Week 4

3D Scanning and Printing.

Engineering Files

3D Printing

My lab space has several reliable 3D printers, so fortunately, I was able to make use of them to complete this week's assignments. We have several Prusa MK3S+'s, and a Bambu printer. While the Bambu printer was convenient to use, with features like real-time monitoring and sending files over wifi, the Prusas were generally more reliable, although much slower.

For this week's assignment, we were required to print something that couldn't be made subtractively. While this wasn't useful for my final project, I thought it would be interesting to print out what are known as "torture tests" in the 3D printing community. They involve complex, small prints with overhangs, bridges, and active mechanisms to evaluate the accuracy of the printer.

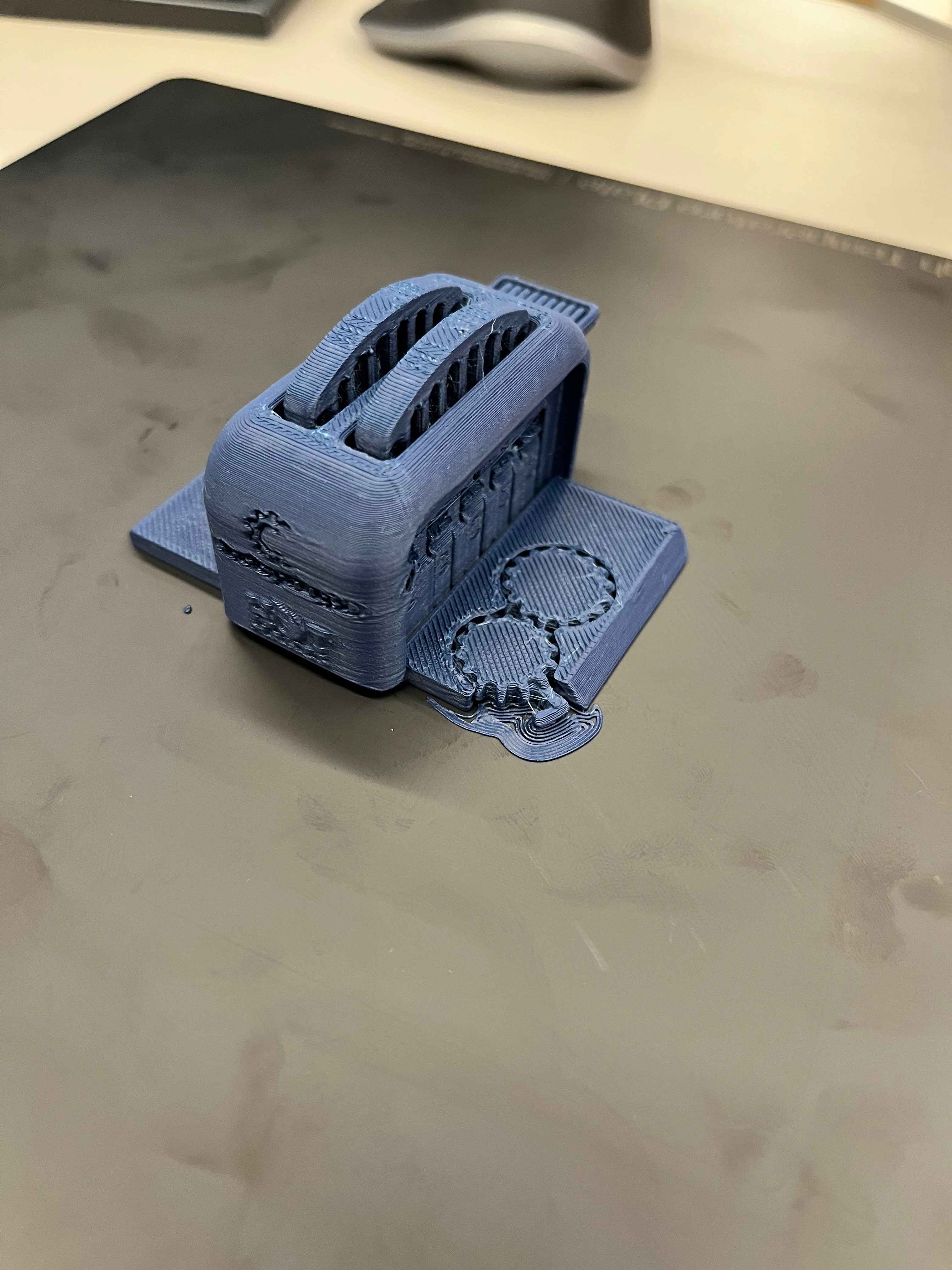

In this case, I opted to try and print this "torture toaster" from Thingiverse. I loaded it in the Bambu software on my Macbook, sliced it, and was able to monitor its progress in real time.

After waiting an hour or two, the finished print was ready. Unfortunately, what the Bambu makes up for in speed, it sacrifices in accuracy. I think I would need to sit down and tune its speed settings, infill percentage, wall layer, and so on before getting a clean print on the Bambu. While the left and right "flaps" of the toaster worked fairly smoothly, it was challenging to turn the gears, and the lever arm of the toaster actually snapped off immediately.

I wanted to make some progress on my final project, so I also began designing and printing some prototype mechanisms of my tourbillon. Because I wanted a higher print quality, I opted to use the Prusa printers instead.

Specifically, I wanted to try printing the escapement mechanism of a mechanical watch. I'm still unsure how to best design the spring of the tourbillon and main drive. It could be 3D printer, but I may have better results with parts from McMaster Carr.

Regardless, I began designing the mechanisms in Fusion, and doing my best to design the pallet fork to properly allow

the escapement to hit each tooth deliberately.

Some initial prints on the Bambu resulted in this.

The Prusa prints were much nicer, and with the frame and some dowel pins, I put the mechanism together.

3D Scanning

For the 3D scanning portion of this week's assignment, I opted to use the Intel Realsense D455 Depth camera. Our lab explored using these for computer vision on board our legged robots, so I wanted to see how I might be able to get 3D scans from them. The website provides an SDK to interface with the camera, and immediately see its data streams, so I began by downloading and exploring the GUI.

I was able to get a 3D view of the camera's data, and I could see that it was able to detect depth and color. I wanted to see if I could export this data, so I began looking through the SDK documentation. I found a sample program that would allow me to export the data as a point cloud, so I compiled and ran it.

As you can see, the pointcloud produced a fairly accurate impression of my controller, but only in one direction. I also noticed it was quite sensitive to the lighting of my desk, and could easily give unrealistic results without the correct environment.