3D Printing

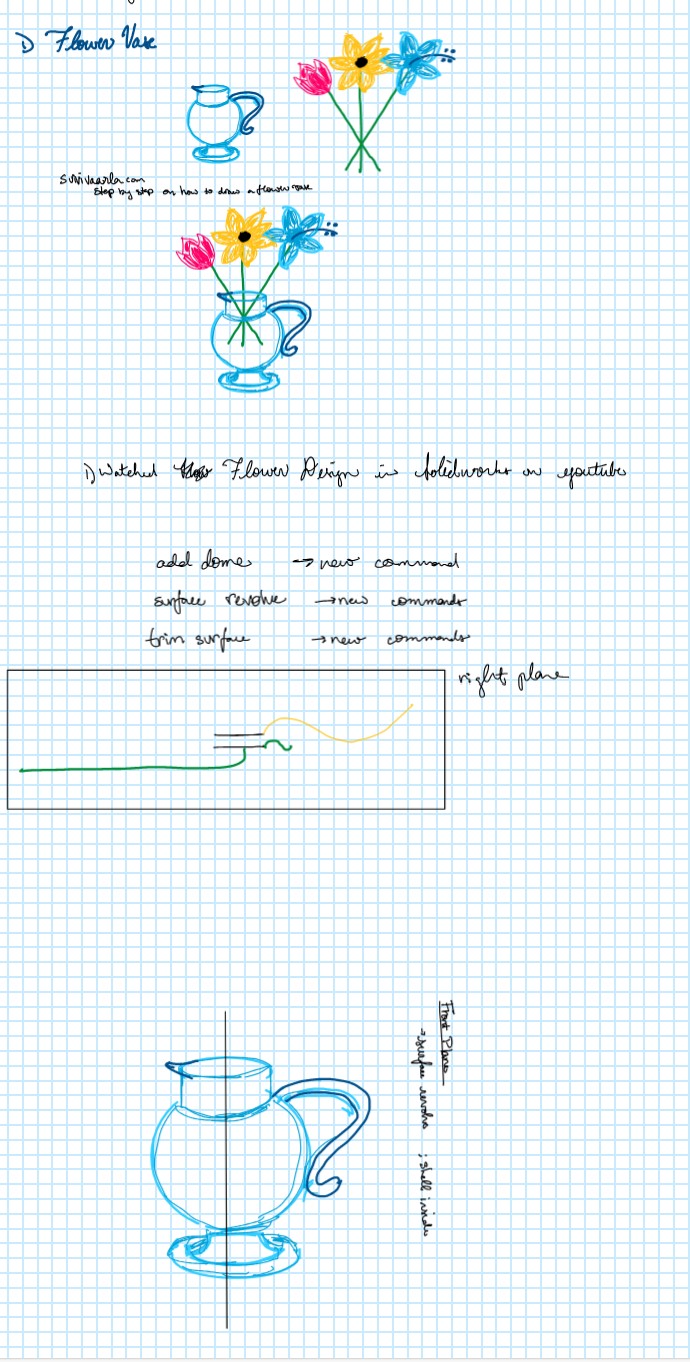

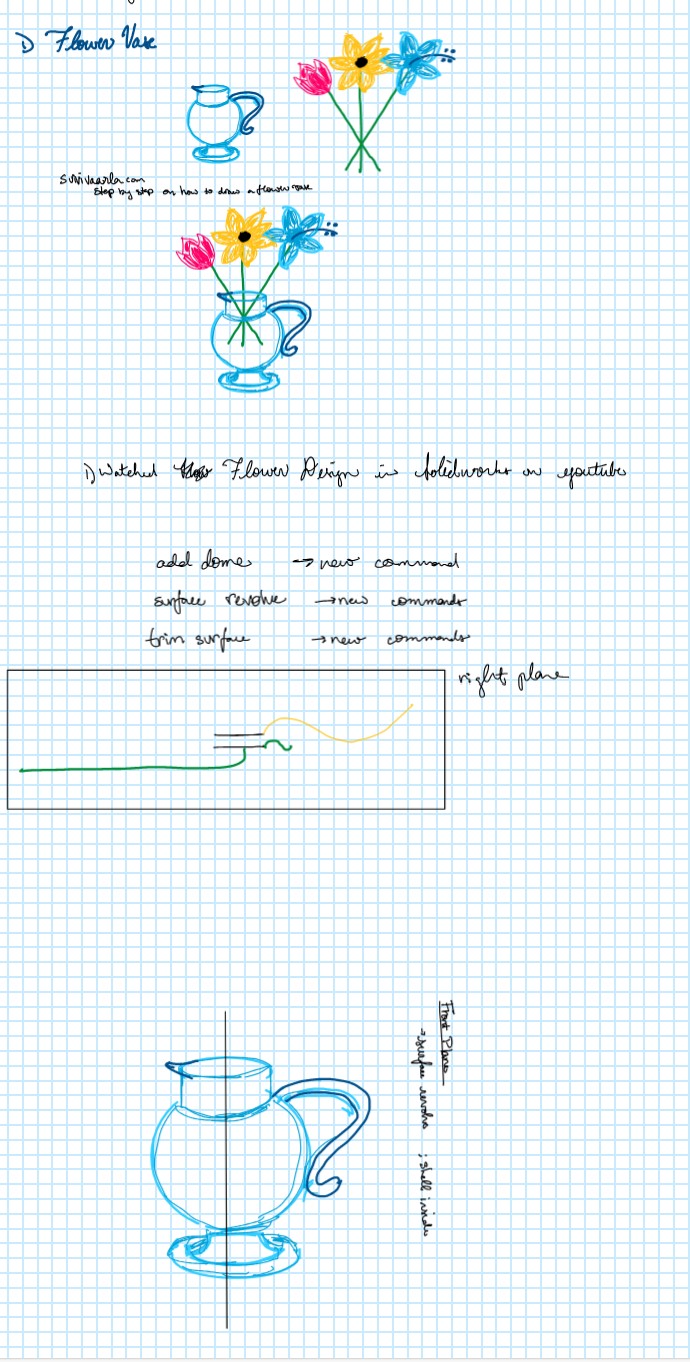

Originally, I was thinking about doing a flower vase and made some sketches in OneNote.

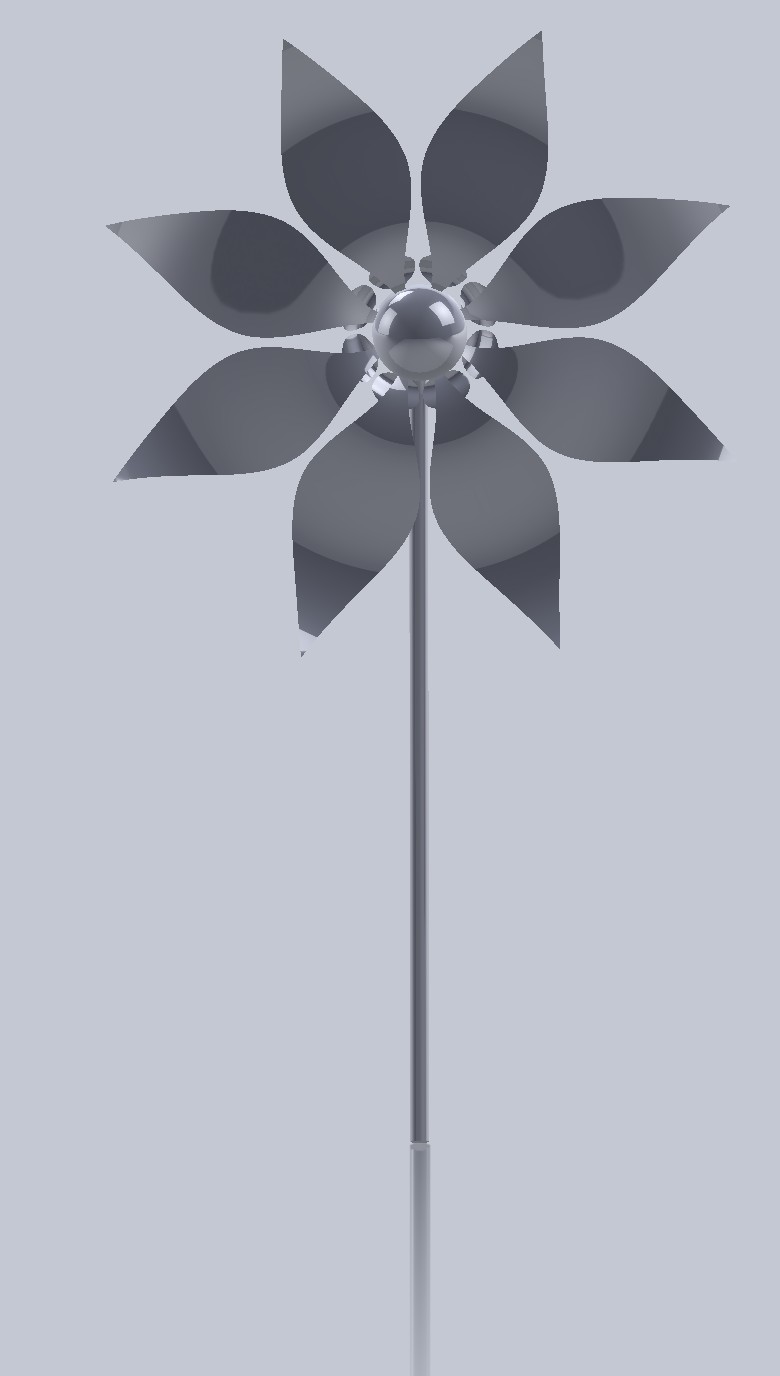

I started building it in SolidWorks by following a YouTube tutorial.

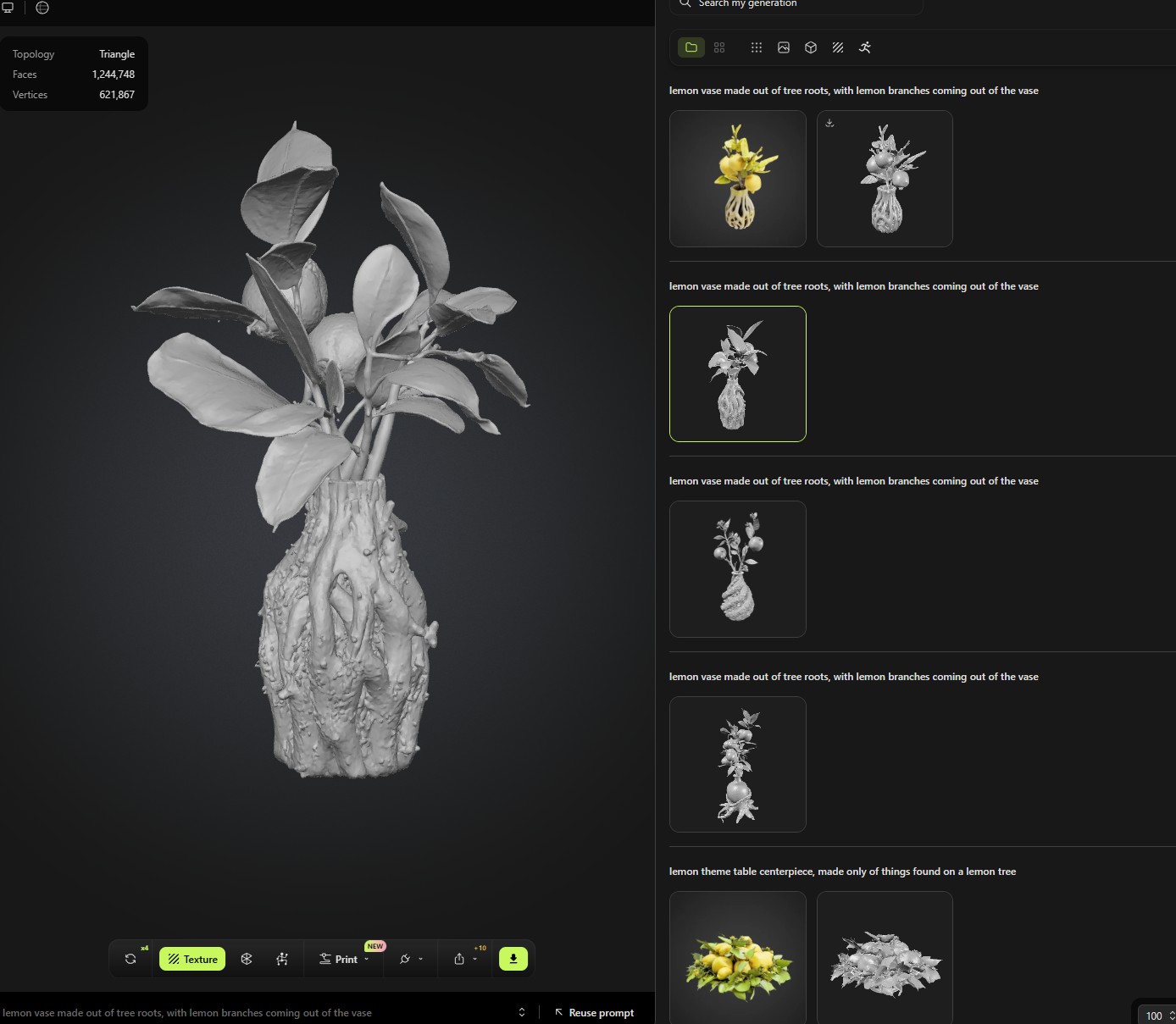

After the recitation on Thursday, I decided to try using one of the AI tools instead. I tried sending the text to Cad first,

but it didn’t work the way I had hoped. I wanted to be less specific, and the Text to Cad was looking for a more explicit input.

