This week the 3D printing assignment was to design and make something with a 3D printer that cannot be made subtractively. My personal goals were to design something I could use outside of the class.

Something that is not made subtractively is difficult. I watched some youtube videos about print in place 3D printing and I decided whatever I made would have some sort of print in place joint, maybe locking mechanism.

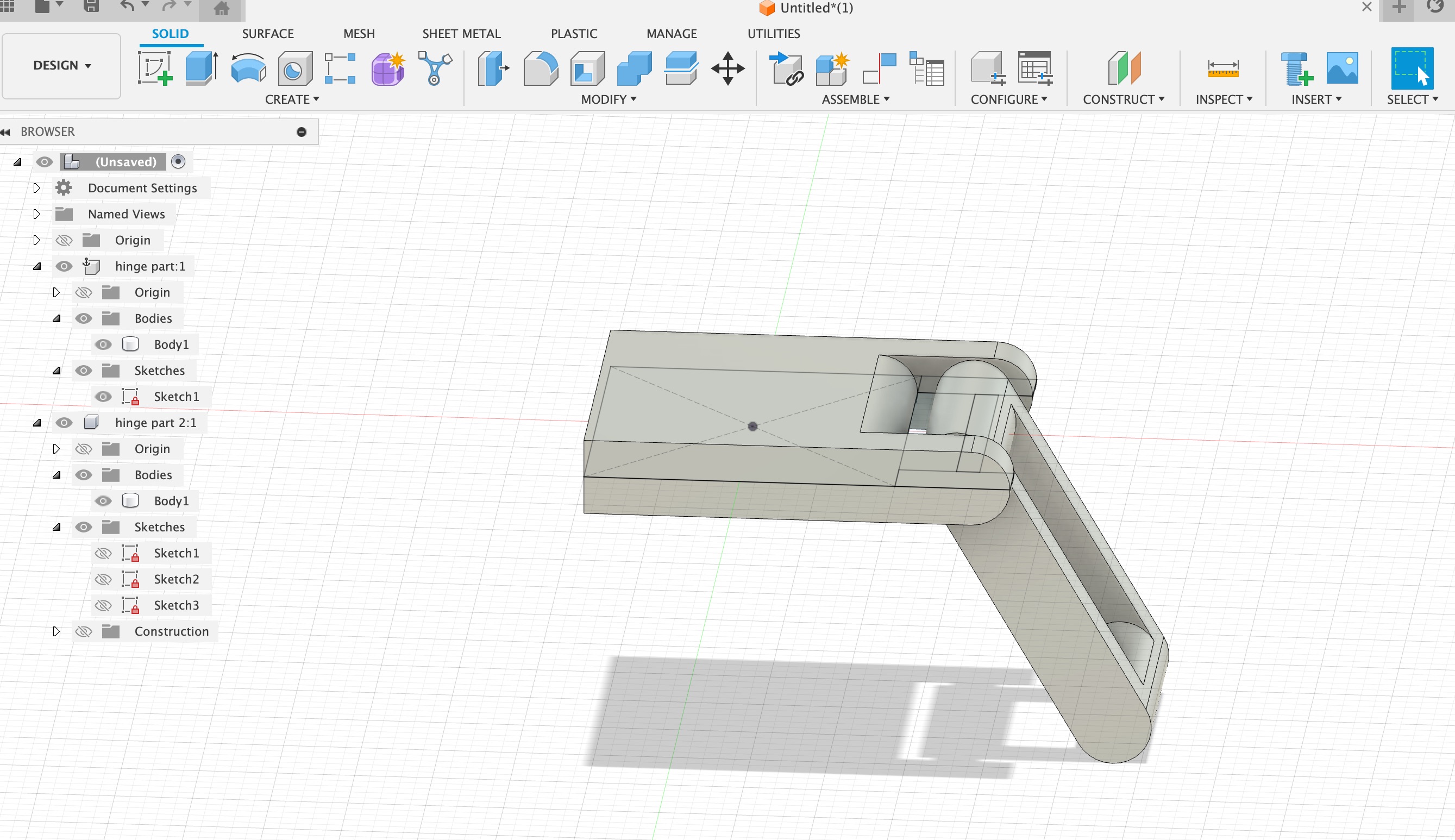

Here's my finished fusion 360 model of the hinge, I used a tolerance of 0.4mm since the 3D printer I was using had a But I couldn’t just make a joint for the assignment so I was having trouble figuring out what to make with a joint.

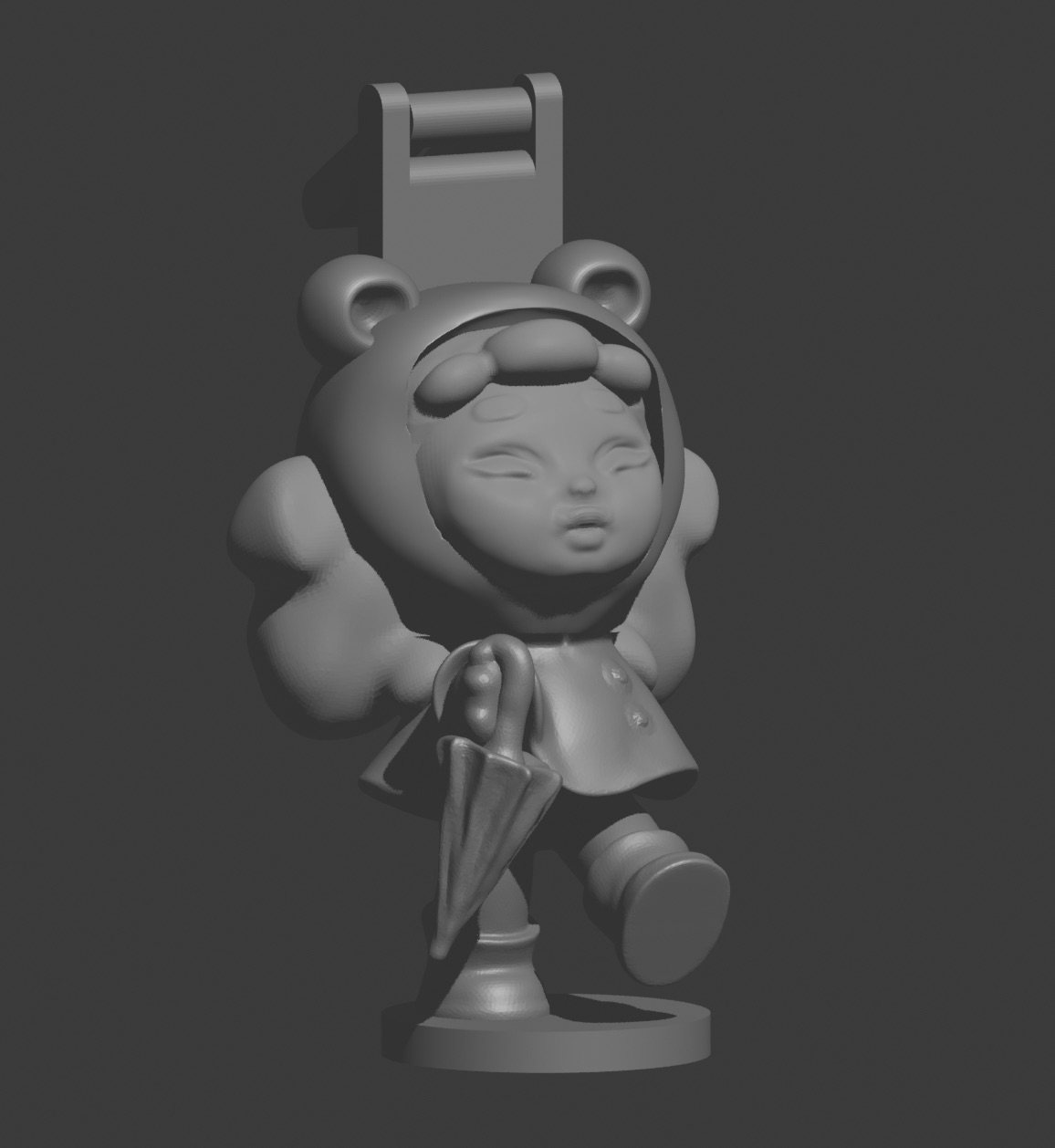

Recently I’ve been really into bag charms and the cute figurines (like skull panda or more popular, labubus)

but I don’t want to spend $30 on something that is just a cute piece of plastic. So naturally thought why not make my own cute piece of plastic ??? haha

First I drew a concept sketch in Procreate. It was just a rough drawing I could place in my modelling software. I decided to go with Blender for my character modelling software. Belnder has always intimidated me and I was excited to have a chance to use it.

Here is a video of me modelling the face in blender. I found some youtube videos on making stylized characters in Blender which really helped.

For the 3D scanning portion of this assignment, I experimented with the lab's 3D scanning equipment. The system uses depth-sensing technology to capture the geometry of physical objects in three dimensions, providing real-time feedback during the scanning process.

This assignment highlighted the differences between scanning and modeling: