Week 1

Assignments: Project Management

read and sign the student agreement, and commit to your repo

- attempted - sent out a commit request on neil's page and received a reply all email from the TAs - sorry about that

- work through a git tutorial

- completed - website edits proof of building html and css vocab - reproducibility list incoming...

- build a personal site in the class archive describing you and your final project

- see here -

Computer Controlled Cutting

- group assignment:

- absent minus safety training

- do your lab's safety training

- completed

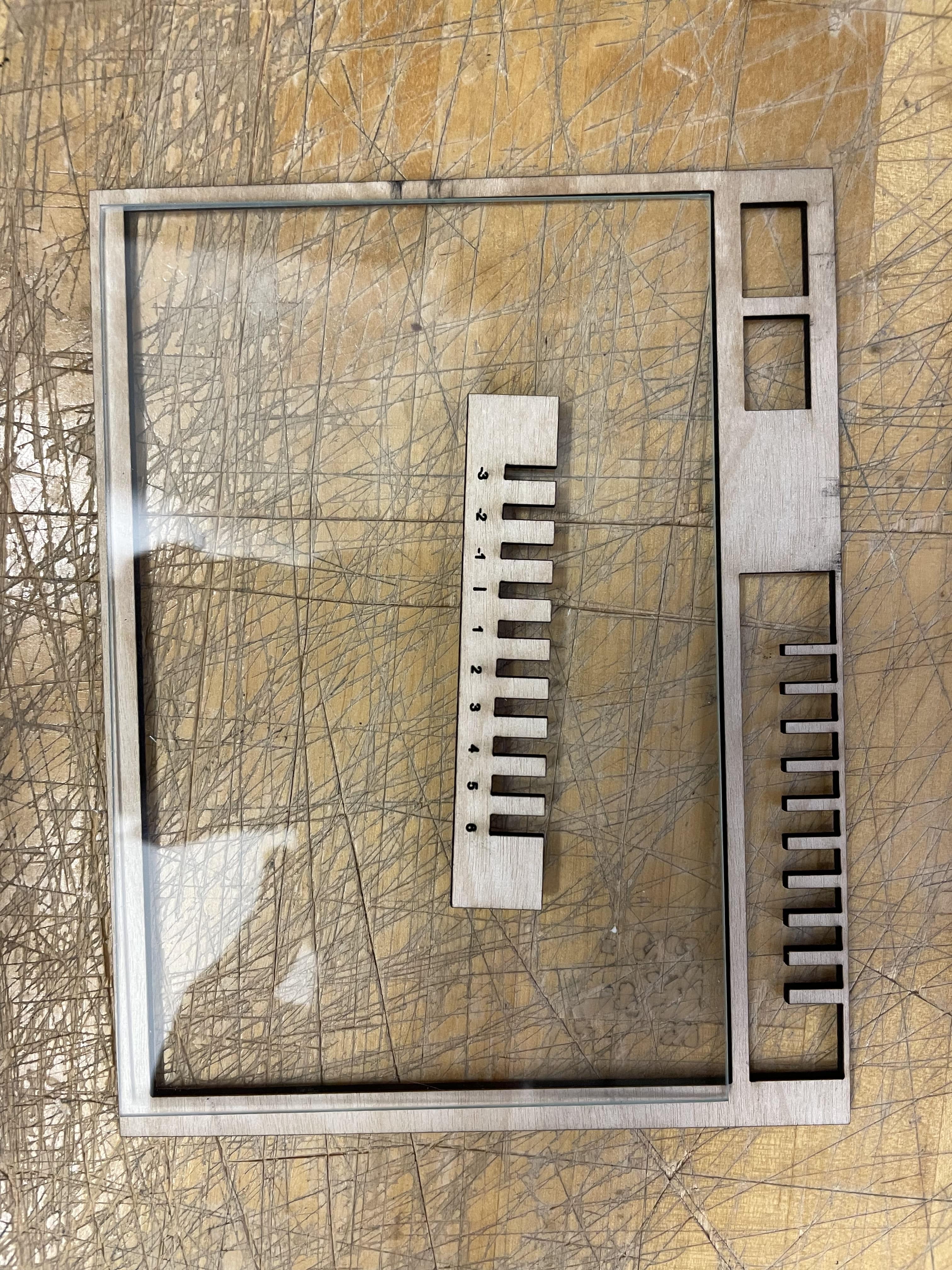

- characterize your lasercutter's focus, power, speed, rate, kerf, joint clearance and types

- roger

individual assignment:

