Project Documentation & Media

Photos, videos, design files, CAD models, and manufacturing documentation

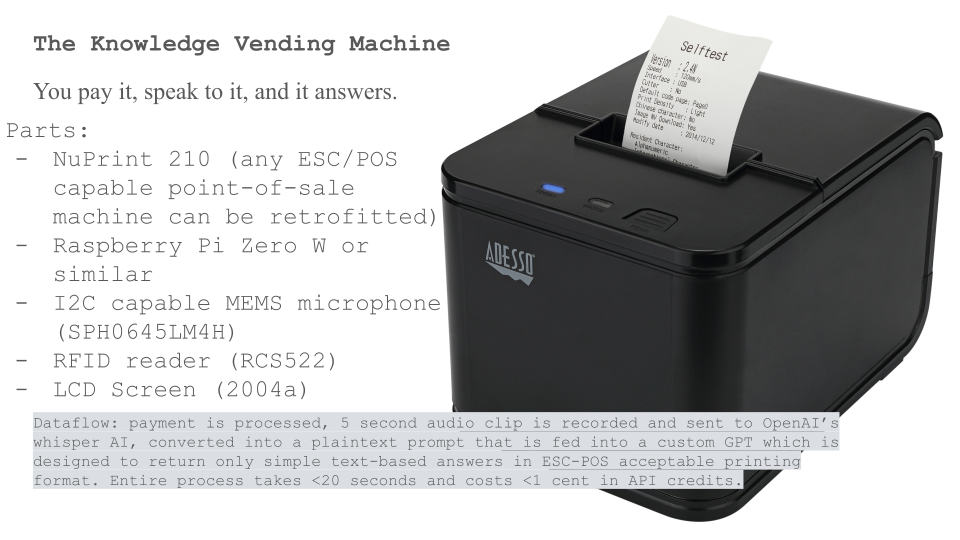

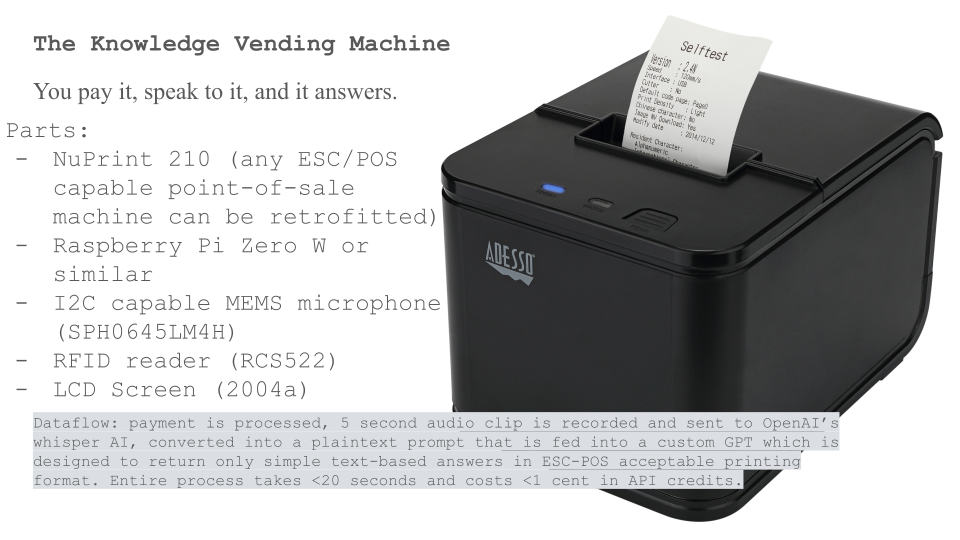

A Knowledge Vending Machine: Retrofitting Legacy Hardware with AI-Powered Information

