🎨 WEEK 10: MOLDING & CASTING

Replicating designs through molds and material transformation.

Molding & Casting Process

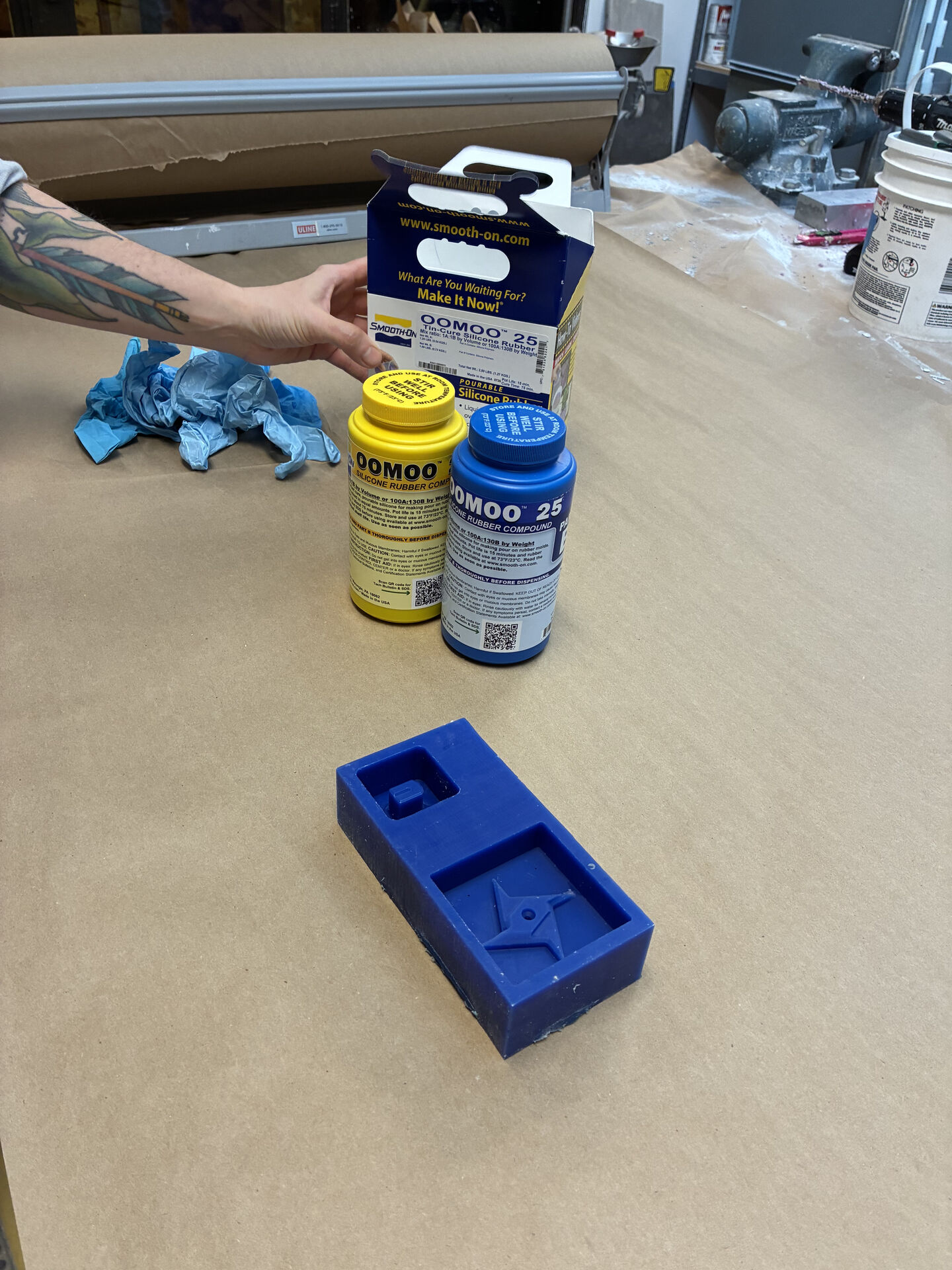

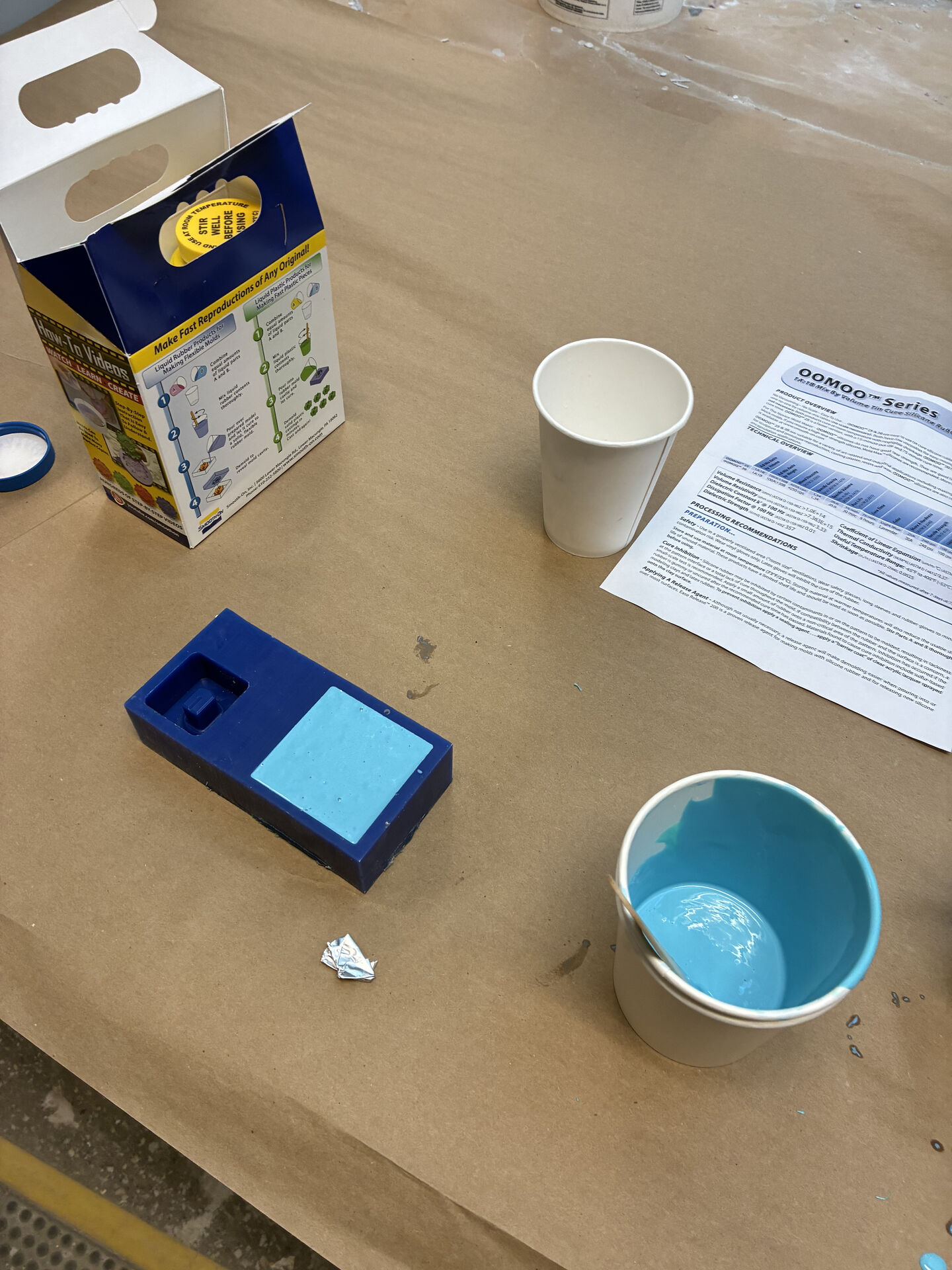

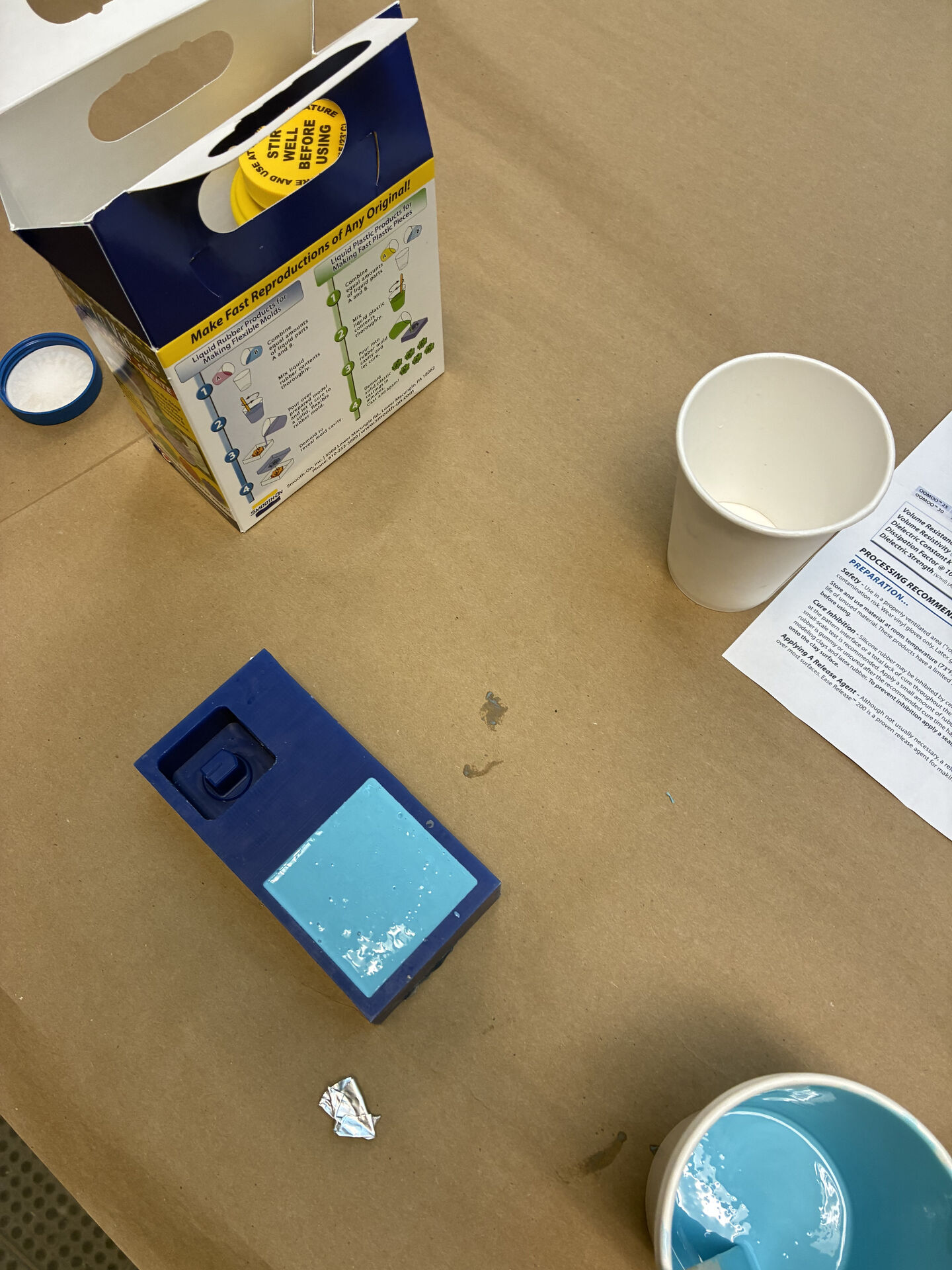

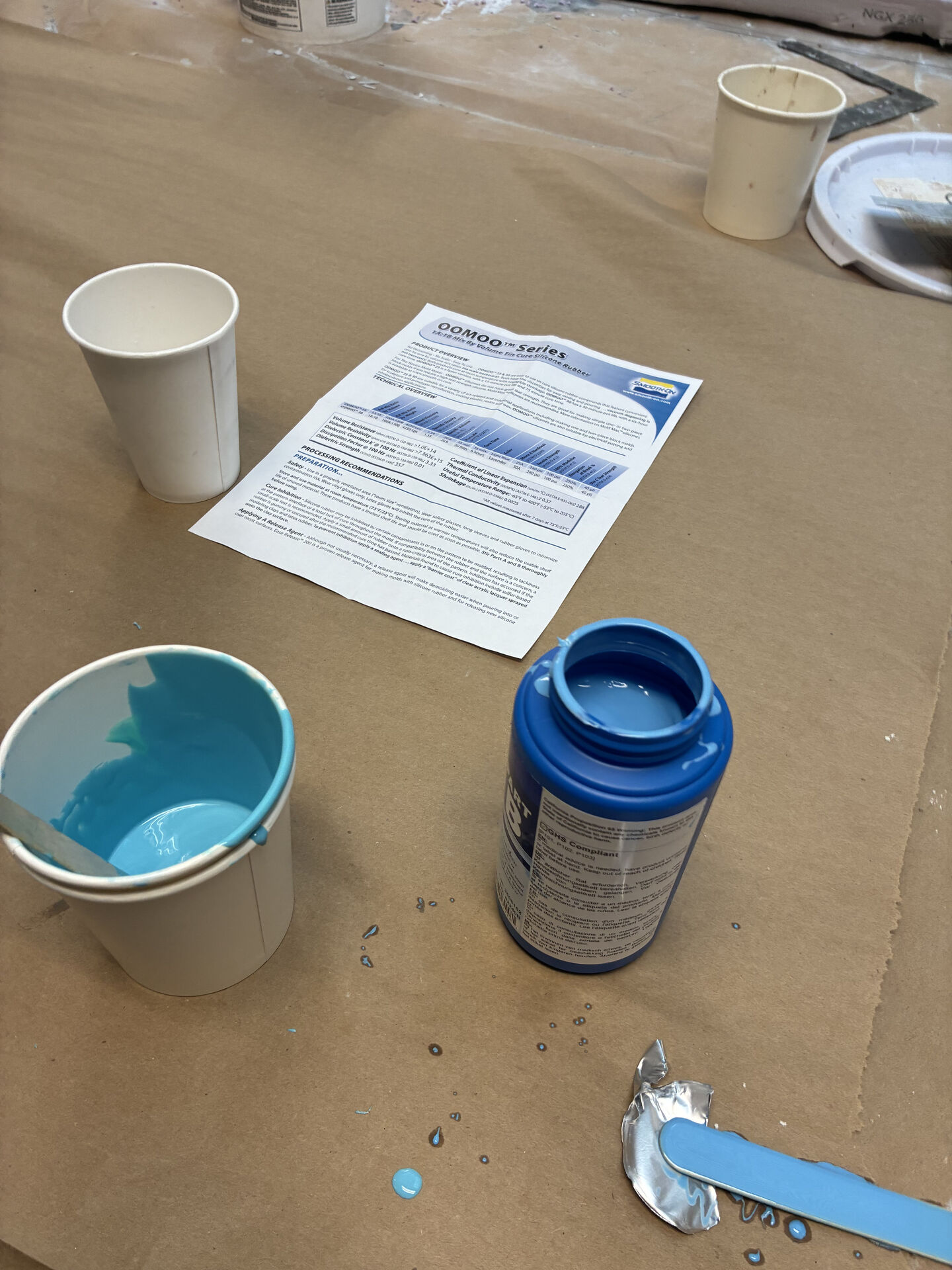

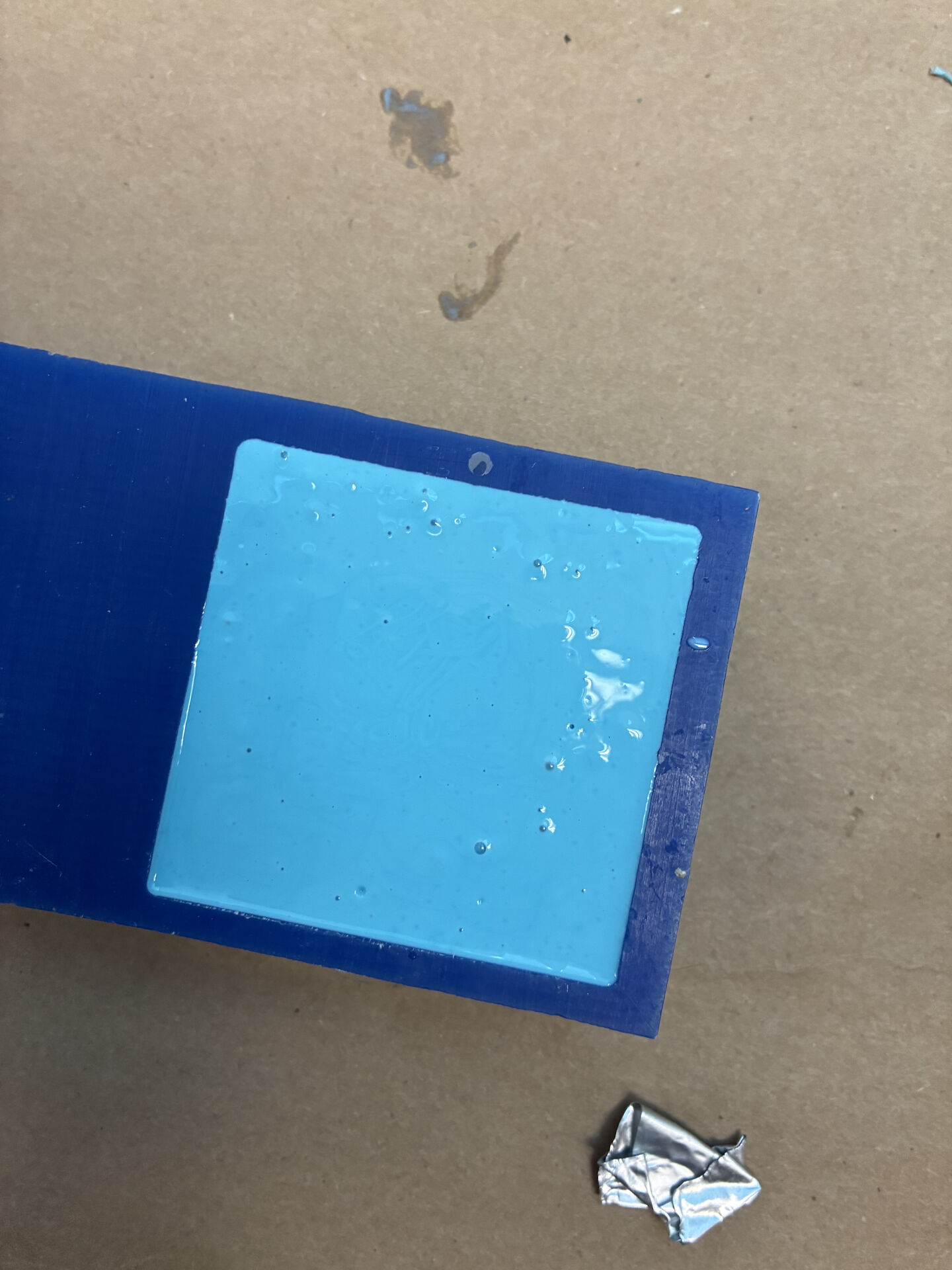

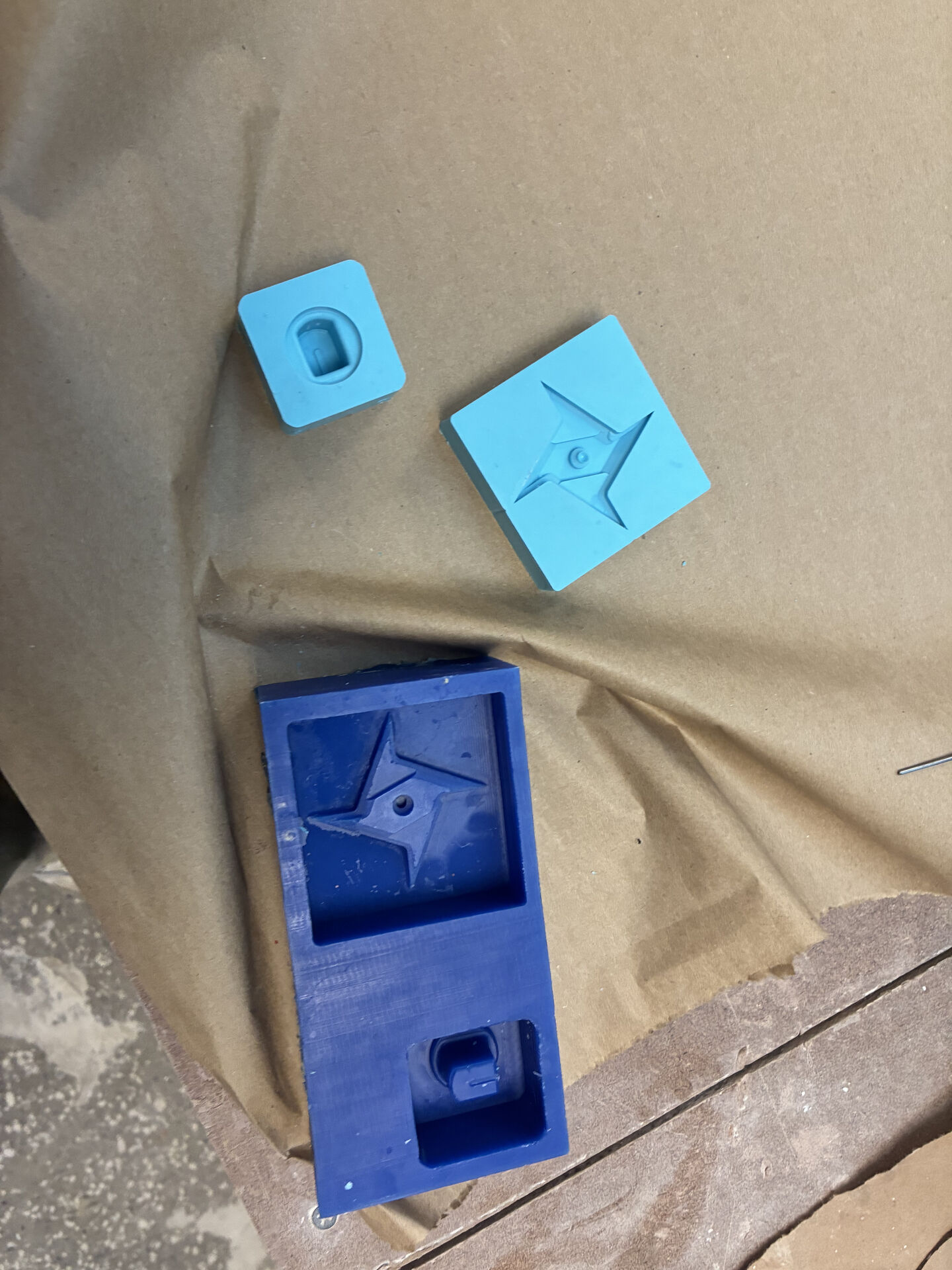

This week explored the complete workflow of creating molds and casting duplicates. Learned safety protocols for working with resin and plaster, techniques for bubble removal and degassing, and the detailed process of creating replicas of engineered designs.

Documentation & Media

Safety protocols, pour techniques, mold casting, and finishing

Material Safety & SDS Review

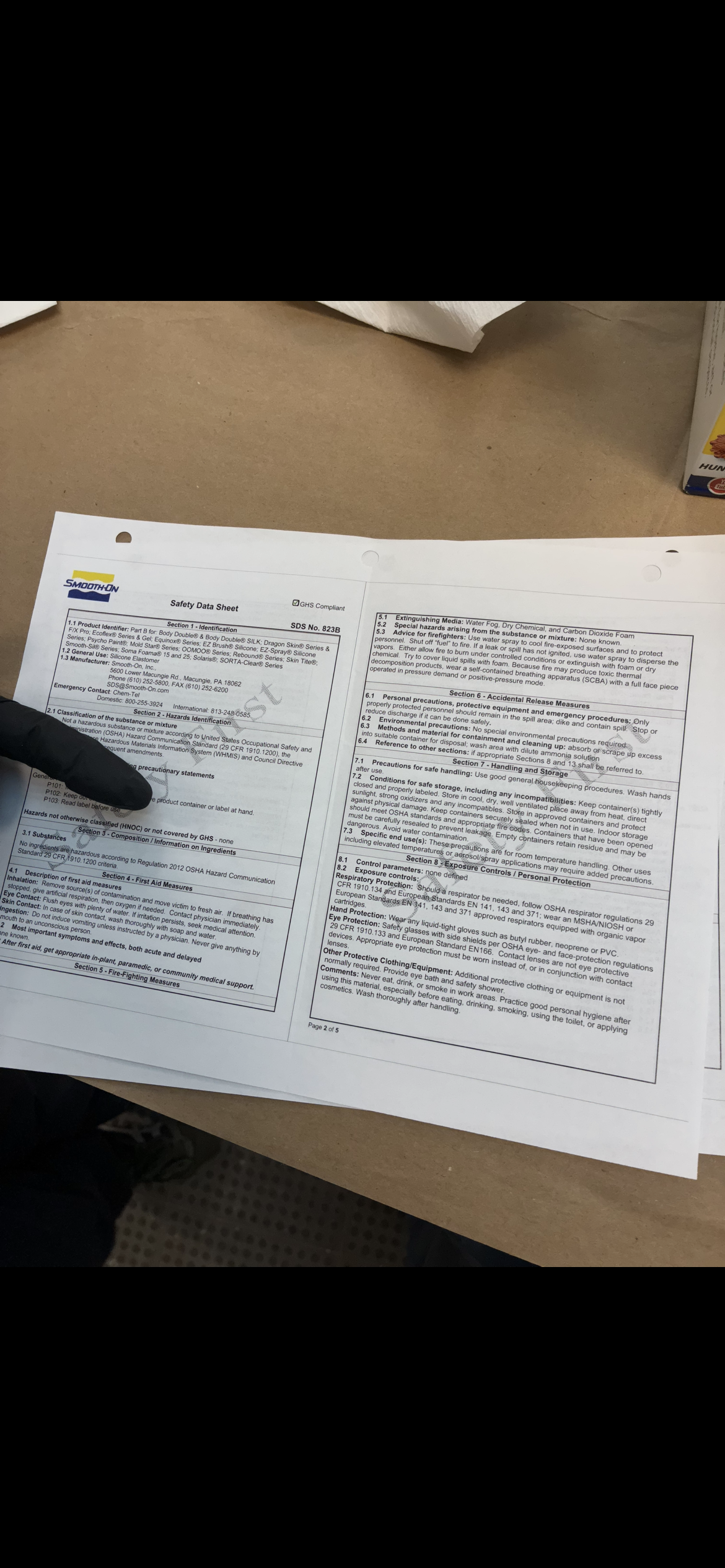

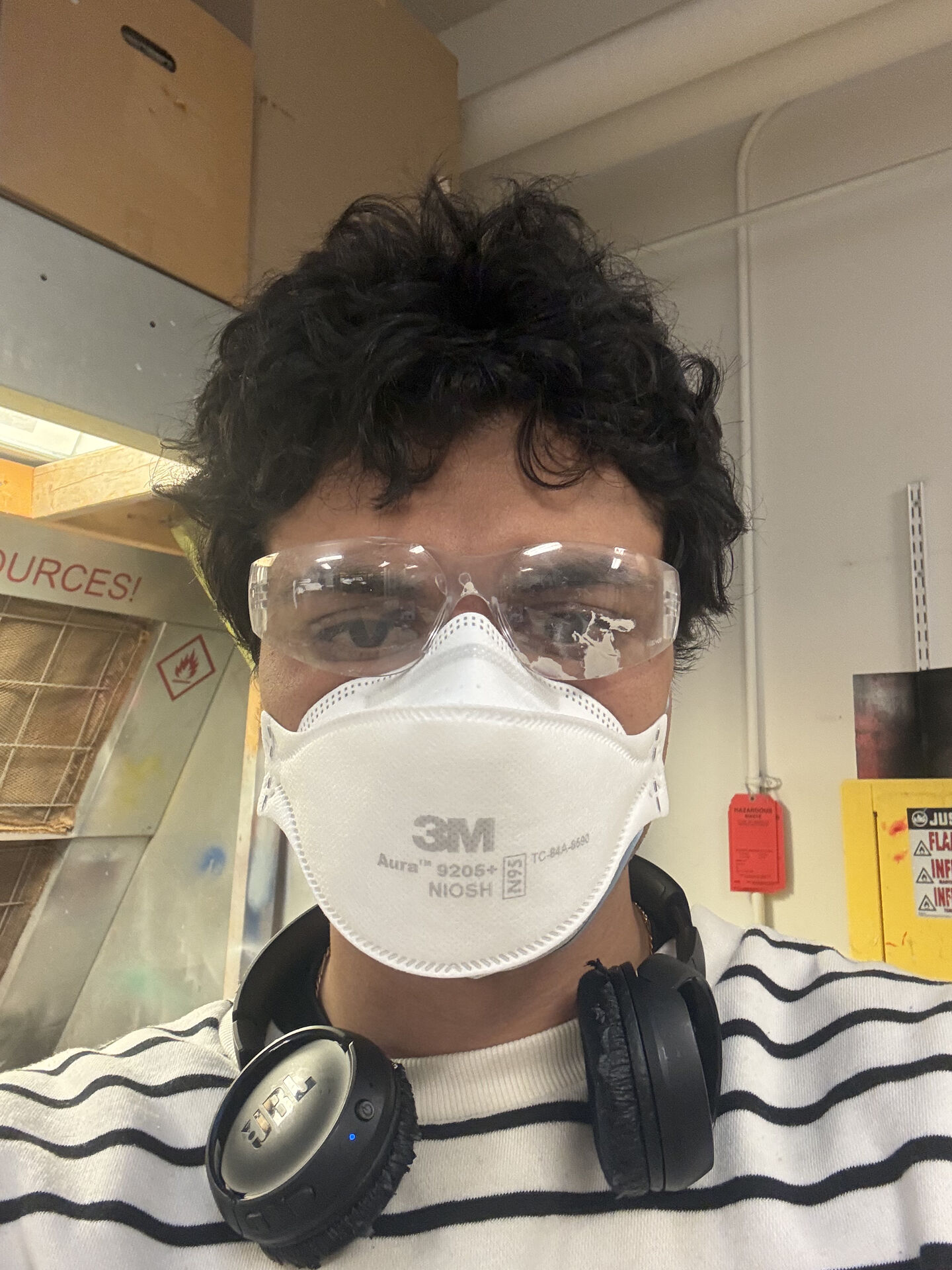

One of the most critical steps in molding and casting is reviewing the Safety Data Sheets (SDS) for each material. I compared the SDS for the Smooth-On silicone elastomer we used with a high-toxicity urethane resin that Jen warned me about.

Our material: The Smooth-On silicon elastomer we used is relatively non-toxic and safe for personal use with basic PPE. Its hazard classification states: "Not a hazardous substance or mixture according to United States Occupational Safety and Health Administration (OSHA) Hazard Communication Standard (29 CFR 1910.1200), the Canadian Workplace Hazardous Materials Information System (WHMIS) and Regulation (EC) No 1272/2008 and subsequent amendments." Download SDS →

The dangerous alternative: Jen shared a story about a fab lab in Spain where someone was hospitalized after using Crystal Clear Urethane. That SDS carries serious warnings: "H331 Acute toxicity, inhalation – Category 3, H334 Respiratory sensitization – Category 1, H335 Specific target organ toxicity – single exposure – Category 3 (respiratory system)." This resin requires industrial-grade ventilation, specialized PPE, and training we don't have. Download SDS →

This comparison reinforced why examining the SDS before purchase is essential—especially for industrial chemicals. Material choice directly impacts safety, and understanding hazard classifications is part of responsible engineering.

Reference: