Week 4 - Group Assignment Summary

Embedded Microcontroller Test Equipment Observation

Assignment Overview

This page summarizes the group assignment for Week 5, where we used test equipment in our lab to observe the operation of an embedded microcontroller. This hands-on experience provided valuable insights into microcontroller behavior, signal analysis, and debugging techniques.

For complete detailed information, visit: Week 4 Group Assignment Section

Group Assignment: Test Equipment Observation

Use the test equipment in your lab to observe the operation of an embedded microcontroller.

Test Equipment Available

The following test equipment was utilized to observe and analyze microcontroller operation. Multimeter and oscilloscope provide 99% of the information needed for comprehensive analysis.

Multimeter

Essential for basic measurements - voltages (slow, twice a second), resistances, and current (in series)

Oscilloscope

High-speed analysis - voltages (fast, 5 million times a second) and digital signal decoding

Logic Analyzer

Digital signal analysis - both cheap and professional models available, can also be done on oscilloscope

Function Generator

Signal generation for testing receiving ends of boards - most scopes have built-in generators

Power Supply

Controlled power delivery for stable microcontroller operation

Breadboard

Circuit prototyping and testing platform

Test Equipment Procedures & Observations

Detailed procedures and observations using various test equipment to analyze microcontroller operation:

Multimeter Measurements

Ideal for measuring supply voltages and DC levels

Essential for continuity testing and fault finding

Critical for power consumption analysis

Press function twice for portable multimeter operation

Oscilloscope Analysis

Captures fast transients and digital signal transitions

Proper grounding essential for accurate measurements

Higher than expected noise levels observed

Consistent ripple characteristics across voltage rails

Electrocardiogram (ECG) Testing

Essential for clean ECG signal acquisition

Optimal for detecting cardiac electrical activity

Potential application for final project development

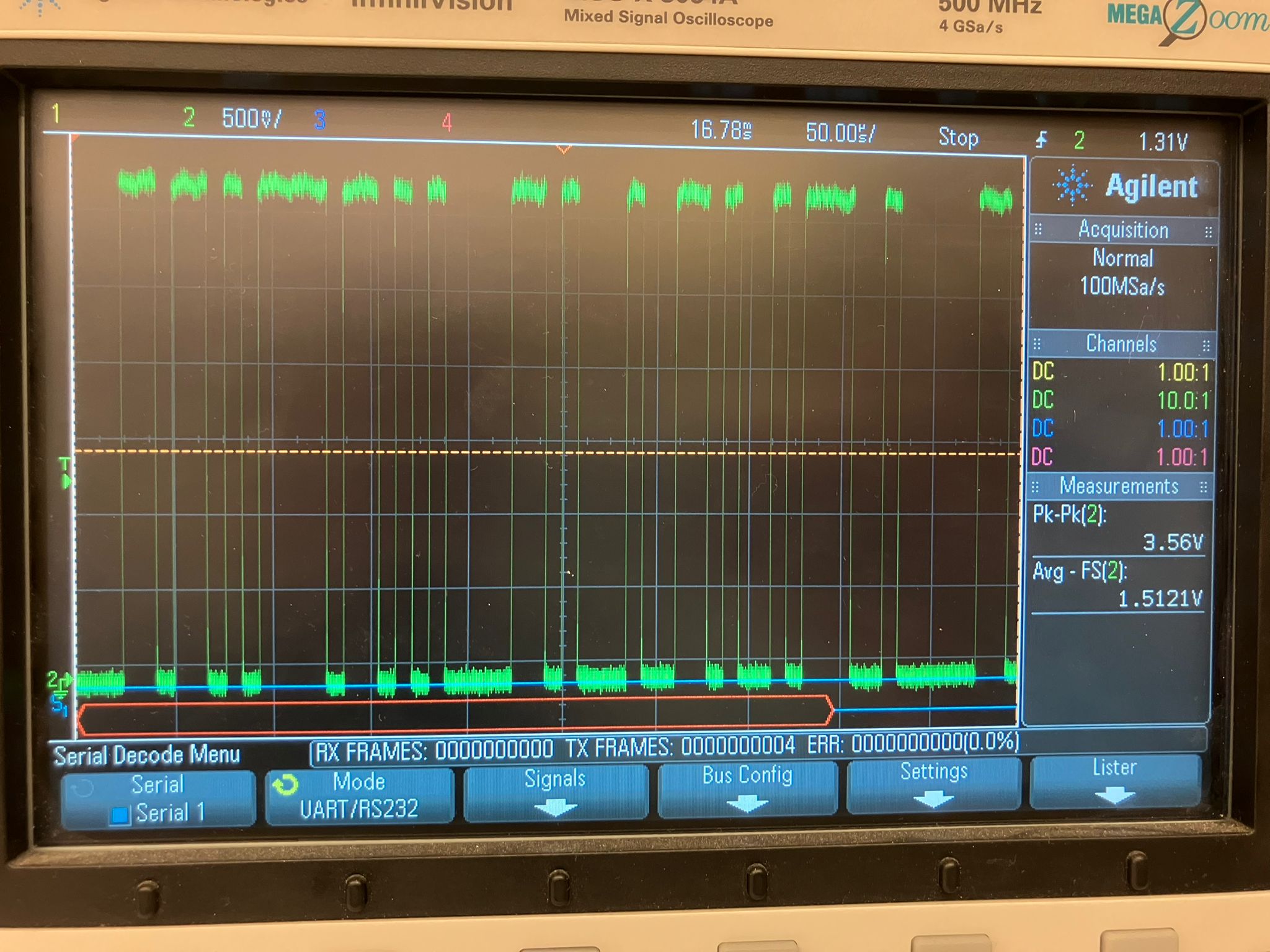

Digital Signal Decoding

Systematic testing of serial data transmission

Proper configuration essential for signal interpretation

Manual decoding reveals transmitted data content

Serial Signal Analysis: Oscilloscope capture showing digital serial communication signals with clear 1s and 0s pattern, enabling ASCII character decoding and protocol verification.