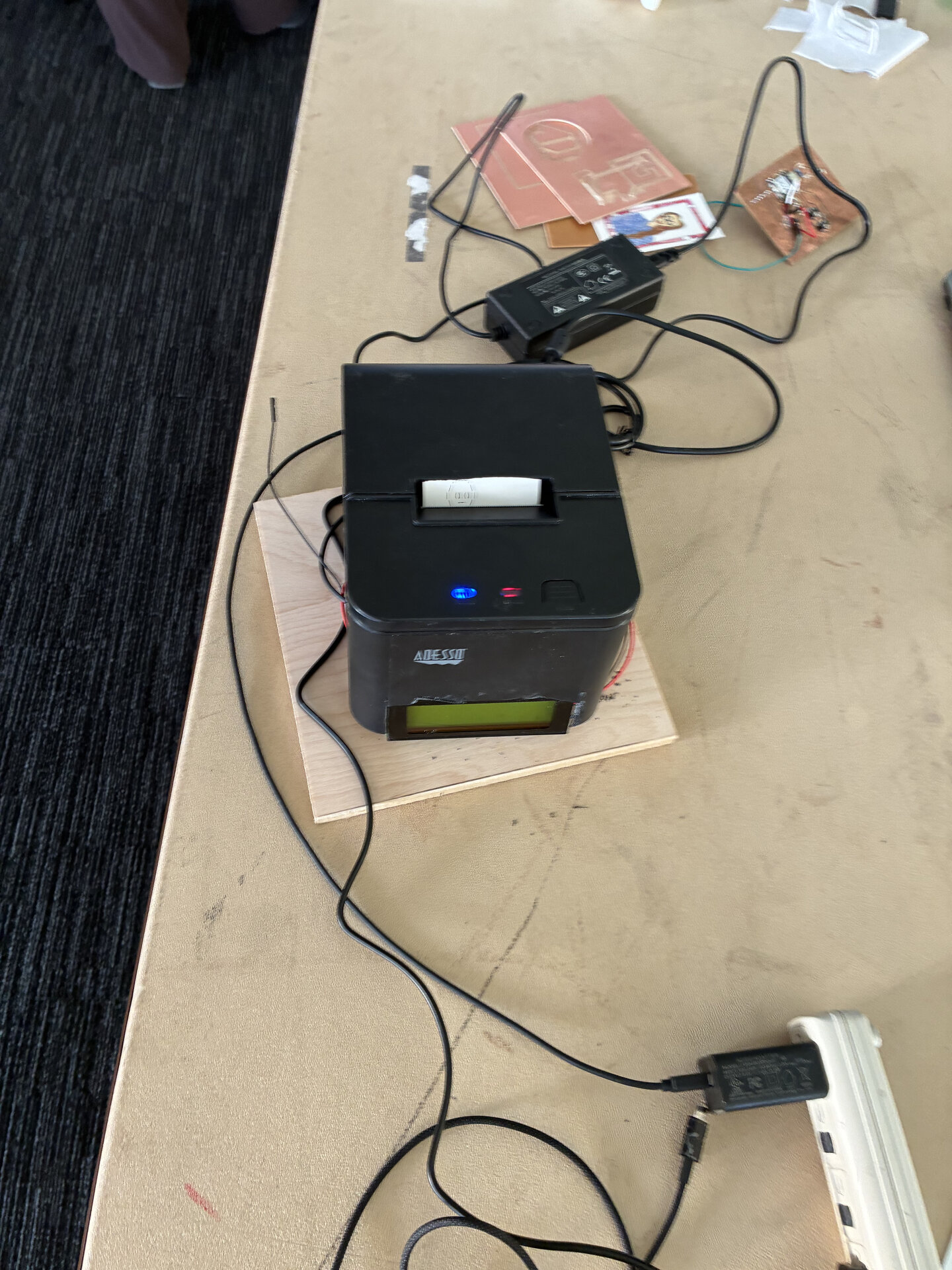

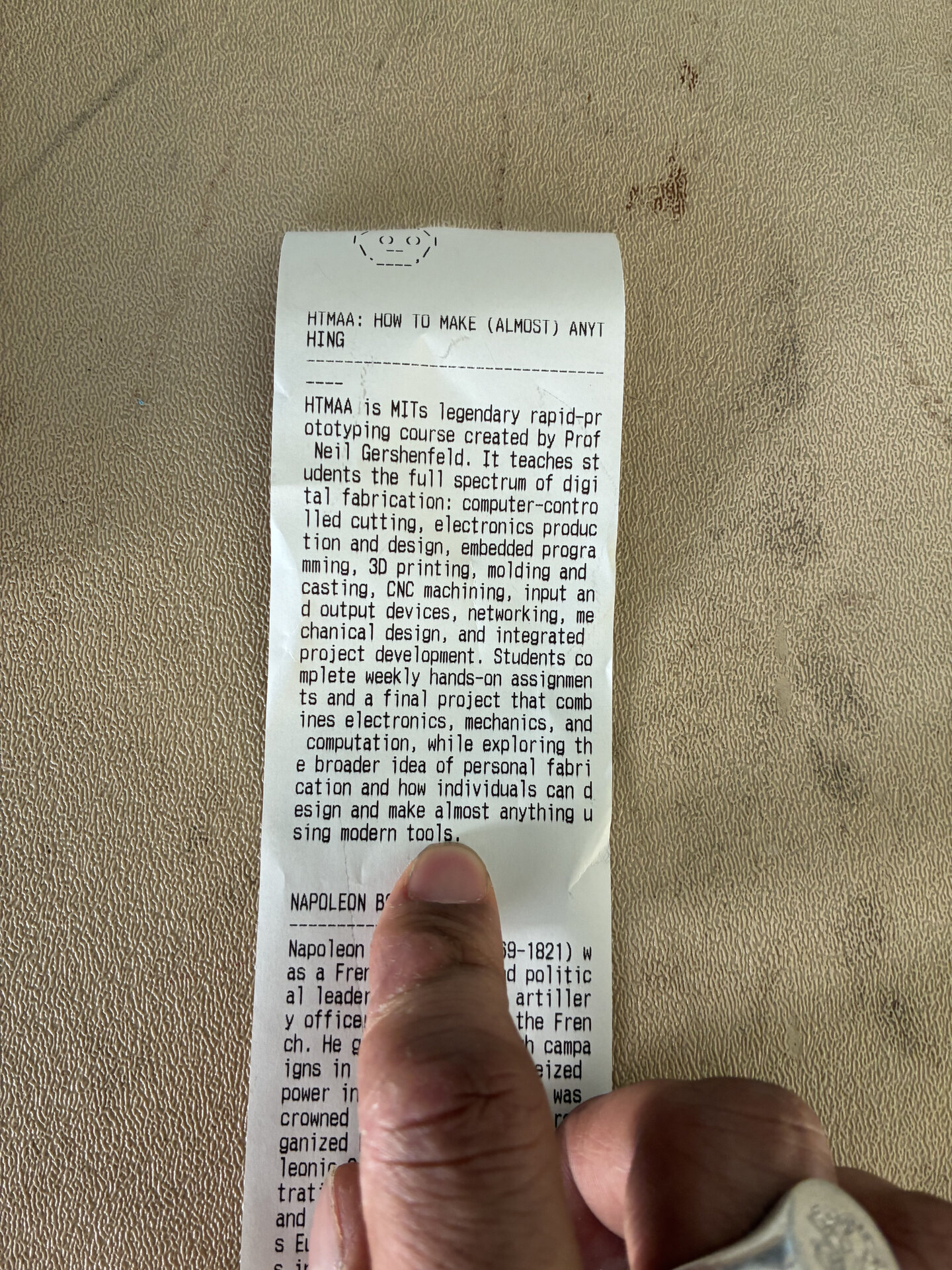

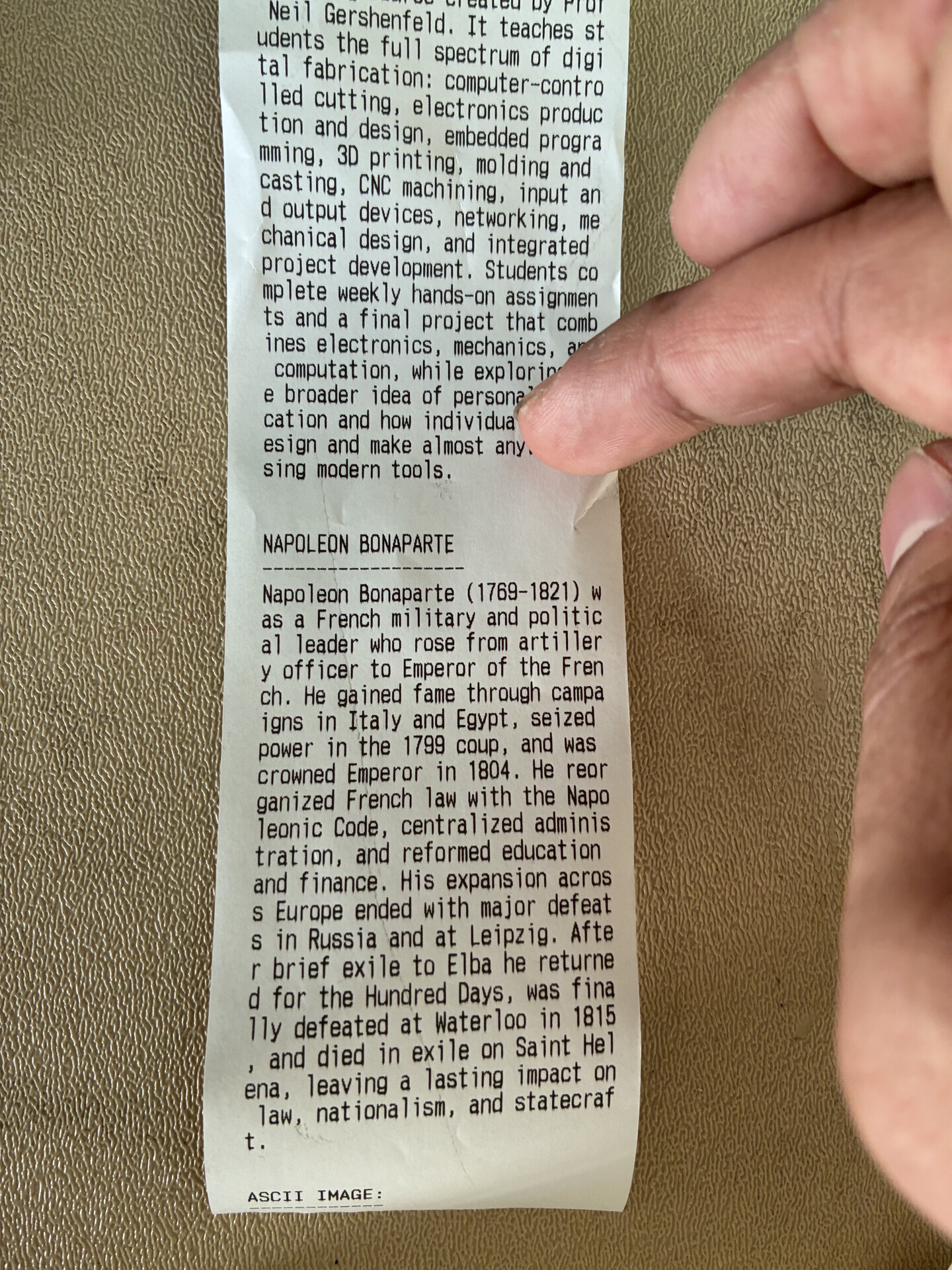

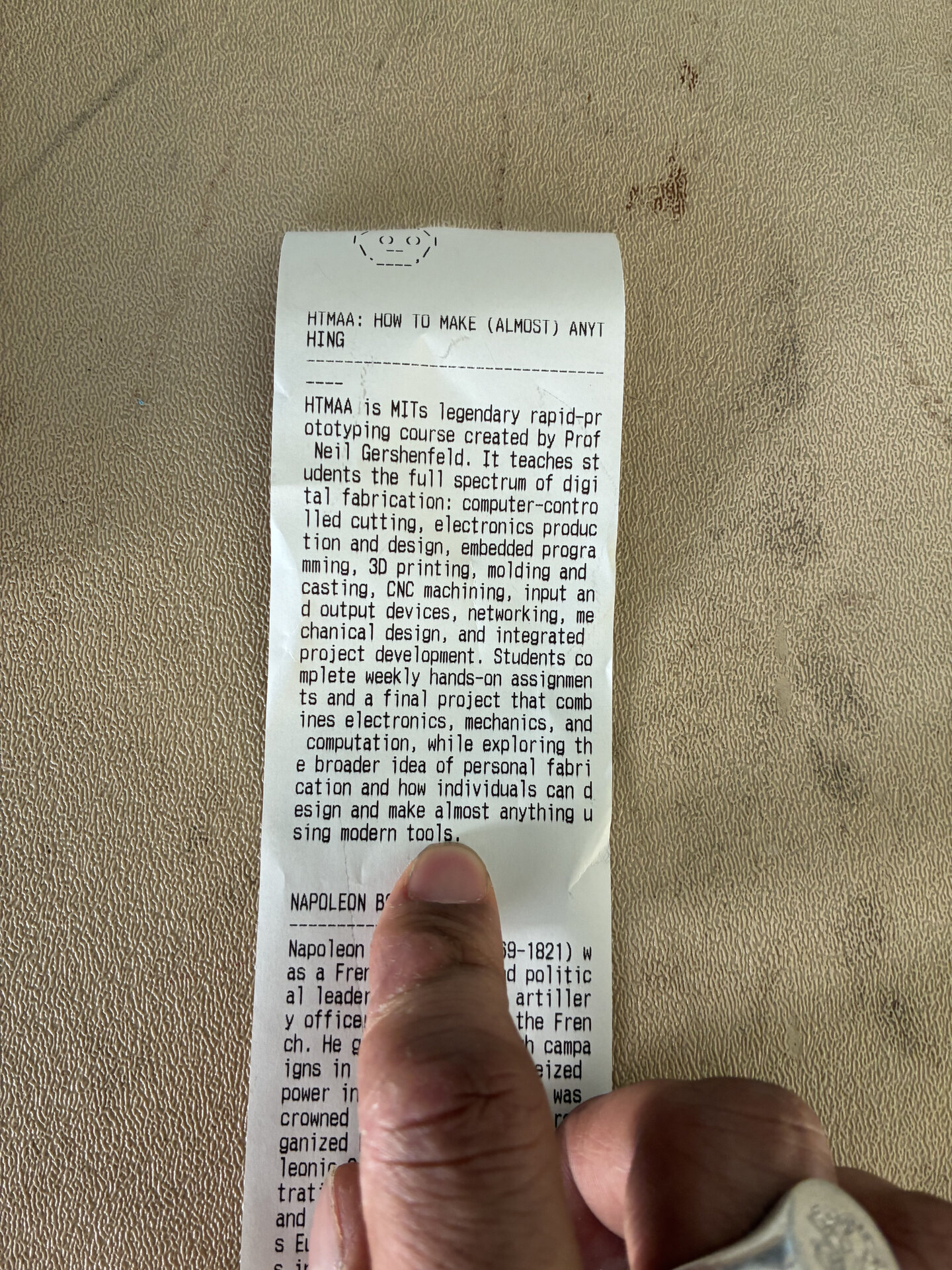

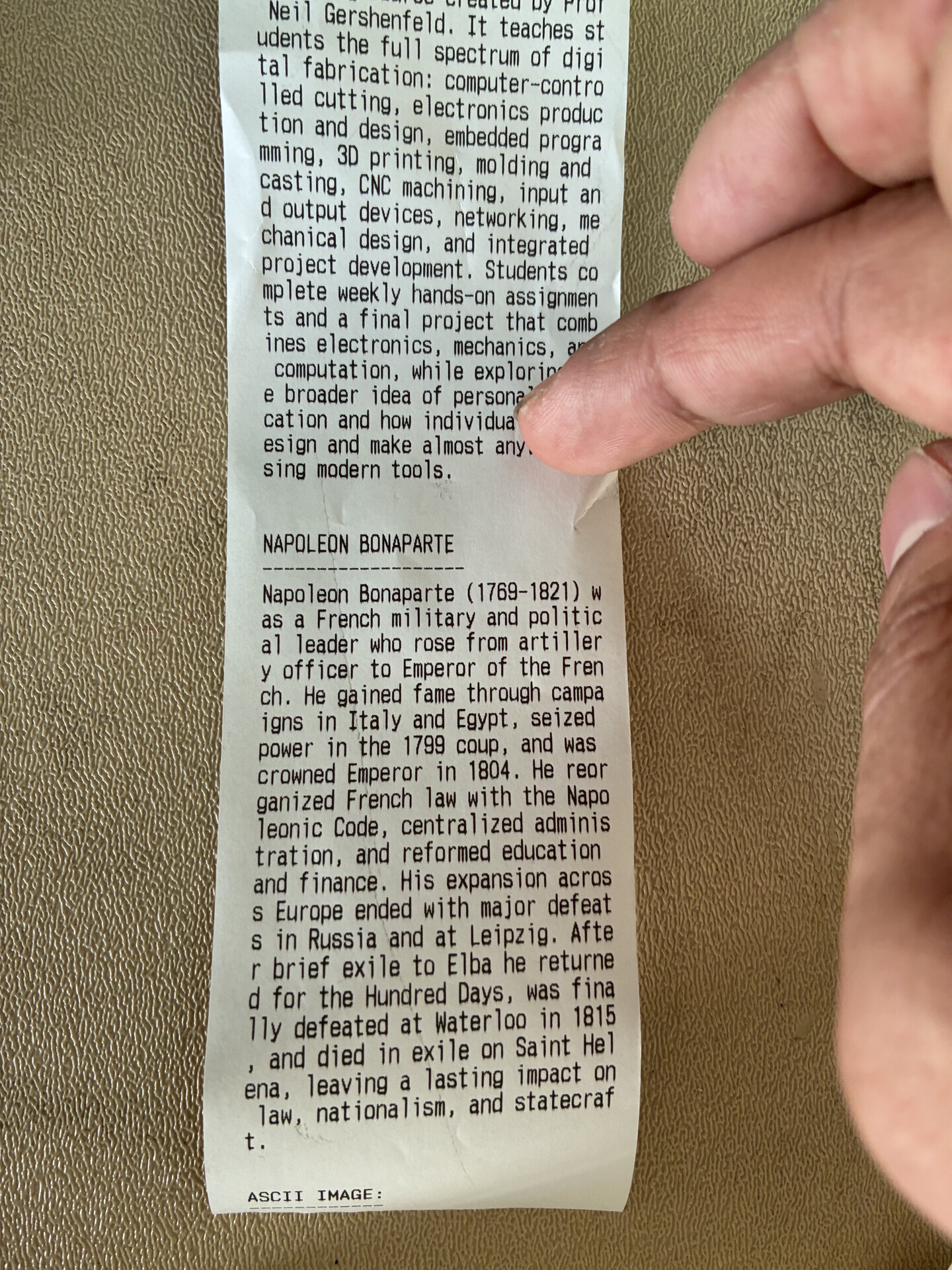

MULTIVAC is a vintage receipt-printing vending machine retrofitted with a Raspberry Pi and AI. You insert payment, ask a question, and get an answer printed on a receipt. It's like a payphone for knowledge—imagining a world without smartphones.

The machine uses a MEMS microphone for voice input, an RFID reader for payment, and a custom PCB to control the original thermal printer. Queries go through OpenAI's API, and responses come back as printed receipts—making information tangible.

REJECTED

Initial idea: smart mirror with voice commands. Too ephemeral—information on a screen doesn't feel real. I wanted something physical.

EVOLVED

Wooden kiosk with e-ink display. Too bulky and slow. But the concept of a physical device sparked the next idea.

SELECTED

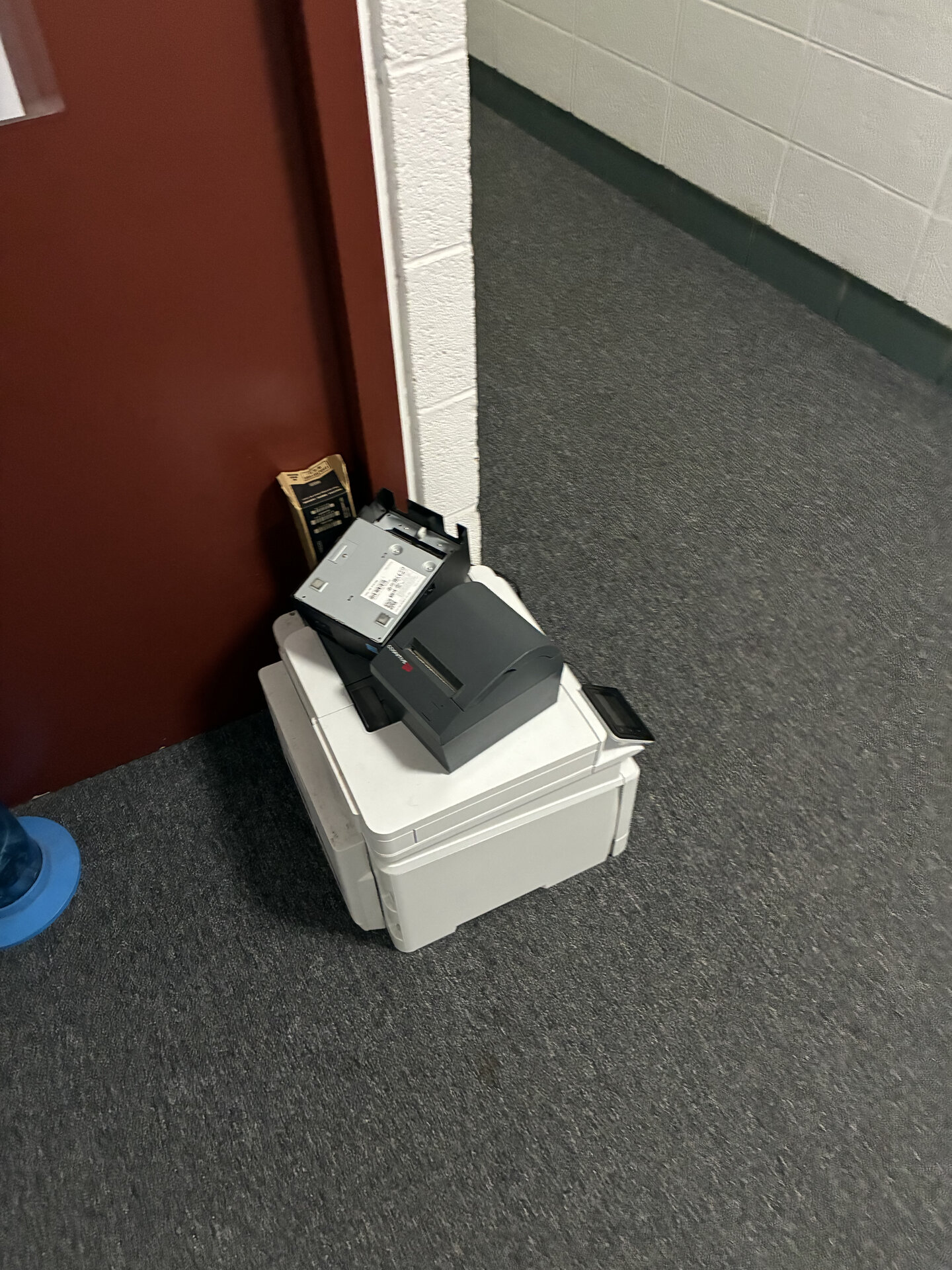

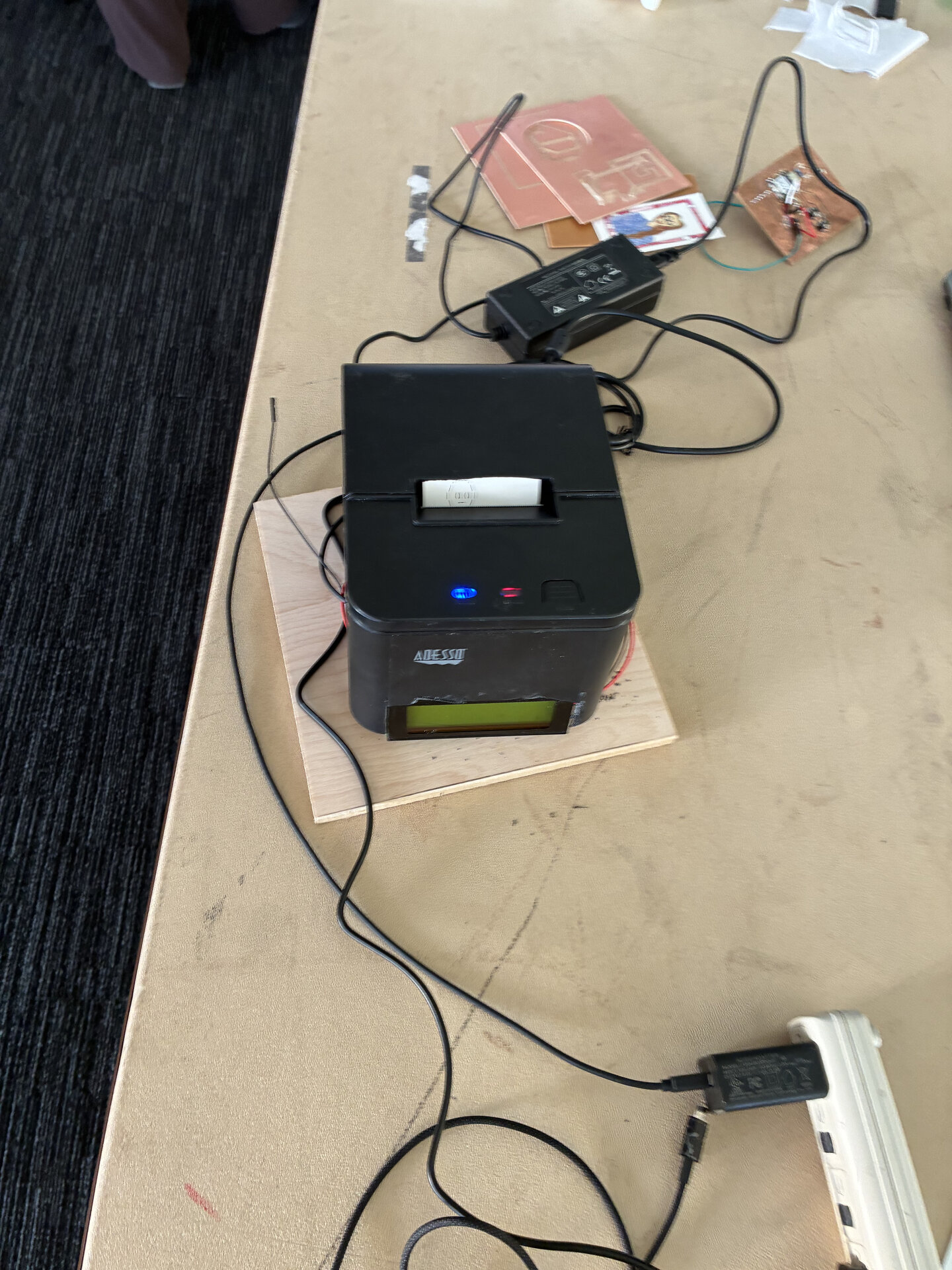

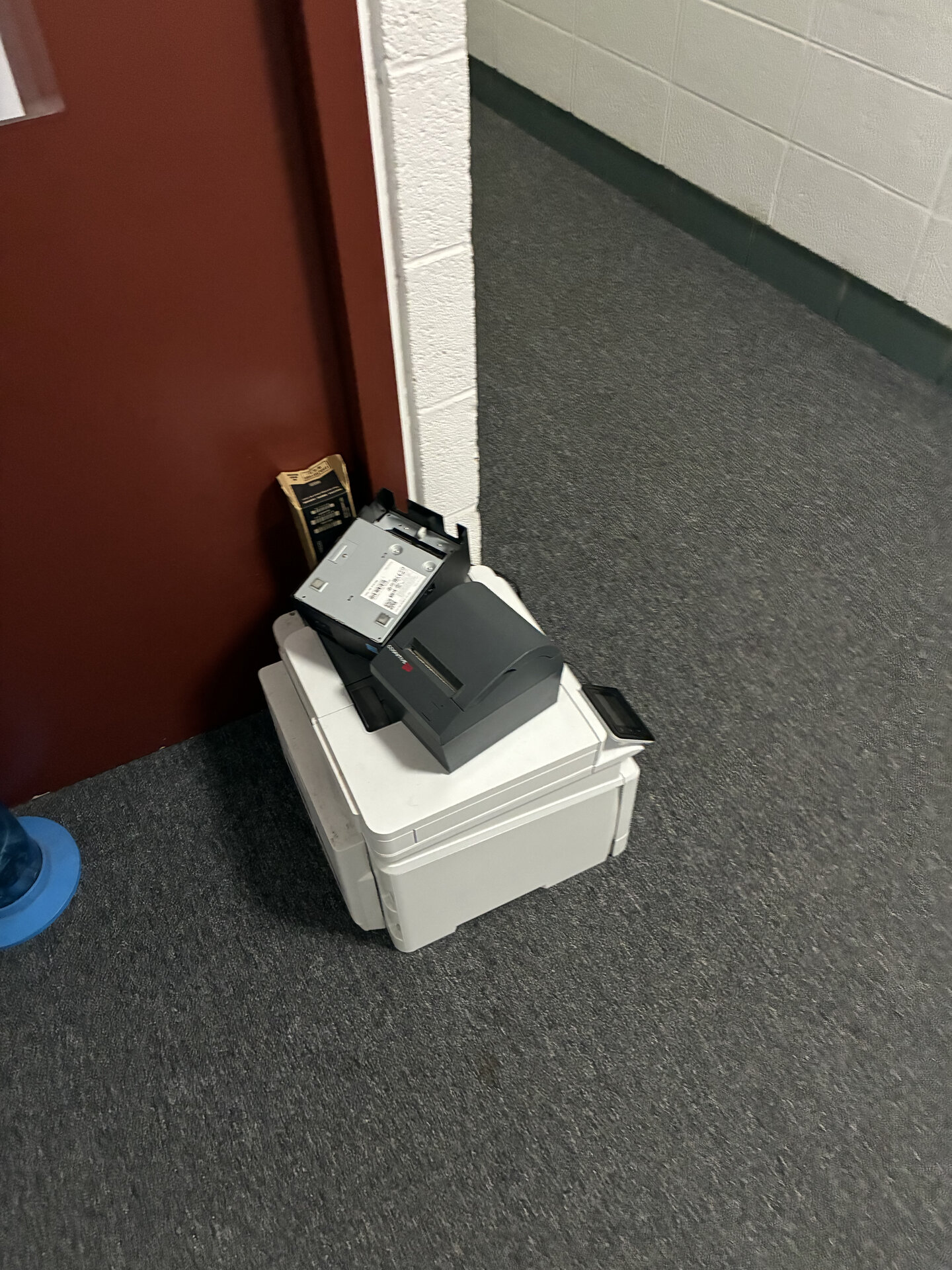

Found a vintage receipt printer at e-waste. The thermal printer creates a beautiful physical artifact. Modern guts, retro exterior.

EXPLORATION

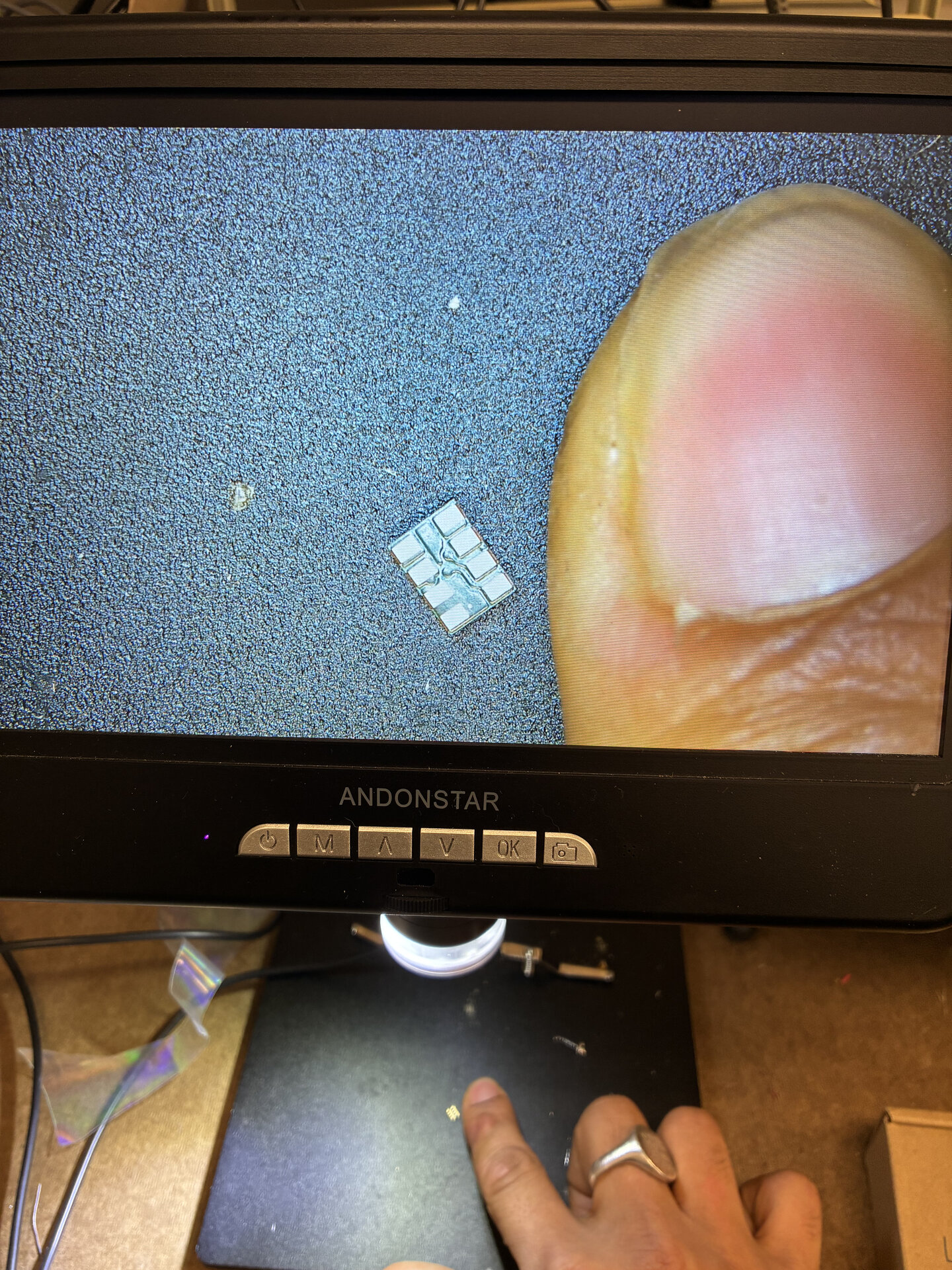

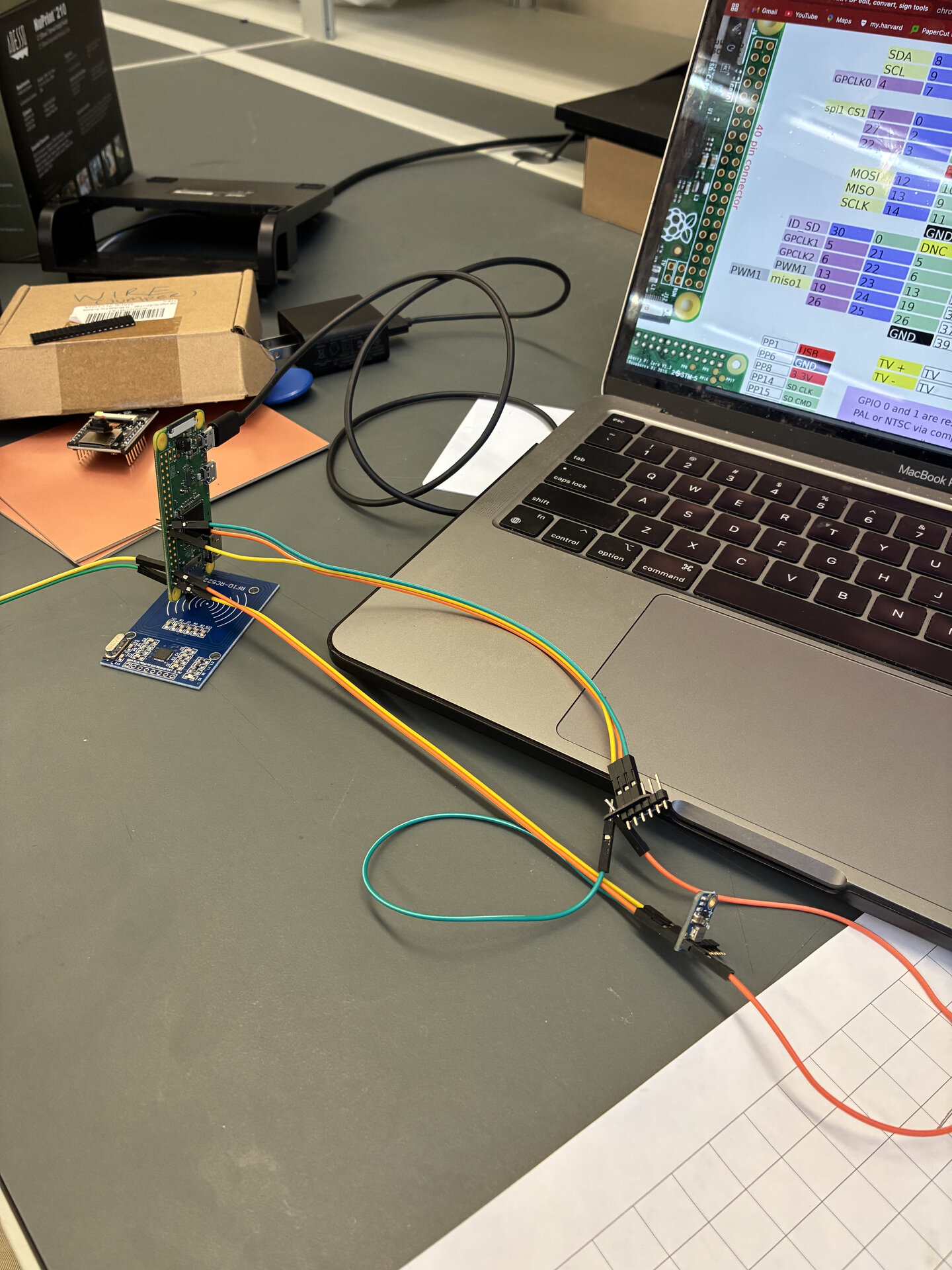

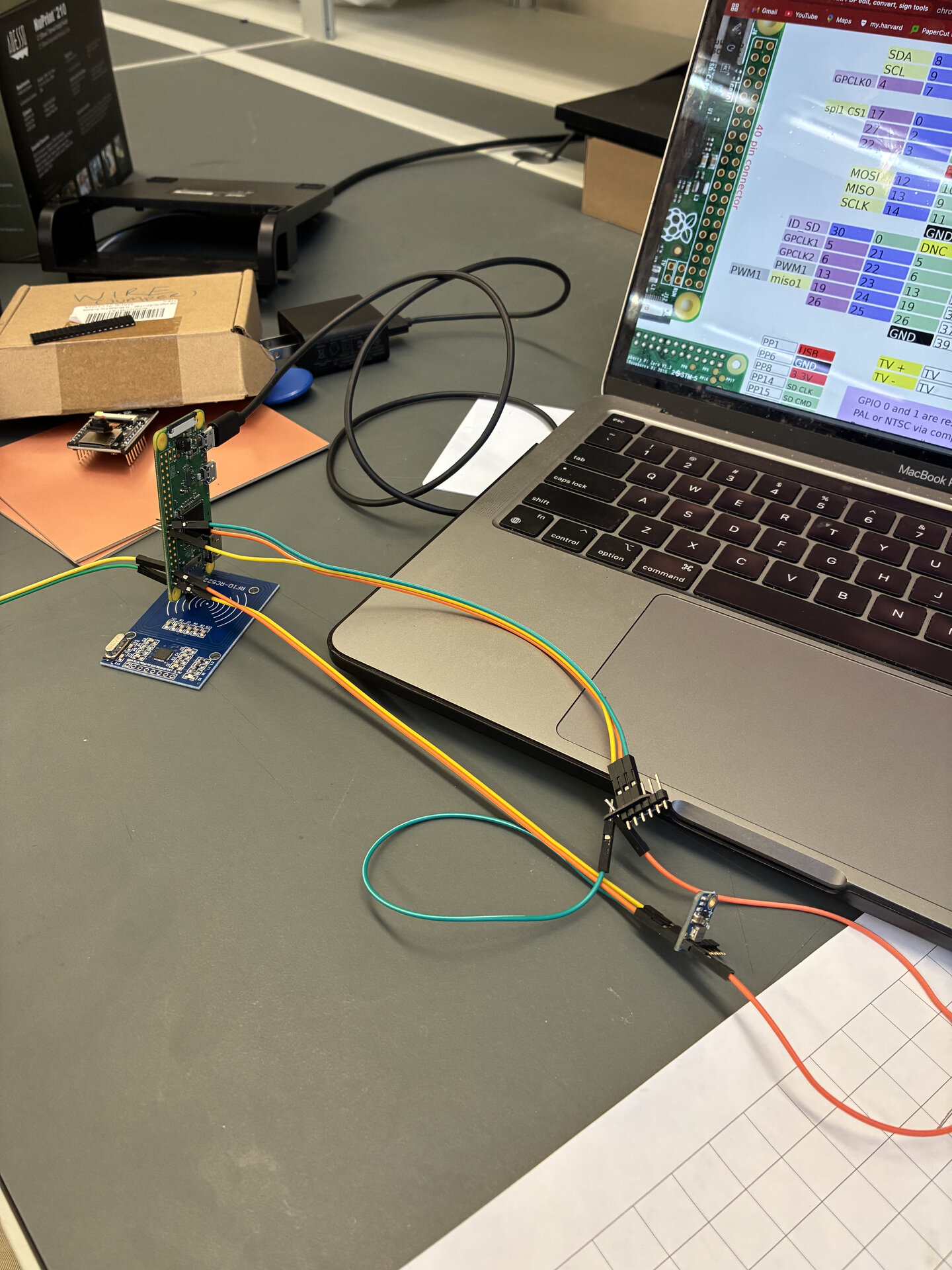

Took apart the machine to understand the thermal printer circuitry, card reader, original LCD, and power system. Documented everything to plan the retrofit.

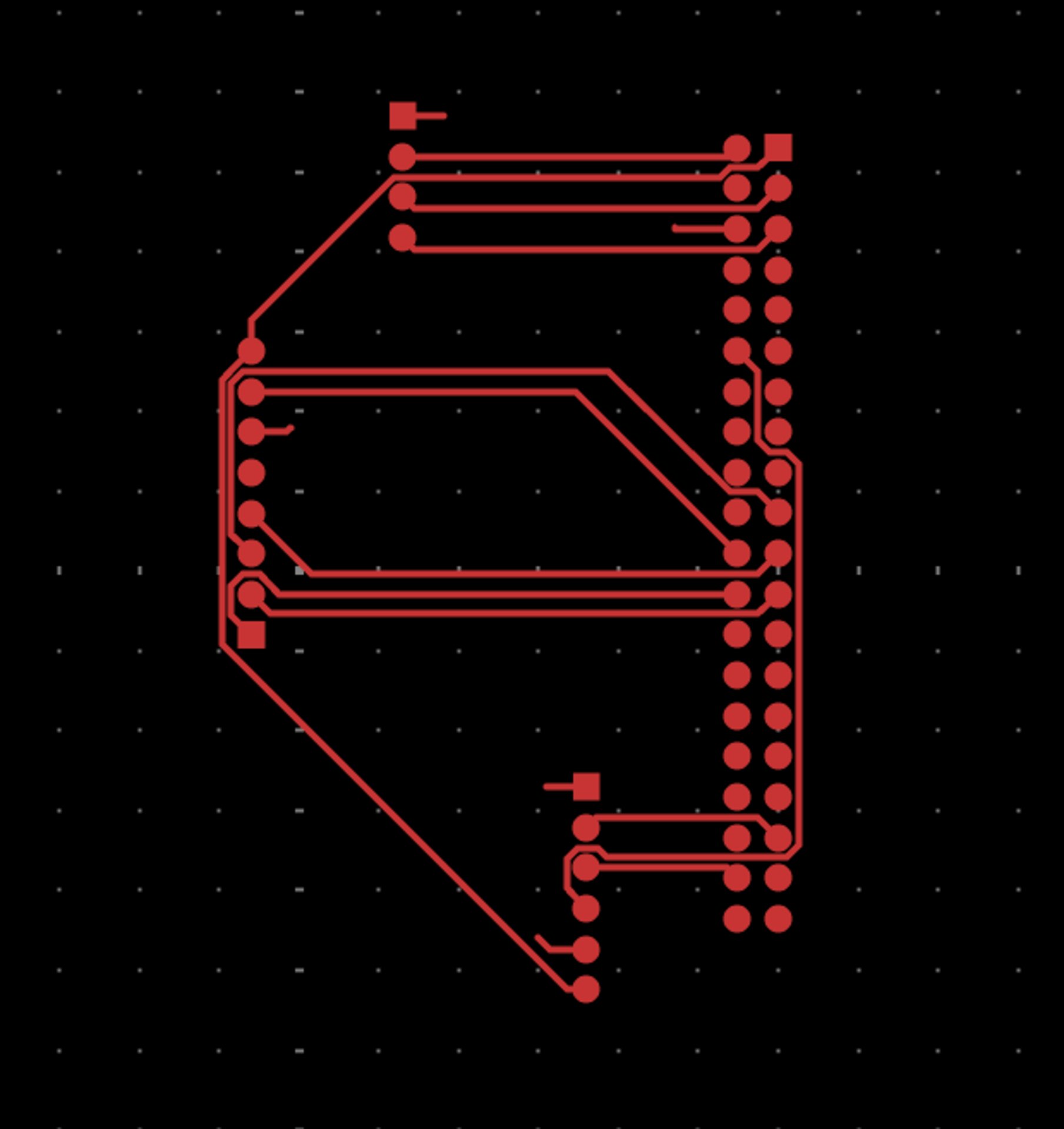

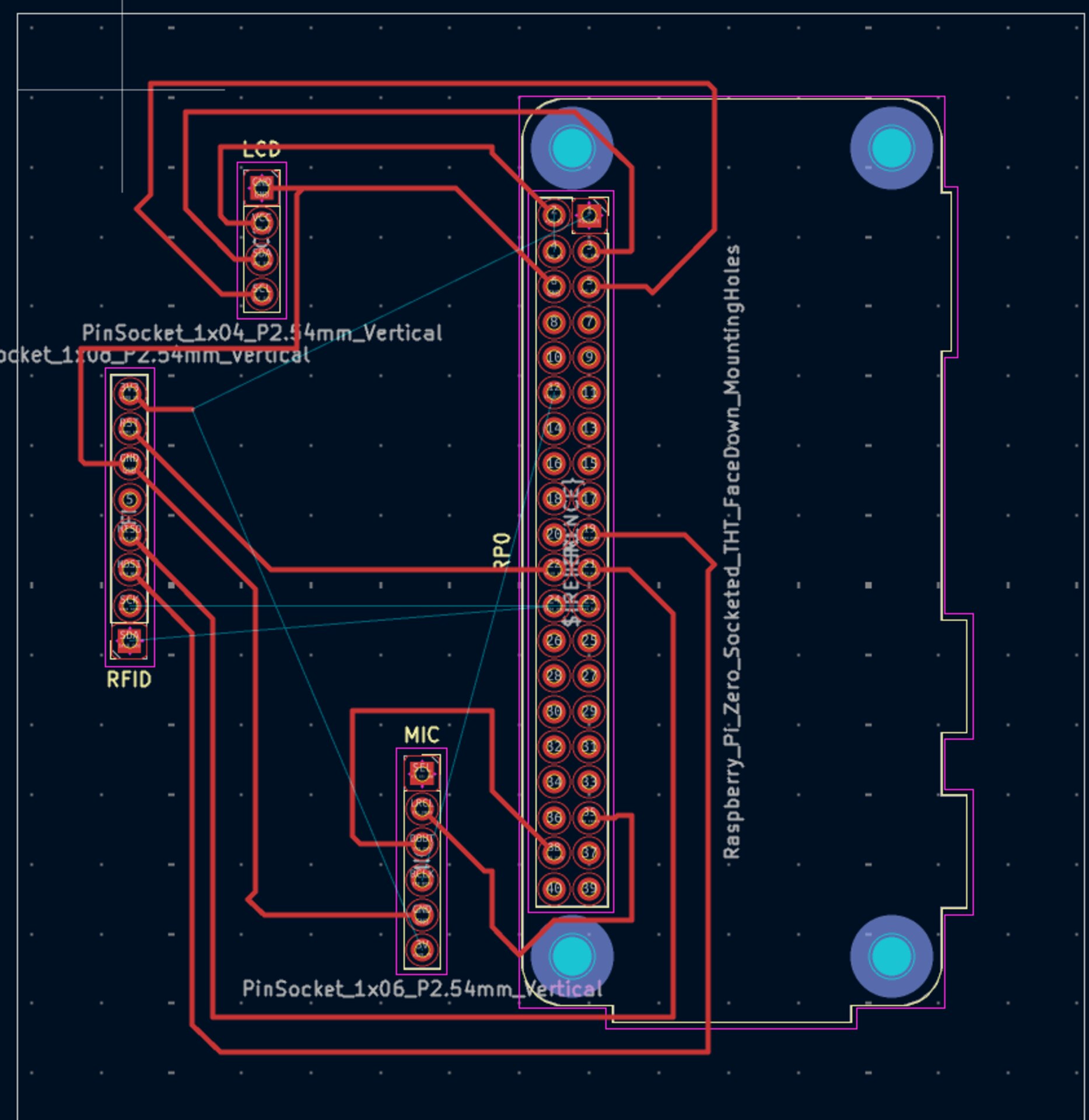

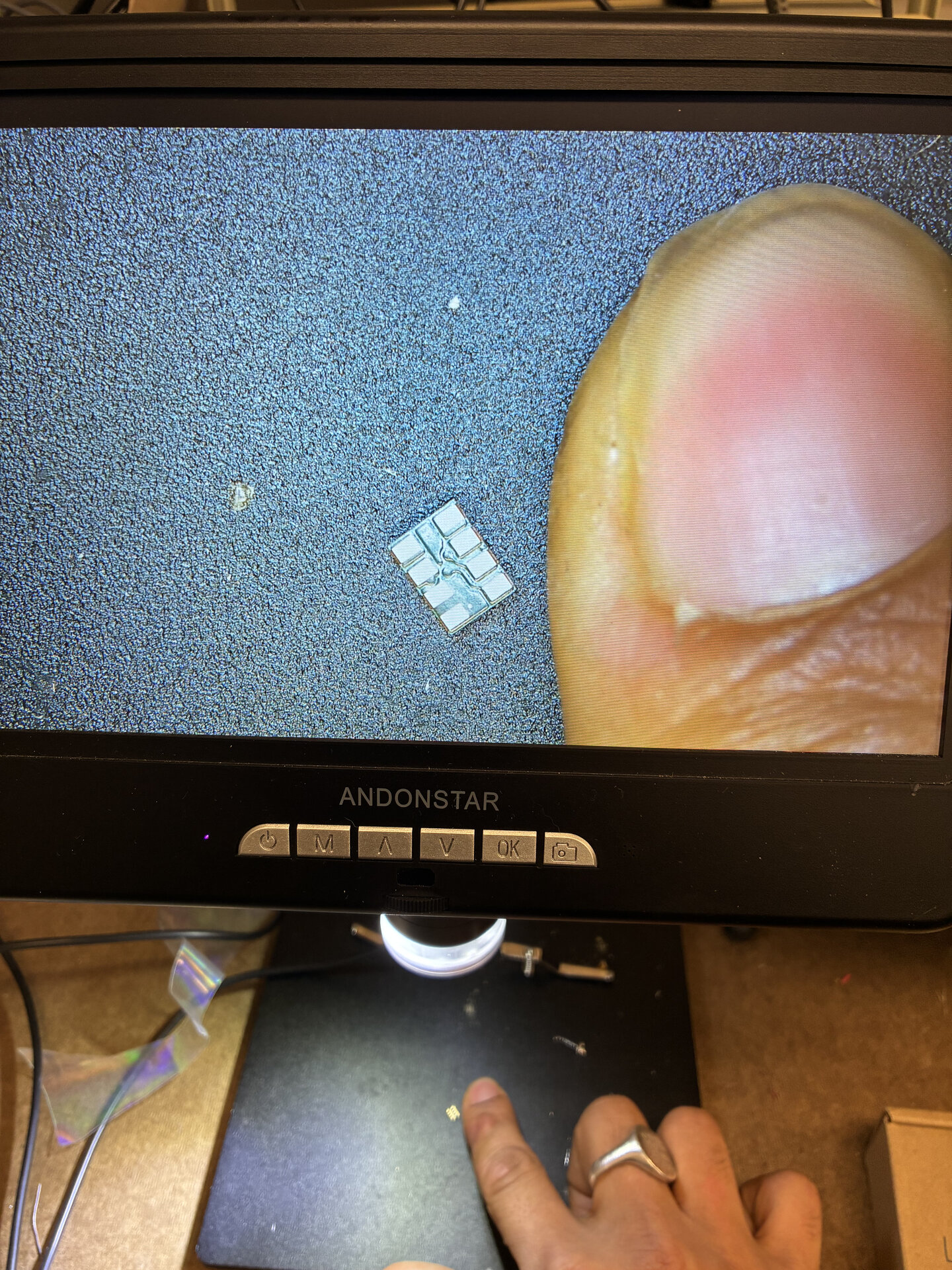

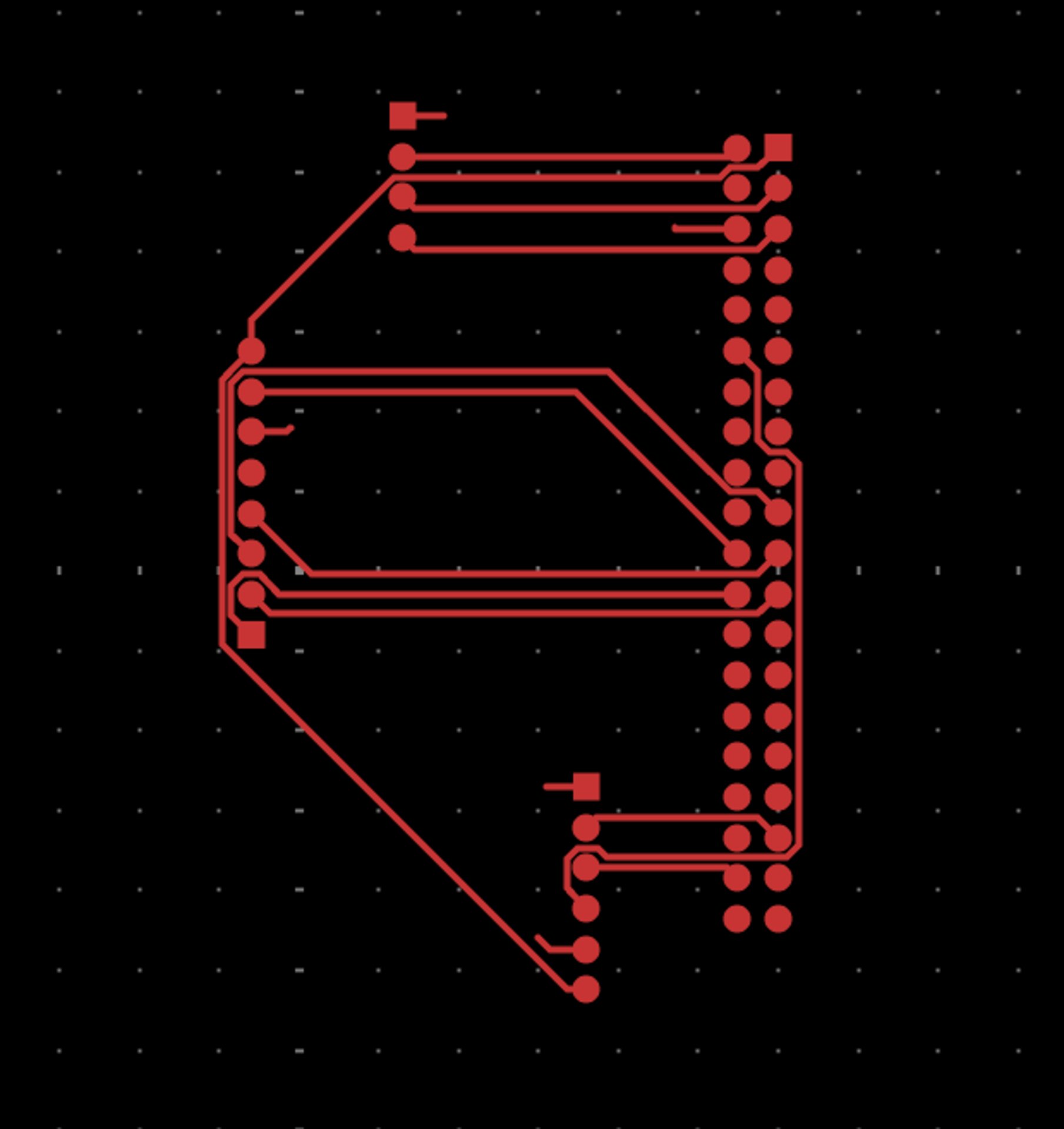

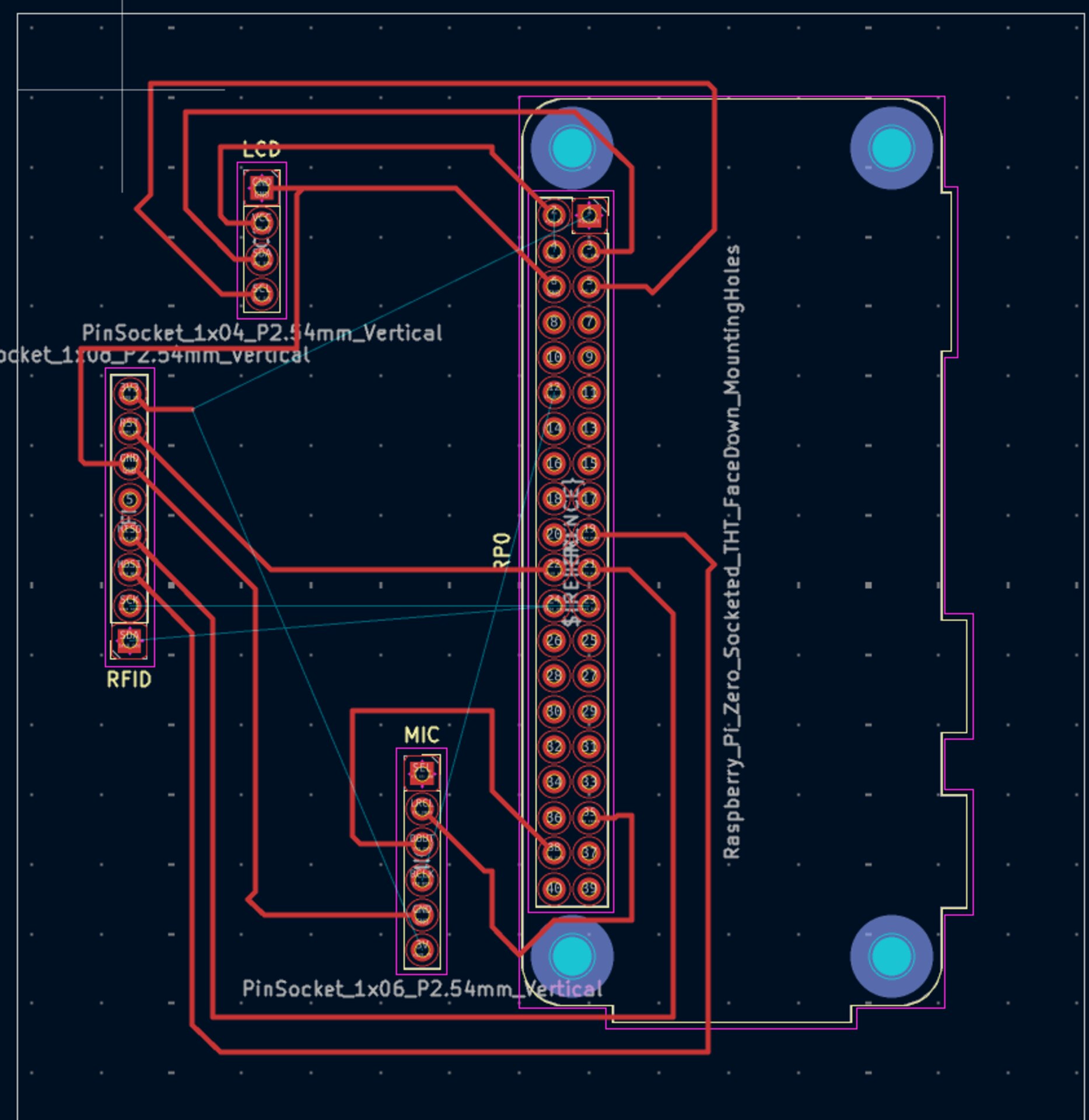

PCB DESIGN

Designed and milled a custom PCB to control the thermal printer from the Pi. Handled power distribution, serial communication, and heat management.

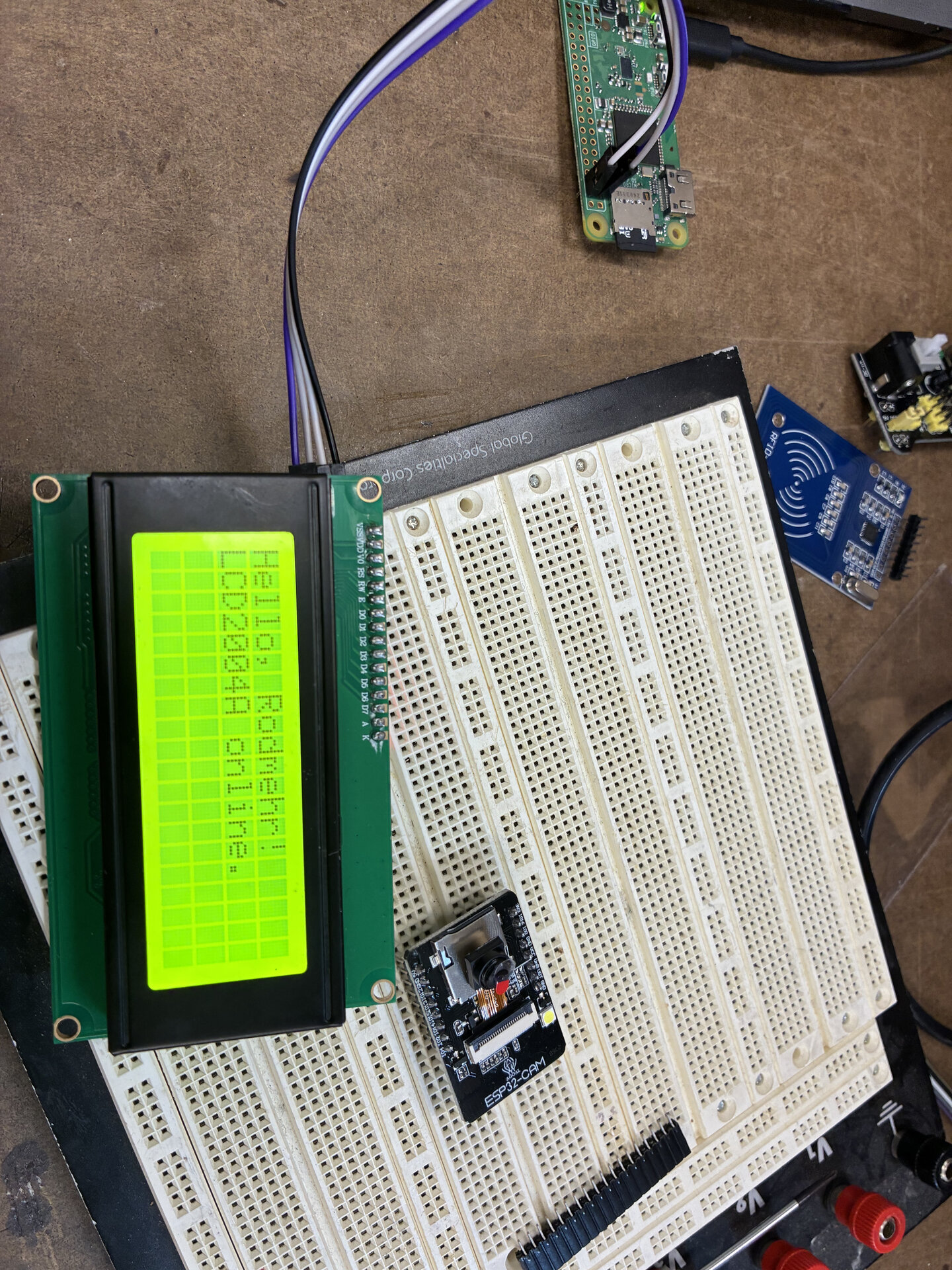

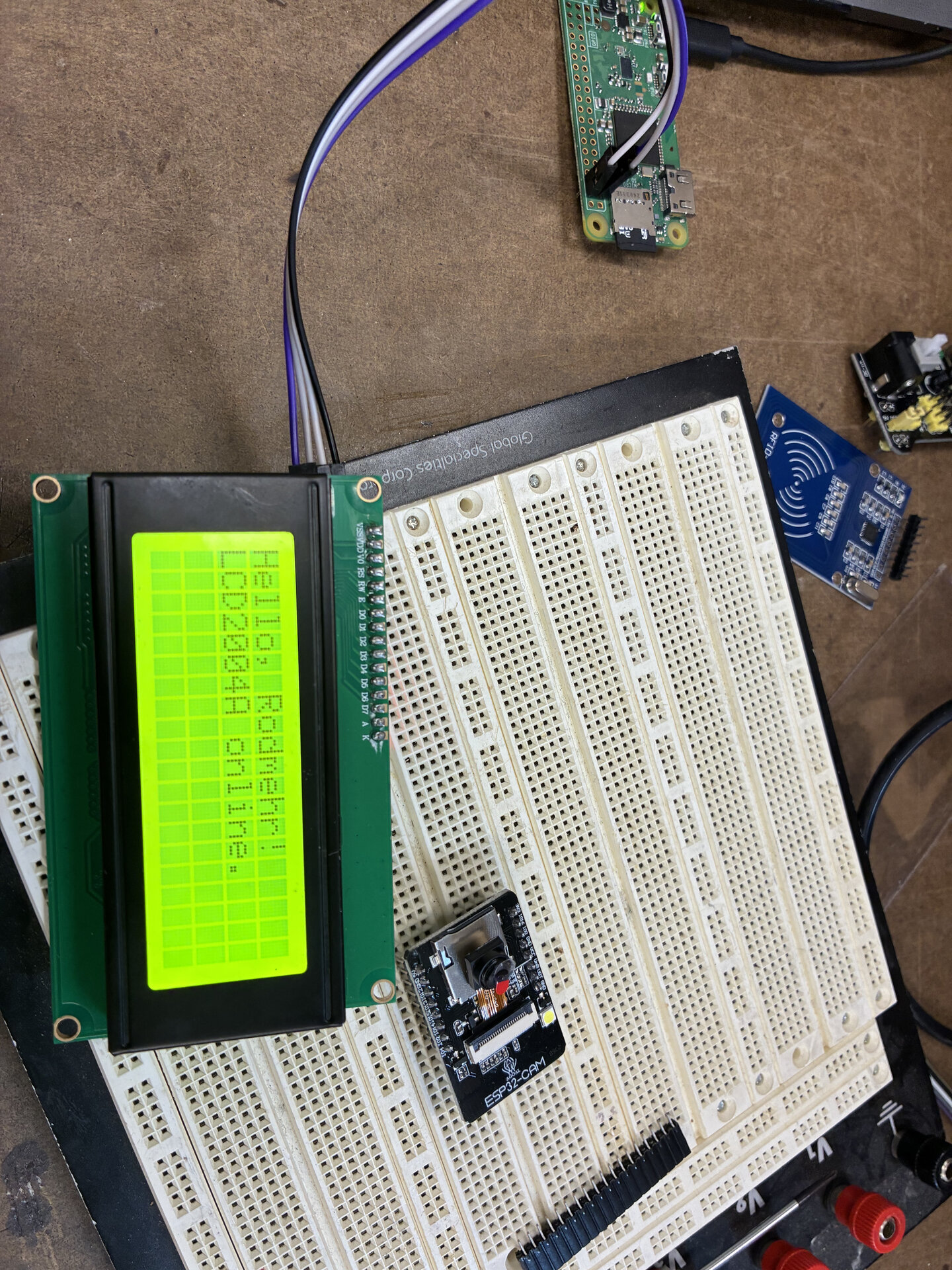

INPUT SYSTEMS

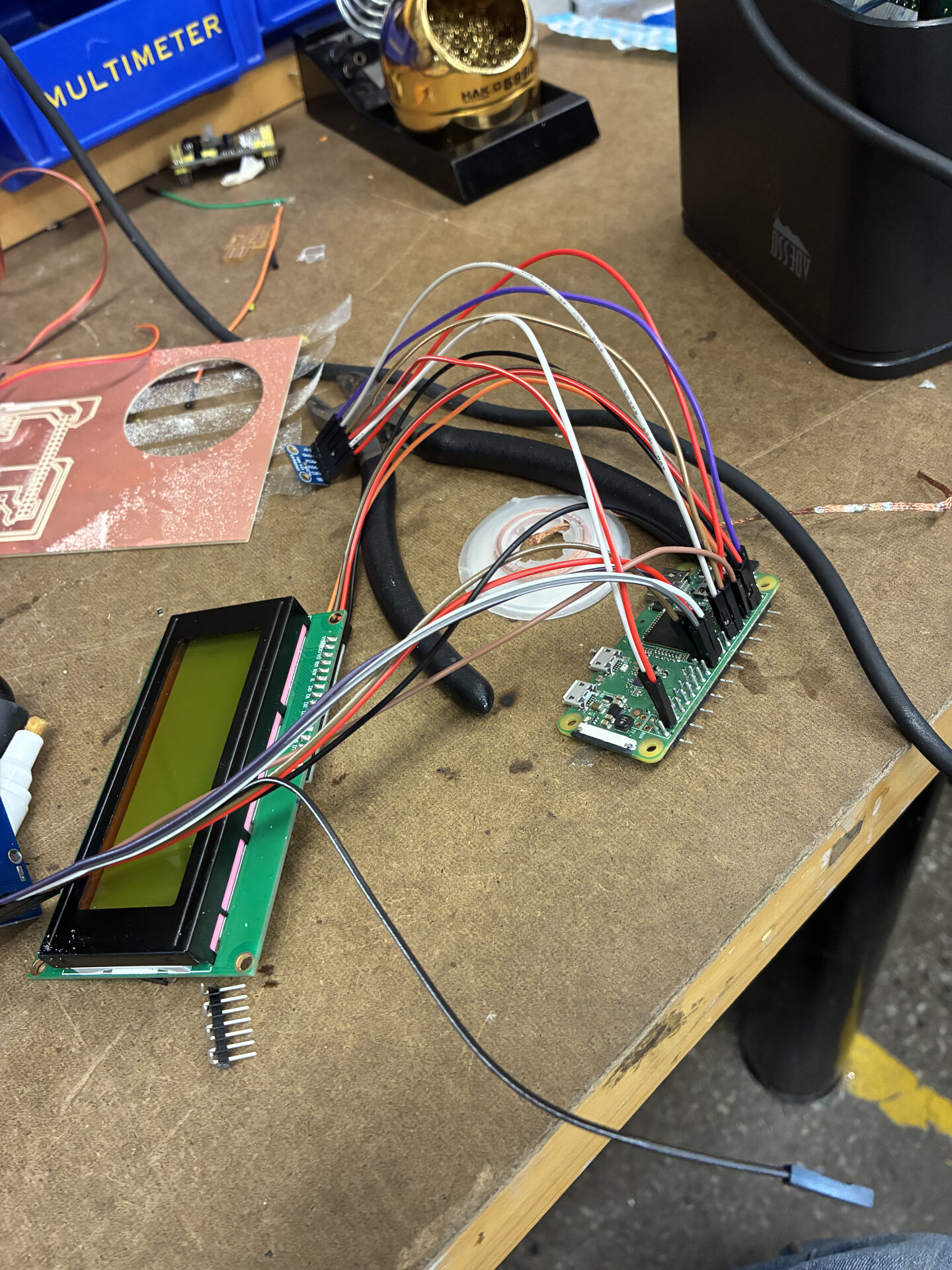

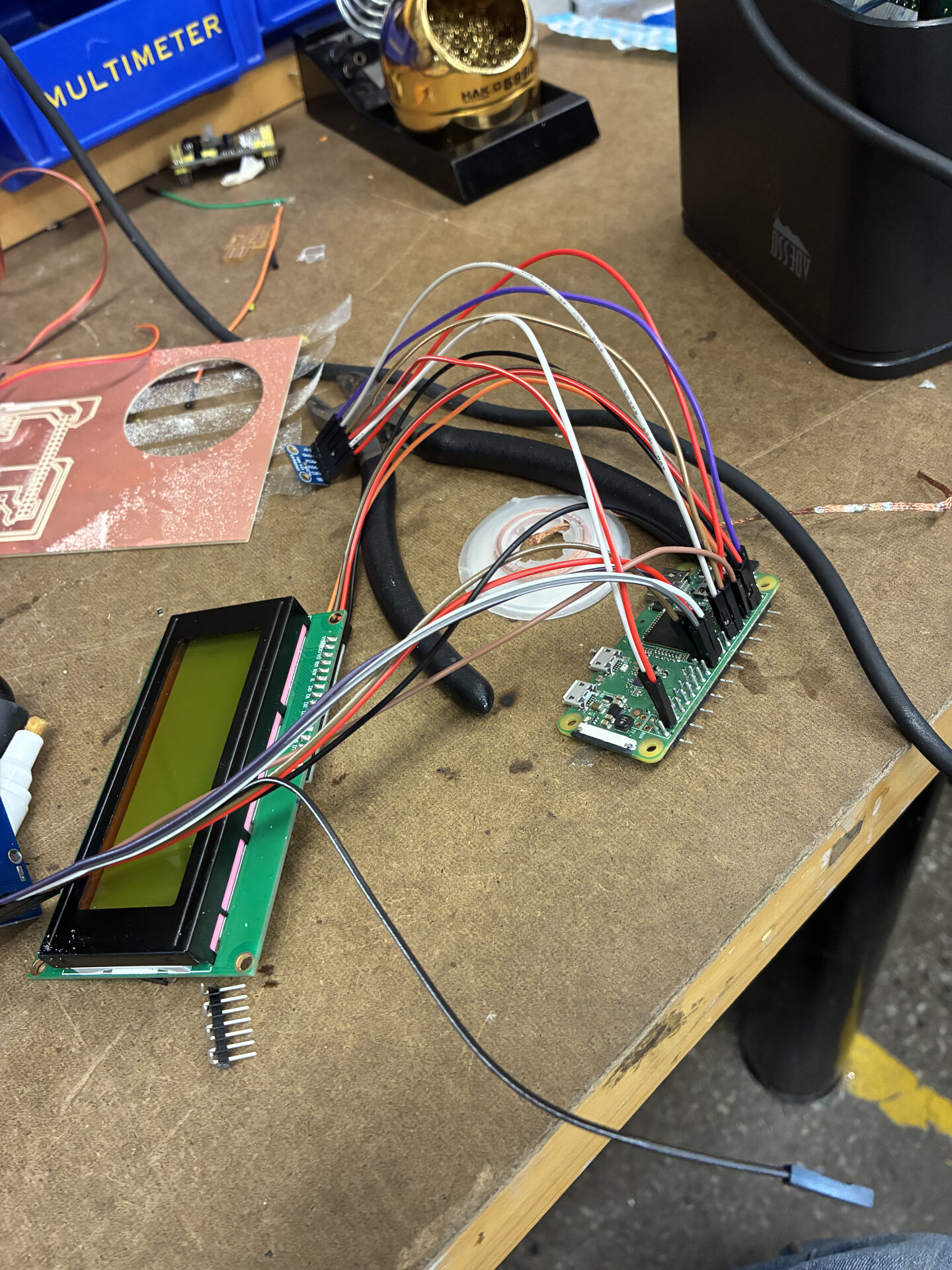

Added a MEMS microphone with audio filtering and voice activity detection. Processes speech for OpenAI's Whisper API.

PAYMENT SYSTEMS

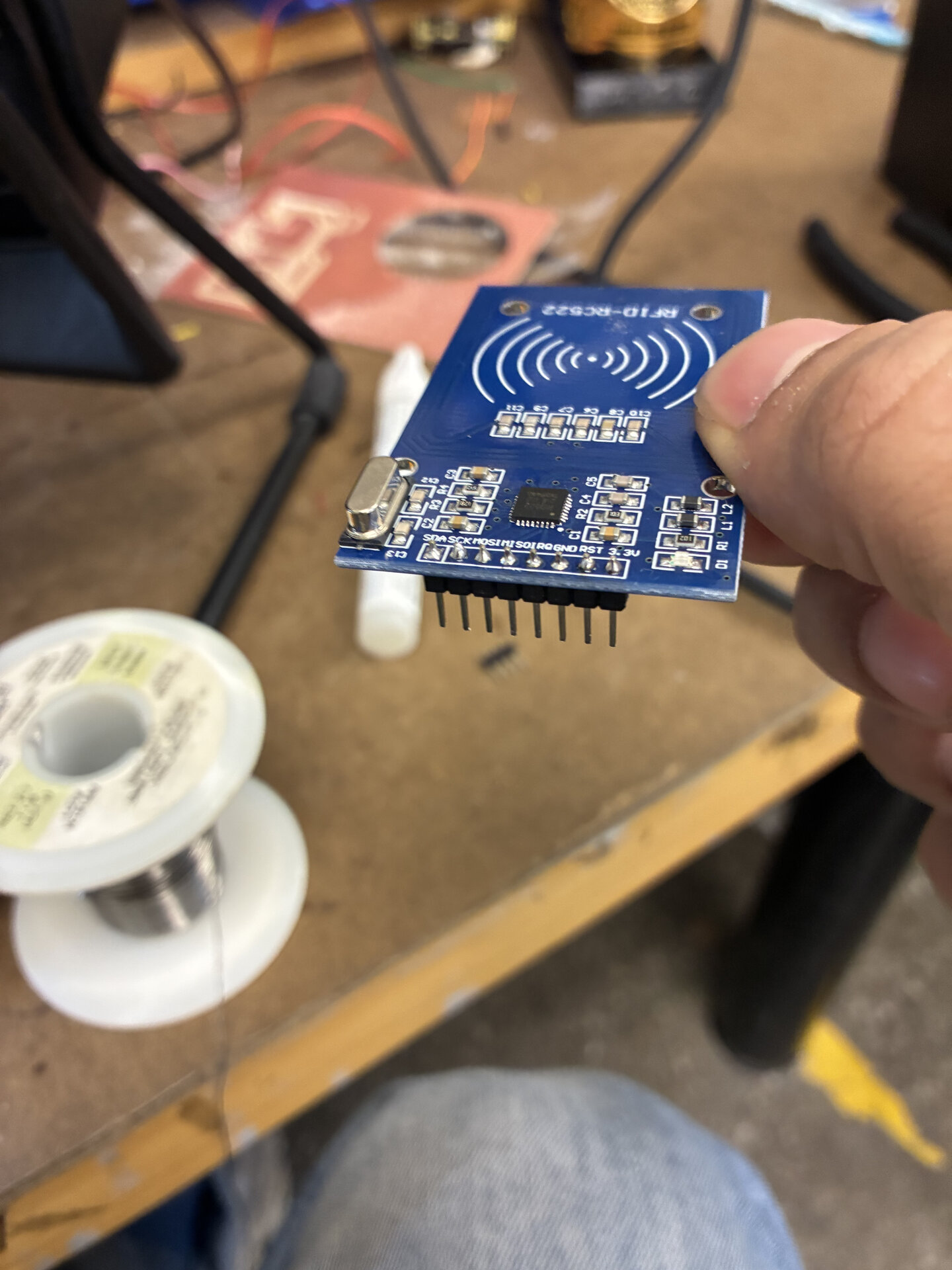

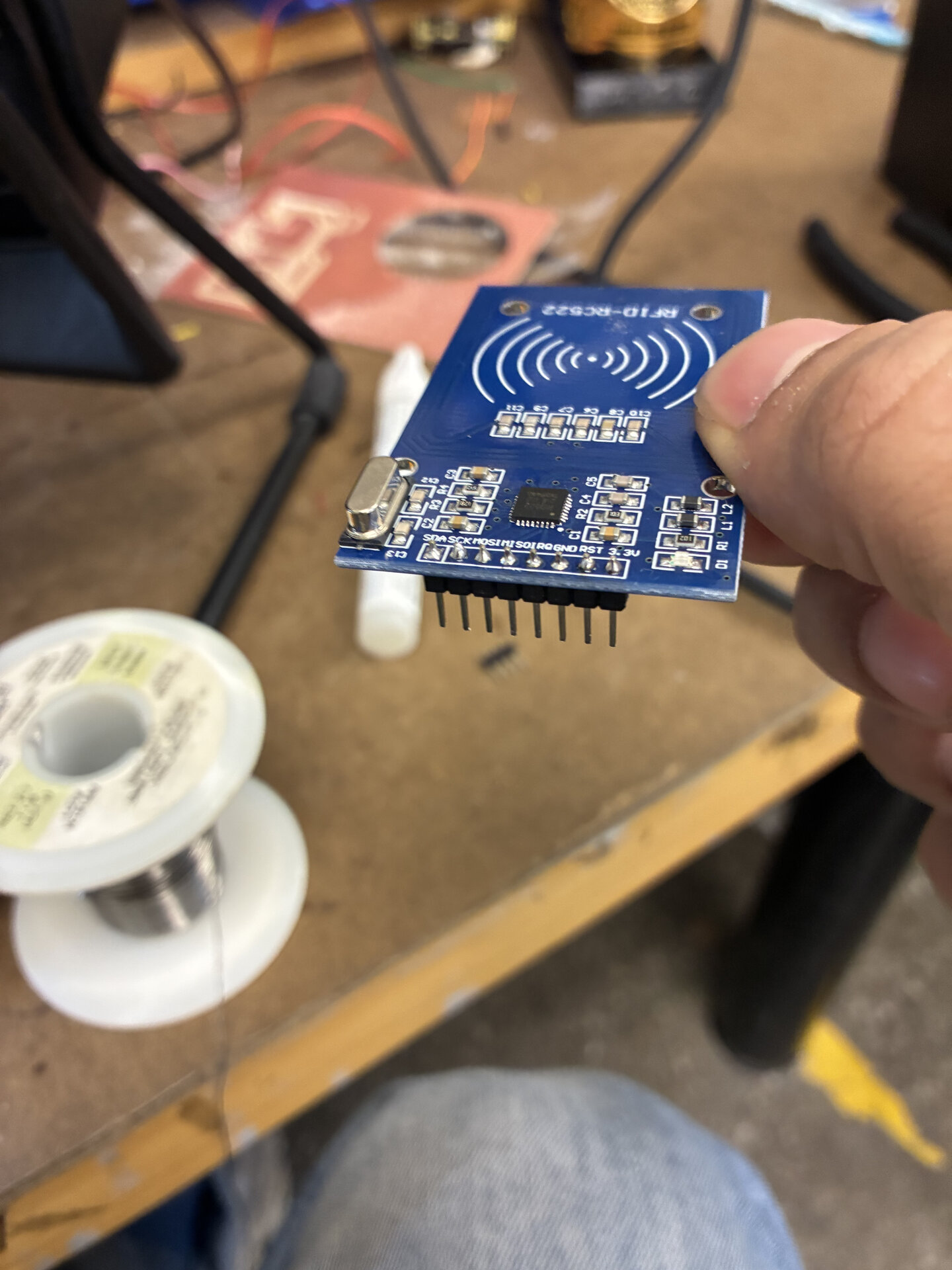

Integrated an RFID reader for payment. Implemented transaction handling and balance tracking while keeping the original housing intact.

OUTPUT & FEEDBACK

Installed a modern LCD screen. Built a simple interface showing recording status, payment, and confirmation before printing.

CORE COMPUTATION

Installed a Pi Zero W inside the original housing. Configured WiFi for reliable network access in public spaces.

INTELLIGENCE

Built Python control system. Integrated OpenAI's Whisper (speech-to-text) and GPT (responses). Handles all hardware coordination.

Python OpenAI API Whisper & GPTPHASE: INDUSTRIAL DESIGN

Critical design challenge: maintain visual similarity to the original while accommodating modern components. Used selective 3D printing, careful wiring routing, and subtle modifications to housing. Preserved branding and physical character of the original device.

PHASE: VALIDATION

Comprehensive system testing: voice recognition accuracy, printer reliability under continuous use, payment security, network stability, and user experience flow. Iterative refinement based on real-world usage patterns. Device ready for public deployment.

Photos, videos, design files, CAD models, and manufacturing documentation

KiCad project files, Gerber outputs, 3D housing, and firmware code

Gerber file for PCB copper layer

KiCad PCB layout file

3D printable custom PCB housing (78 MB)

Complete firmware code for device programming

Complete Python implementation for MULTIVAC device control and AI integration

A machine that receives payment and produces knowledge in physical form. Like a payphone for information. Imagine a world without smartphones—this would exist in convenience stores and libraries.

I've seen thermal printer builds, Raspberry Pi + LLM integrations, and DIY payment systems. But I didn't copy any single design—this combines pieces in a new way.

Electronics, housing, PCB, information pipeline, GUI, and the core idea. Everything from hardware integration to software architecture.

Housing: PLA (3D printed)

Printer & case: NuPrint210 (scavenged from Harvard's mailroom)

PCB: Copper (arch lab)

Electronics: Raspberry Pi Zero W ($13), RFID RC522 (archshops), MEMS mic ($6.95)

KiCad design, 3D printing, PCB milling, cutting, filing, soldering, and integration.

Worked: Printer, AI pipeline, voice input, display.

Didn't work: Payment terminal (payment processing is more complex than expected; I have an RFID scanner reading generic cards instead).

This semester has been extraordinary. I want to thank Adin, the architecture TAs Jen and Gert, and Neil for their mentorship and support. The friends in the Architecture Section made this work possible, and I've learned more in these few months than I could have imagined. Thank you for believing in the ideas, providing feedback, and making this an unforgettable experience.