cut something on the vinylcutter

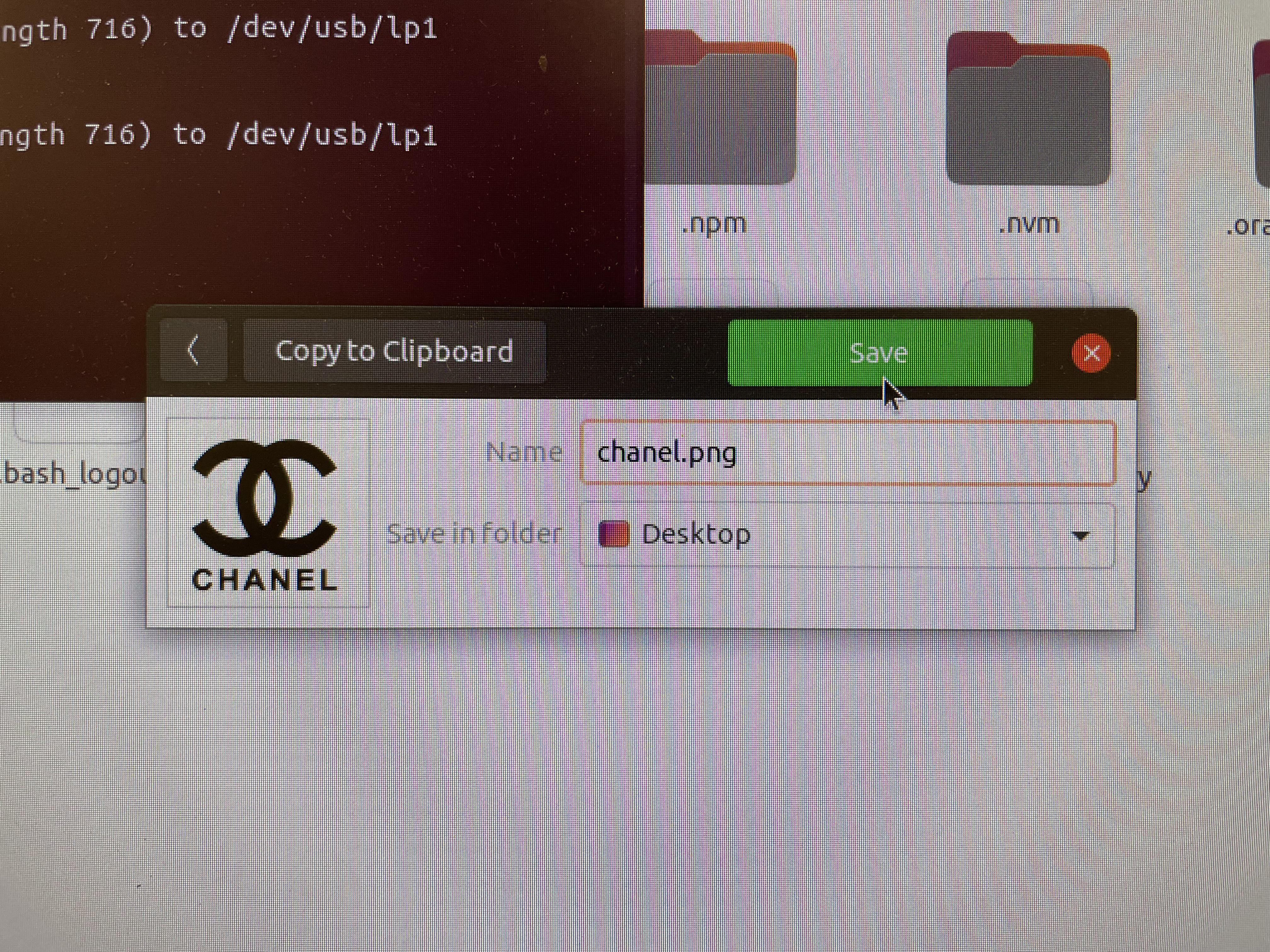

- I photoshopped a screenshot of a chanel logo and compressed it into a small black and white JPEG with clean boundaries using the compress and levels tools.

