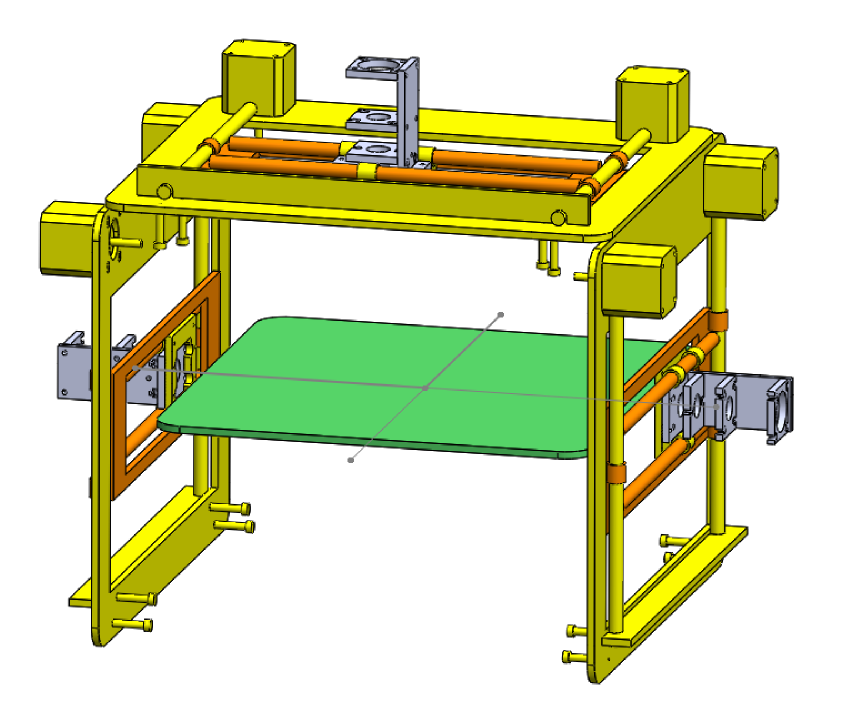

Inspiration/motivation for this project was two fold: CoreXY techniques for cartesian motion and Modular Single Axes MTM both from previous version of the class.

Ilan Moyer implemented a waterjet aluminum version of his corexy system. Low profile, most parallel dynamics, fixed stepper motors.

Nadya Peek and James Coleman worked modular machines that use single axis as stages. This work actually started as stages constructed out of aluminium and polymetal, and then developed into cardboard stages for easy and quick prototyping.

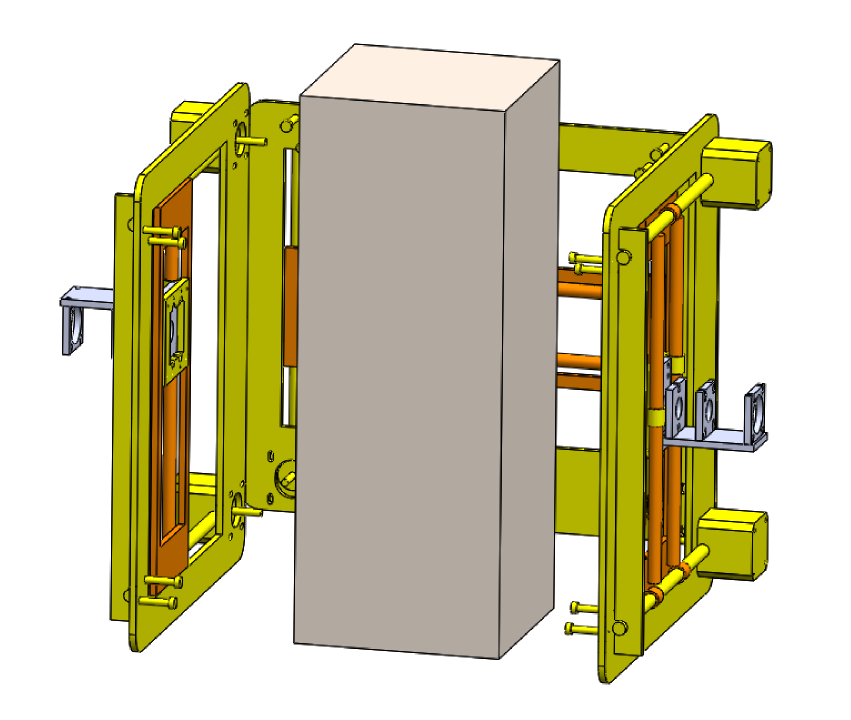

Implementations I have seen of single axis linear cardboard stages seemed to all start with coupling two stages to get cartesian motion. Even all four teams last semester in How To Make Almost Anything started off with this. My group in particular had difficulty with this approach because the thickness of two stages made it difficult to fit in a small area

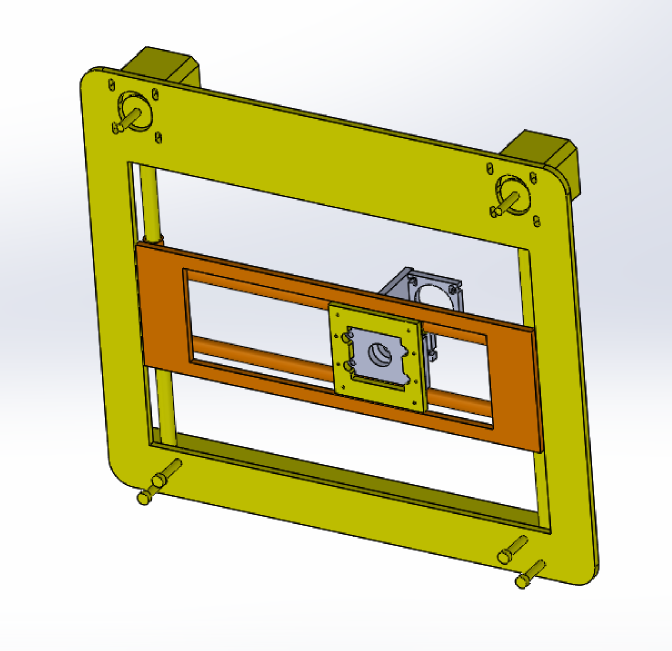

Cue, CoreXY, which is a lower profile cartesian implementation. Rather than using single axis stages, stages can be dual axis. With using CoreXY as a stage, may different configurations of machines can be built.

The idea is to use various two axis plates as builders.