Motion-tracked Dragon Staff

made with all the maker skills

To Do

Individual Assignment

- Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, embedded microcontroller design, interfacing, and programming, system integration and packaging

- Prepare a summary slide and a one minute video showing its conception, construction, and operation

- Document a final project masterpiece that integrates the range of units covered, answering:

- What does it do? Track motion of a dragon staff.

- Who's done what beforehand? I have spun the staff before and modeled my design off of existing props.

- What did you design? I designed the dragon staff body, wick holders, electronics enclosure, PCB, and code to read data.

- What materials and components were used? PLA, copper clad, ESP32-S3, BNO055, steel tubes, Kevlar wicks

- Where did they come from? makerspace stock, fire spinning team stock, Adafruit, Dark Monk

- How much did they cost? Totalled $~75.

- What parts and systems were made? The dragon staff body and the electronic motion sensor were the primary parts made.

- What processes were used? 3D printing, CNC PCB milling, welding, networking and connections

- What questions were answered? How does the dragon staff move during successful runs and failed runs?

- What worked? What didn't? The 6-axis accelerometer worked, whereas the 9-axis one had burnt out due to my mishandling of the soldering iron. It's good that an earlier spiral worked.

- How was it evaluated? I evaluated by seeing if I could find the failure point in the accelerometer data.

- What are the implications? Now, I can better understand how the dragon staff behaves in relation to object manipulation.

Tools

- Software: Kicad, Onshape, Arduino IDE, Python

- Machines: laser cutter, 3D printer, PCB mill OtherMill

Materials

- PLA

- copper clad

- ESP32-S3

- BNO055

- steel tubes

- fire spinning wicks

- electronics components

I want to build a motion-tracked dragon staff for fire spinning. The input would be movement of the staff and the output would be a computer visualization of the movement.

To execute this project, I broke it down into smaller chunks:

1. Design the metal enclosure and electronic components

2. Weld the staff

3. Integrate the electronics into the staff

4. Test the motion of the staff

5. Create computer visualization with the data

To gain the skills needed to execute this project, I started asking around for help. My friend Audrey did a one-off MIG welding training for me, so now I know how to weld. I’m not very good, so I plan to go in to practice a few more welds before working on the dragon. As for the electronics, I chatted with some TAs about how to capture the movement of the staff. They recommended accelerometers and possibly camera detection.

Examples of dragon staff motion:

Failing at executing moves during spinning practice:

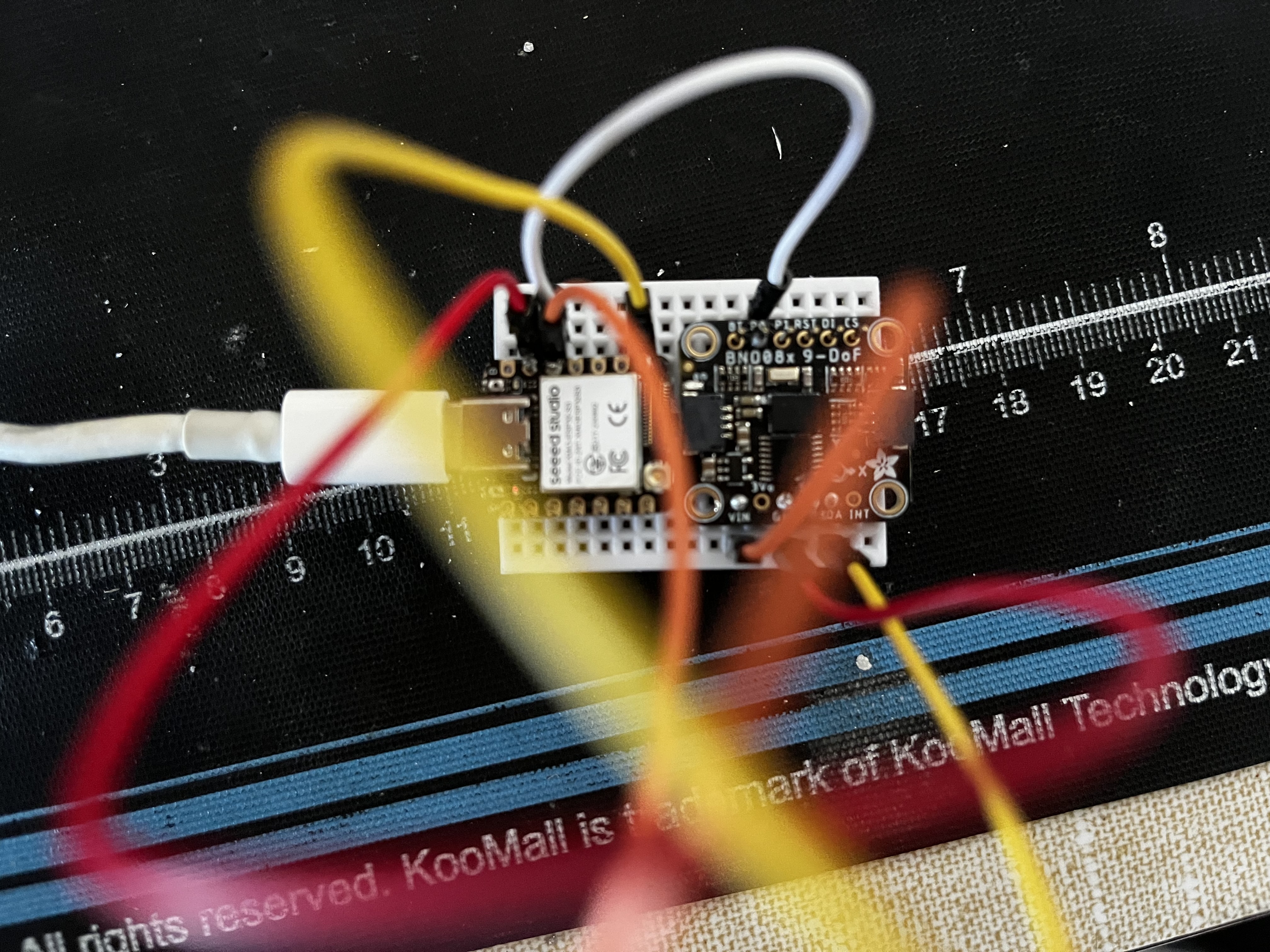

PCB Design

I designed the PCB in two main spirals: (1) interfacing with a 6-axis acc. and (2) interfacing with a 9-axis acc. I used an ESP32-S3, BNO055, Elegoo MEGA 2560 R3, and MPU 6050.

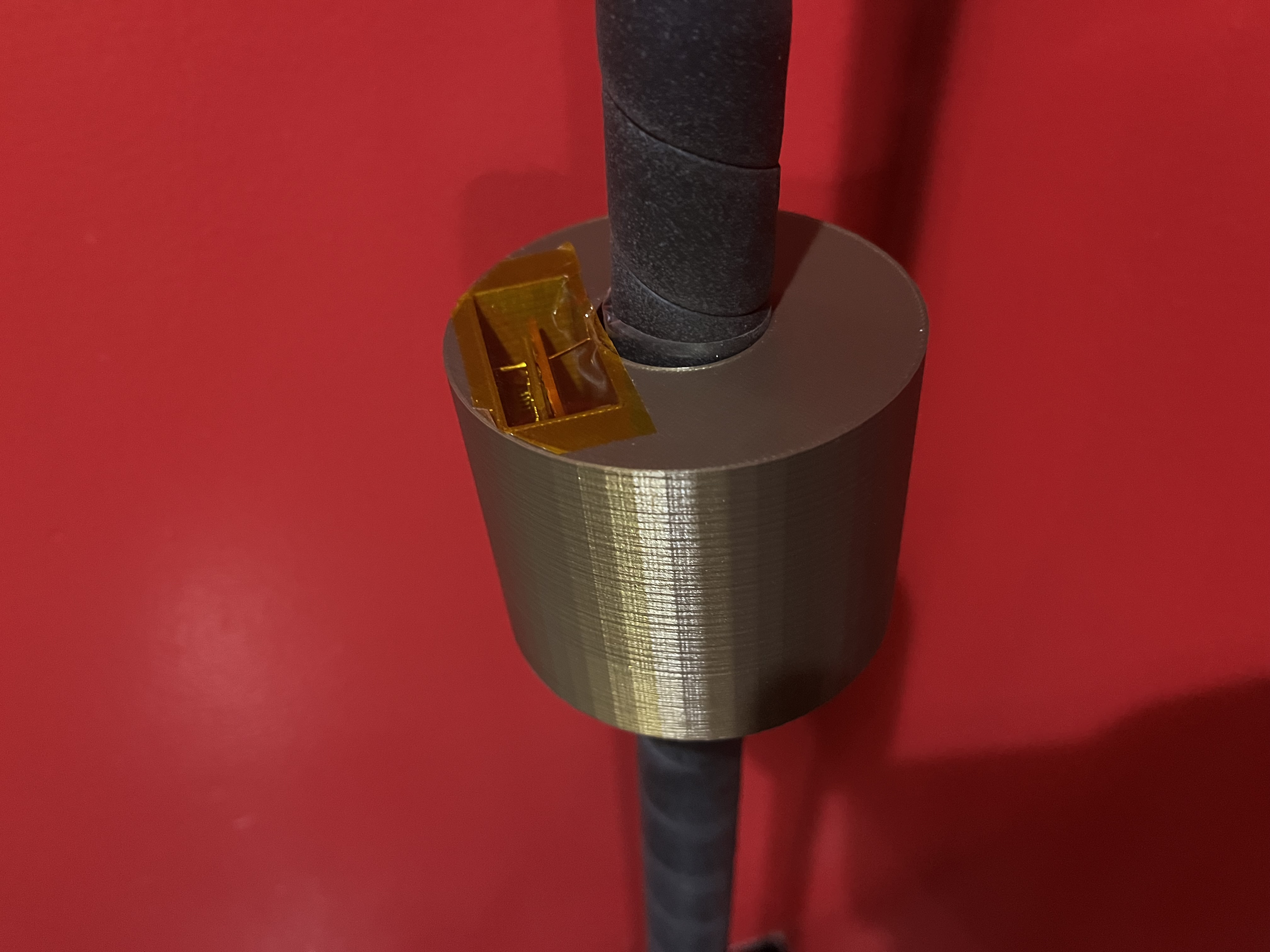

3D-printed Wick Mount

I designed custom wick holders for the staff so the staff. Working with existing wicks gave me a good creative restraint in that they had to be screwed in with M6 threads.

Integration of works

With both the dragon staff body and electronics finished, I had to integrate the two components together.

.jpg)

My friends and I celebrating the finale of the class during the open house:

We did it! Hurrah!