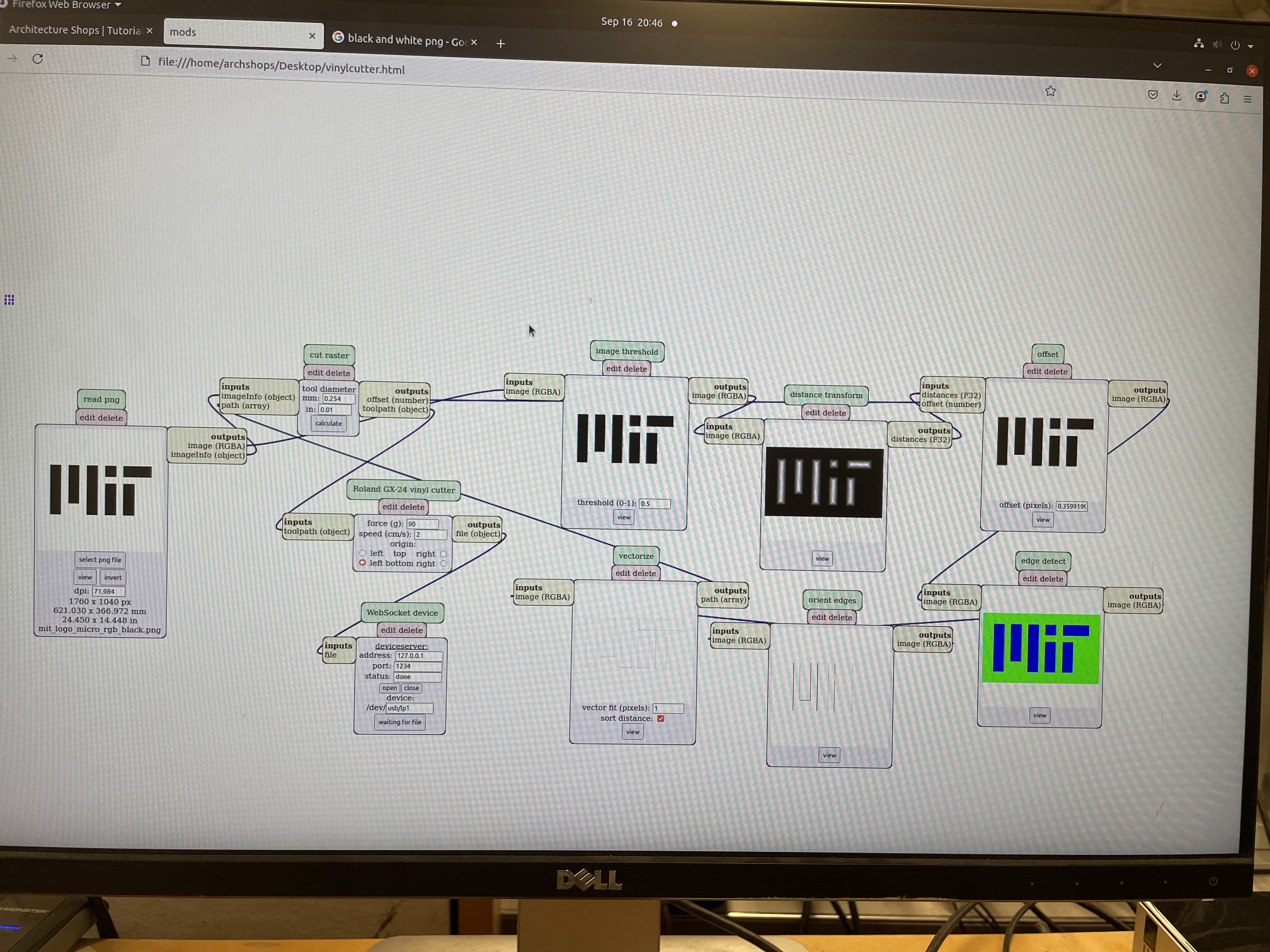

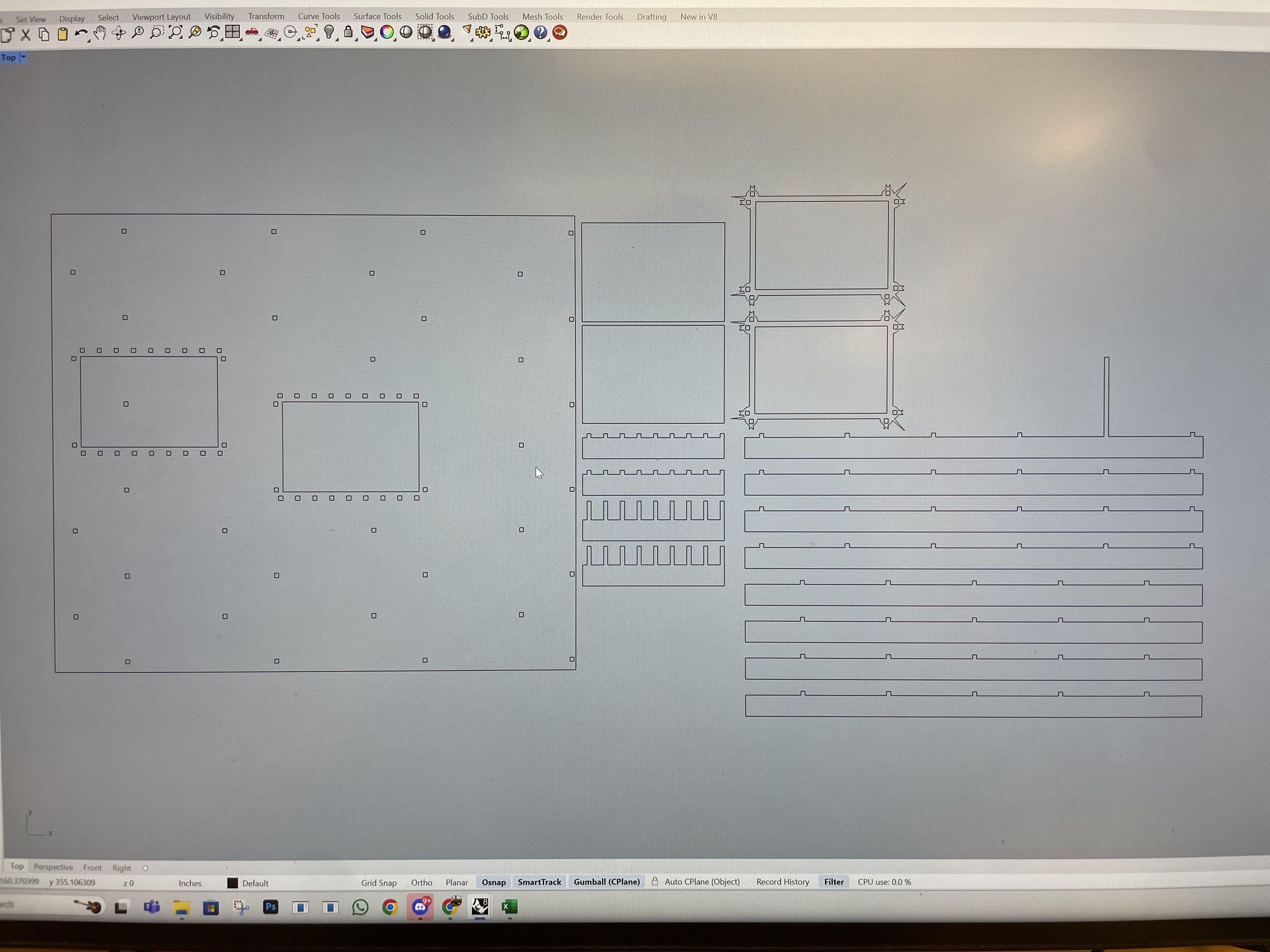

- Using the software provided (figure 2) I used the calculation and origin settings to locate the cut surface (figure 3)

- See chanel file w/ clean borders (figure 5)

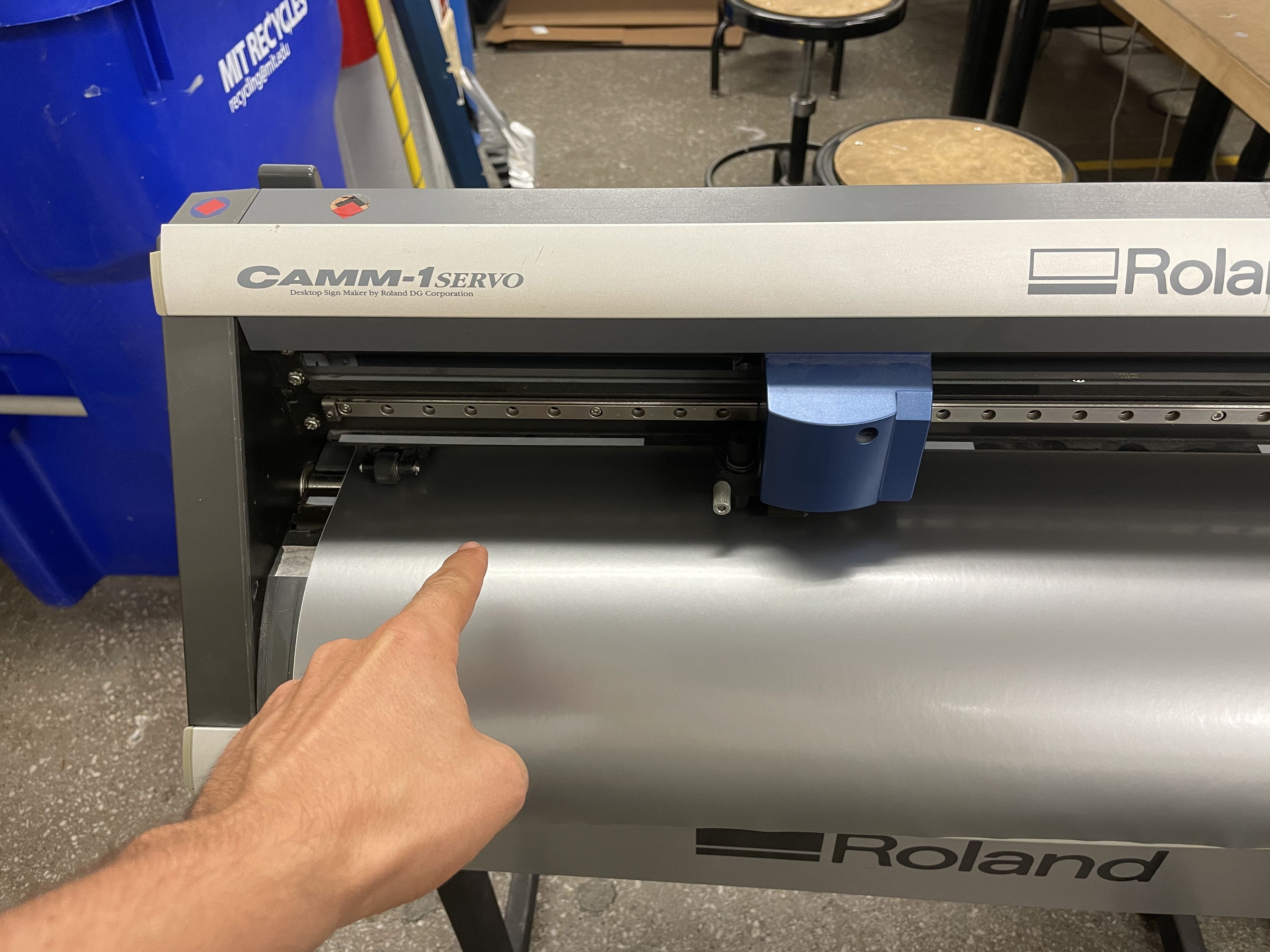

- Me pointing to my origin (figure 6)

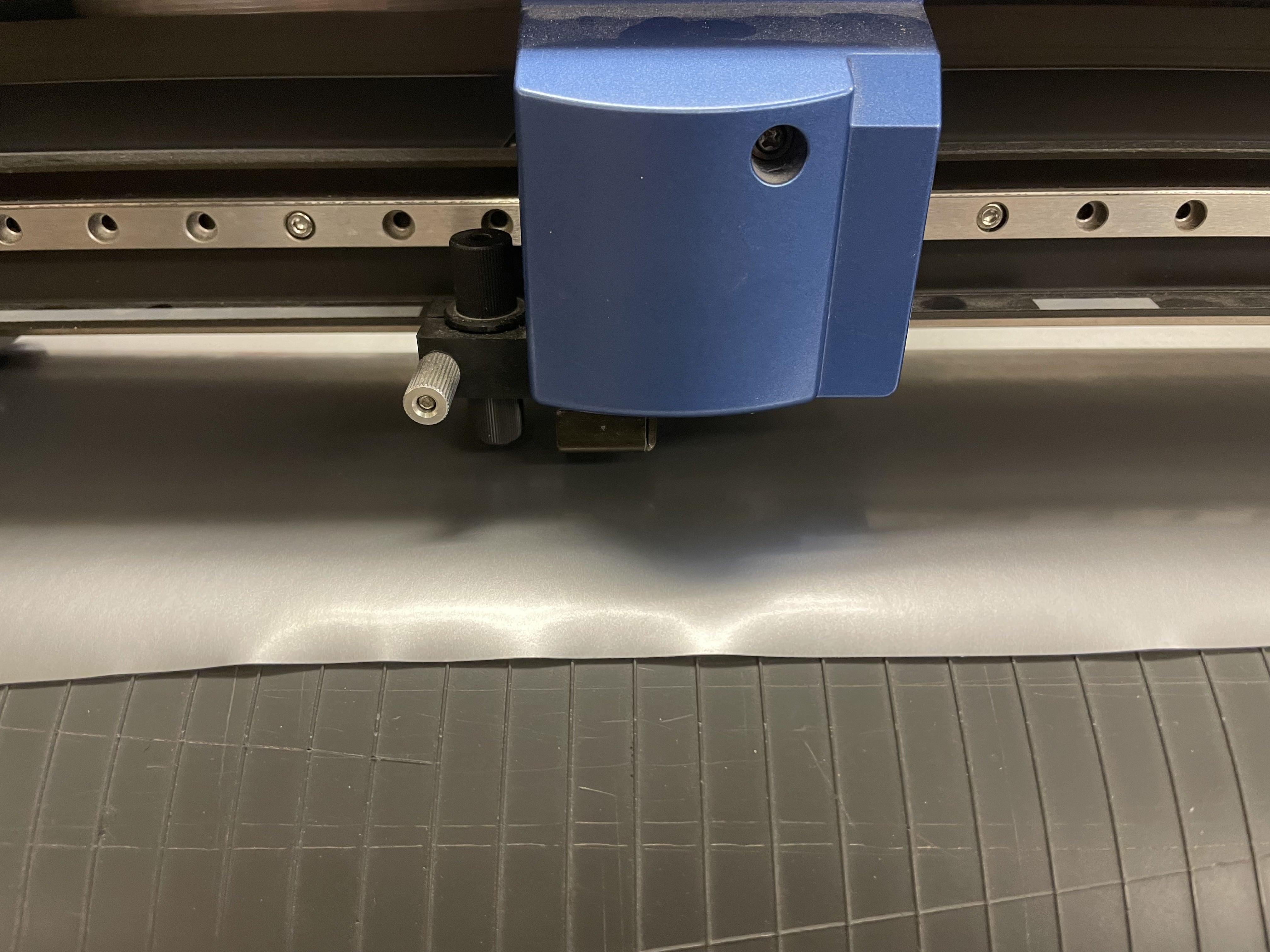

- Cutting settings were properly calibrated already but I went through the steps to select the setting for roled vinyl and moderate cutting pressure. (figure 7,8).

- I cut the section of sticker away from the roll (figure 9) and then removed the outer material (figure 10) ready for transferring.

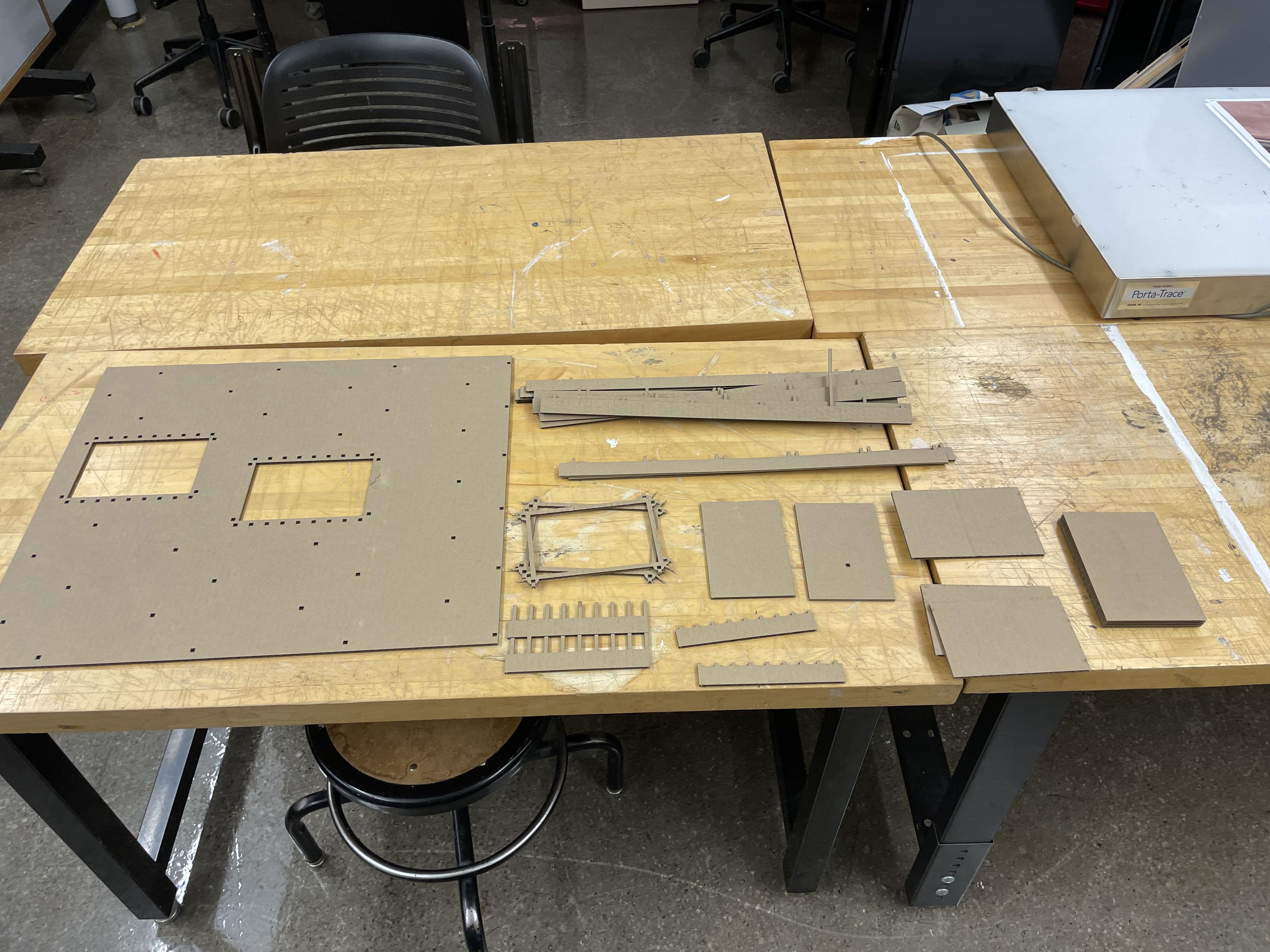

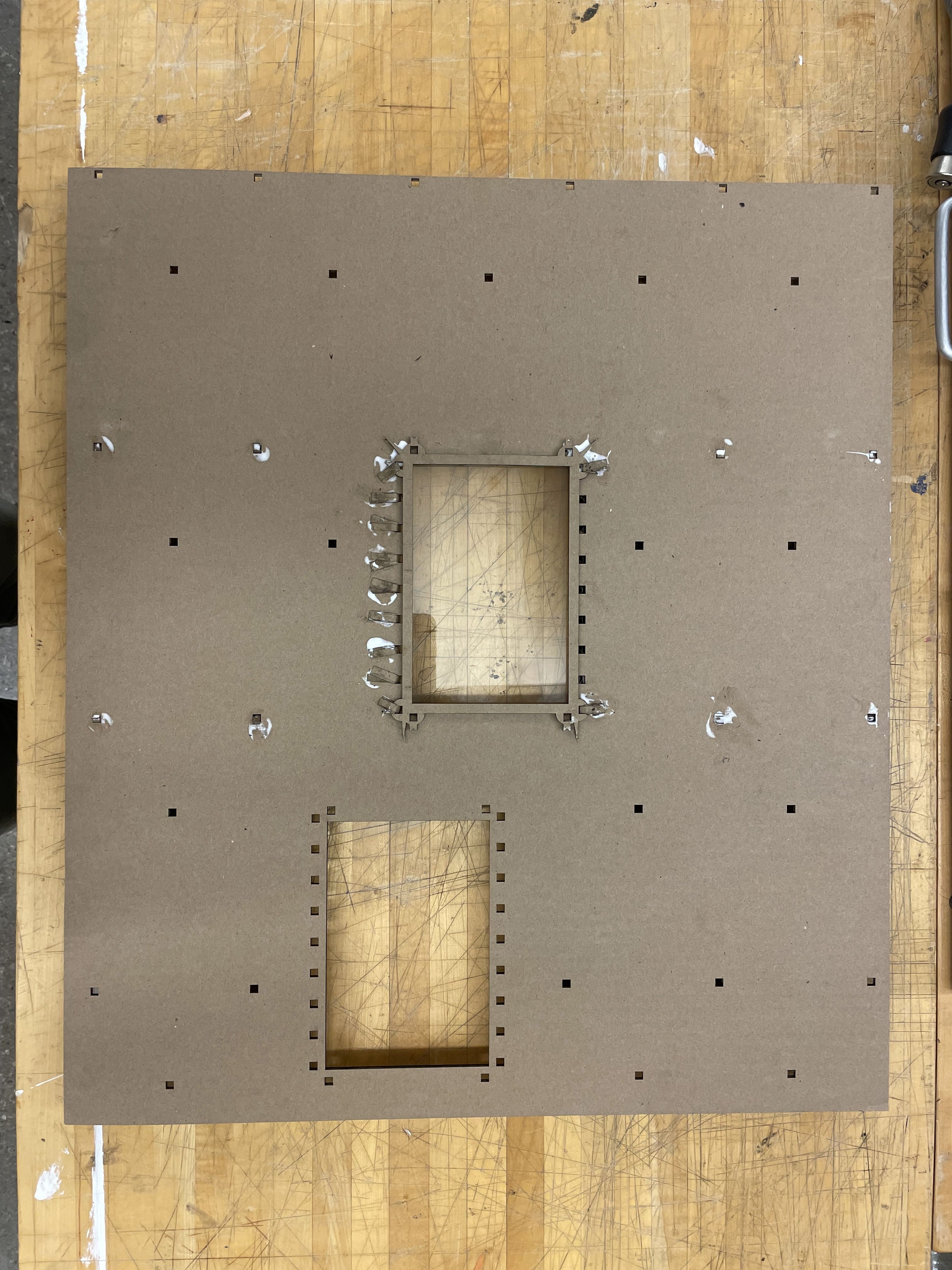

