Week 7

Molding and Casting.

Engineering Files

Material Safety

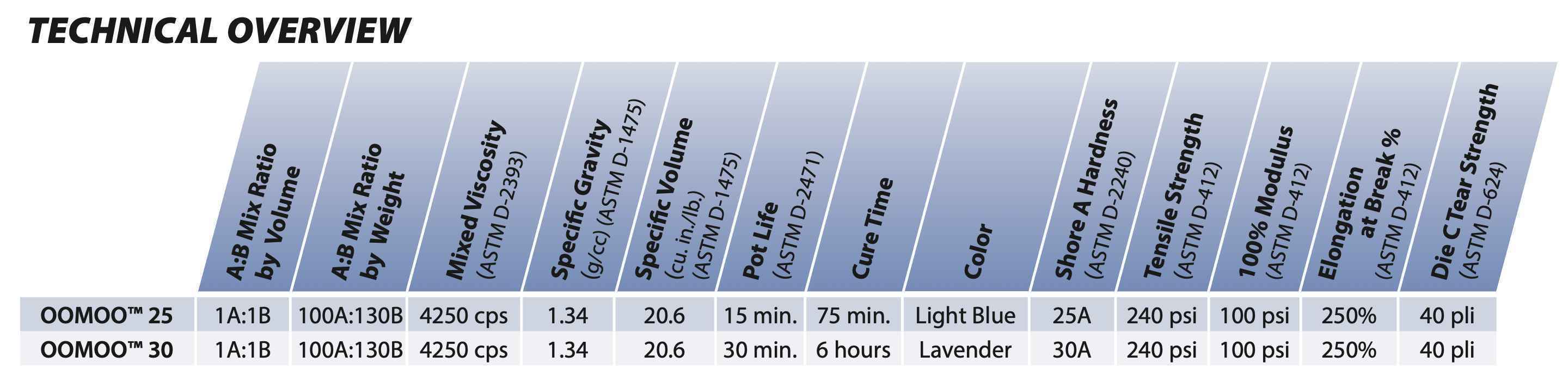

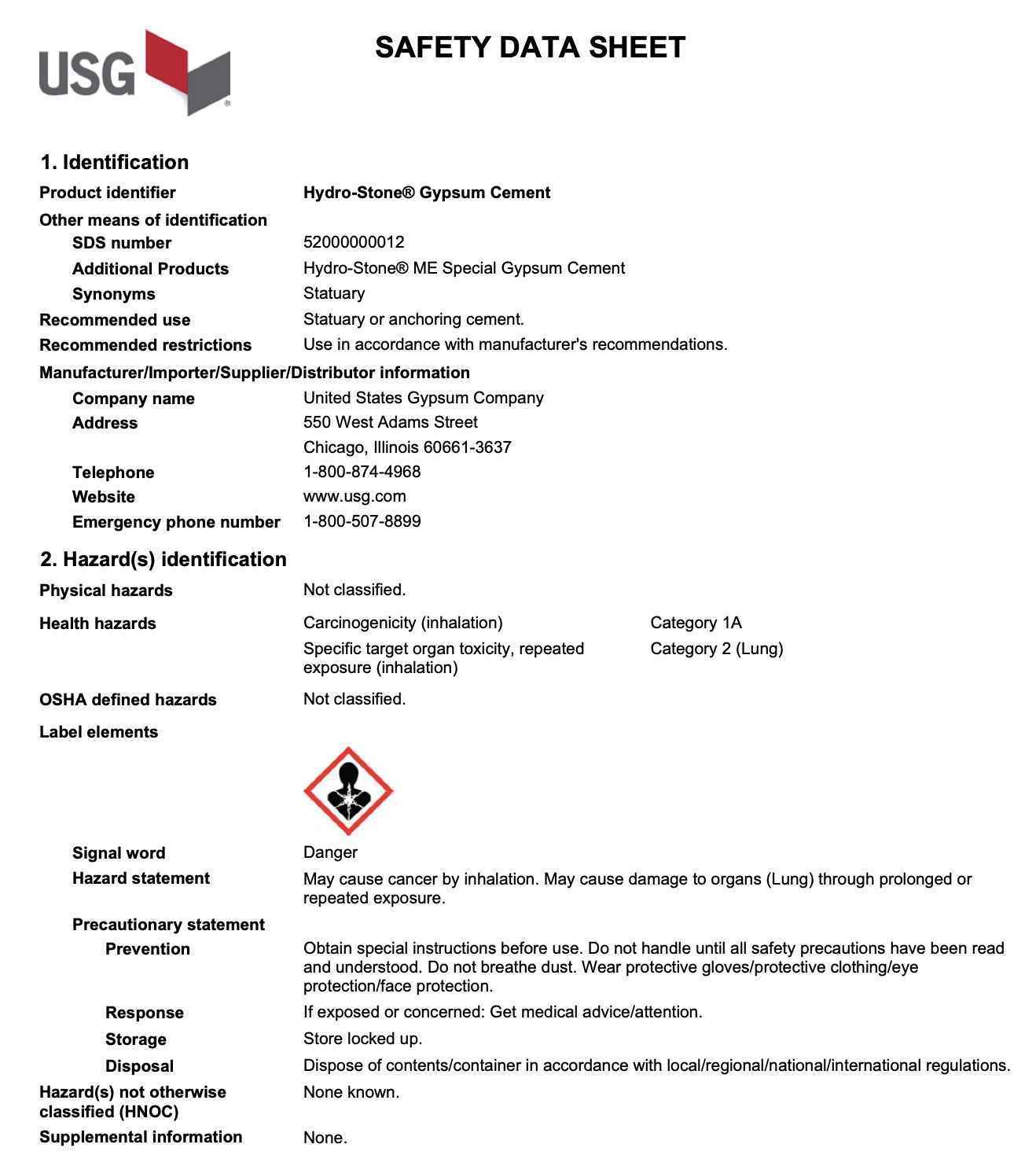

For this week's assignment, we were going to use silicone molds made from Oomoo, and then casting our negatives with Hydro-stone cement. Consequently, we needed to first look at the Safety Data Sheets (SDSs) for both, which are shown below.

The SDSs for both materials were fairly similar, and both had similar warnings. The main warnings were to avoid contact with skin and eyes, and to avoid breathing in the dust. The SDSs also recommended wearing gloves and safety glasses when handling the materials.

Casting and Molding Lego

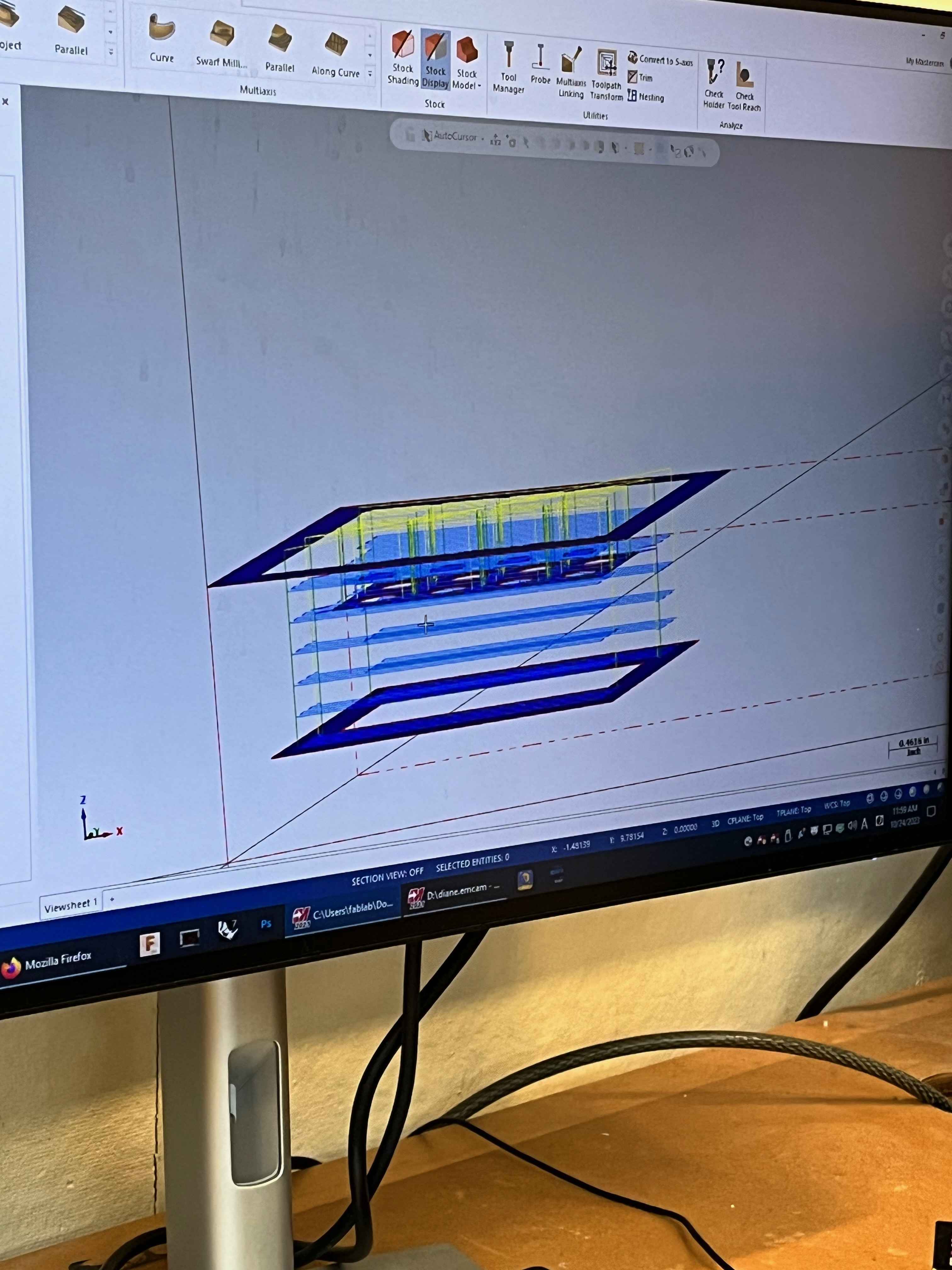

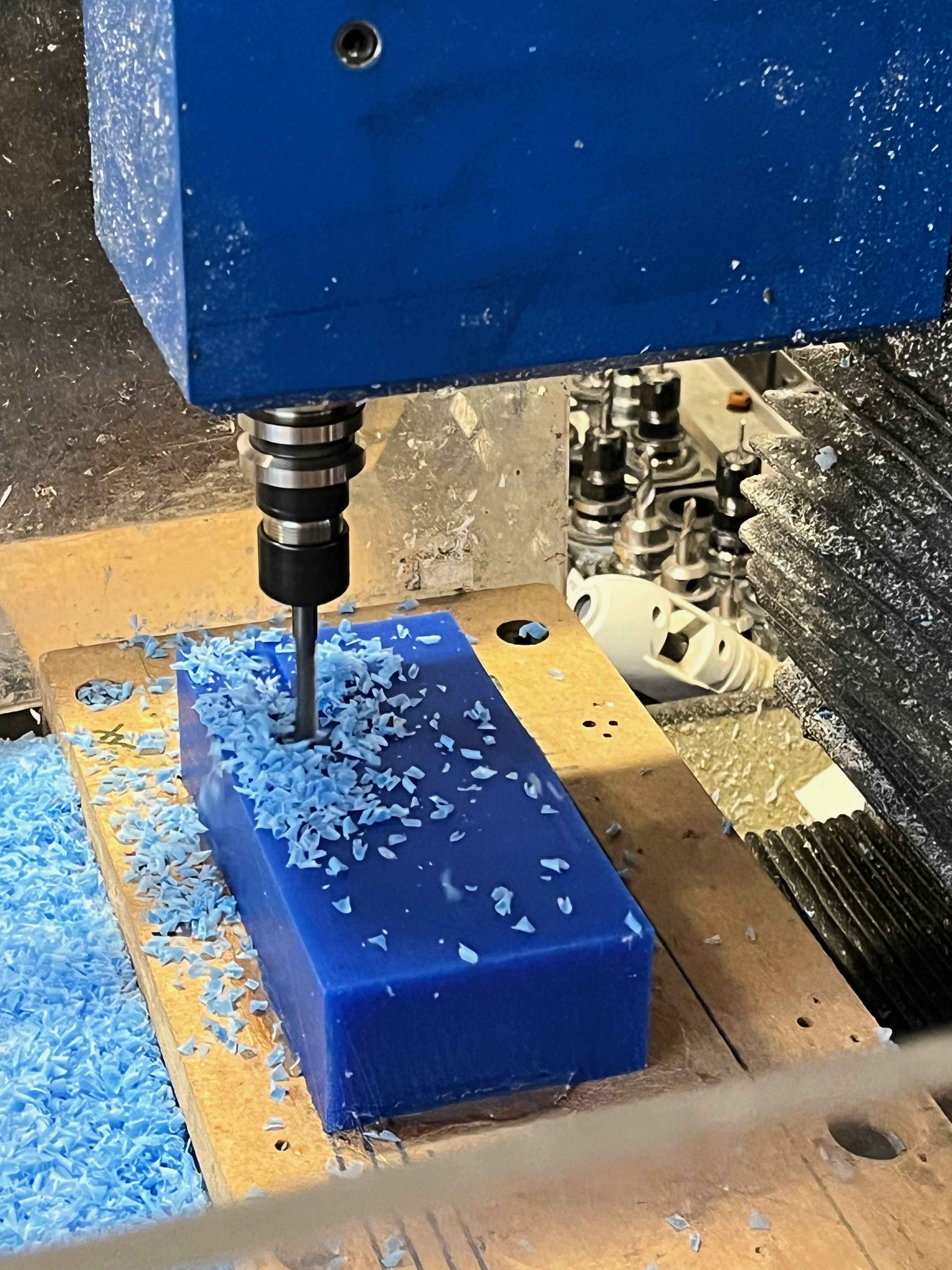

I wanted to make something with simple geometry that could easily be cast, but also recognizable. Since someone else had already made the house from Monopoly, I wanted to try my hand at the classic 2x4 Lego brick. It was trivial to CAD, and after sending my STEP file to Jen, we could begin milling right away after the CAM was setup.

'

'

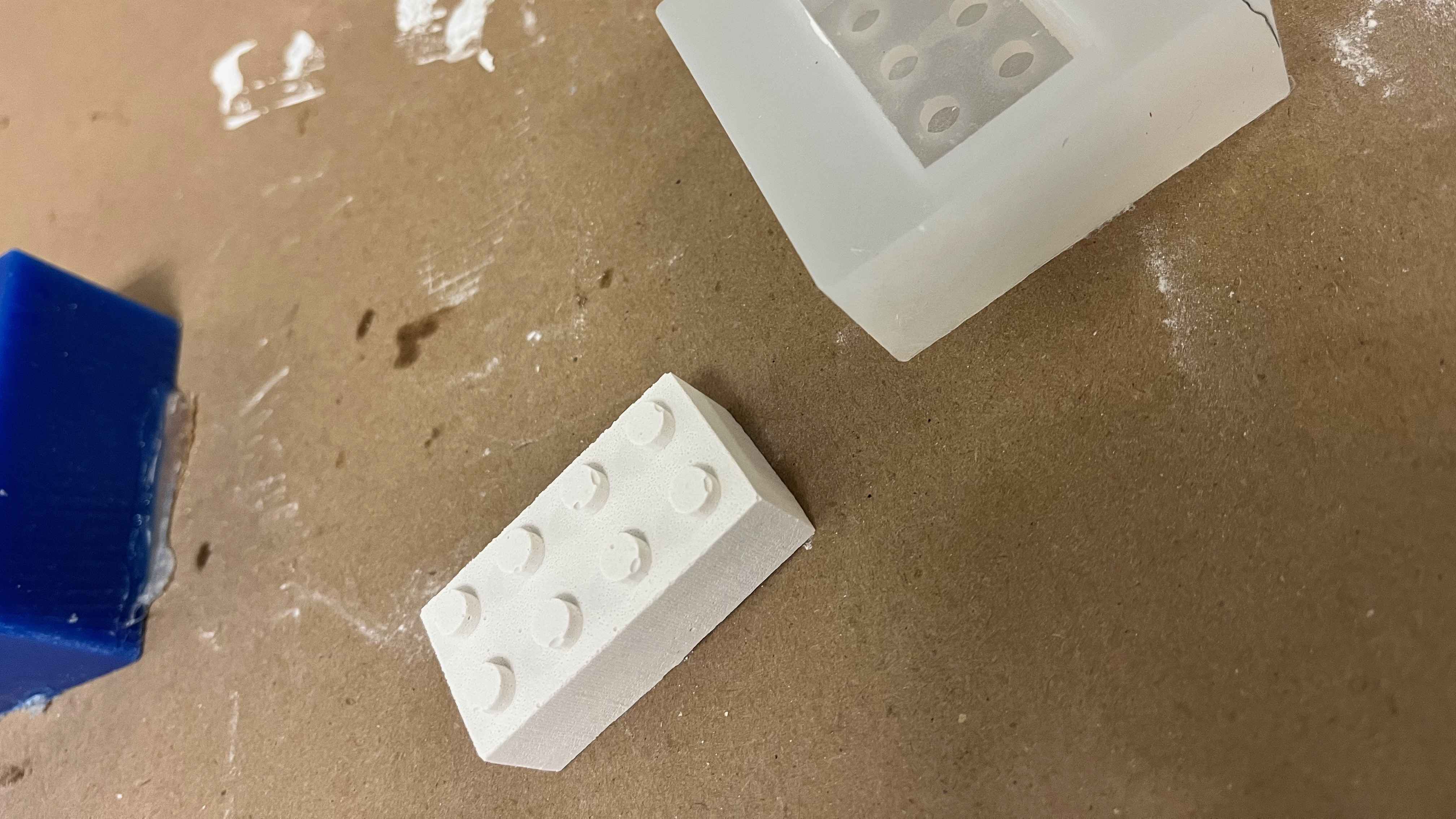

The positive was milled (although it could have been 3D printed), and I poured the Oomoo silicone mixture into a cup in a 1:1 ratio, and stirred the solution lightly. I then poured the mixture into the mold, and let it sit for around 2 hours.

Turns out, my eyeballed 1:1 ratio was completely wrong, and while most people's cured silicone mold were blue, mine remained a healthy white.

Finally, I poured in the Hydrostone cement mix into my negative mold, and I let it sit for another 2-3 hours. I was able to peel back the mold fairly easily, and I got my plaster Lego brick.

While I don't think I'll be using this process for my final project, I was happy with how clean the cast turned out. If I wanted to make 3D objects out of specific materials that couldn't easily be 3D printed, I would certainly want to try this again.