Introdcution

The homework for this week is a group assignment, and our group needs to design a special movable machine with MCU-controlled motors. Finishing it in just one week is a very arduous task, and both of our group members contributed a lot of effort.

Our design is a rollable Icosahedron machine, with twenty servo motors driving twenty pistons to push itself and roll. We call it Neilbot 2000 because on each surface, there will also be Neil’s face, so in total, 20 of them. The group documentation can be found here: NEILBOT!

I belong to the mechanical subgroup. My contribution to this project can be concluded as follows: Concept proposal, geometric calculation, panel molding, and final assembly.

Concept proposal:

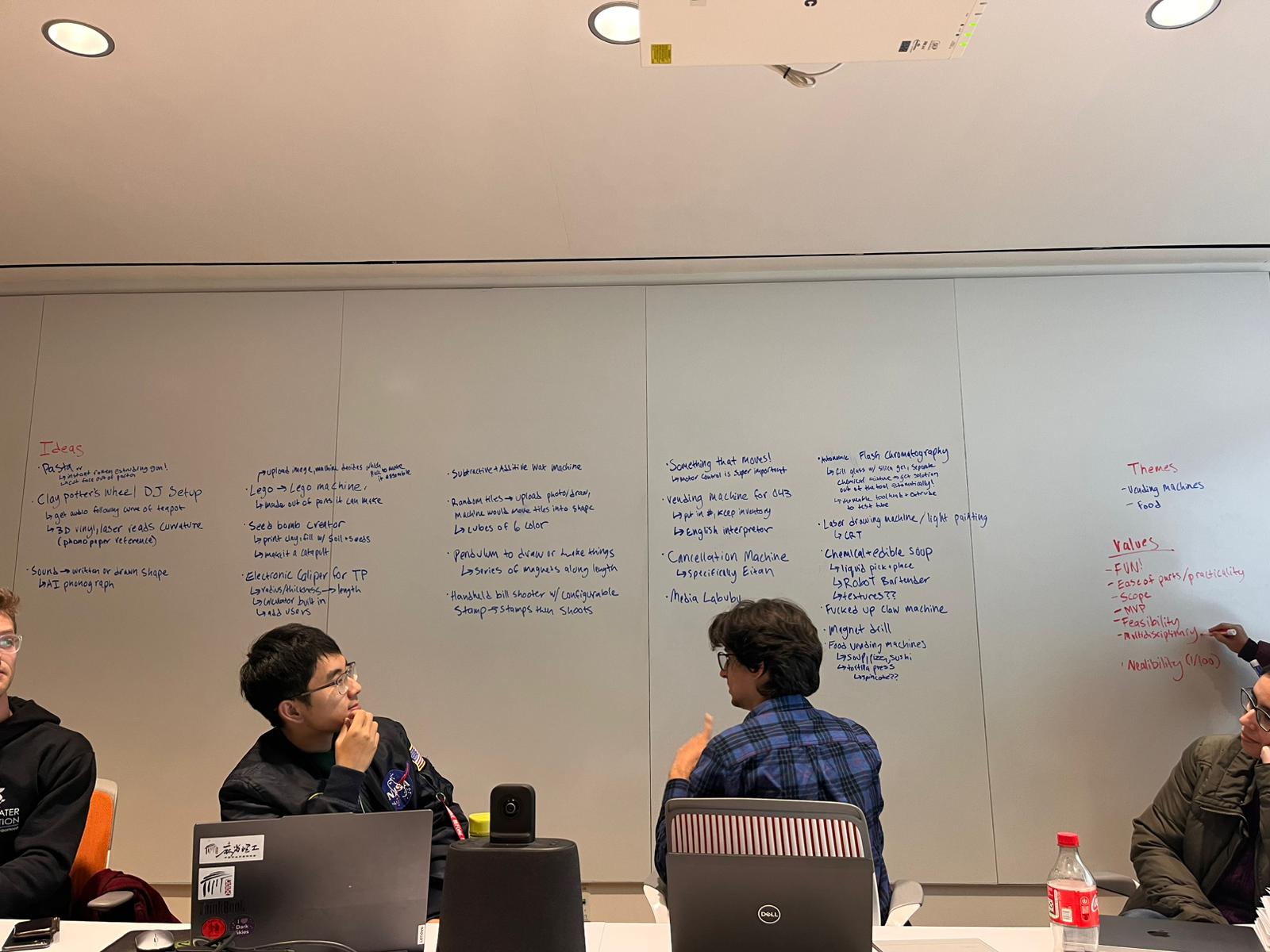

On November 6, we scheduled a group meeting about the initial ideas for the machine to be built. I proposed the idea of making an auto chromatography machine, with a movable robot arm to pick the test tubes for the solutions to collect. However, it’s not funny enough when compared with others’ ideas. Finally, I also voted for the Icosahedron machine, but not my idea, because I feel it’s very challenging.

Geometric calculation

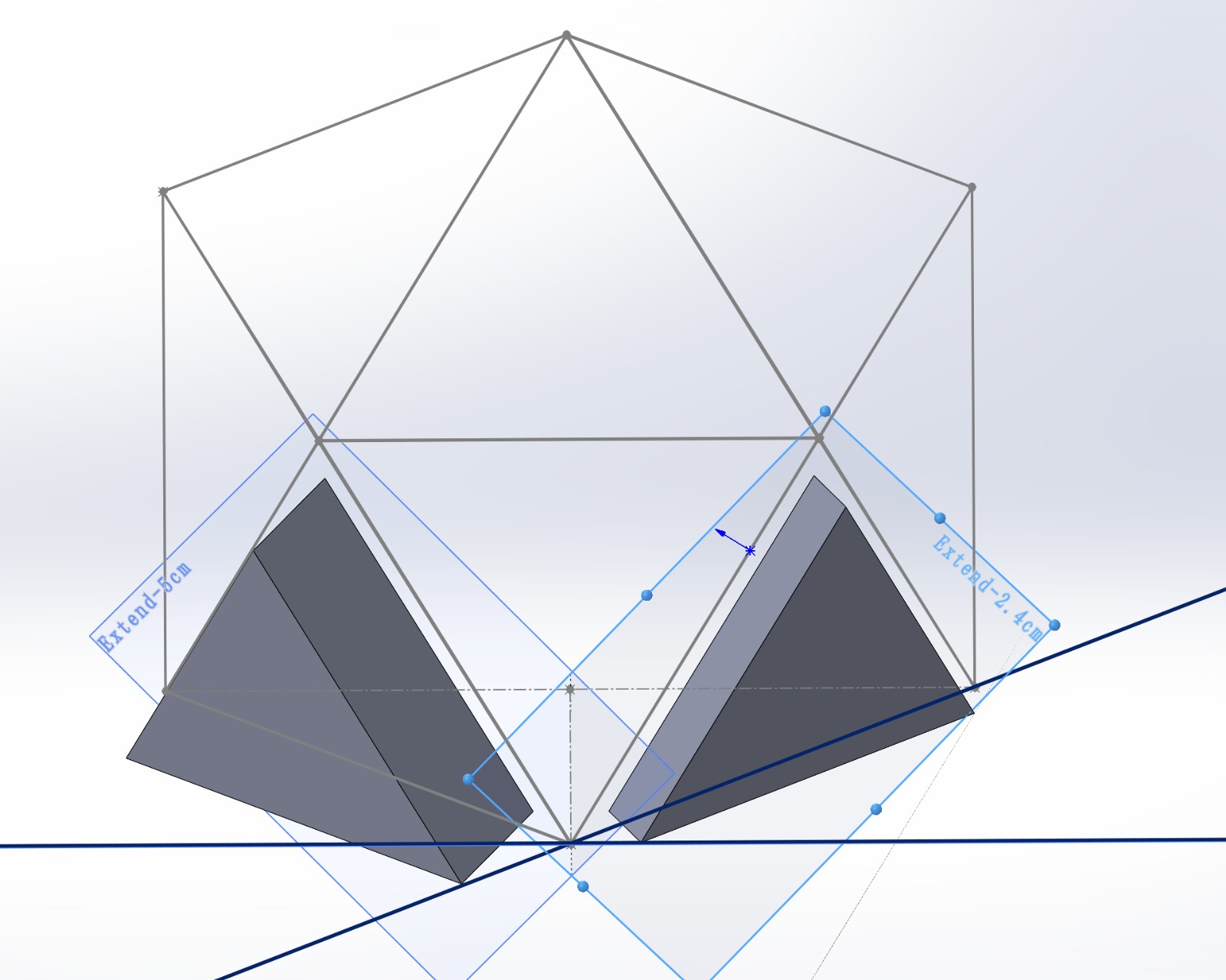

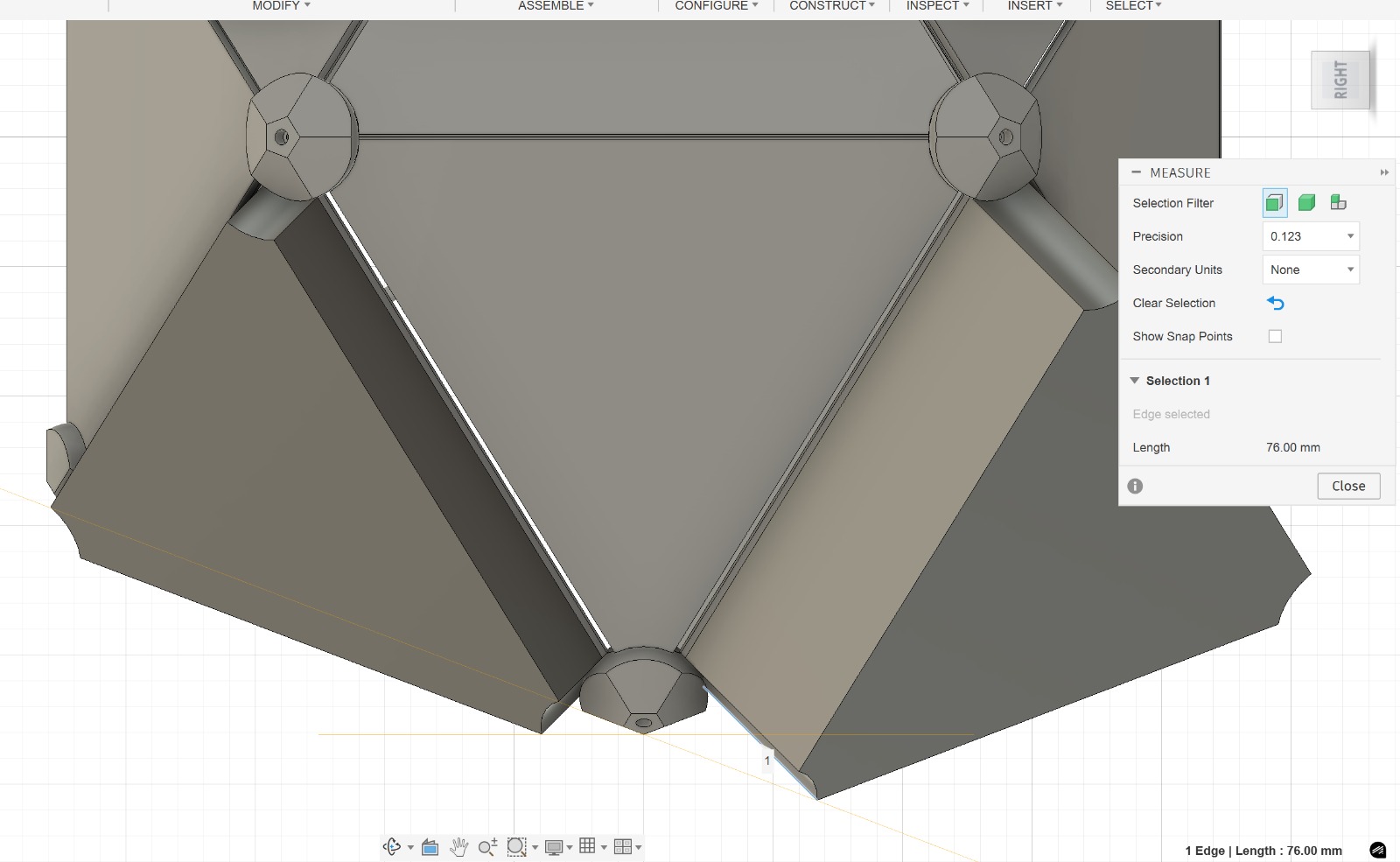

After we decided to build this, I volunteered to be a group member for the mechanical design. The first problem we encountered was how long we needed to extend the pistons to push the machine itself to flip. To do that calculation, I used CAD software to simulate that: I tried SolidWorks first, but then I figured out it’s not easy to share the SolidWorks files if others are using Fusion. My first calculation gave us 2.2cm extension for the flipping threshold, and 5 cm extension for the full flipping. It looks like this:

But our mechanical design changed in the middle, and we adjusted the size of the faces. As a result, I recalculated with Fusion directly from the shared CAD cooperation file. It can simulate the shape of the whole machine much better than my former attempt, and then it gave us ~3cm flipping threshold and ~7.6cm for the full flip.

The original CAD file can be downloaded here: calculation.f3d

Panel molding

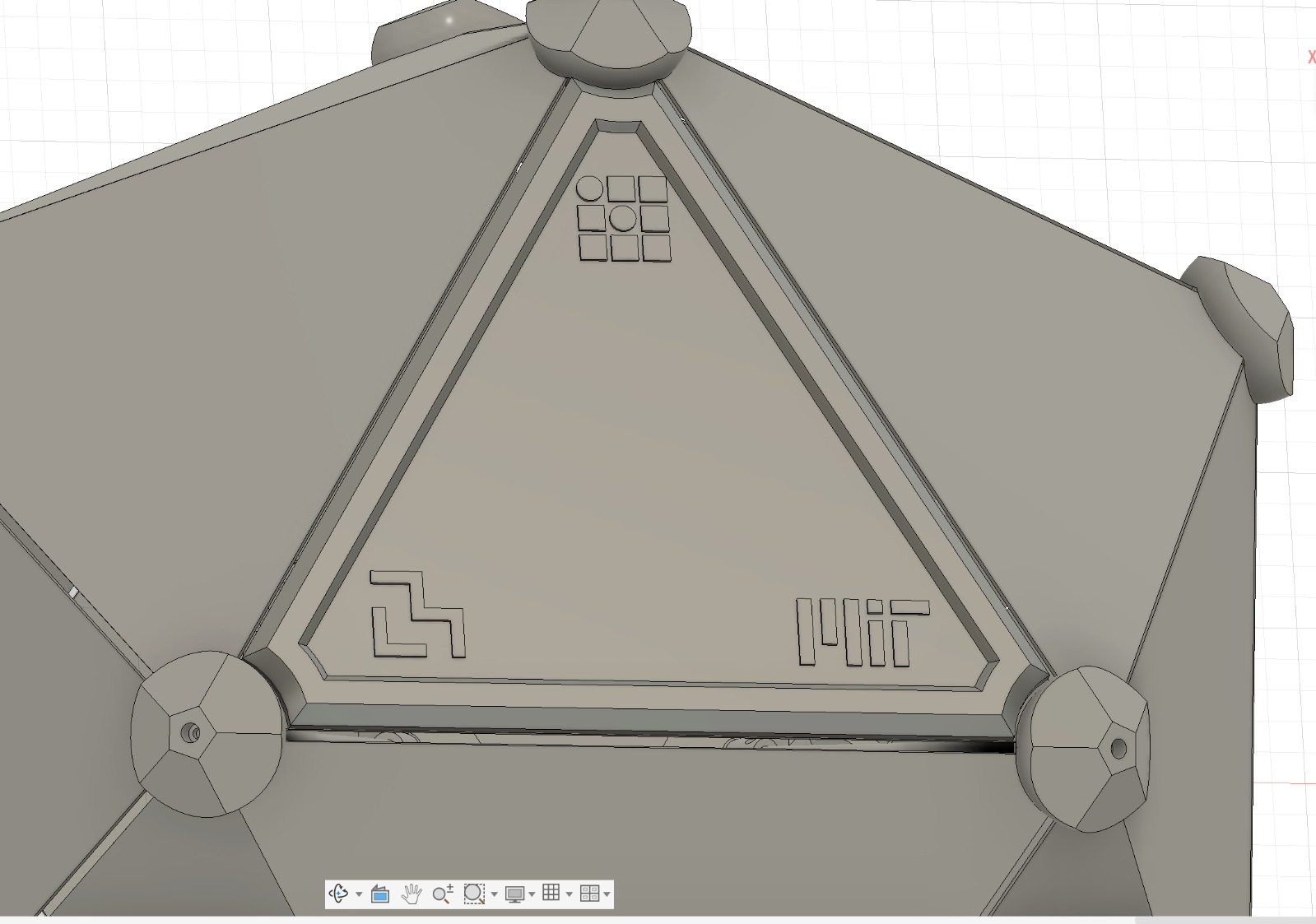

In order to maximize my capabilities, I decided to mold twenty of Neil’s faces based on my last week’s assignment: Huanyu HTMAA 2025 week 10. I redesigned the mold to make it bigger, with a specific triangular shape that matches our machine design, and also some logos at three points: MIT logo, Media Lab logo, and CBA logo.

After I put Neil’s face on it and got ready to SLA print it, I noticed it’s too big for the SLA printers. As a result, I finally decided to use my Bambu lab H2D to print that because of its big size hot plate. I thought about using acetone vapor to do the post-processing to make the mold smoother, so I used the ABS filament for printing. However, after a whole night of acetone vapor treating, it still didn’t change. I guess it might be too big, so the acetone can’t reach all surface evenly.

But I finally still struggled to cast 20 Neil’s faces and got a Neil Army! It looks magnificent with all of them together:

Final assembly

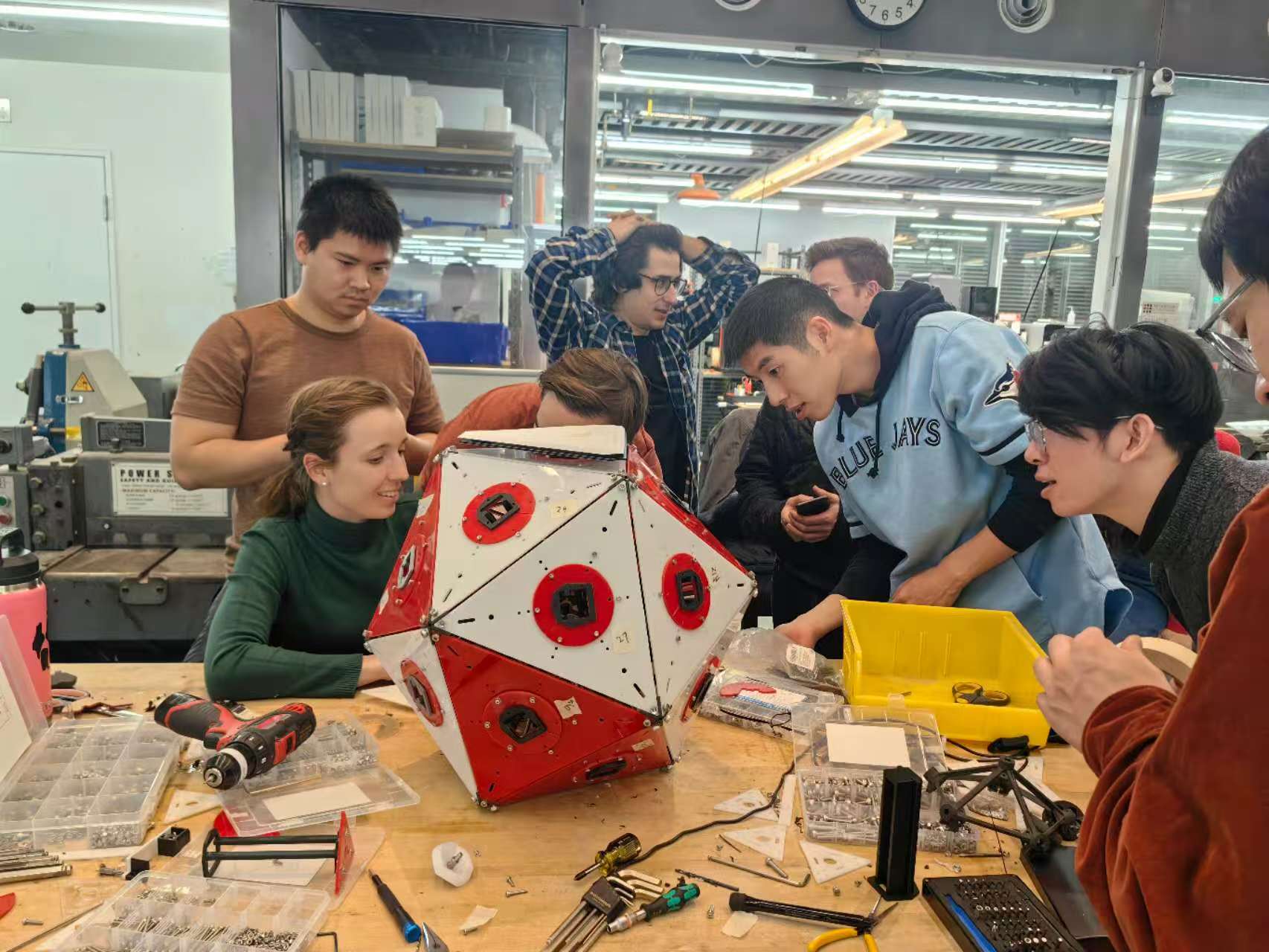

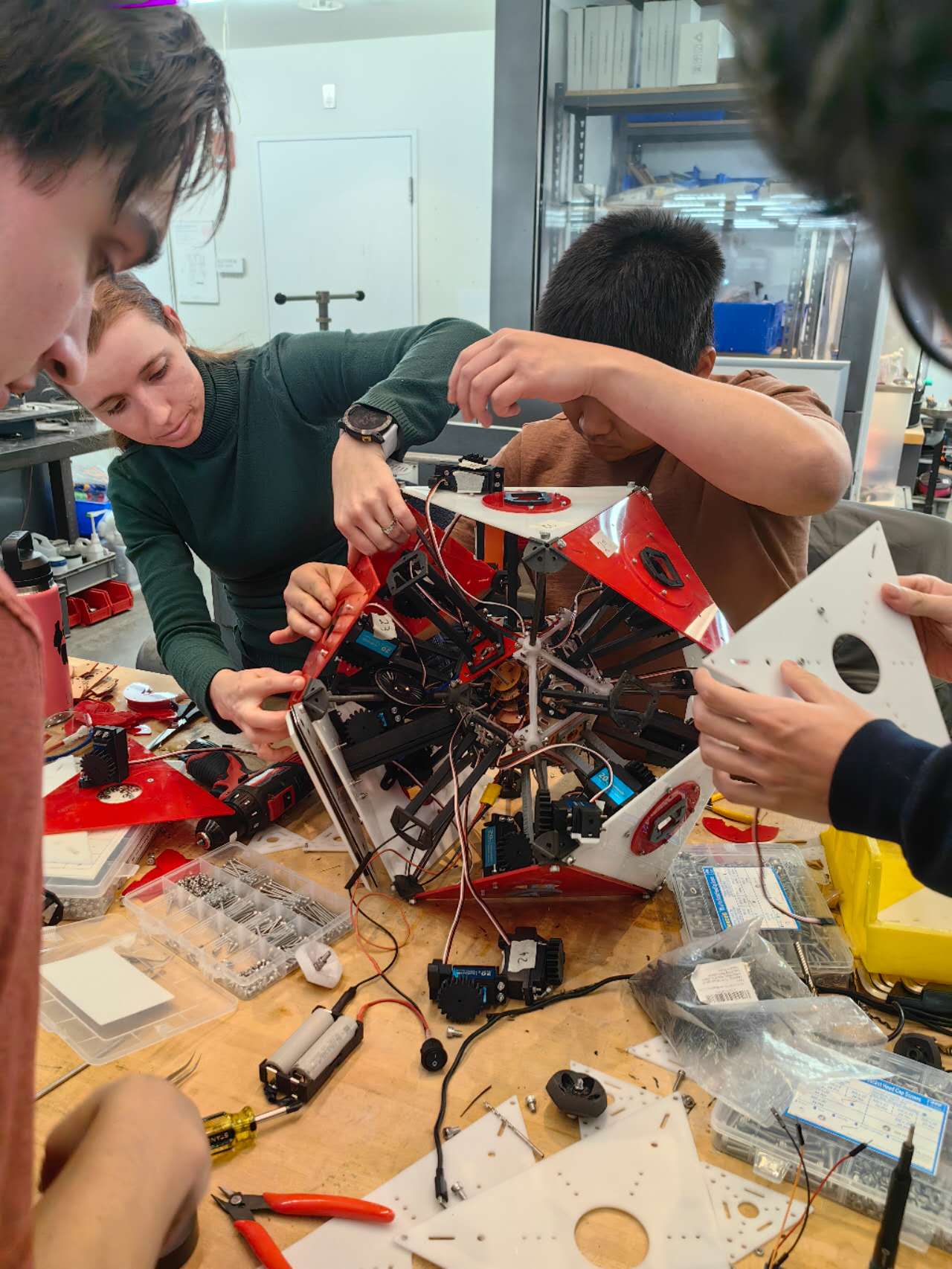

The final night was very tiring but an unforgettable memory. This is my first time staying up late with over 10 members for the group assignment, and everyone contributed a lot! I volunteered to help assemble the machine. Since it has 4 layers (two inner acrylic layers, one metal layer, and one resin layer), it took us several hours to tighten 500+ screws. It’s still funny though! Let me share some of the documents I got from that night here: