✂️ WEEK 2: COMPUTER-CONTROLLED CUTTING

Precision meets creativity. Lasers and digital control systems bend to our will.

[ MISSION OBJECTIVE ]

Master the art of precision cutting with computer control. From vinyl cutters to laser engravers, we'll explore the tools and techniques that bridge digital design with physical creation.

[ INDIVIDUAL ASSIGNMENT ]

Cut something on the vinyl cutter.

[ GROUP ASSIGNMENT ]

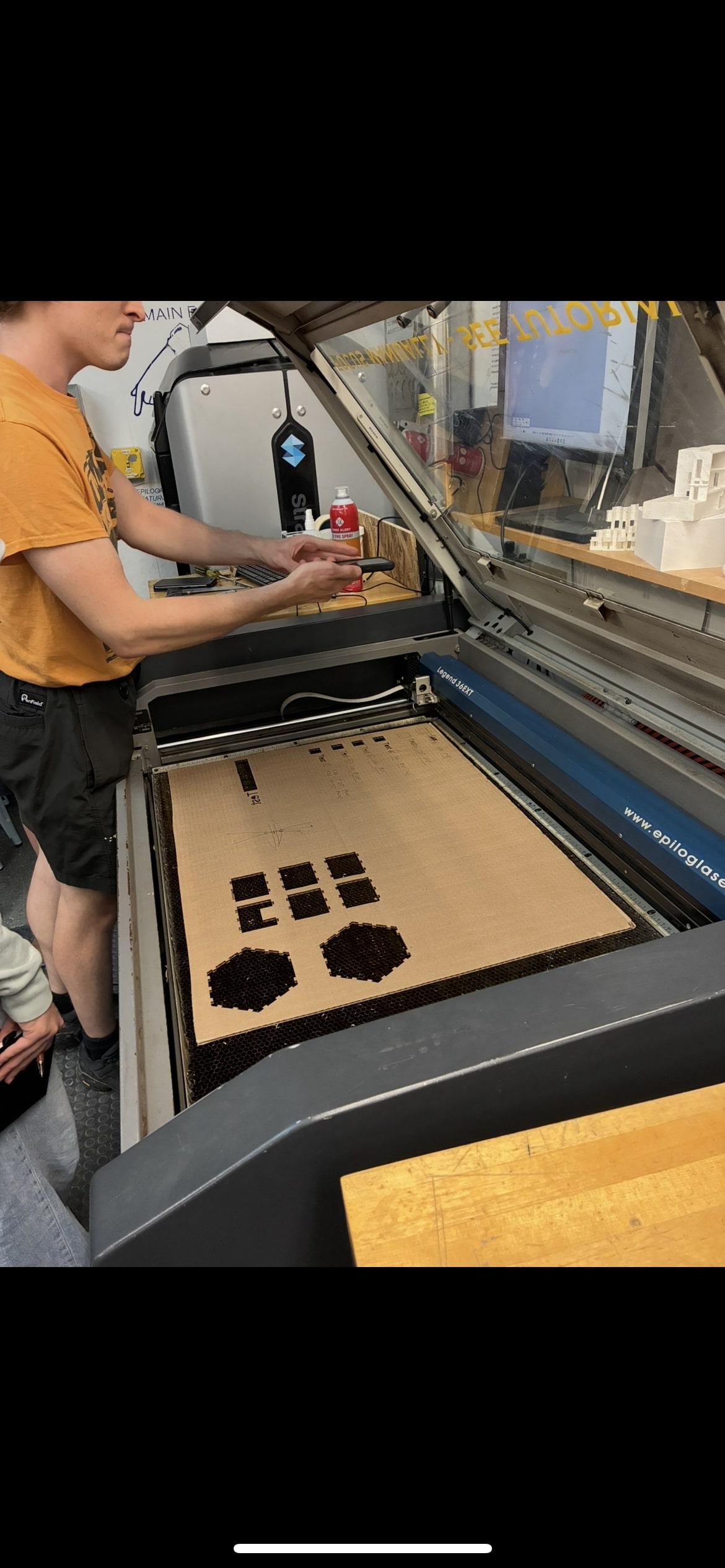

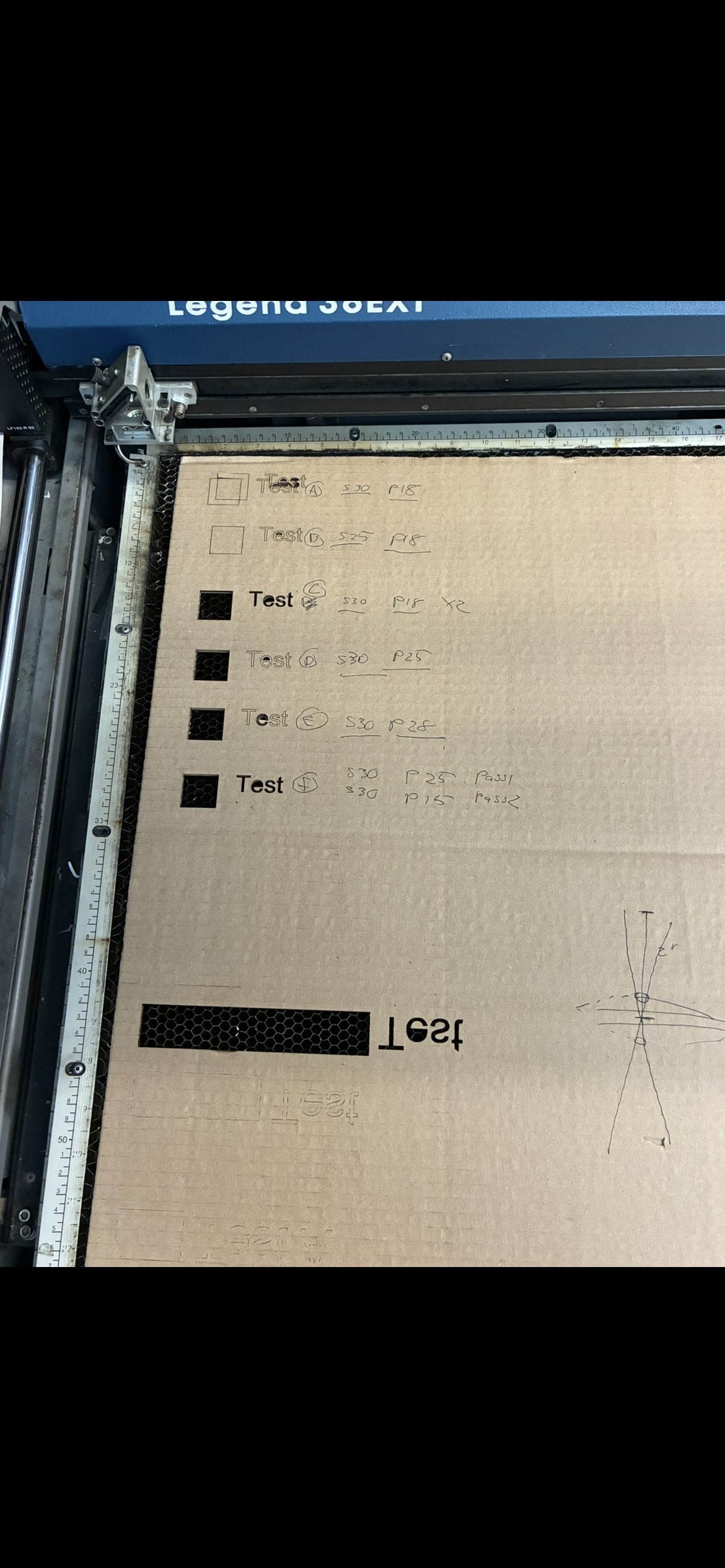

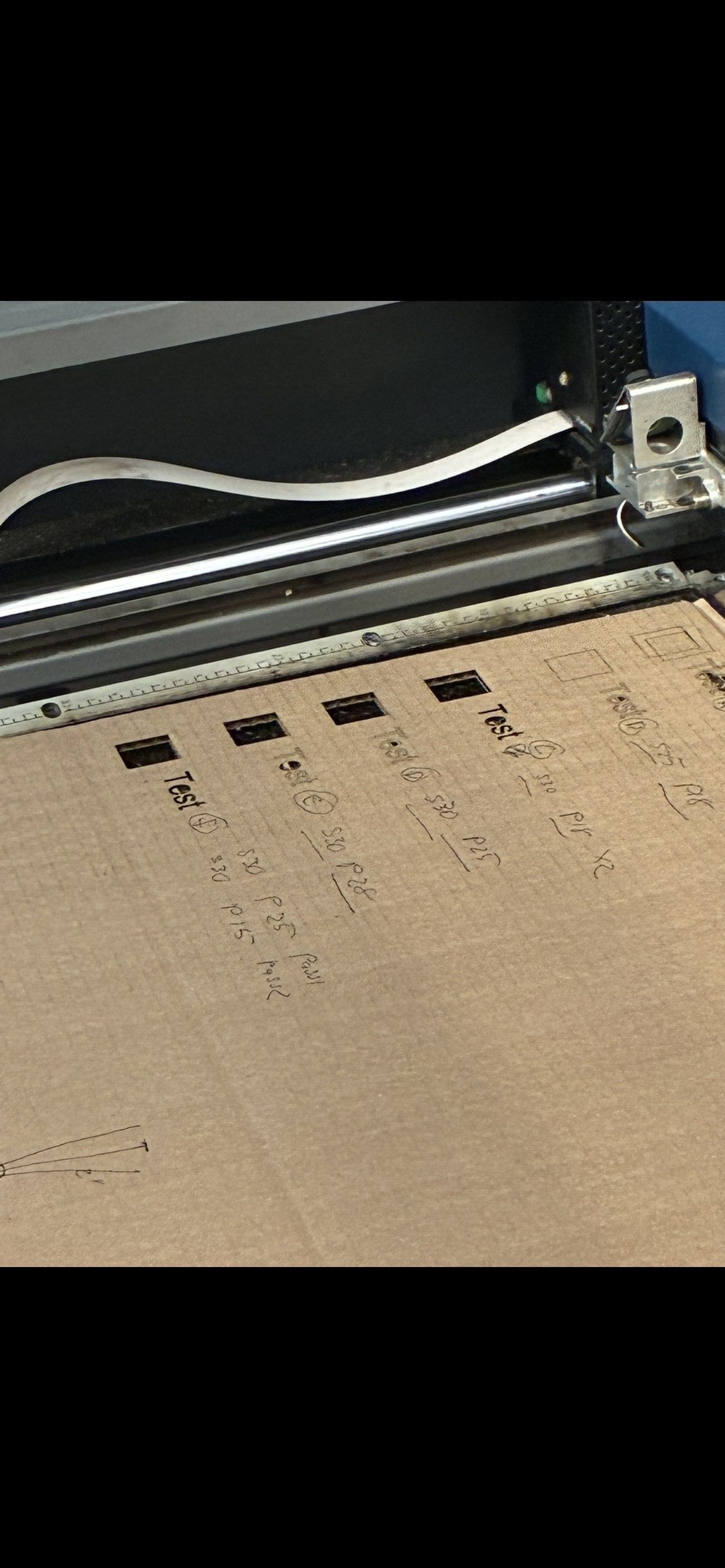

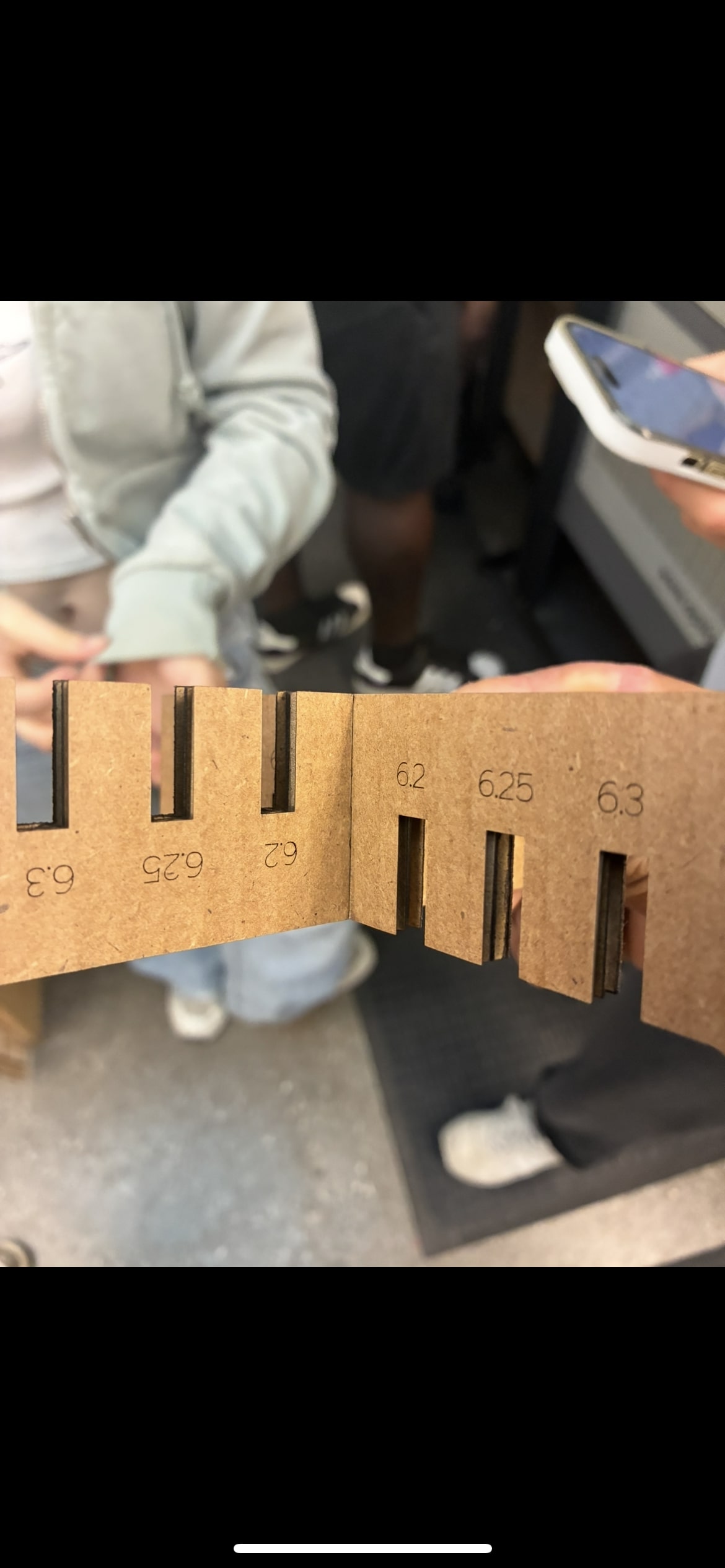

Characterize your laser's kerf.

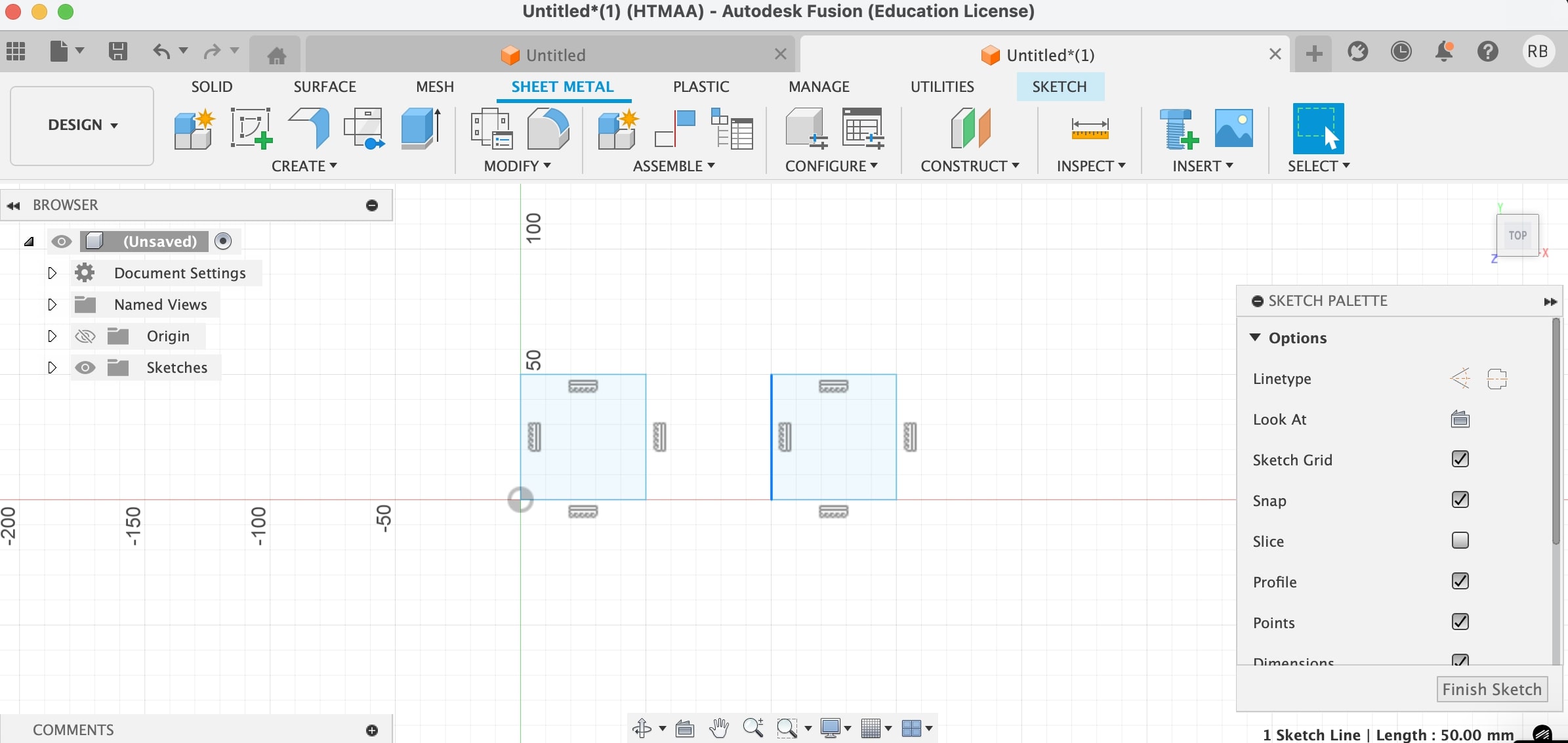

[ PARAMETRIC CONSTRUCTION KIT ]

Design, lasercut, and document a parametric construction kit.