🏗️ WEEK 11: MACHINE WEEK

Group mechanical design, automation, and collaborative engineering.

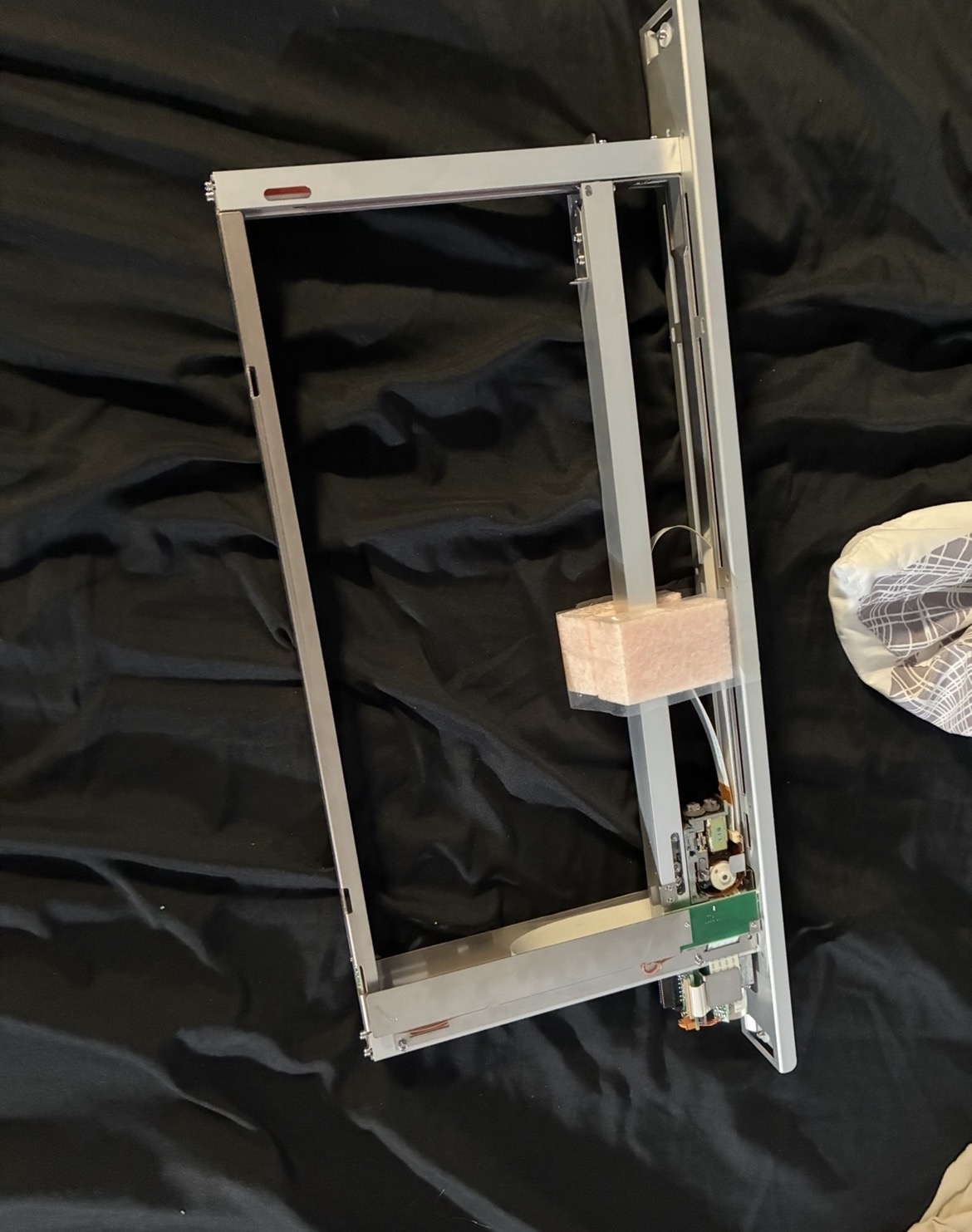

Ouija Board Gantry Project

This week was a collaborative group assignment focused on designing and building an automated X-Y gantry system. Due to illness (COVID), I contributed remotely to the gantry design team, focusing on hardware sourcing, mechanical components, and print-in-place pulley bracket design. Despite limited capacity, I was able to participate in the redesign of critical components and learned significantly from the project.

Documentation & Media

Hardware sourcing, mechanical design, and pulley bracket development

3D Design Files

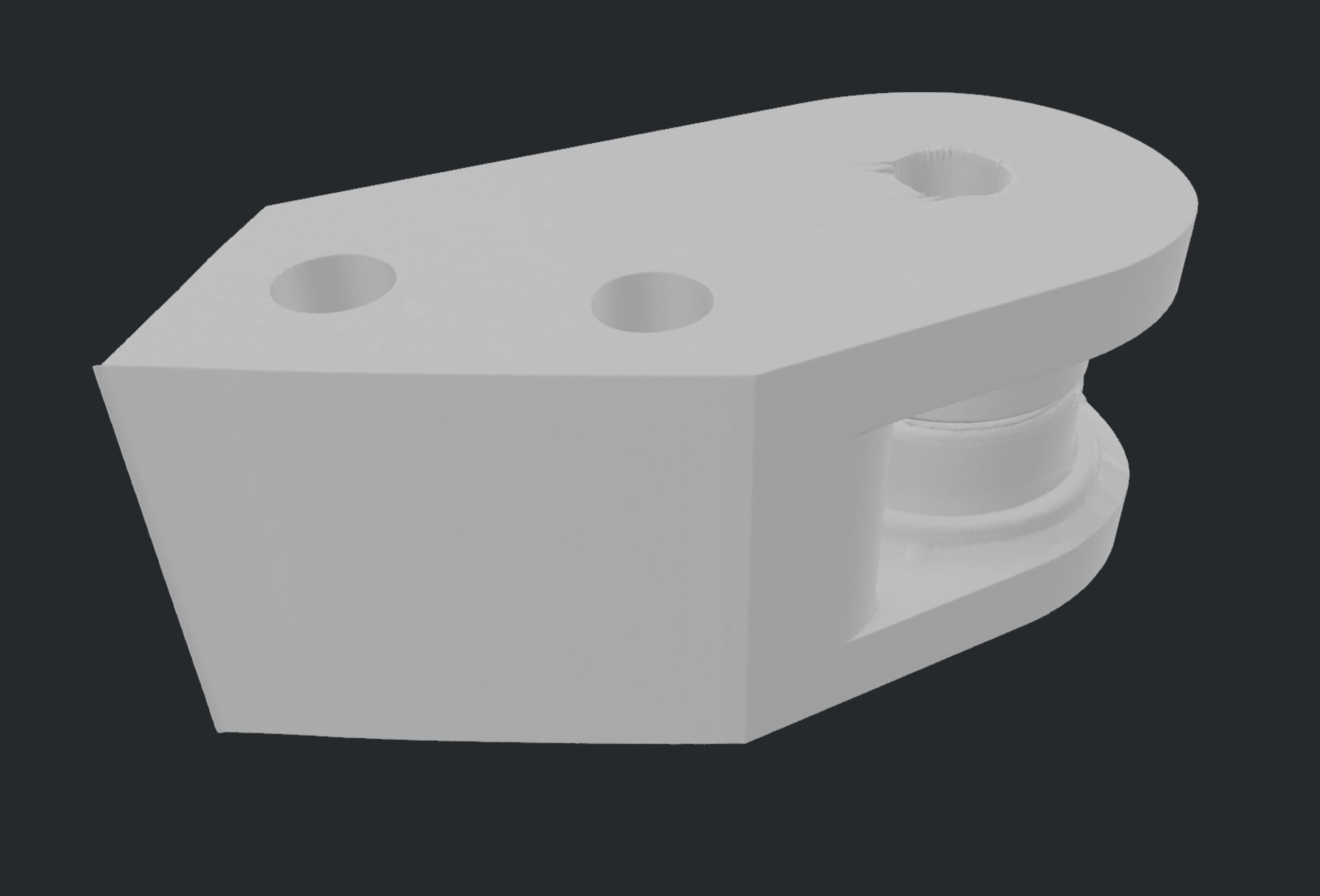

Print-in-place pulley bracket STL with 3D visualization

printinplacebracket.stl

Print-in-place pulley bracket redesign for the X-Y gantry system. This component allows for smooth motion without additional assembly or fasteners.

⬇ Download STL FileRemote Contribution & Team Collaboration

I tested positive for COVID this week and was generally very sick (spoke to Gert about remote participation). Despite the limitation, I was able to contribute to the gantry design team by:

- Sourcing potential AIO X-Y gantry hardware from lab resources

- Collaborating on print-in-place pulley bracket redesign

- Learning from team members about gantry dynamics and motion control

- Planning for future projects (potential automatic chessboard build)

I was very impressed with the final product and grateful for my teammates' flexibility during my illness. This experience reinforced the value of collaborative engineering and remote participation capabilities.