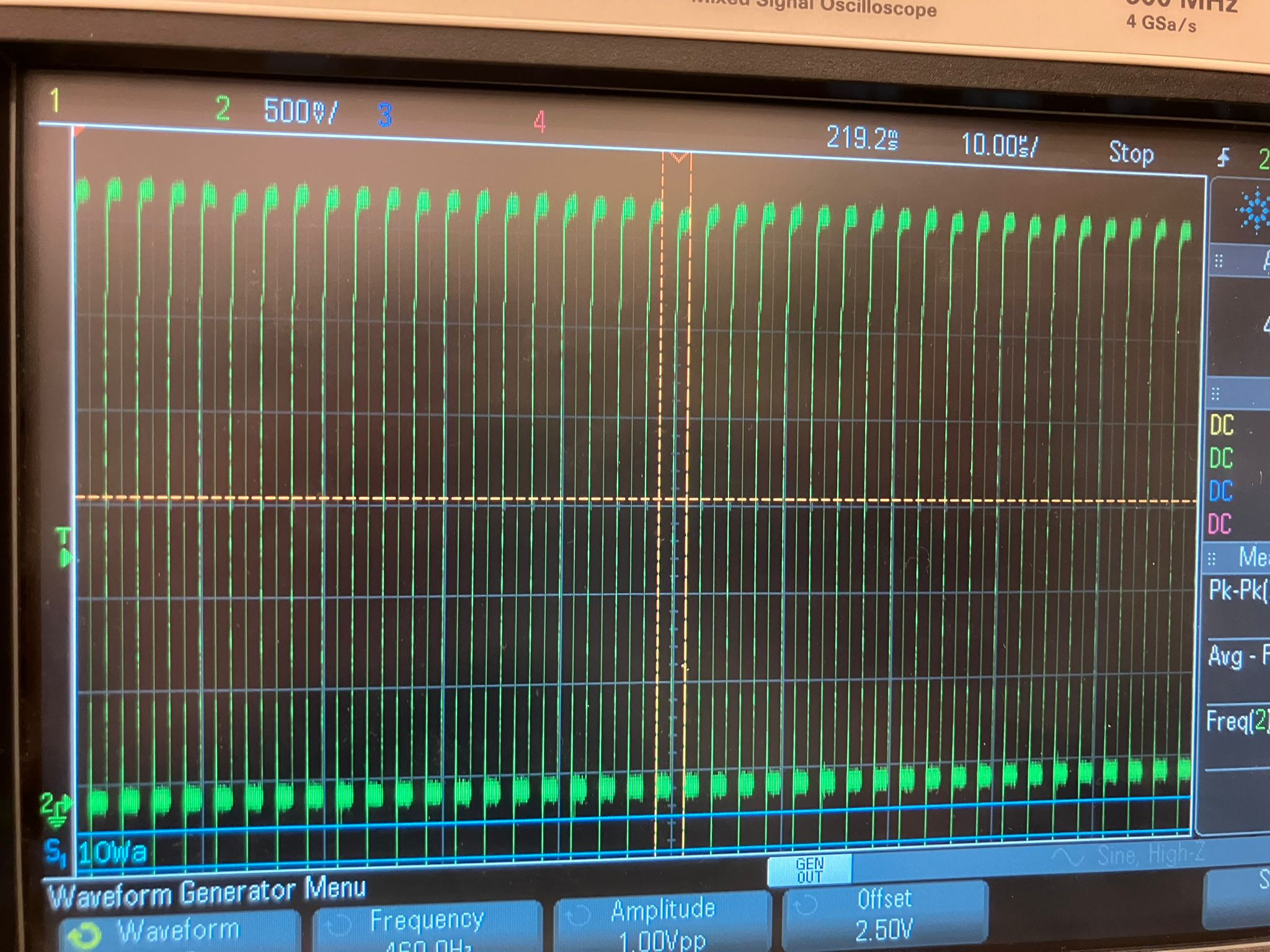

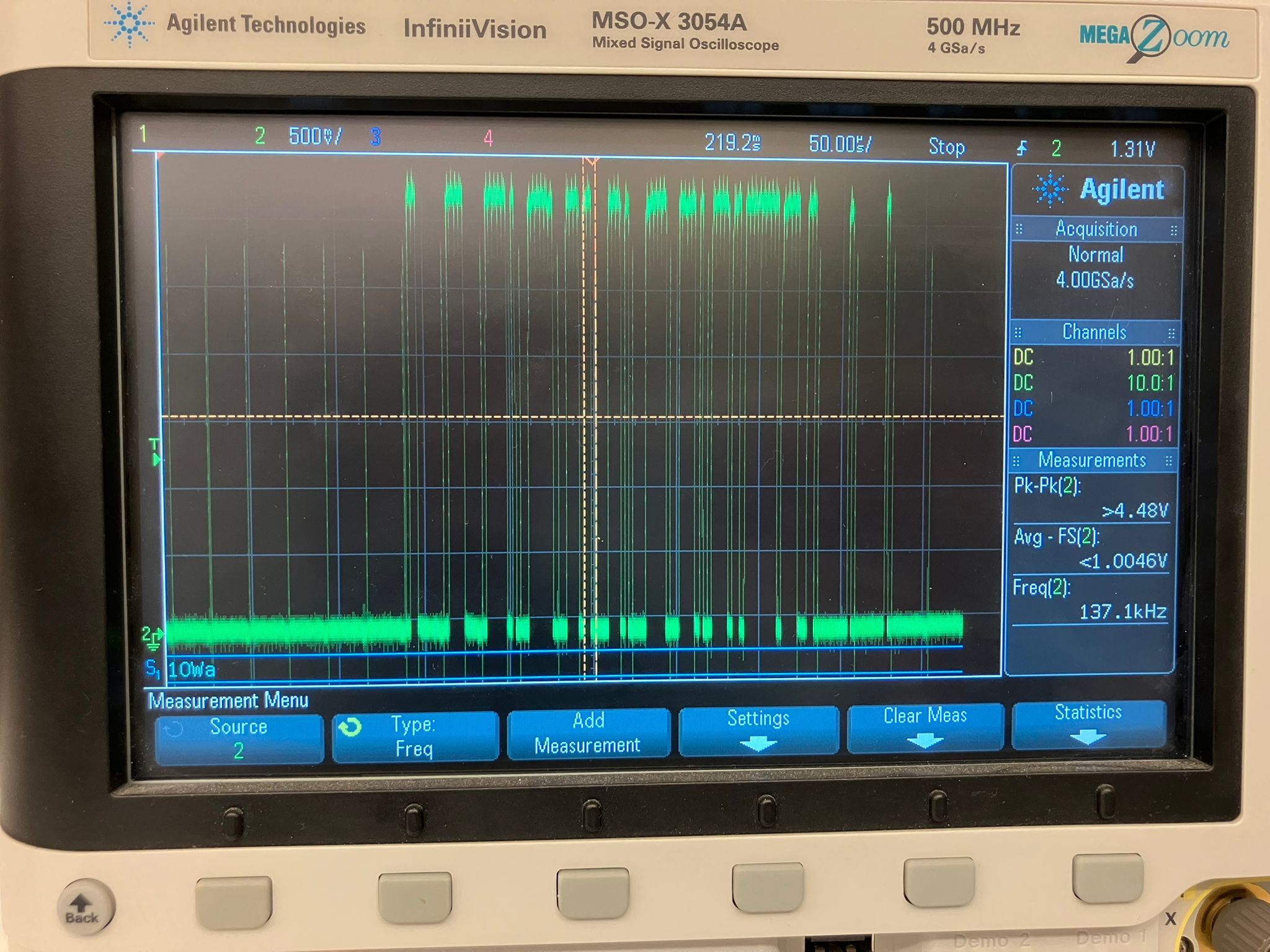

I2C Communication Analysis

Standard I2C clock frequency for fast mode

Data changes on SCL falling edge, stable during SCL high

Confirms correct I2C implementation

SCL Clock Signal: Oscilloscope capture of I2C SCL (Serial Clock) line showing clean 400kHz square wave with proper falling edge timing for data synchronization.

SDA Data Signal: Oscilloscope capture of I2C SDA (Serial Data) line showing data bits changing on SCL falling edges, demonstrating proper I2C protocol timing and data transmission.

Signal Generation Testing

Validates input circuit functionality

Convenient all-in-one testing solution

Enables advanced biomedical signal analysis

Test Equipment Setup Procedures

Oscilloscope Probing Setup:

- Plug alligator clip of ground probe to ground reference

- Use main probe clip to probe signal pins

- Adjust oscilloscope view for optimal signal display

- Start with 5V supply pin for initial voltage verification

Multimeter Continuity Testing:

- Set multimeter to resistance mode

- Press 'select' function for continuity mode

- Device beeps when resistance is under 50 ohms

- Press function twice for portable multimeter operation

Measurement Techniques

Systematic Approach: We employed a systematic approach to observe microcontroller operation, starting with basic power supply verification and progressing to complex signal analysis. This methodology ensured comprehensive coverage of all critical operational aspects.

Each measurement was documented with specific test conditions, equipment settings, and observed results to provide a complete picture of microcontroller behavior under various operating conditions.

Key Findings & Practical Applications

Comprehensive analysis of test equipment effectiveness and real-world applications:

🔌 Power Supply Analysis

📊 Multimeter Effectiveness

📈 Oscilloscope Capabilities

📡 Serial Communication

🔗 I2C Protocol

❤️ ECG Signal Capture

⚙️ Equipment Integration

🎯 Equipment Selection

Special Thanks to Our Section

We would like to express our sincere gratitude to all members of our section for their invaluable collaboration throughout this group assignment. Your contributions were essential to the success of this comprehensive microcontroller observation project.

Collaboration Activities

- Equipment setup and calibration

- Measurement coordination and data collection

- Signal analysis and interpretation

- Documentation and result sharing

Knowledge Sharing

- Test equipment operation techniques

- Measurement best practices and tips

- Signal analysis methodologies

- Troubleshooting strategies and insights

This collaborative effort demonstrates the power of teamwork in technical education and hands-on learning. The collective knowledge and shared experiences significantly enhanced our understanding of microcontroller operation and test equipment usage.

References

- Course Materials

Embedded systems lecture notes and technical documentation - Lab Equipment Manuals

Oscilloscope, multimeter, and logic analyzer operation guides - Microcontroller Datasheets

Technical specifications and electrical characteristics - Test Equipment Documentation

Equipment-specific measurement procedures and best practices - Full Assignment Details: https://fab.cba.mit.edu/classes/863.25/people/SaleemAldajani/week4.html#group-assignment

Complete detailed documentation and results

Ethical AI Use

Documentation of AI tool usage for this week's group assignment summary and website development work.

Week 5 - Group Assignment Summary Development

This session covers the development of the Week 5 page for the embedded microcontroller test equipment observation group assignment, including content structure, technical documentation, and comprehensive coverage of microcontroller analysis areas.

AI Development Documentation

Complete development transcript documenting the AI-assisted creation of the Week 5 group assignment page, including content structure, technical documentation, and website development process.

Key AI Activities

- Content Structure

Creation of comprehensive HTML structure for microcontroller observation documentation - Technical Documentation

Development of detailed sections covering various aspects of microcontroller analysis - Equipment Integration

Implementation of test equipment information and measurement techniques - Navigation Integration

Addition of Week 5 link to main index page for seamless course navigation

AI Tools Used

- Cursor AI

Code generation, content structuring, and website development assistance - Technical Content Generation

Creation of comprehensive microcontroller observation documentation - Website Design

Implementation of consistent styling and responsive layout