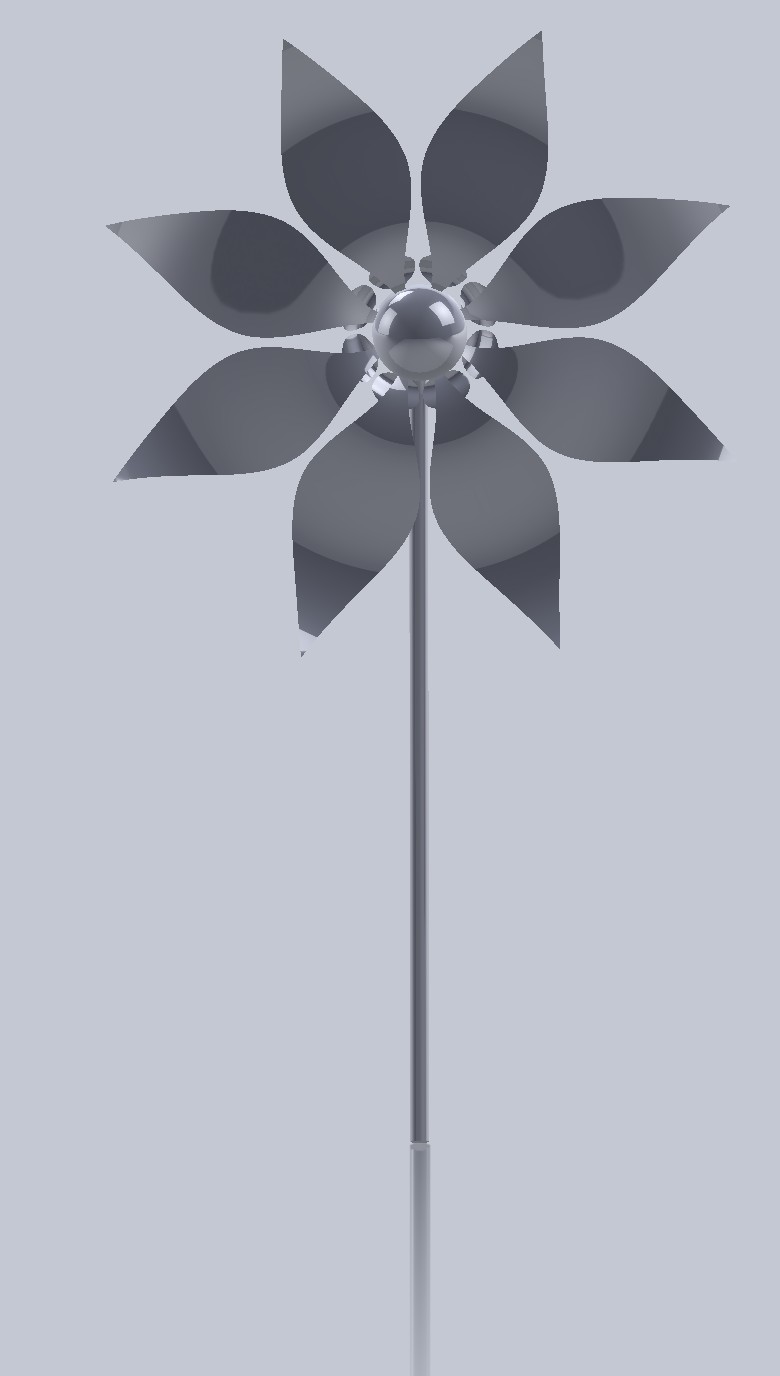

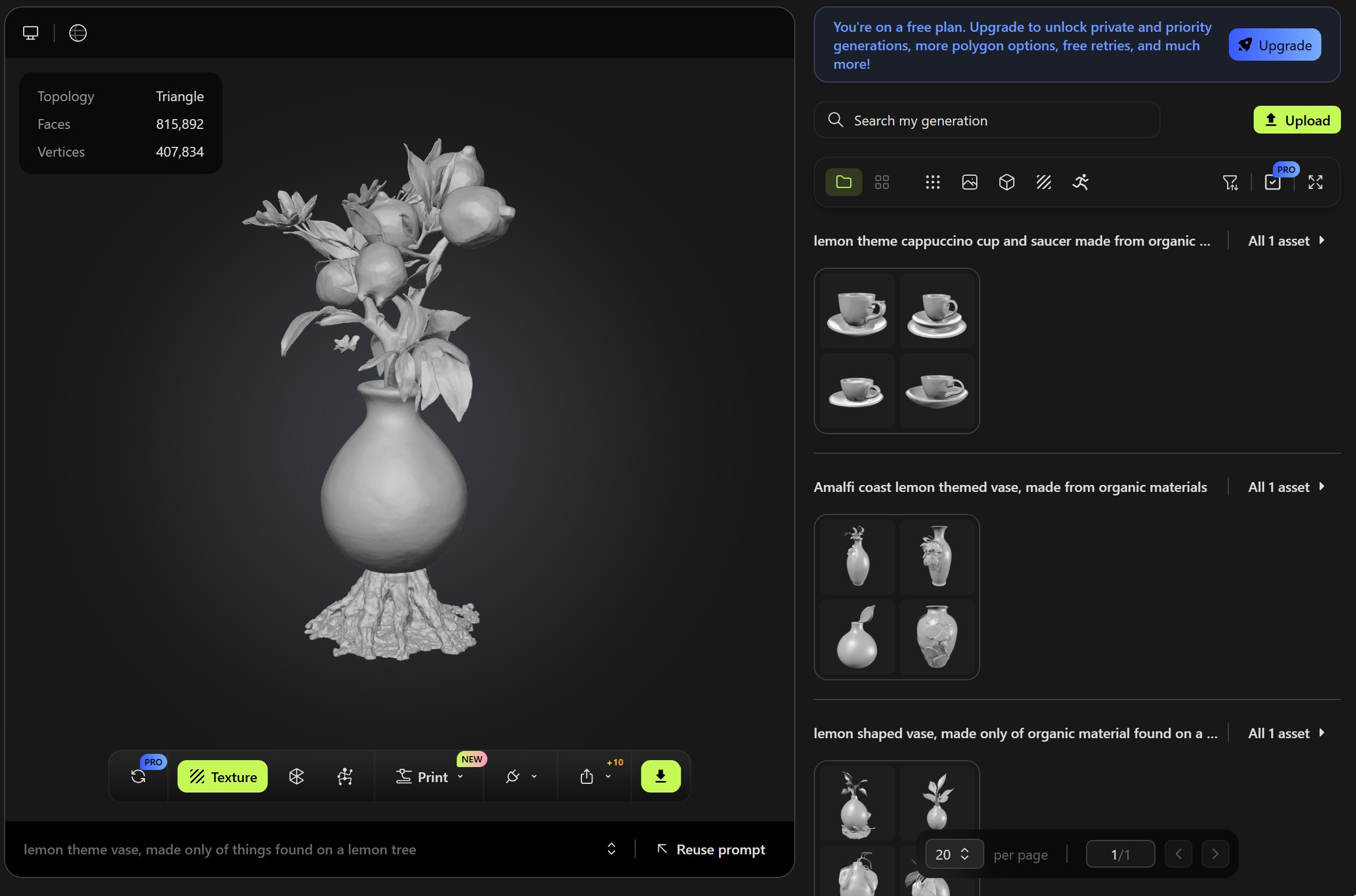

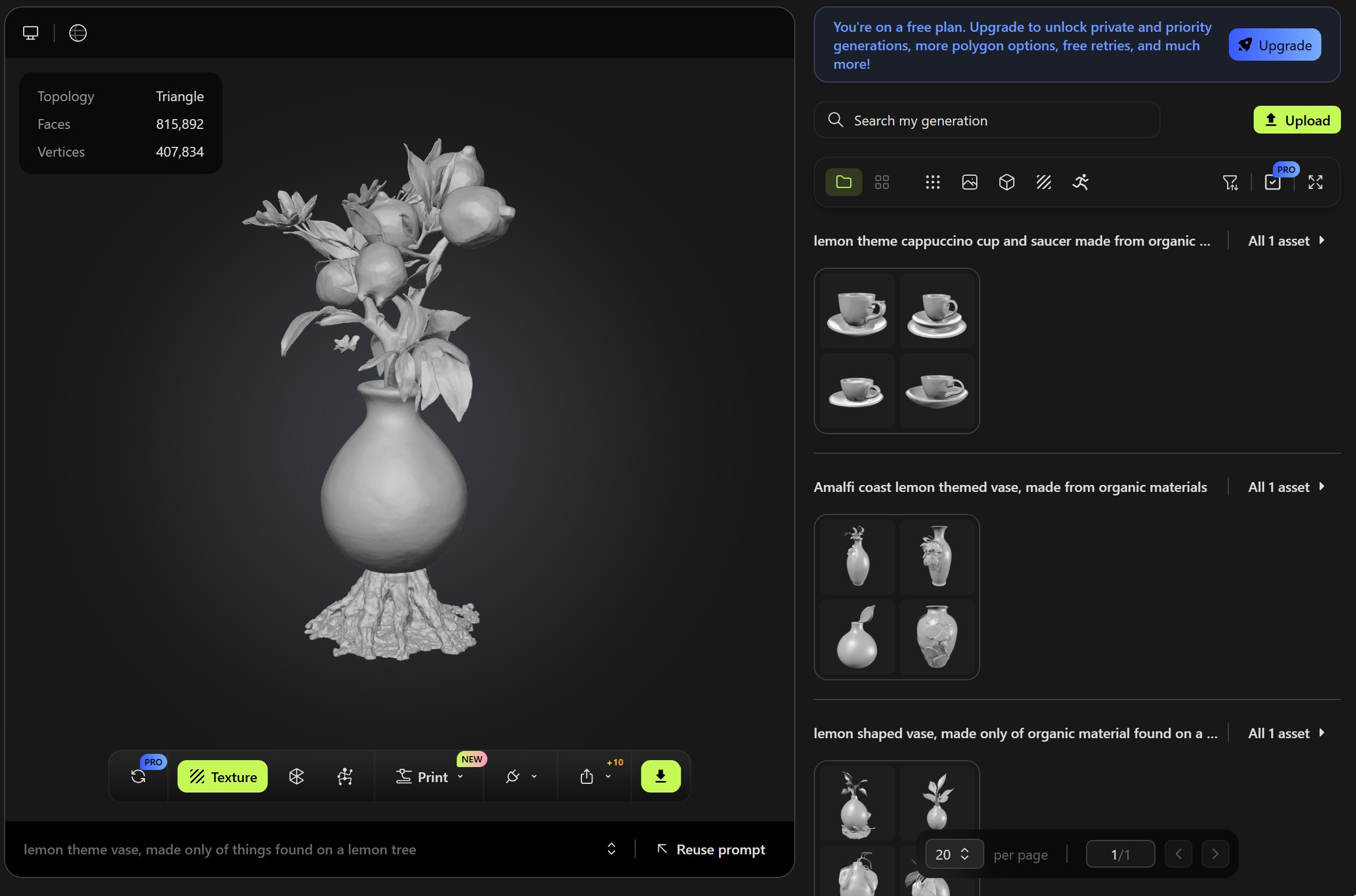

Next, I tried mesh.ai and was a little disappointed at first with some of the results:

Input and images:

I wanted to use one of the designs; however, to export it as an STL, I had to subscribe for a month (cost $4).

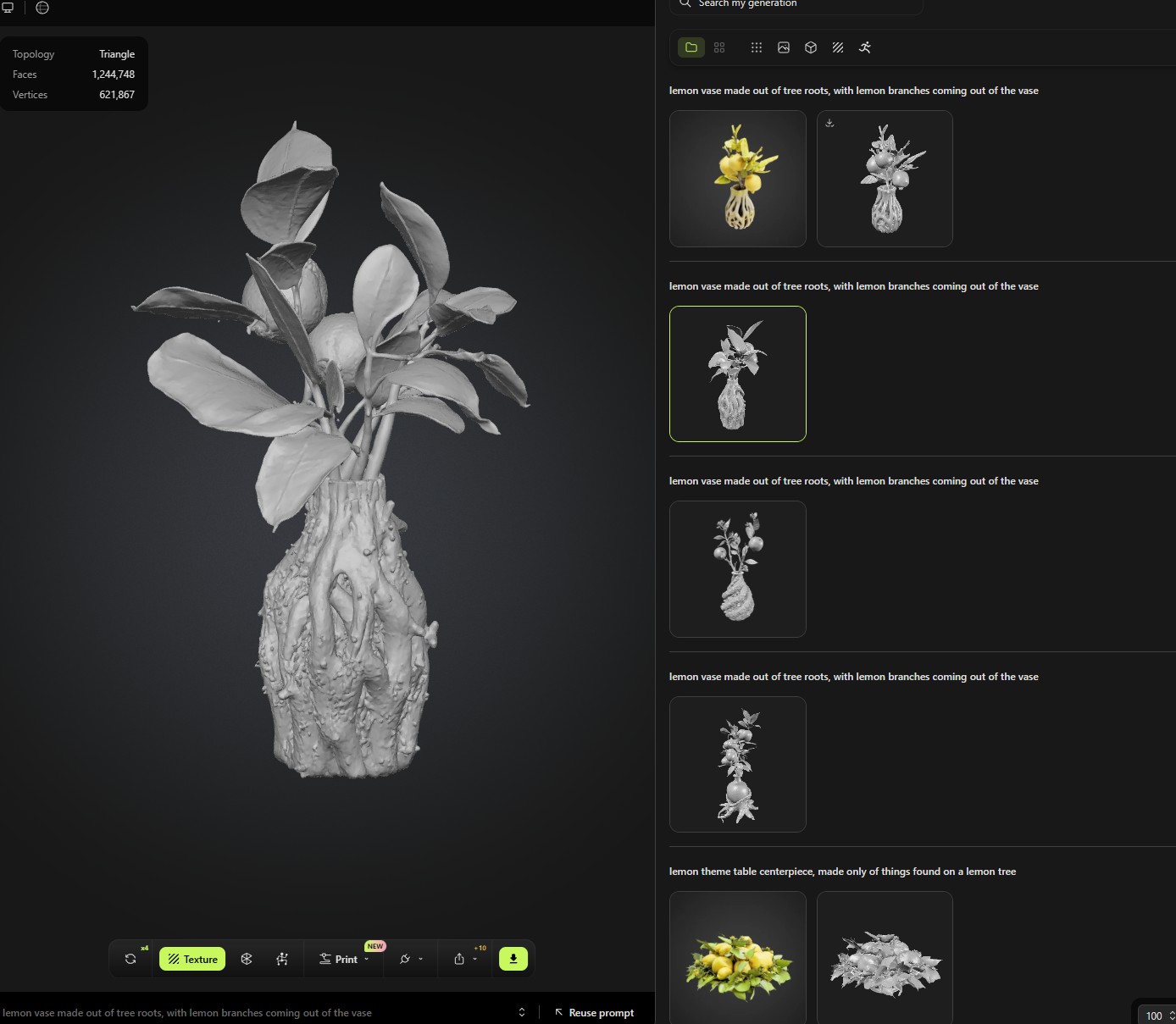

Once I subscribed to MeshyAi, I was able to access a better AI model. There is a feature where you can use the same

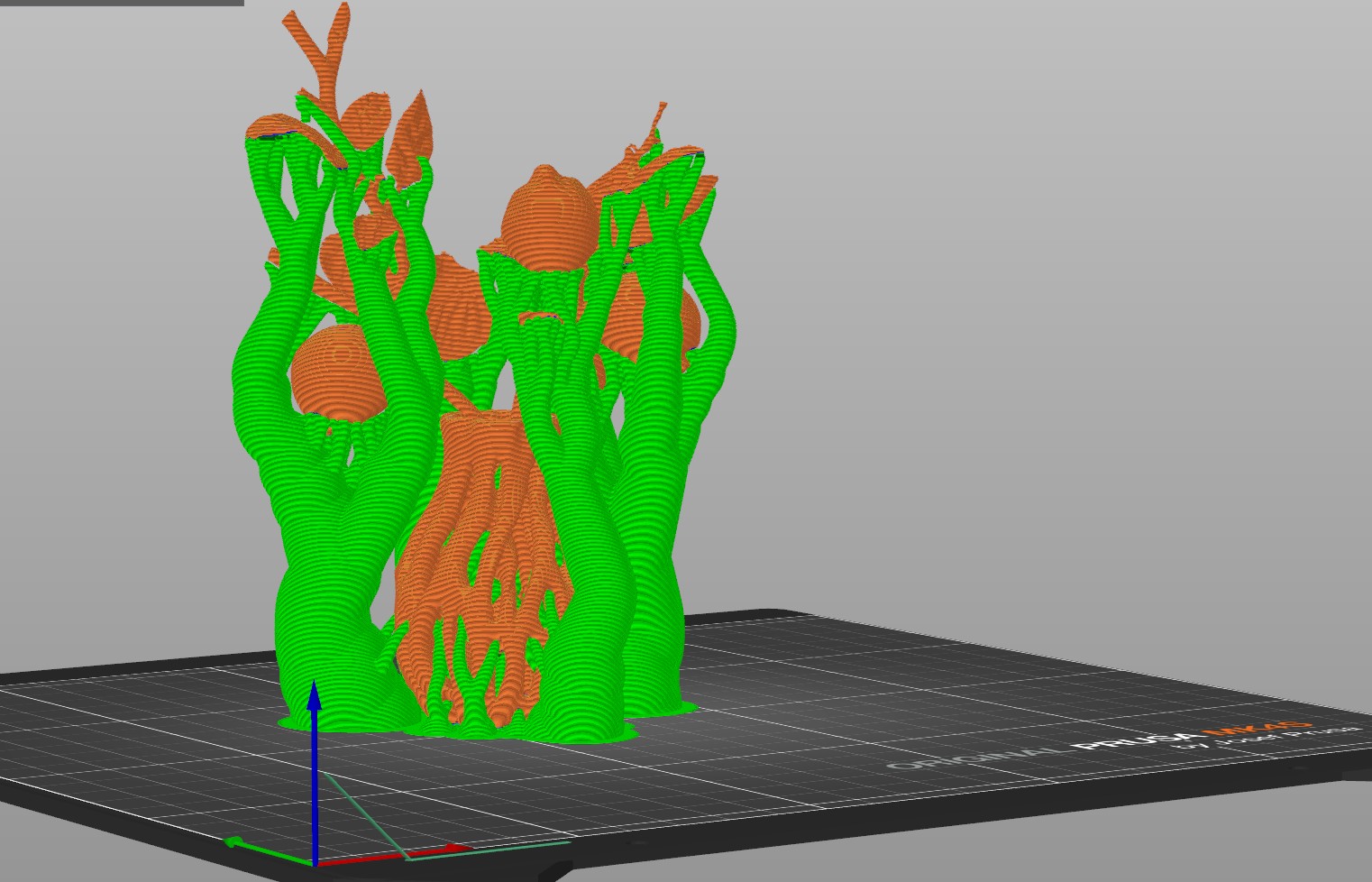

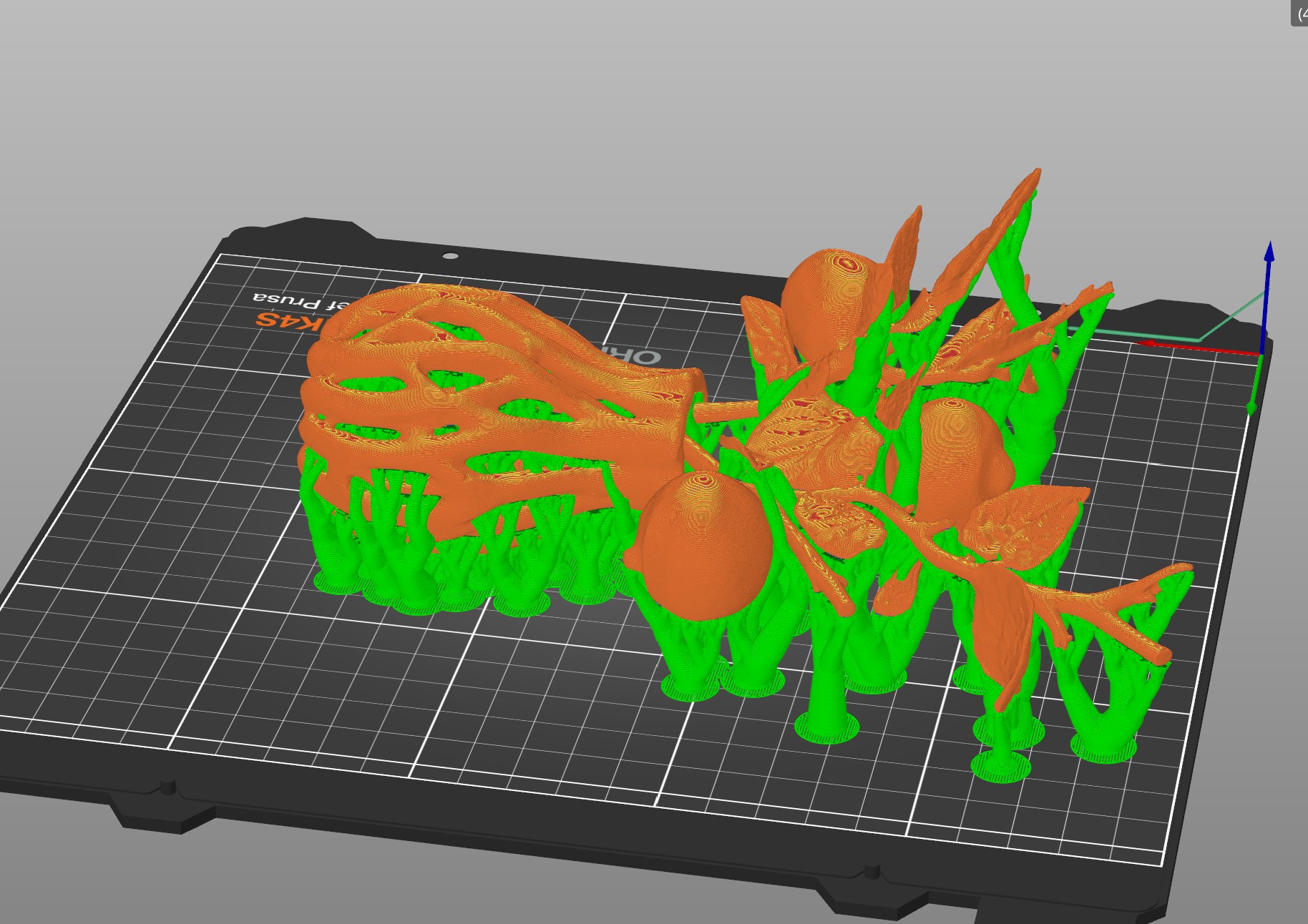

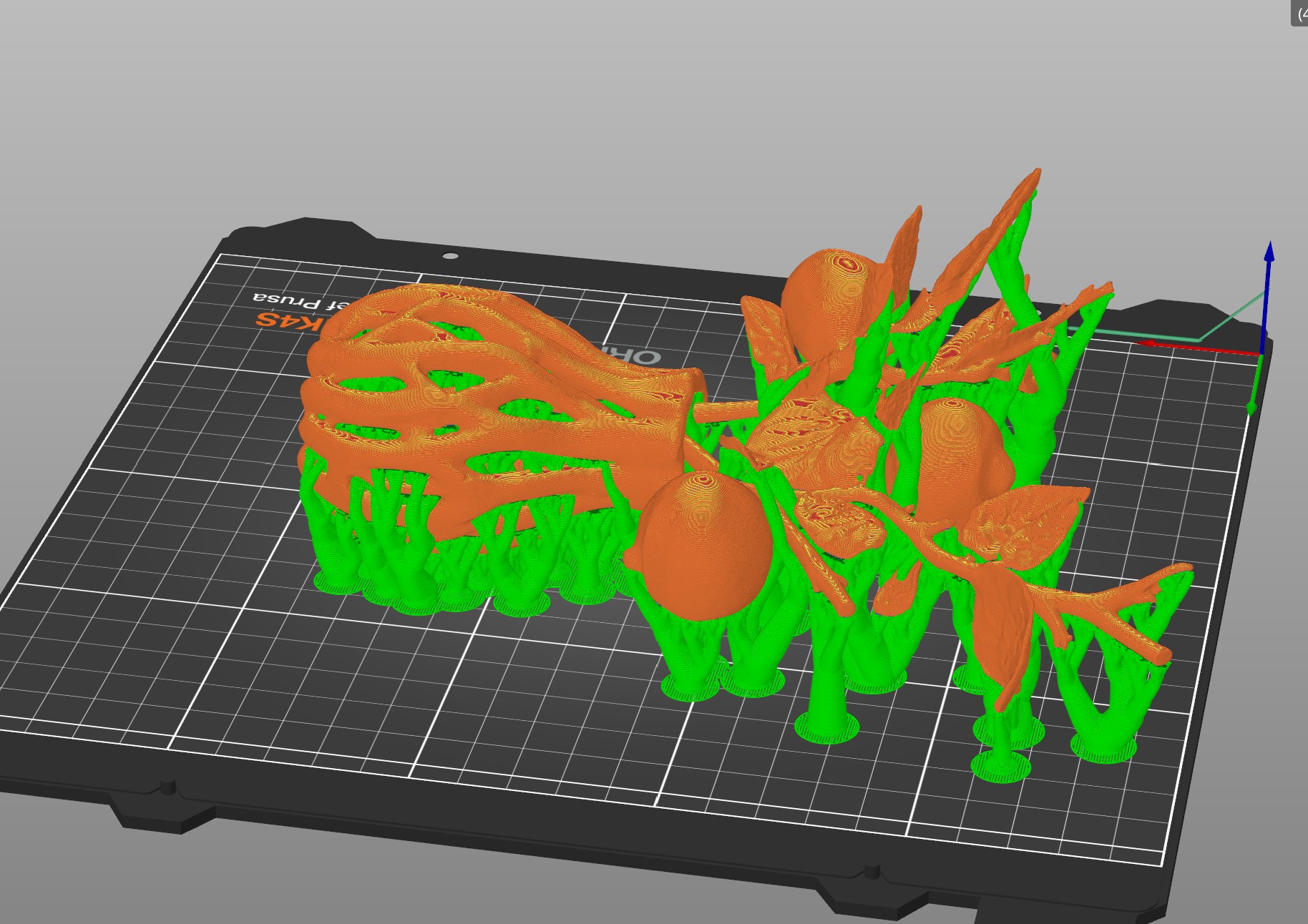

prompt to generate multiple different outputs. See images below:

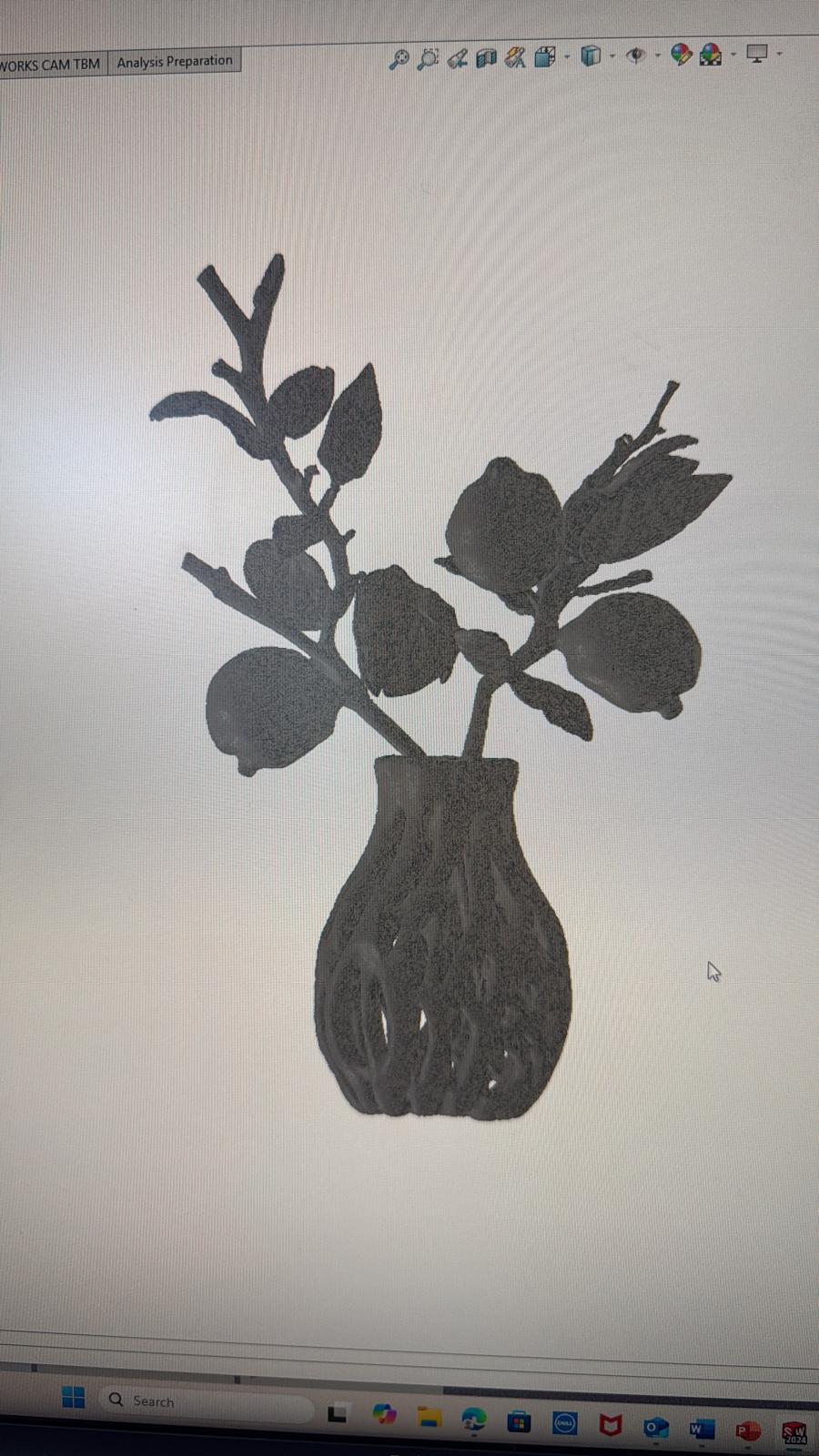

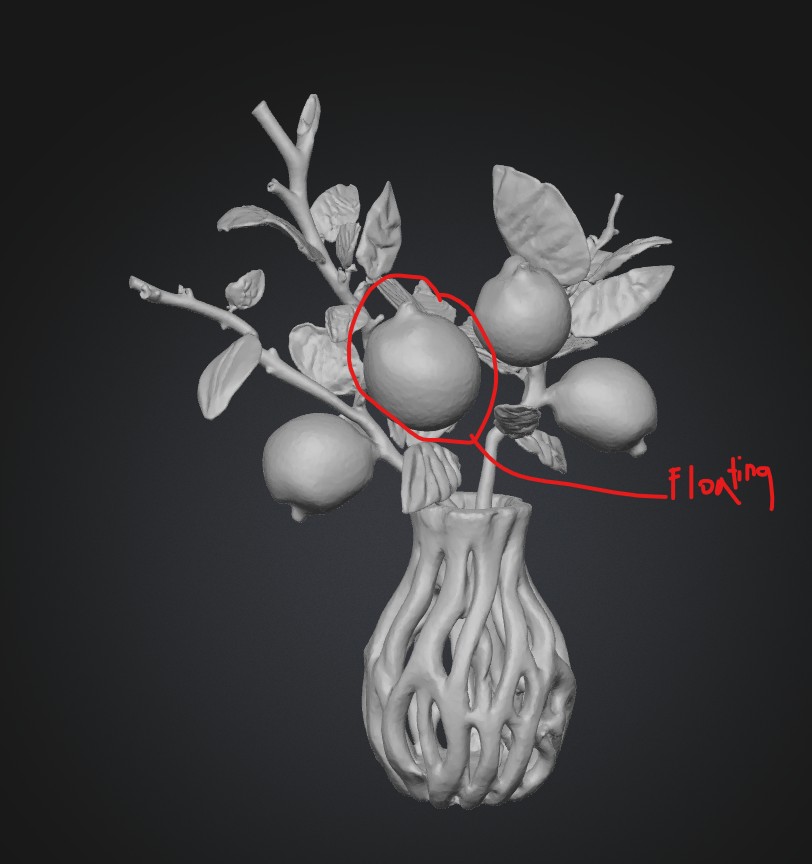

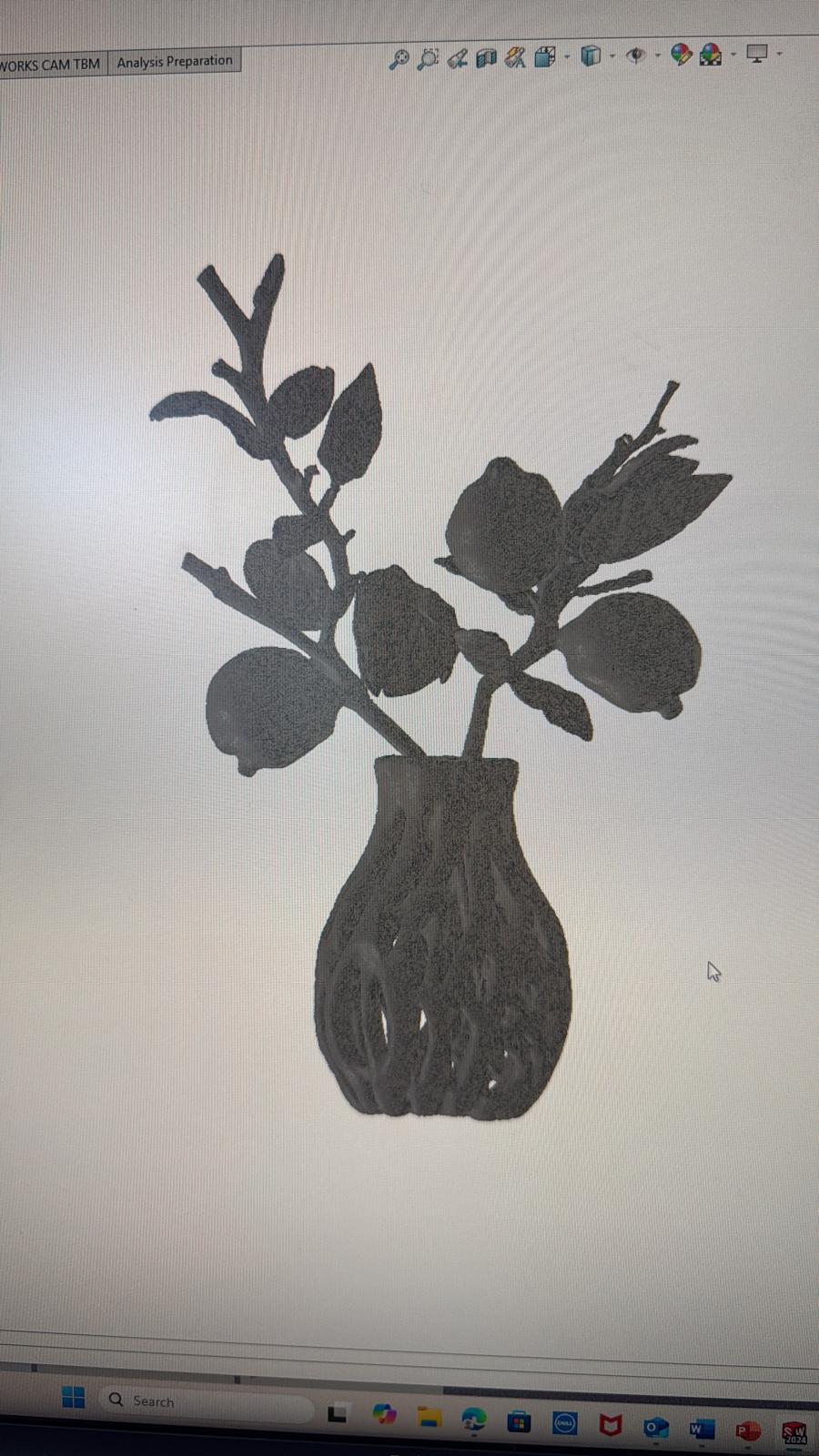

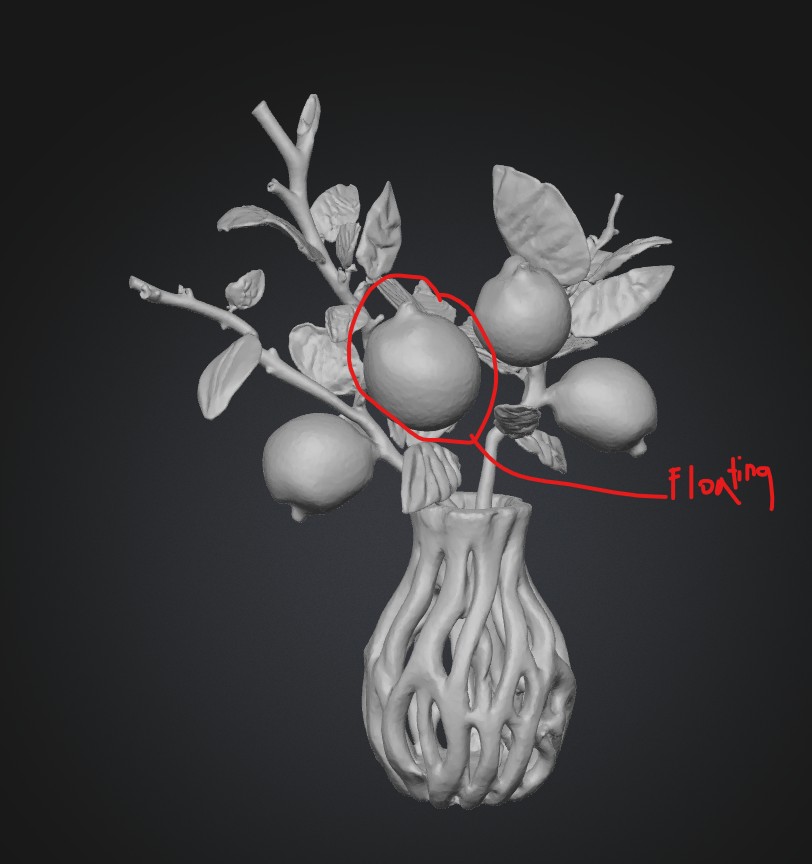

I ultimately chose this design. There were a few drawbacks; the design had a few floating parts,

and it was difficult to edit the part in SolidWorks (I was unable to convert it into a solid body, so I could not modify the design).

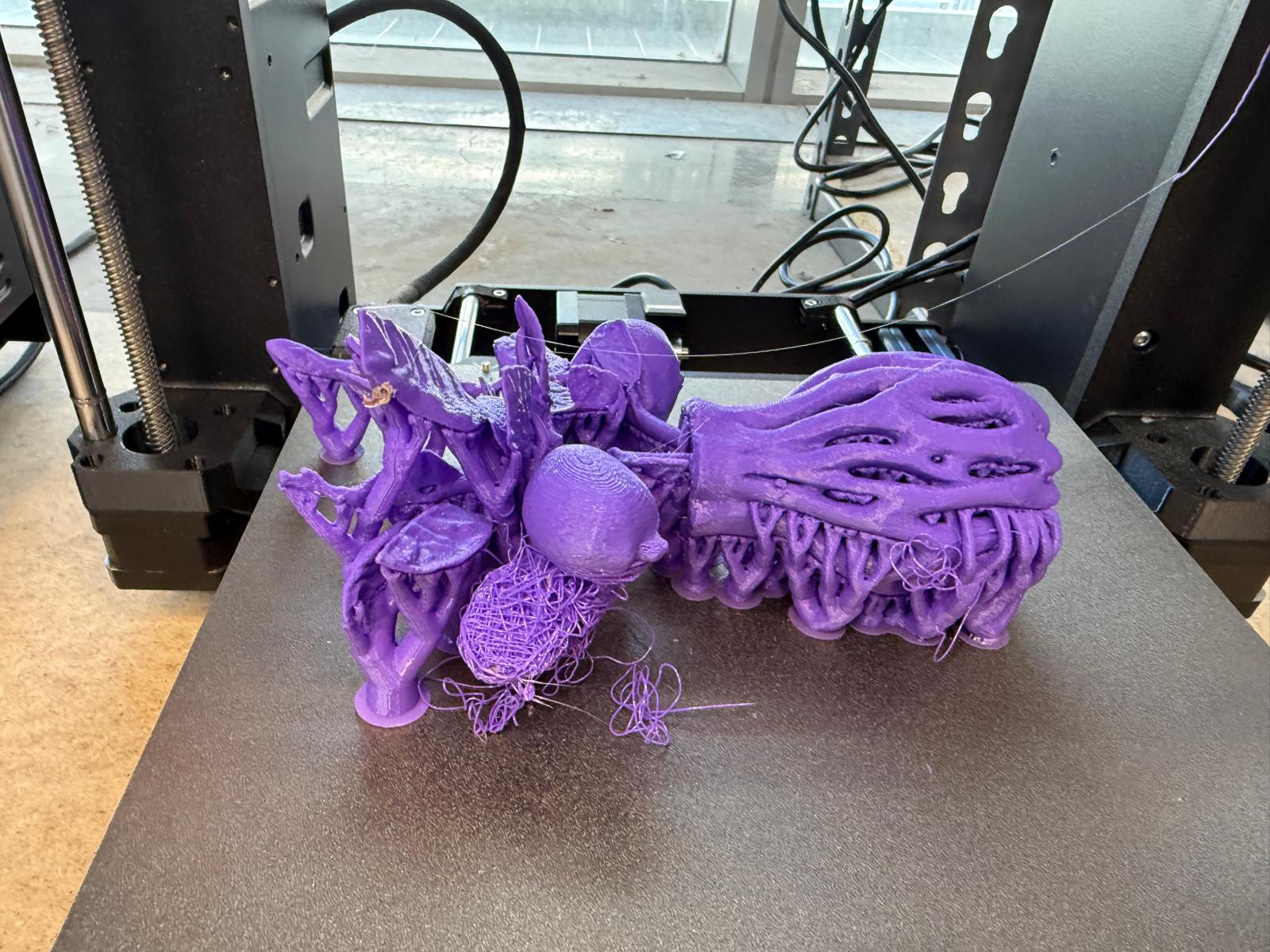

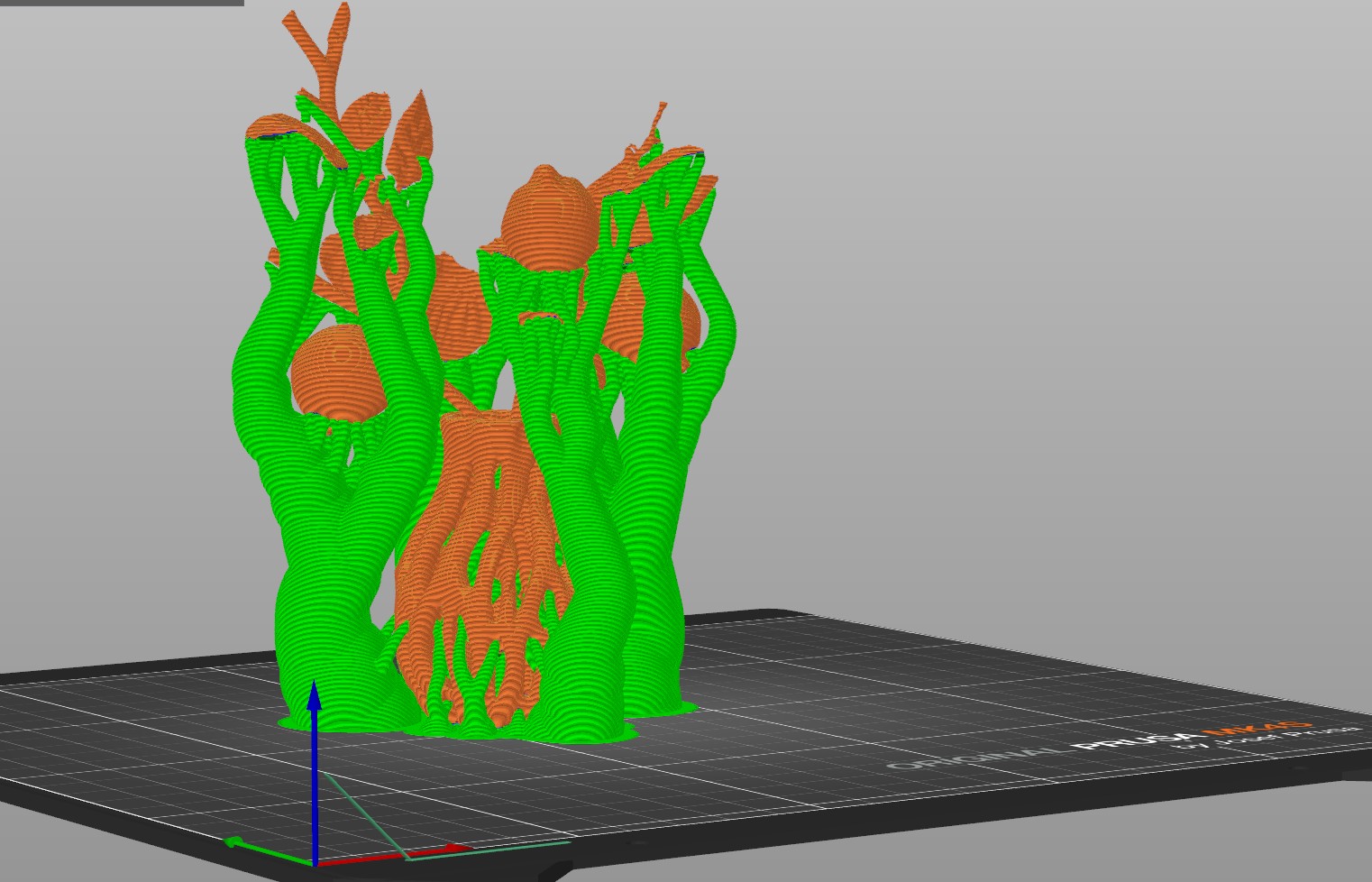

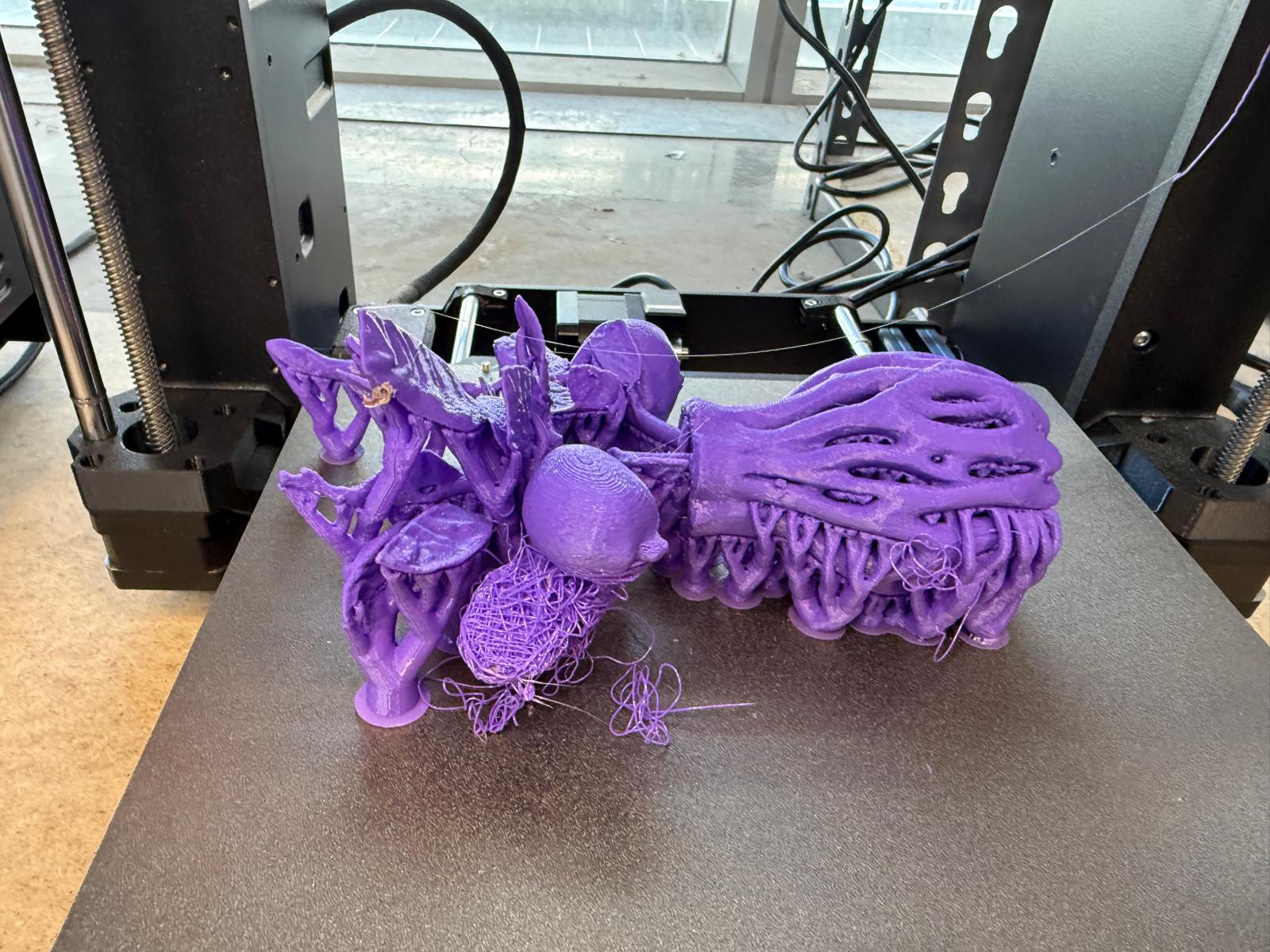

Once I removed the floating parts, I attempted to print the design in the Z-direction.

It was somewhat successful, but also a failure in some aspects. I couldn't remove the support material without

damaging the branches.

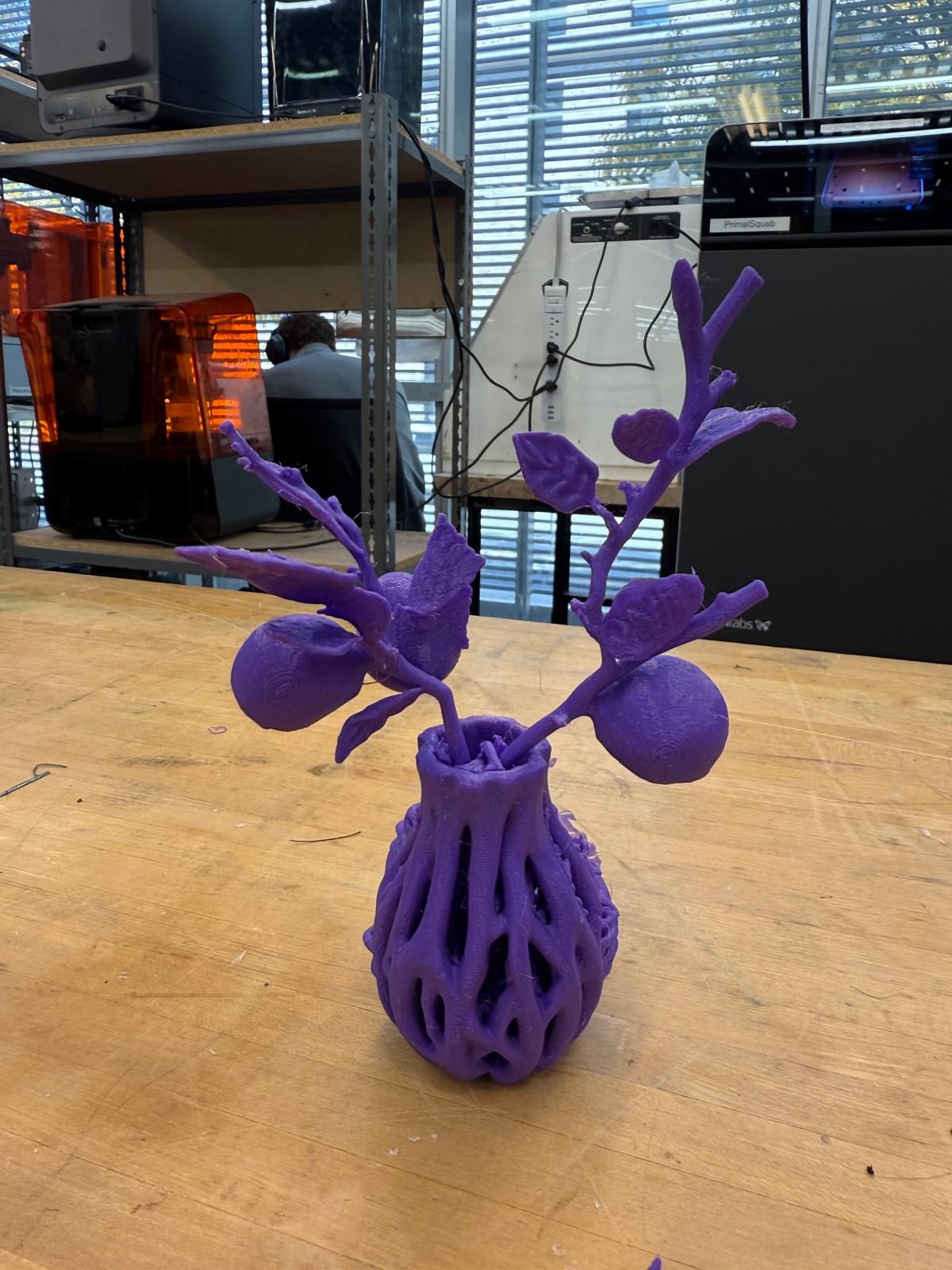

I tried again, increasing the size of the object, printing in the x-y direction,and modifying

a few print settings to hopefully make it easier. In the Support Material settings,

I reduced the xy distance from 80% to 75%, increased the z-distance to 0.25 mm, set the

support spacing to 3 mm, and maximized the interface layer spacing.

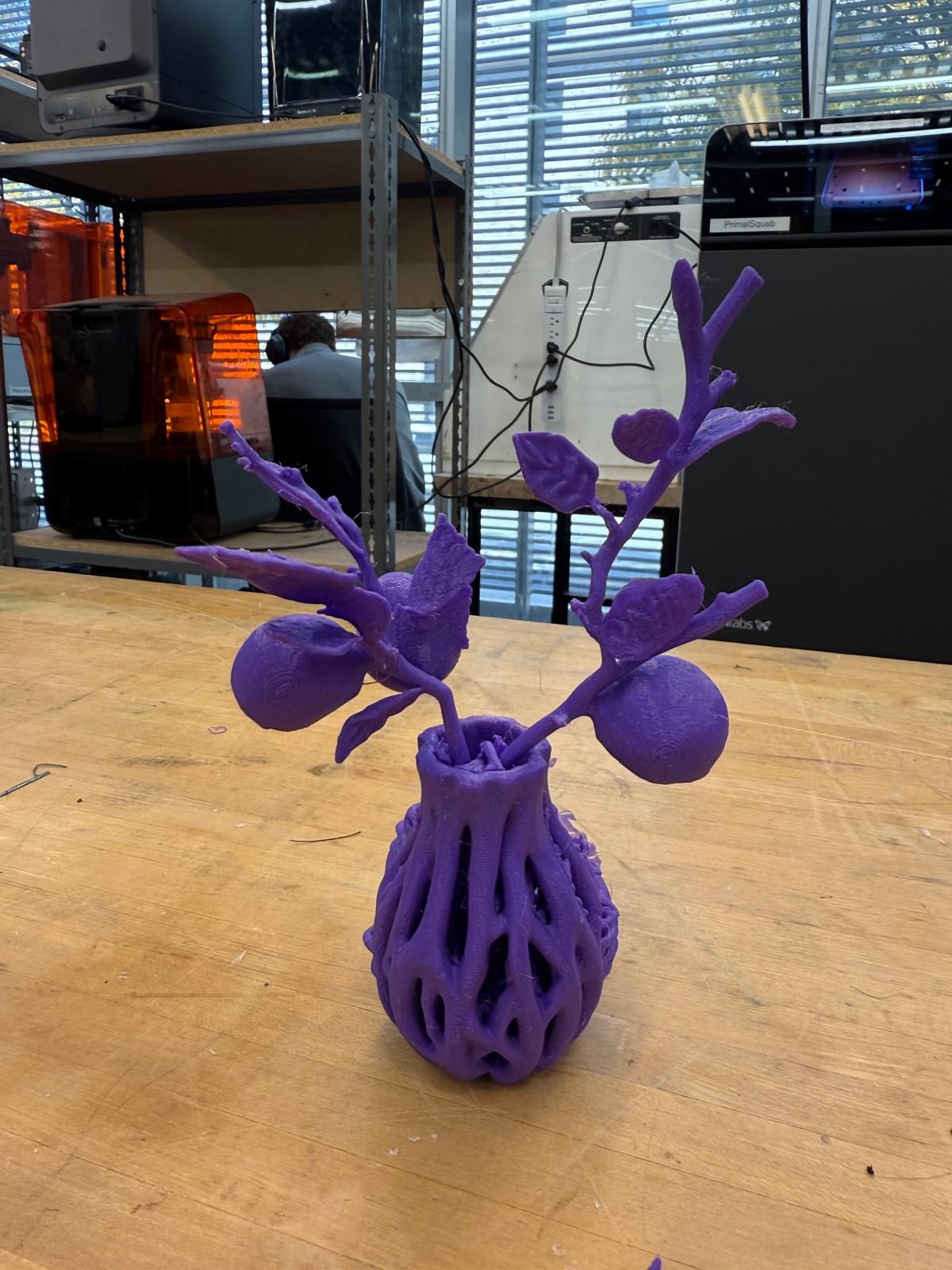

This was mostly successful! It took 1.5 hours to remove all the supports. I should have started from the base and worked up, because knocked a few leaves off while removing the supports from the base.

3D Scanning

I chose to 3D scan and print a Queen Moor head that I bought in Palermo a few years ago because I find the story behind this handmade Sicilian vase fascinating. If you're curious, you can read more about it here.

Too get started with scanning, I typed “3D scanner app” into the app store and downloaded all three apps. First, I opened Polycam 3D scanner and chose the free week trial. I selected new -> obj->

then quickly took photos of the vase from different angles. It took a few tries to find the best spot in my apartment, which turned out to be a corner on the ground with two white walls. To add the 3D scan to my site, I followed the instructions located here

Once I was happy with the scan, I exported it as an STL. That is when the problems started… SolidWorks flagged the file as corrupt, but I was able to open it in Prusa Slicer. I would have tried to print it if

the bottom of the vase had been closed. I went to office hours for help, and Alfonso opened it in RHINO without any issues, helping me reduce the mesh and close the bottom in RHINO by changing it from an stl into an stp.

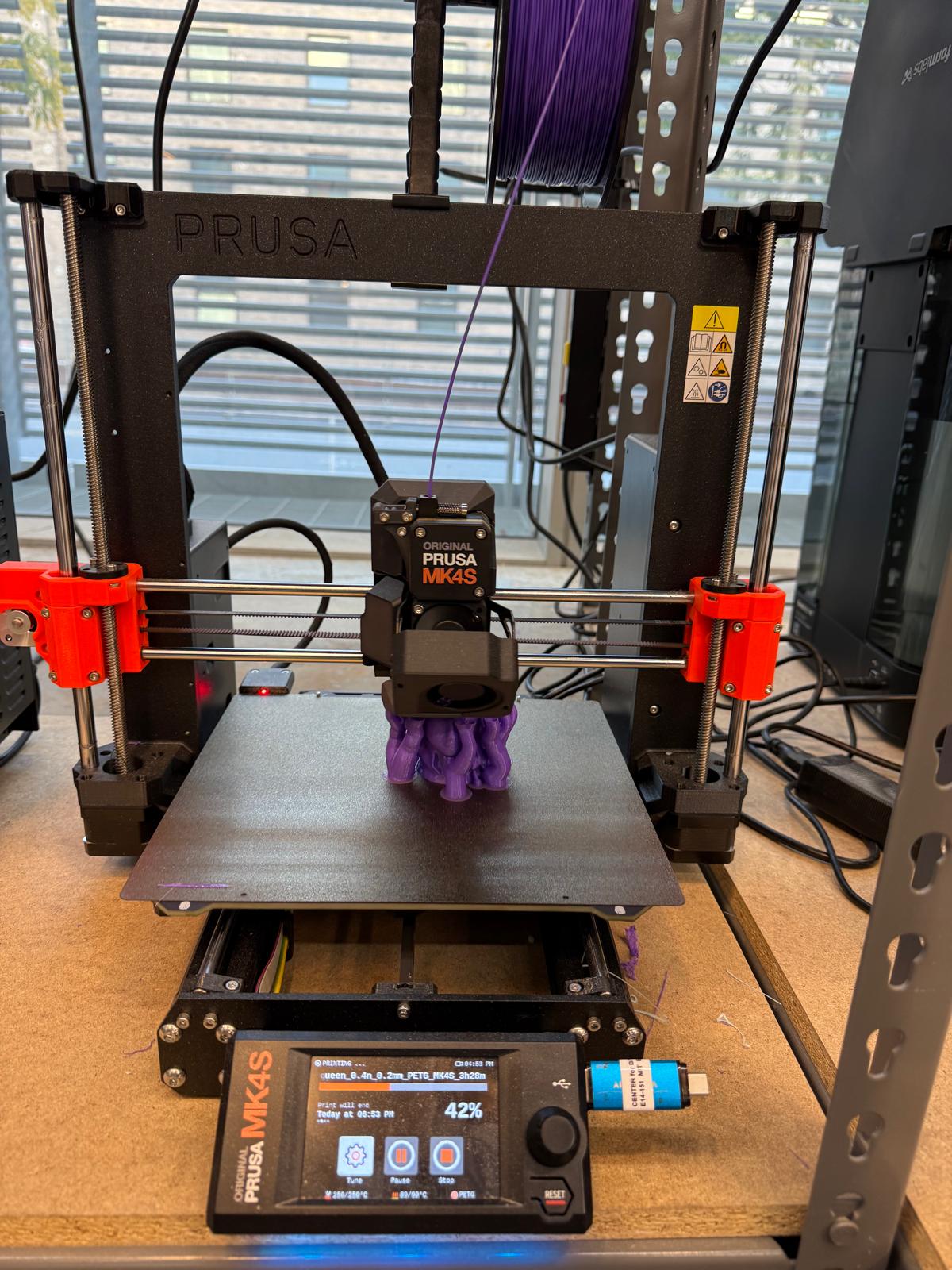

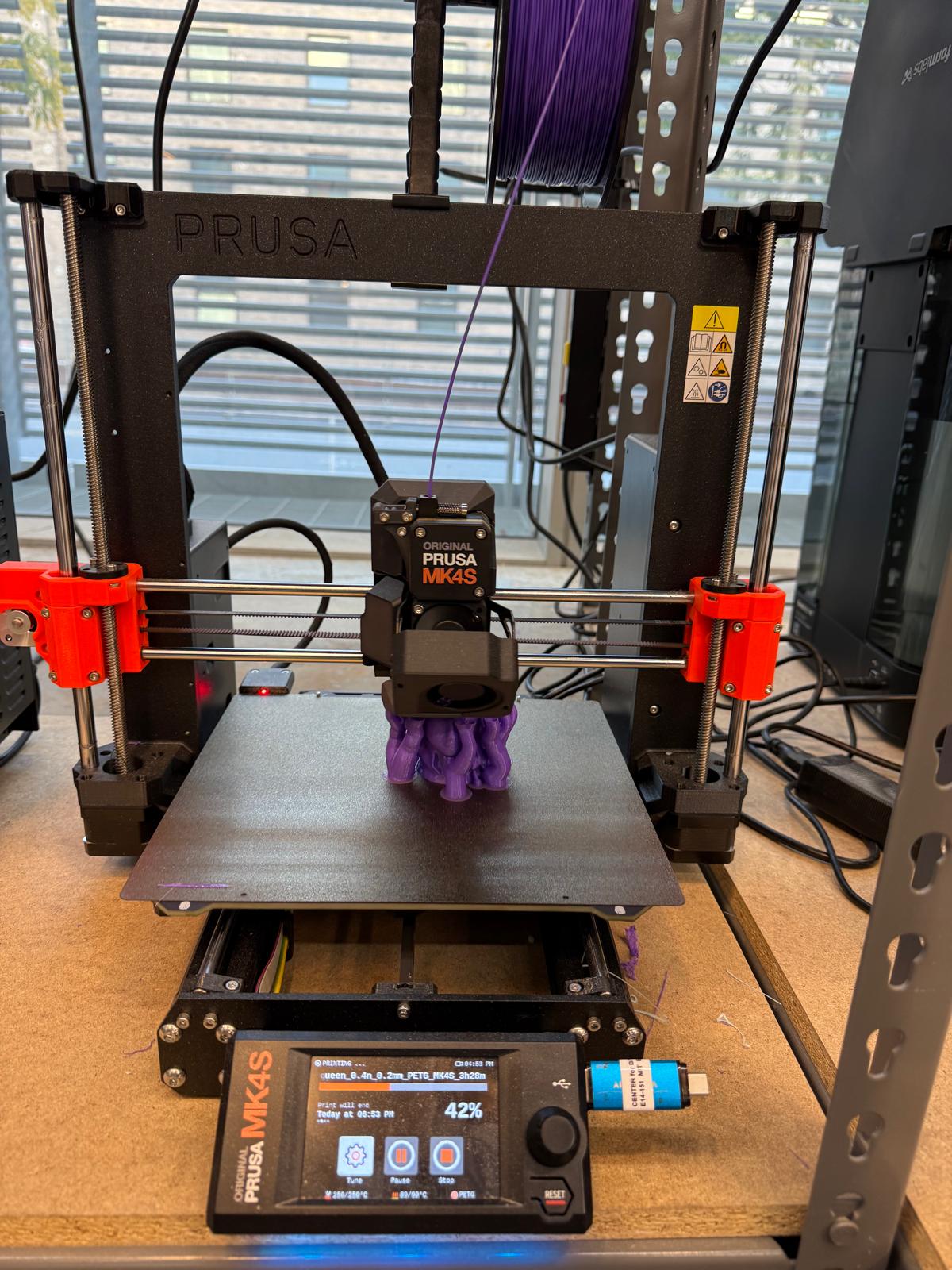

I printed it on PRUSA MK4S using PETG.