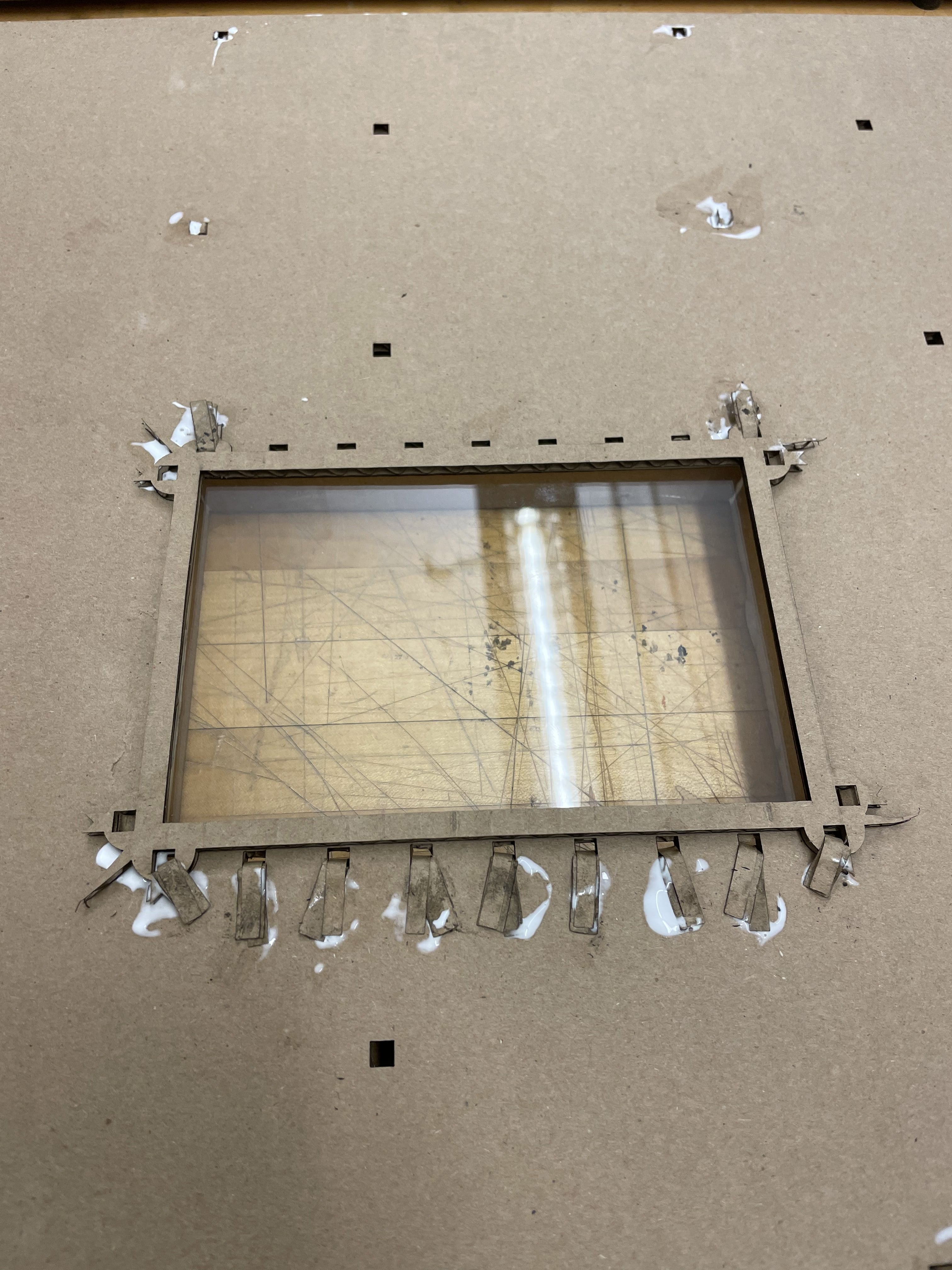

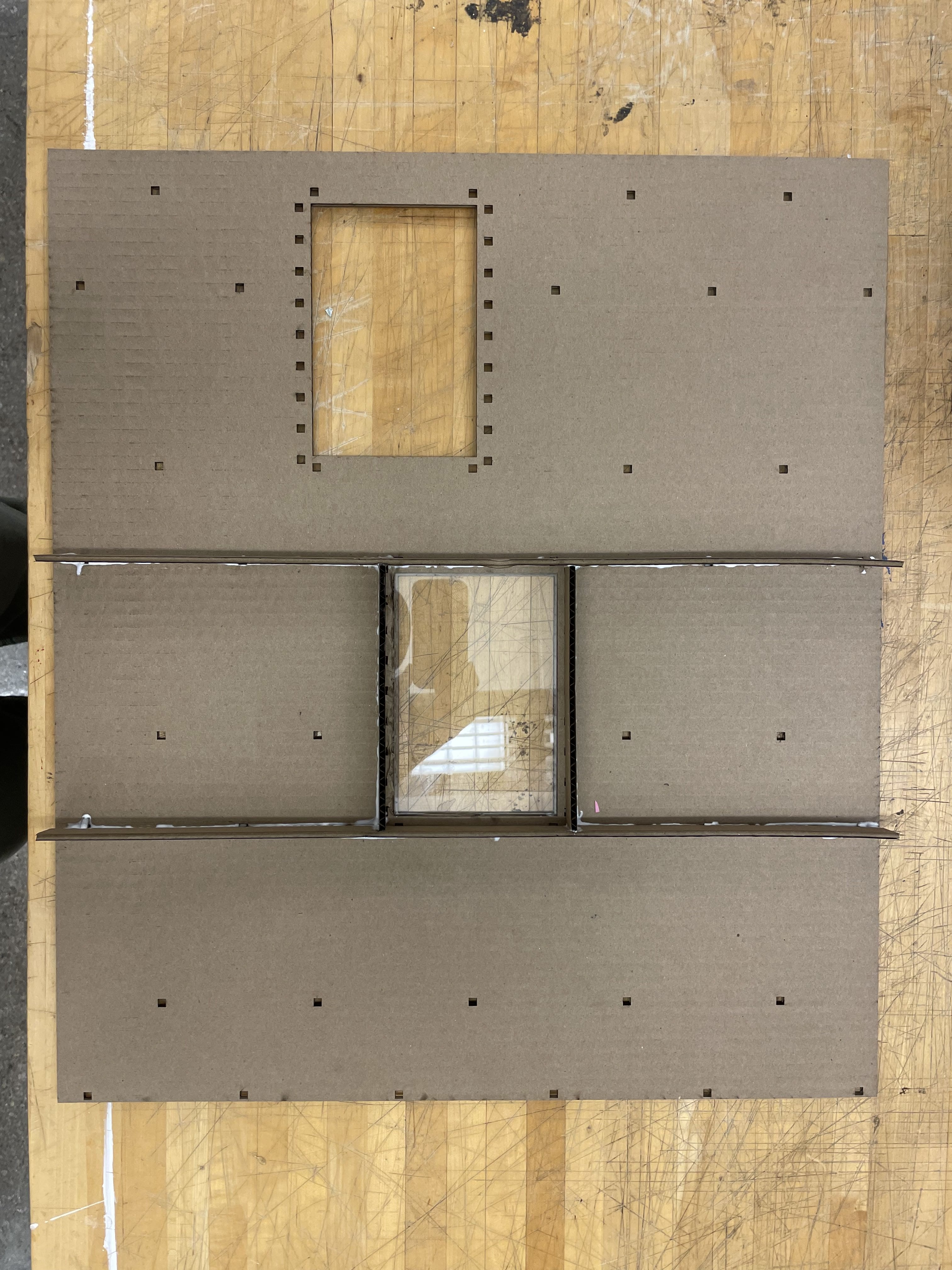

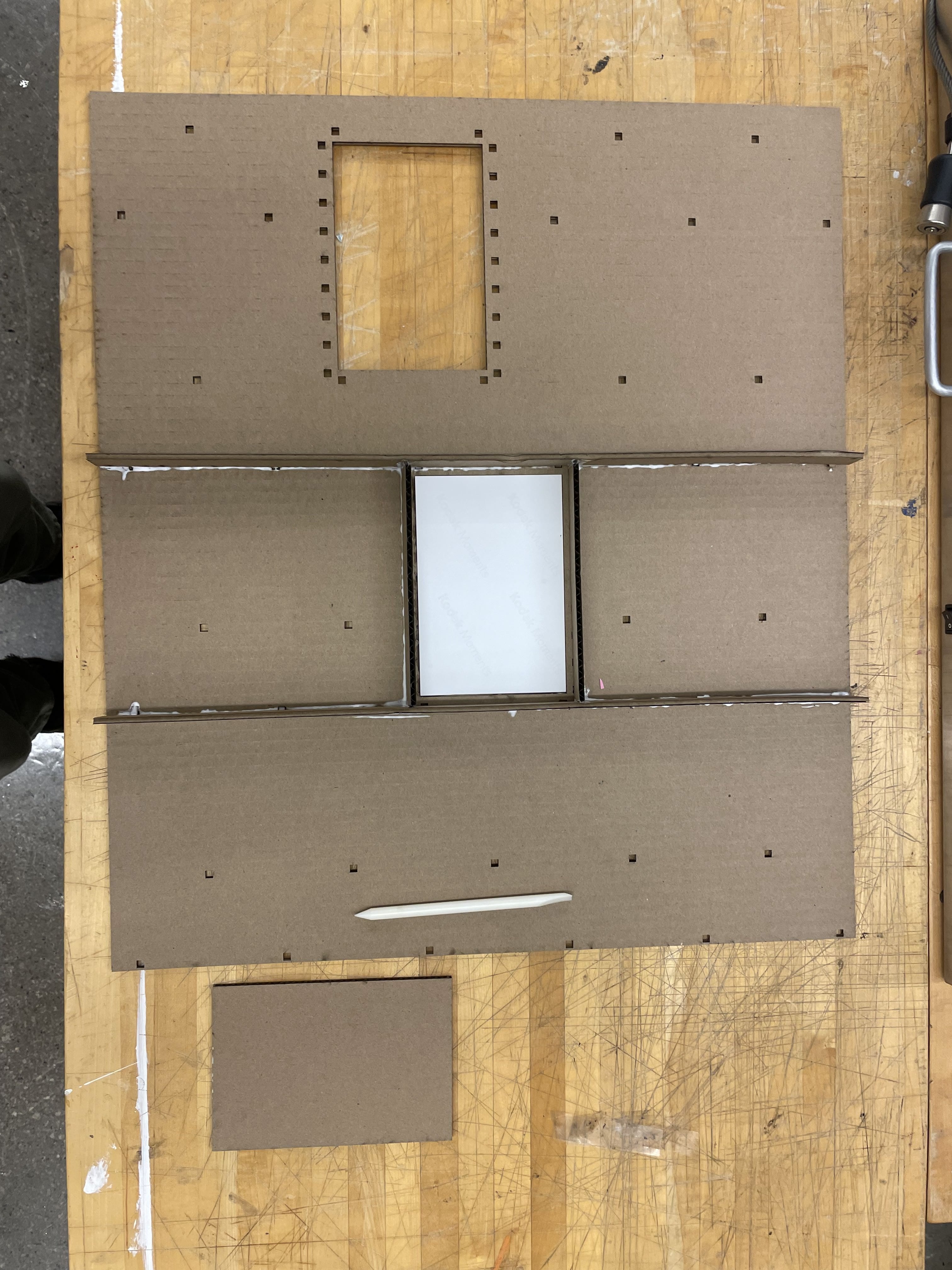

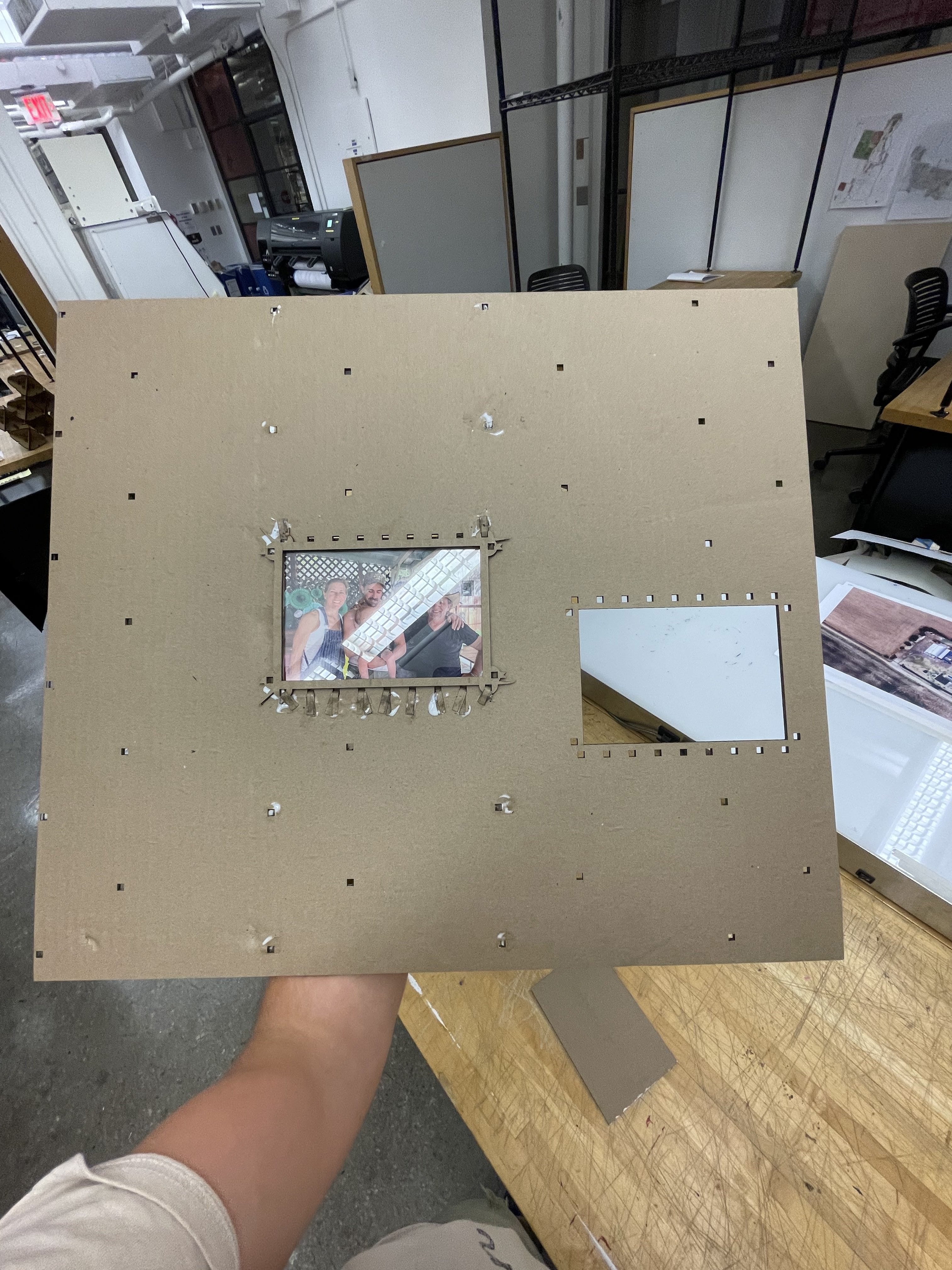

design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways