Tests & Operation

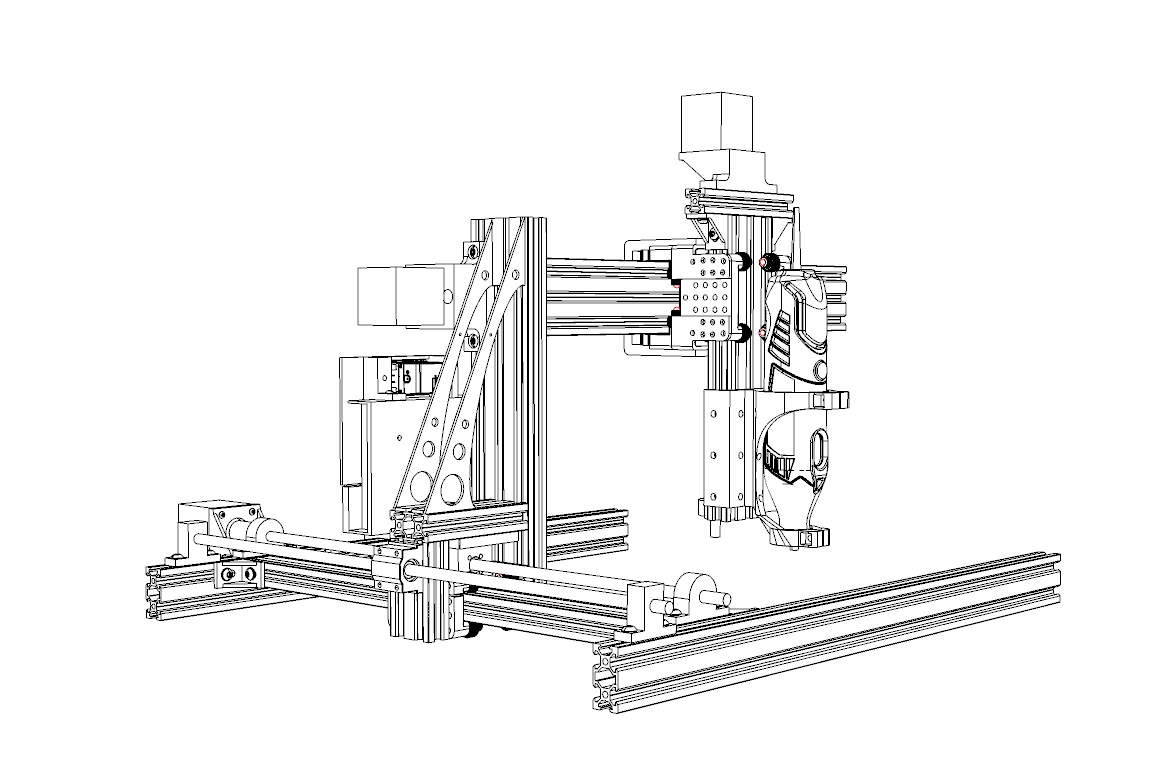

Modifications

The total cost of the machine is around $500. The most expensive parts are the TinyG controller and power supply. Most parts ended up being 3D printed

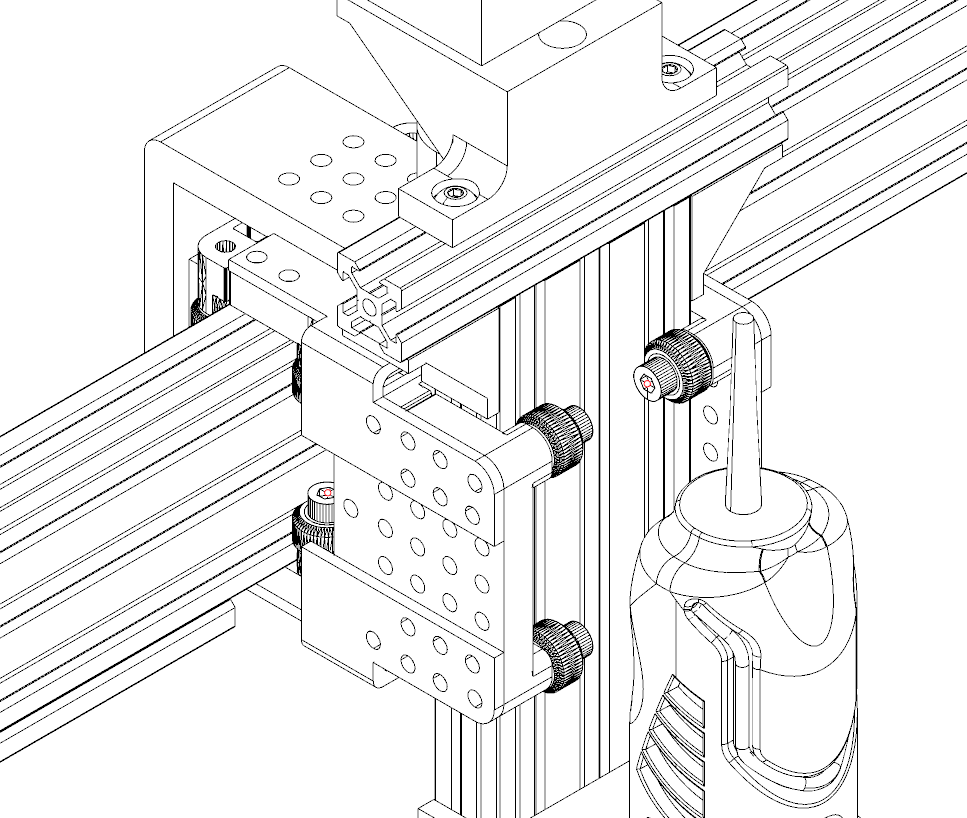

After some testing on machine movements, the final design for the machine has more connection points to keep it rigid.

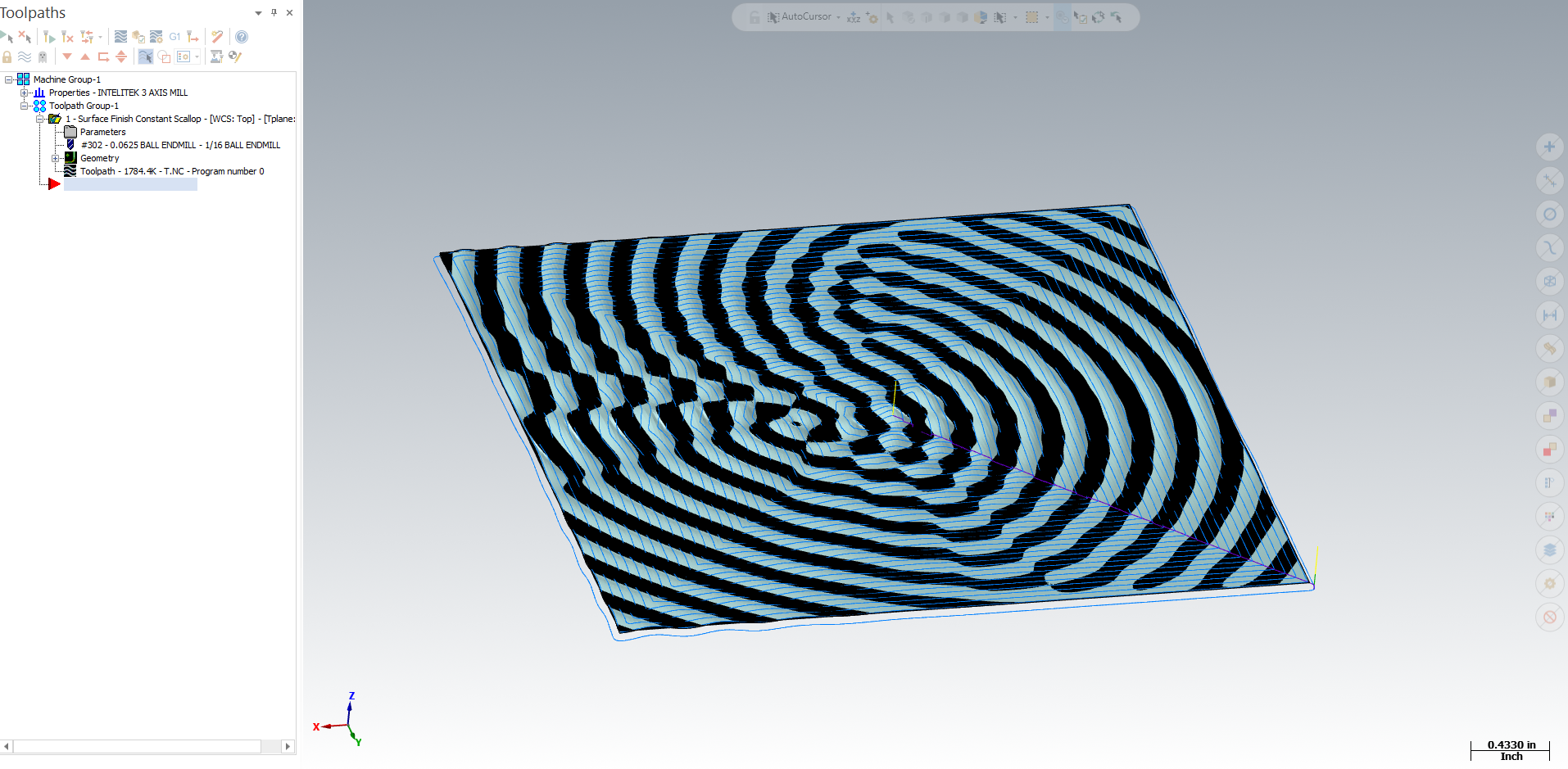

Path Planning

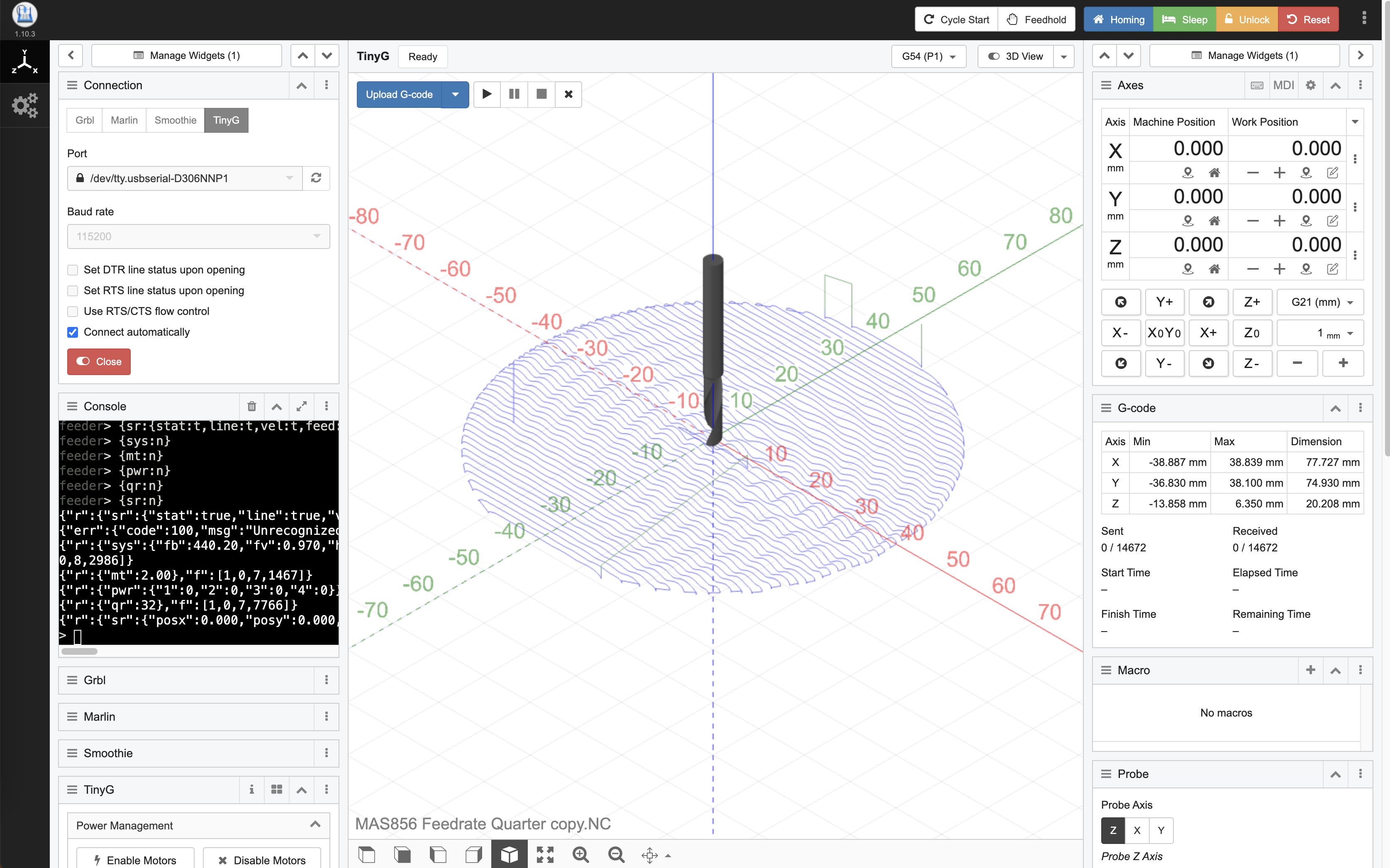

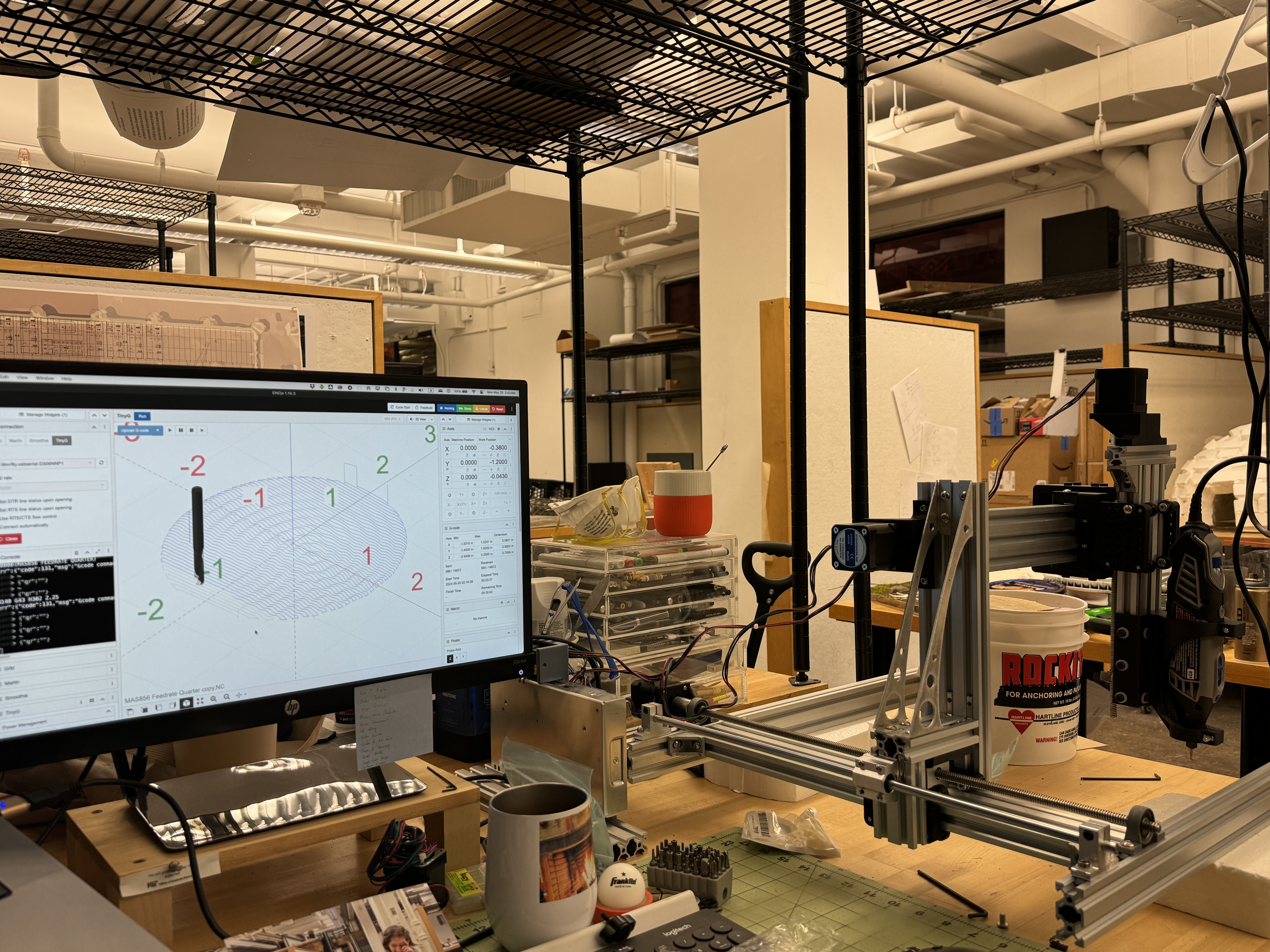

The G-Code for this machine is made from MasterCAM. It is worth noting that when translating MasterCAM to CNCjs, there are slight misalignments, such as feedrate, that needs to be double checked.

Dry-run of the G-Code before operating.

Limestone Test

The decision to test on limestone is due to its hardness is an inbetween of soap stone and granite.

The set-up is very rudimentary, the main goal is to stablize the stone and submerge it just below water surface.

Grinding the stone was a breeze. Because the simple tool path and diamond sanding bit.

Engraving the stone took some effort. Because the uneven surface, the machine had some trouble. In the future, this machine needs to be much heavier and rigid.

Result

Result from grinding turned out suprisingly well. Though there are some burnmarks and uneveness, it is very smooth and round!

Result from etching is not so good. The machine need to be far more ridgid than what it is now

Reflection & Future Development

This machine can definitely be heavier. To grind or engrave granite, a 1.5 hp rotary motor is likely needed. The good news is that a machine like this is inexpensive to make, making it accessible to many people. However, the challenge remains in protecting the hardware from water damage and ensuring sufficient rigidity.I would also like to develop the water basin further. Perhaps an underwater vise to grip onto the subject would be nice.