequence is more effective as a memory trigger when it is more predictable.

H3: The temporal pattern of a scent sequence is more effective as a memory trigger when it is more consistent.

Attachments

3D Models (STL Files)

Historical Design Files

Base2.stl

Sensor Mount v1.stl

SmellPhone Case Front v4.stl

SmellPhone Cover Back 3mm.stl

SoundSpeaker.stl

SoundSpeaker2.stl

Top Container.stl

PCB Design FilesSensor Mount v1.stl

SmellPhone Case Front v4.stl

SmellPhone Cover Back 3mm.stl

SoundSpeaker.stl

SoundSpeaker2.stl

Top Container.stl

Historical Design Files

Final Project Outcomes

The Scent Dial successfully demonstrates:

• Interface Design: Creating an intuitive, nostalgic interface that makes scent technology accessible and engaging

• System Integration: Combining hardware fabrication, networking, and interface programming into a complete functional system

• User Experience: Transforming scent control from digital menus into meaningful, tactile interactions

• Technical Implementation: Successfully integrating rotary dial sensing, Bluetooth communication, and ultrasonic scent emission

• Creative Application: Using familiar objects (rotary phone) to create new interaction paradigms for emerging technologies (scent control)

• System Integration: Combining hardware fabrication, networking, and interface programming into a complete functional system

• User Experience: Transforming scent control from digital menus into meaningful, tactile interactions

• Technical Implementation: Successfully integrating rotary dial sensing, Bluetooth communication, and ultrasonic scent emission

• Creative Application: Using familiar objects (rotary phone) to create new interaction paradigms for emerging technologies (scent control)

Credits and Contributions

This project would not have been possible without the generous support and contributions of many individuals. Special thanks to:

Project Support and Collaboration

Project Support and Collaboration

• Gigi Minsky: For concept ideation, experience design, narrative, and scent design

• JB Labrune: For concept ideation, feedback, and support in bringing the Scent Dial to life

• Quentin Bolsée: For feedback on ideation, hardware fabrication, PCB design, soldering and laser engraving and milling of the IMU sensor PCB

• Richard Zhang: For collaborative ideation, designing and 3D modeling the modular scent diffuser, concept sketches, and support throughout the project development and final presentation

• Hye Jun Youn: For filming, editing, and promotion on social media

• Cursor AI: For vibe coding the website documentation, networking system, and project management

Faculty Guidance• JB Labrune: For concept ideation, feedback, and support in bringing the Scent Dial to life

• Quentin Bolsée: For feedback on ideation, hardware fabrication, PCB design, soldering and laser engraving and milling of the IMU sensor PCB

• Richard Zhang: For collaborative ideation, designing and 3D modeling the modular scent diffuser, concept sketches, and support throughout the project development and final presentation

• Hye Jun Youn: For filming, editing, and promotion on social media

• Cursor AI: For vibe coding the website documentation, networking system, and project management

• Hiroshi Ishii: For guidance and mentorship throughout the project

• Neil Gershenfeld: For guidance and mentorship throughout the course

Their contributions, expertise, and encouragement were invaluable in transforming the Scent Dial from concept to reality.

• Neil Gershenfeld: For guidance and mentorship throughout the course

Links