![[Profile Image Placeholder]](profile.jpg)

Week 4

Electronics Design

Week Highlights

This week focuses on electronics design using EDA tools to create embedded microcontroller systems. We'll learn schematic design, PCB layout, design rule checking, and simulation techniques.

Table of Contents

Course Content

Training & Documentation

Electronics Design Week

This week introduces Electronic Design Automation (EDA) tools for creating embedded microcontroller systems. We'll learn to design schematics, create PCB layouts, perform design rule checks, and simulate circuit operation before fabrication.

This Week's Goals

- Master EDA Tools

Learn KiCad or Eagle for schematic capture and PCB layout design - Design Embedded System

Create a complete microcontroller system using parts from the Fab inventory - Simulate & Verify

Use simulation tools to verify circuit operation before fabrication - Test Equipment Proficiency

Learn to use oscilloscopes, multimeters, and other test equipment

Assignments

- Group Assignment

Use test equipment to observe embedded microcontroller operation - Individual Assignment

Design embedded system with EDA tool, check design rules, and simulate

Tools & Materials

- EDA Software

KiCad, Eagle, or Altium Designer - Test Equipment

Oscilloscope, multimeter, function generator - Simulation Tools

LTspice, ngspice, Wokwi - Fab Inventory Parts

Microcontrollers, passive components, connectors

Training Documentation

Essential training materials for electronics design, EDA tools, and test equipment operation.

EDA Tool Training

- KiCad schematic capture

- PCB layout and routing

- Design rule checking

- Footprint libraries

Test Equipment

- Oscilloscope operation

- Multimeter measurements

- Function generator setup

- Probe calibration

Useful Documentation

Essential resources for electronics design, EDA tools, and embedded systems development.

EDA Tools & Software

- KiCad — Open-source EDA suite

- Eagle — Professional PCB design

- Altium Designer — Advanced PCB design

- Wokwi — Online Arduino simulator

Simulation & Testing

- LTspice — Circuit simulation

- ngspice — Open-source SPICE

- Falstad Circuit — Interactive simulation

- Fab Inventory — Available components

Test Equipment Guides

- Oscilloscope Basics — Tektronix tutorial

- Multimeter Usage — SparkFun guide

- MIT Academy Electronics Design — Course reference

Design Guidelines & EDA Tools

Key design rules and EDA tool recommendations from course Slack discussions.

PCB Design Rules

- 1 mil = 0.001 inches (not millimeters!)

- Trace width: >10mil minimum

- Trace spacing: >16mil between traces

- Component sizes: ~1206 or larger recommended

- Flexibility: Break out extra pins, multiple power/ground copies

Microcontroller Options

- Xiao: All-in-one, multiple footprint choices

- ATtiny/SAMD: More parts but powerful and cheap

- Note: Tape-bottomed components need Kapton tape

EDA Tool Options

Leo's Open Source Tool

Easiest starting point for this class

KiCad

Open source, widely used, improved UI

Fusion 360

Cloud-synced part libraries, team access

Feedback Available: Send schematic/PCB files and screenshots for design review. View Design Guidelines Discussion • View EDA Tools Discussion

Class Week Resources

Official course resources for electronics design and EDA tools.

Lecture Information

-

Electronics Design - MIT Academy

Comprehensive resource covering electronics design principles, EDA tools, circuit simulation, PCB design, and embedded systems development. Includes tutorials on KiCad, Eagle, and other EDA platforms.

Recitation Information

-

Electronics Design Recitation - Vimeo

Hands-on tutorial covering electronics design workflows, EDA tool usage, circuit simulation techniques, and PCB design best practices for embedded systems development.

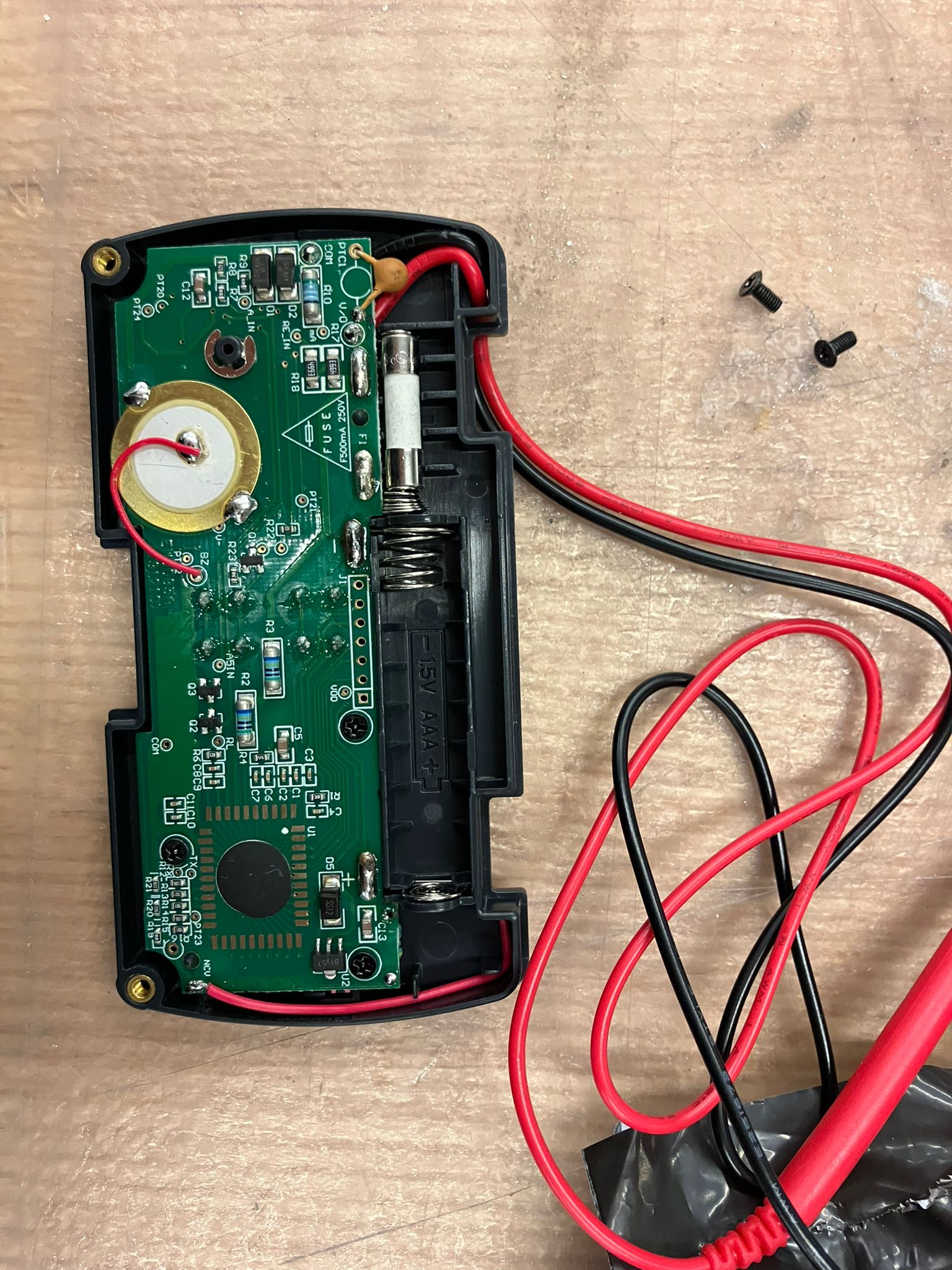

Group Assignment: Test Equipment Operation

Use the test equipment in your lab to observe the operation of an embedded microcontroller. This assignment focuses on understanding how to use oscilloscopes, multimeters, and other test equipment to analyze microcontroller behavior and circuit operation.

Group Assignment Link: View Complete Group Assignment Summary

Test Equipment Available

The following test equipment was utilized to observe and analyze microcontroller operation. Multimeter and oscilloscope provide 99% of the information needed for comprehensive analysis.

Multimeter

Essential for basic measurements - voltages (slow, twice a second), resistances, and current (in series)

Oscilloscope

High-speed analysis - voltages (fast, 5 million times a second) and digital signal decoding

Logic Analyzer

Digital signal analysis - both cheap and professional models available, can also be done on oscilloscope

Function Generator

Signal generation for testing receiving ends of boards - most scopes have built-in generators

Power Supply

Controlled power delivery for stable microcontroller operation

Breadboard

Circuit prototyping and testing platform

Test Equipment Procedures & Observations

Detailed procedures and observations using various test equipment to analyze microcontroller operation:

Multimeter Measurements

- Voltage Measurements: Slow sampling rate (twice per second) for steady-state analysis

- Resistance Testing: Component and trace resistance verification

- Current Measurement: Series connection required for accurate current readings

- Continuity Testing: Resistance mode then 'select' for continuity (beeps under 50 ohms)

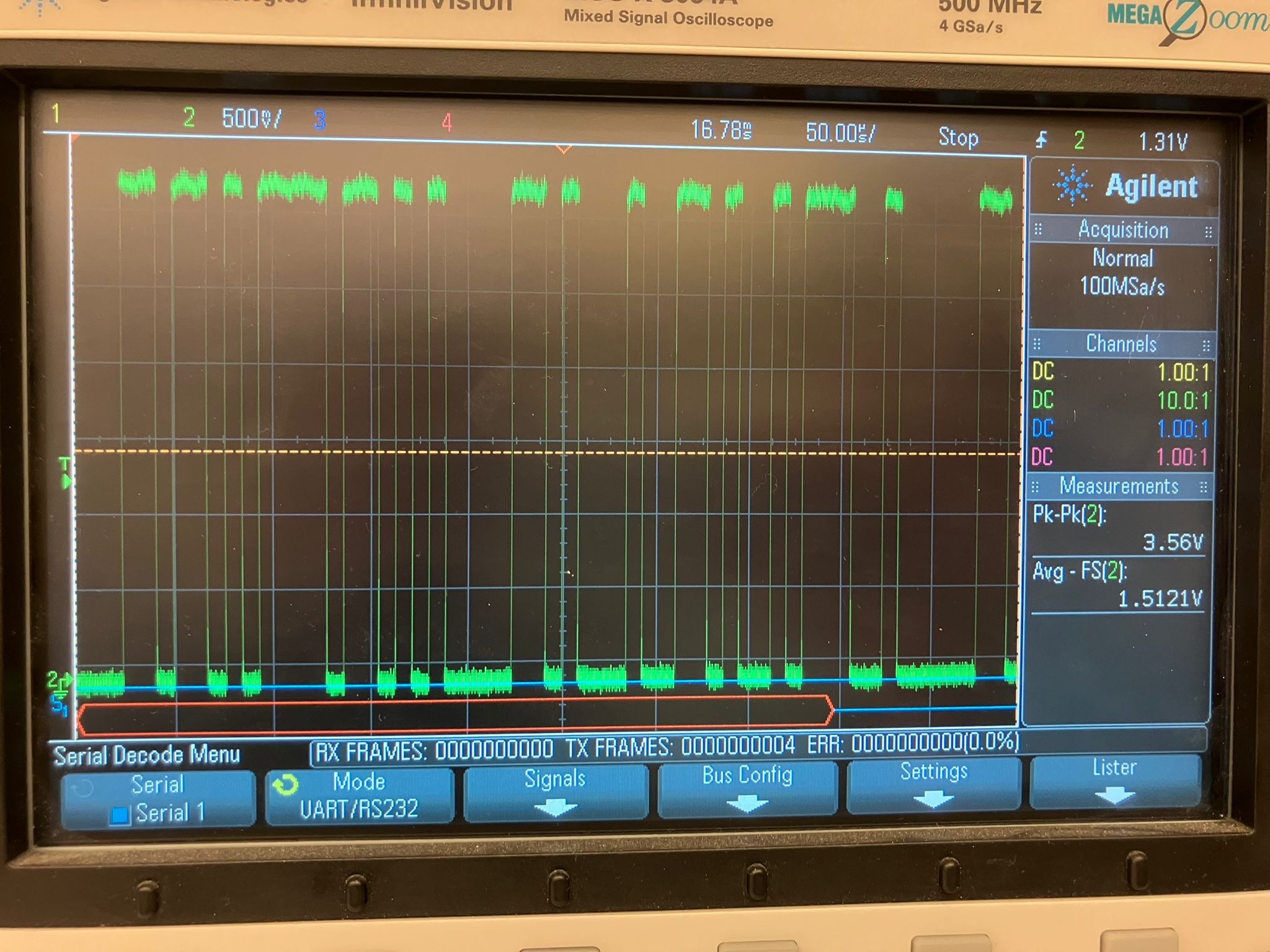

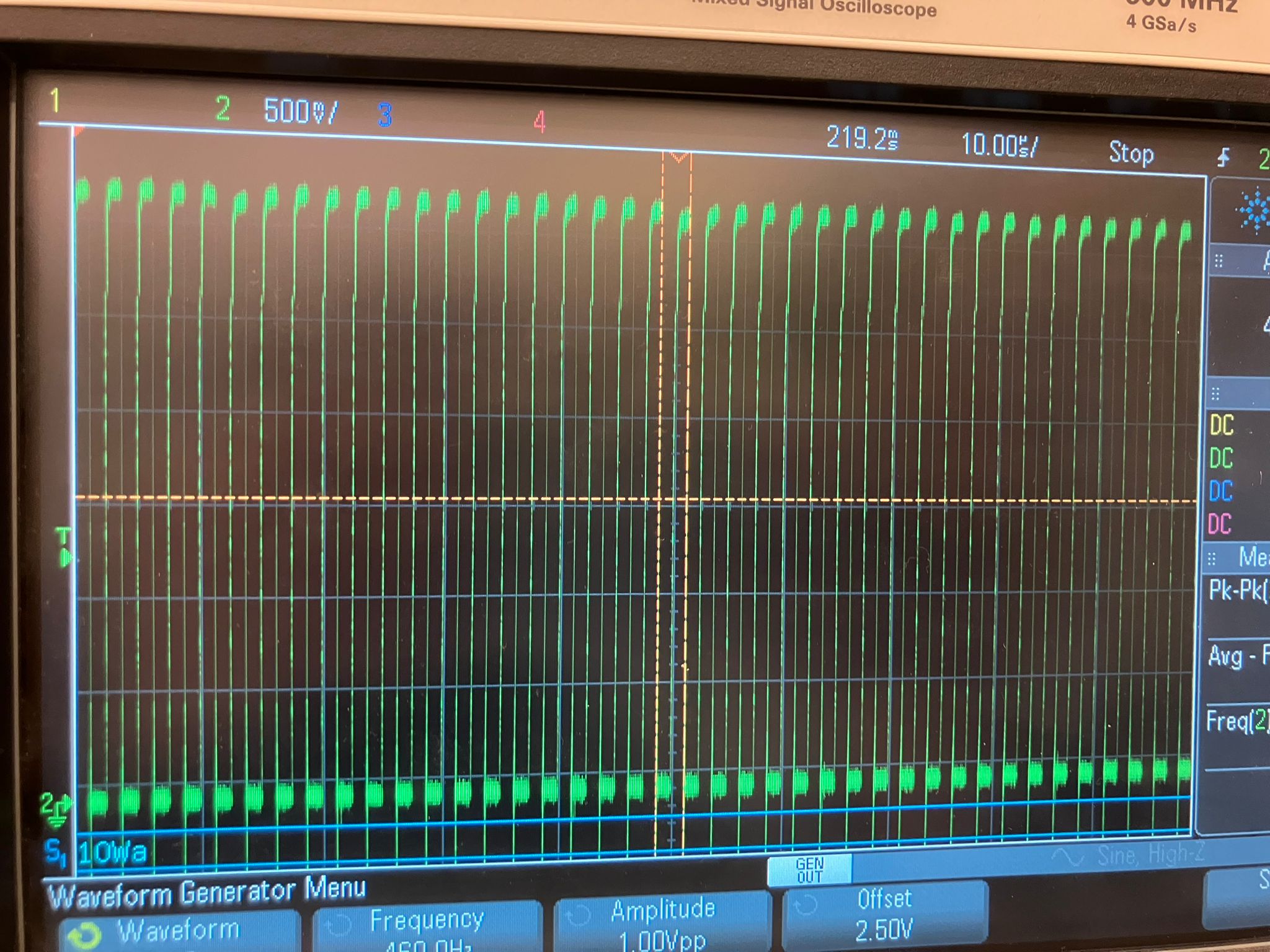

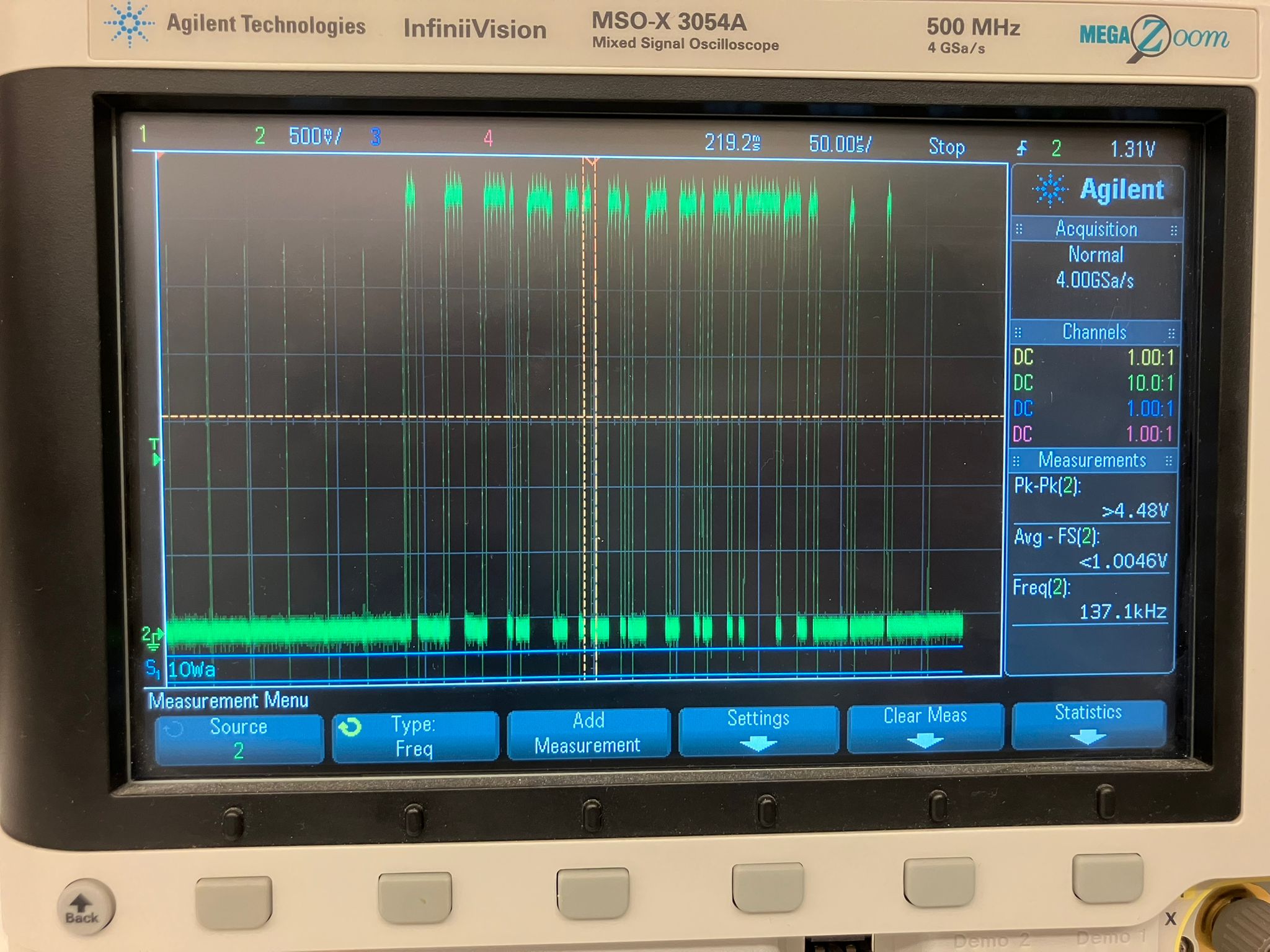

Oscilloscope Analysis

- High-Speed Sampling: 5 million times per second for detailed signal analysis

- Probing Technique: Ground alligator clip to ground, main probe to signal pins

- 5V Supply Analysis: Measured 4.96V actual with ~300mV noise/ripple

- 3.3V Supply Analysis: Measured 3.23V actual with similar ~300mV ripple

Serial Communication Analysis

Digital signal decoding and serial communication protocol analysis using oscilloscope capabilities.

Serial Signal Analysis: Oscilloscope capture showing digital serial communication signals with clear 1s and 0s pattern, enabling ASCII character decoding and protocol verification.

I2C Communication Analysis

- SCL Clock Line: 400 kHz square wave observed (falling edge trigger)

- SDA Data Line: Serial data stream of 1s and 0s

- Protocol Verification: Proper start/stop conditions and addressing observed

ECG Signal Testing

- Low-Pass Filter Setup: Configure oscilloscope with low-pass filter

- Probe Placement: Shoulder-to-shoulder probe positioning

- Signal Observation: Clear electrocardiogram waveform captured

SCL Clock Signal: I2C SCL line showing clean 400kHz square wave

SDA Data Signal: I2C SDA line showing data bits changing on SCL falling edges

Key Findings & Practical Applications

Comprehensive analysis of test equipment effectiveness and real-world applications:

Power Supply Analysis

- 5V Rail: Measured 4.96V with ~300mV noise/ripple

- 3.3V Rail: Measured 3.23V with similar ripple characteristics

- Application: Understanding noise characteristics for stable operation

Equipment Effectiveness

- Multimeter: Essential tool providing 99% of needed information

- Oscilloscope: High-speed sampling (5MHz) for detailed analysis

- Integration: Most oscilloscopes include built-in signal generators

Test Equipment Setup Procedures

Oscilloscope Probing Setup:

- Plug alligator clip of ground probe to ground reference

- Use main probe clip to probe signal pins

- Adjust oscilloscope view for optimal signal display

- Start with 5V supply pin for initial voltage verification

Multimeter Continuity Testing:

- Set multimeter to resistance mode

- Press 'select' function for continuity mode

- Device beeps when resistance is under 50 ohms

- Press function twice for portable multimeter operation

Key Learnings

Understanding how to properly probe circuits, interpret oscilloscope traces, and use test equipment to diagnose embedded system operation. This foundation is essential for debugging and verifying circuit designs before and after fabrication. The systematic approach starting with basic power supply verification and progressing to complex signal analysis ensures comprehensive coverage of all critical operational aspects.

Individual Assignment: EDA Design & Simulation

Use an EDA tool to design an embedded microcontroller system using parts from the inventory, check its design rules for fabrication, and simulate its operation. This assignment involves complete schematic capture, PCB layout, design rule checking, and circuit simulation.

Fusion360 Design Process

Complete step-by-step workflow for designing embedded systems in Fusion360 EDA:

Schematic Design Steps

-

1

Add board outline and define board dimensions

-

2

Add switch component and configure properties

-

3

Add LED component with proper orientation

-

4

Add resistor for current limiting

-

5

Add net connectors for dev board integration

PCB Layout Steps

-

6

Switch to PCB view and arrange components

-

7

Ensure no component overlaps

-

8

Route traces (flip and add holes if needed)

-

9

Resize board and create polygon pour

-

10

Add mounting holes and finalize design

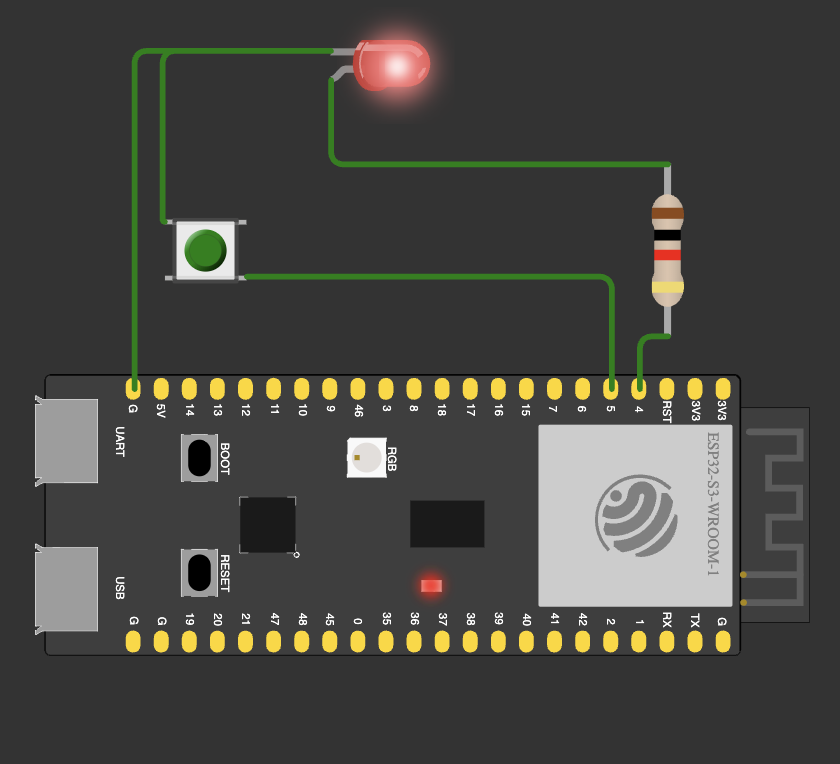

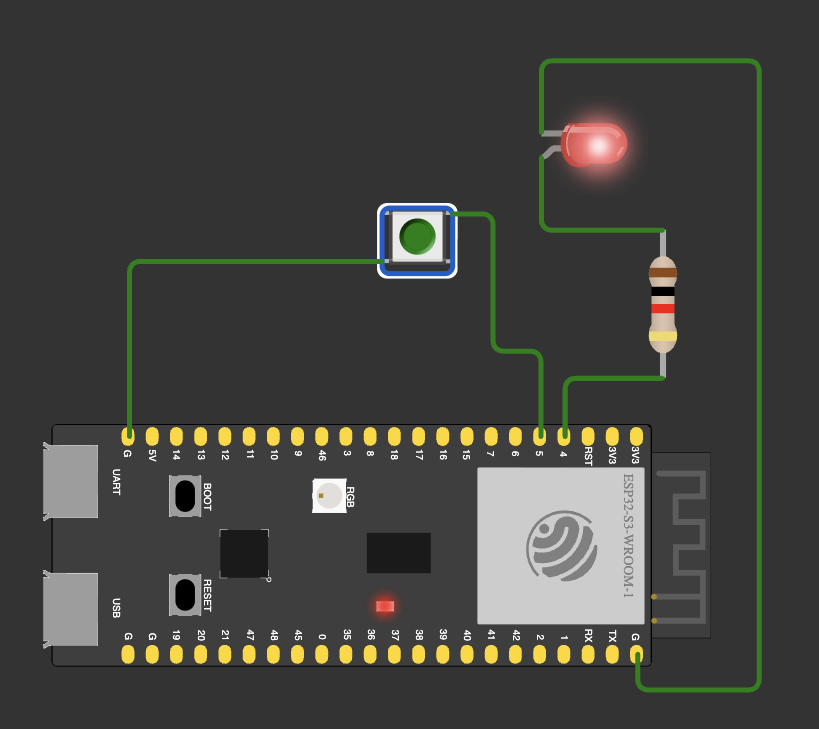

Simulation: After completing the PCB design, remake the circuit in simulation websites like Wokwi to verify operation before fabrication.

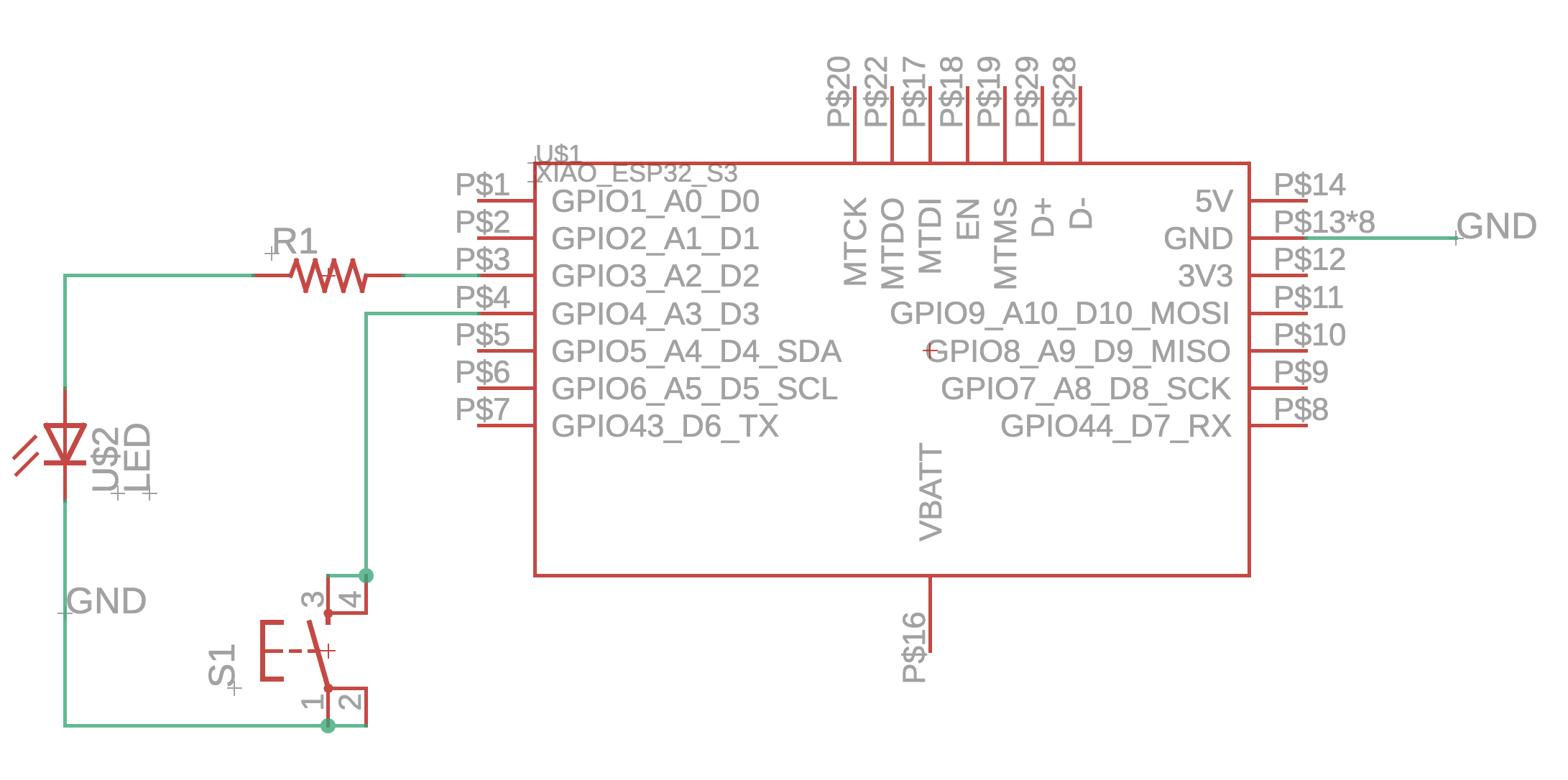

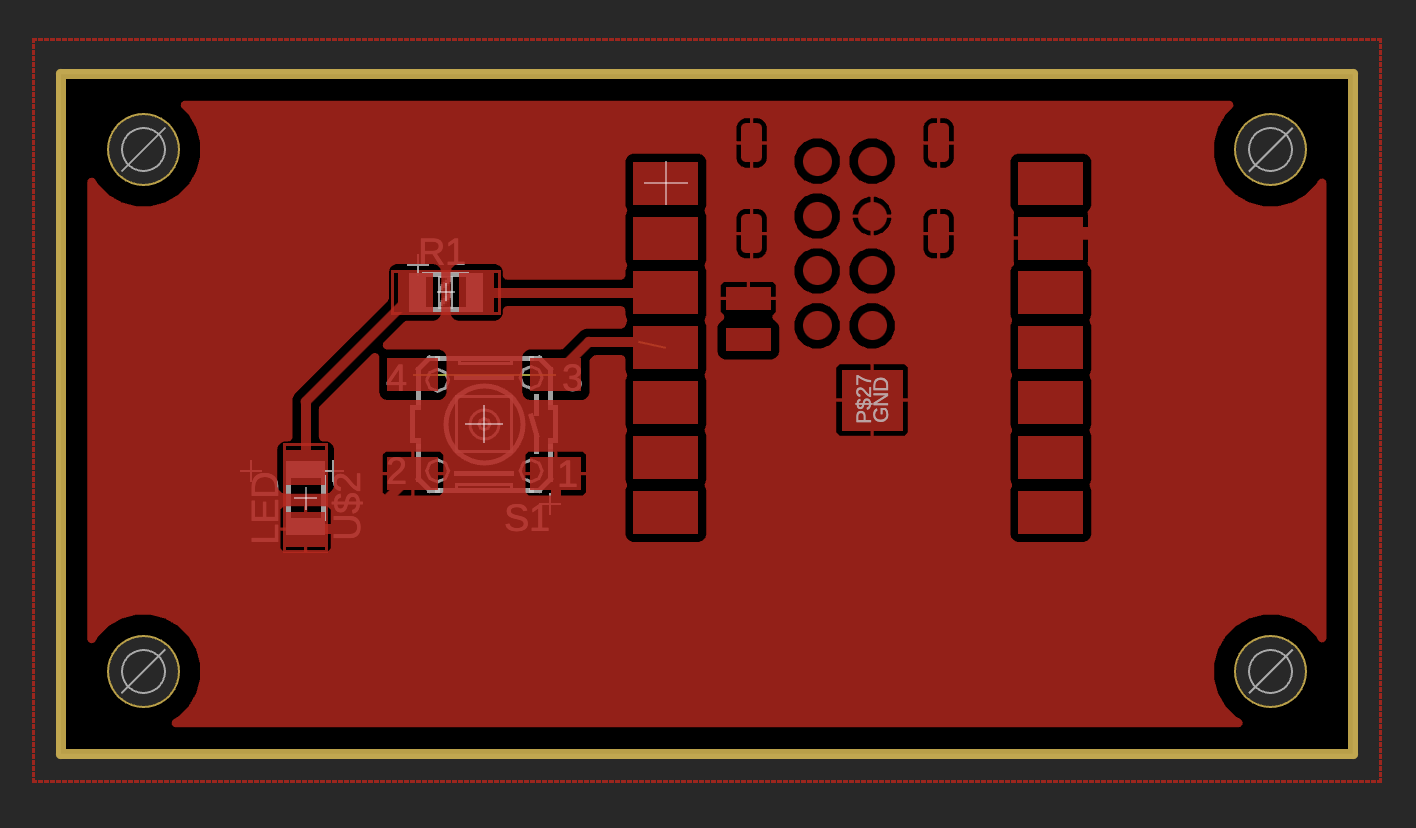

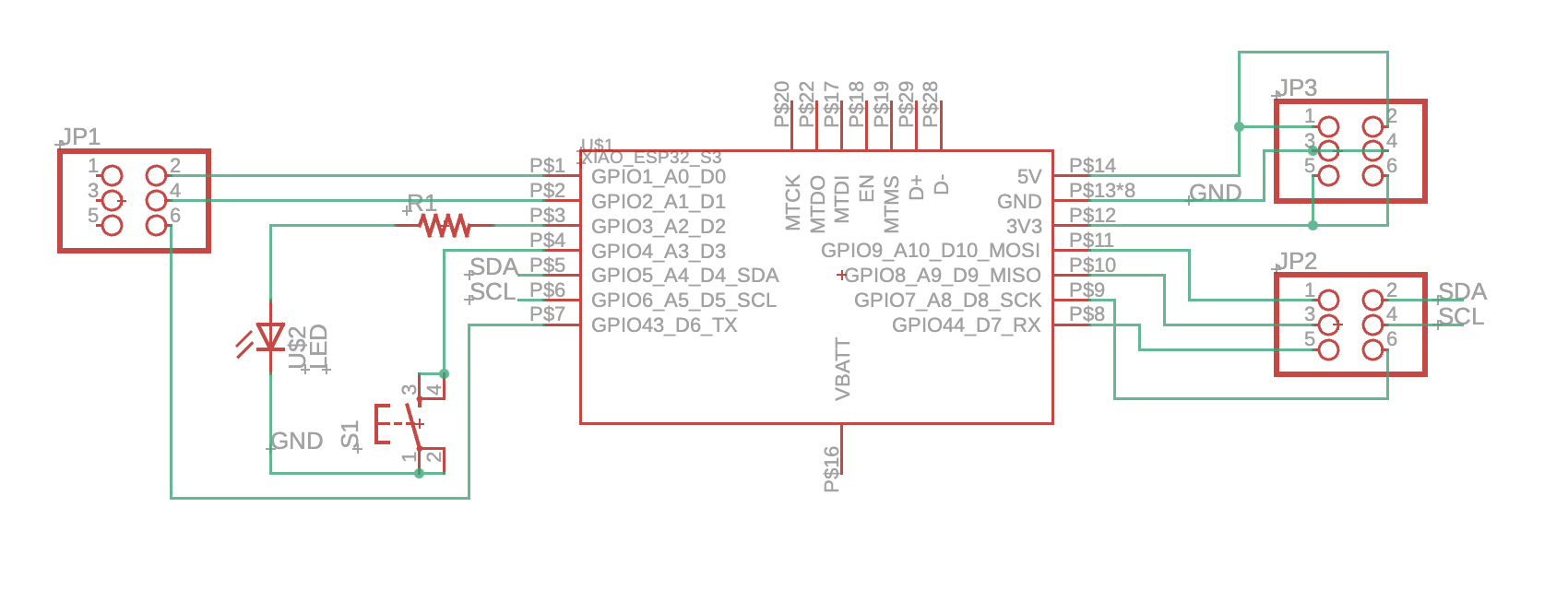

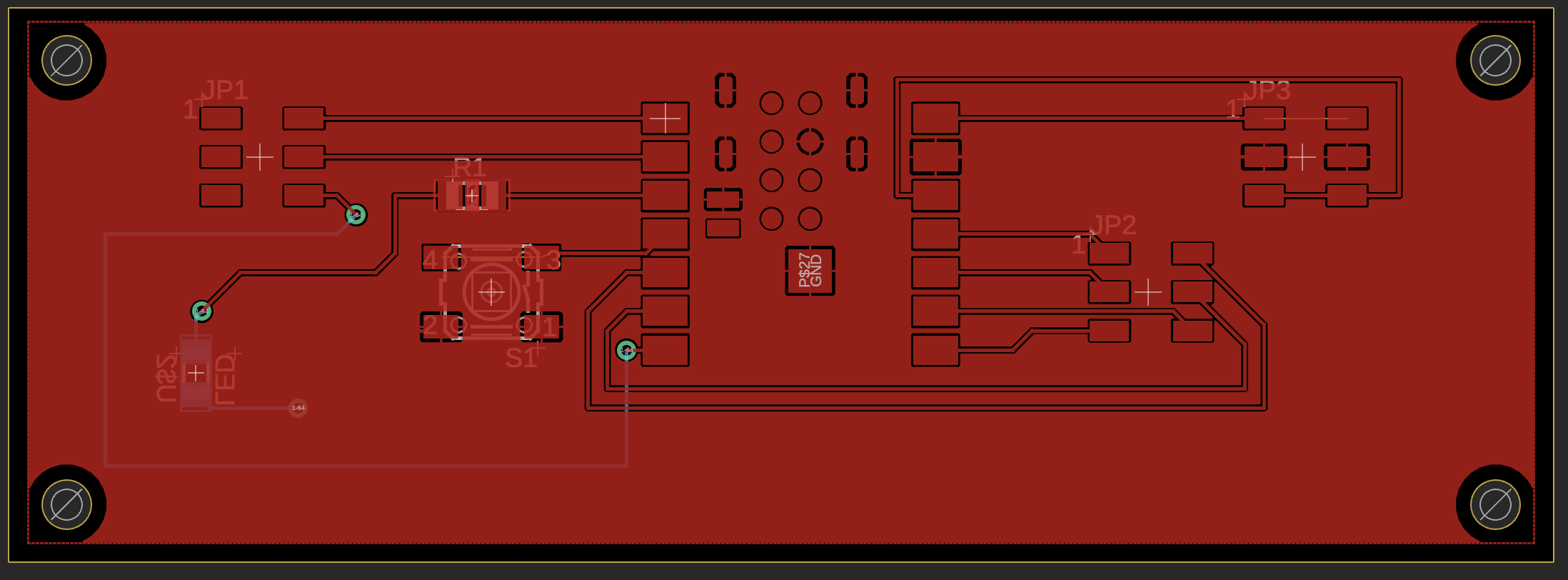

Board Designs

Two ESP32S3-based designs created using Fusion360 EDA: a standalone LED board and a dev board connector with LED on the back.

ESP32S3 LED Base Design

Standalone LED board design for ESP32S3 microcontroller with integrated LED and supporting circuitry.

Schematic Design

📥 Download .sch file

PCB Layout with Polygon Pour

📥 Download .brd fileESP32S3 Dev Board Connector Design

Development board connector design with LED mounted on the back for easy integration with ESP32S3 development boards.

Schematic Design

📥 Download .sch file

PCB Layout with Polygon Pour

📥 Download .brd fileDesign Process

- Schematic capture

- Component selection

- PCB layout design

- Design rule checking

Simulation & Verification

- Circuit simulation

- Timing analysis

- Power consumption

- Signal integrity

Design Requirements

- Use components from Fab inventory

- Include microcontroller and supporting circuitry

- Pass design rule checks for fabrication

- Simulate operation before fabrication

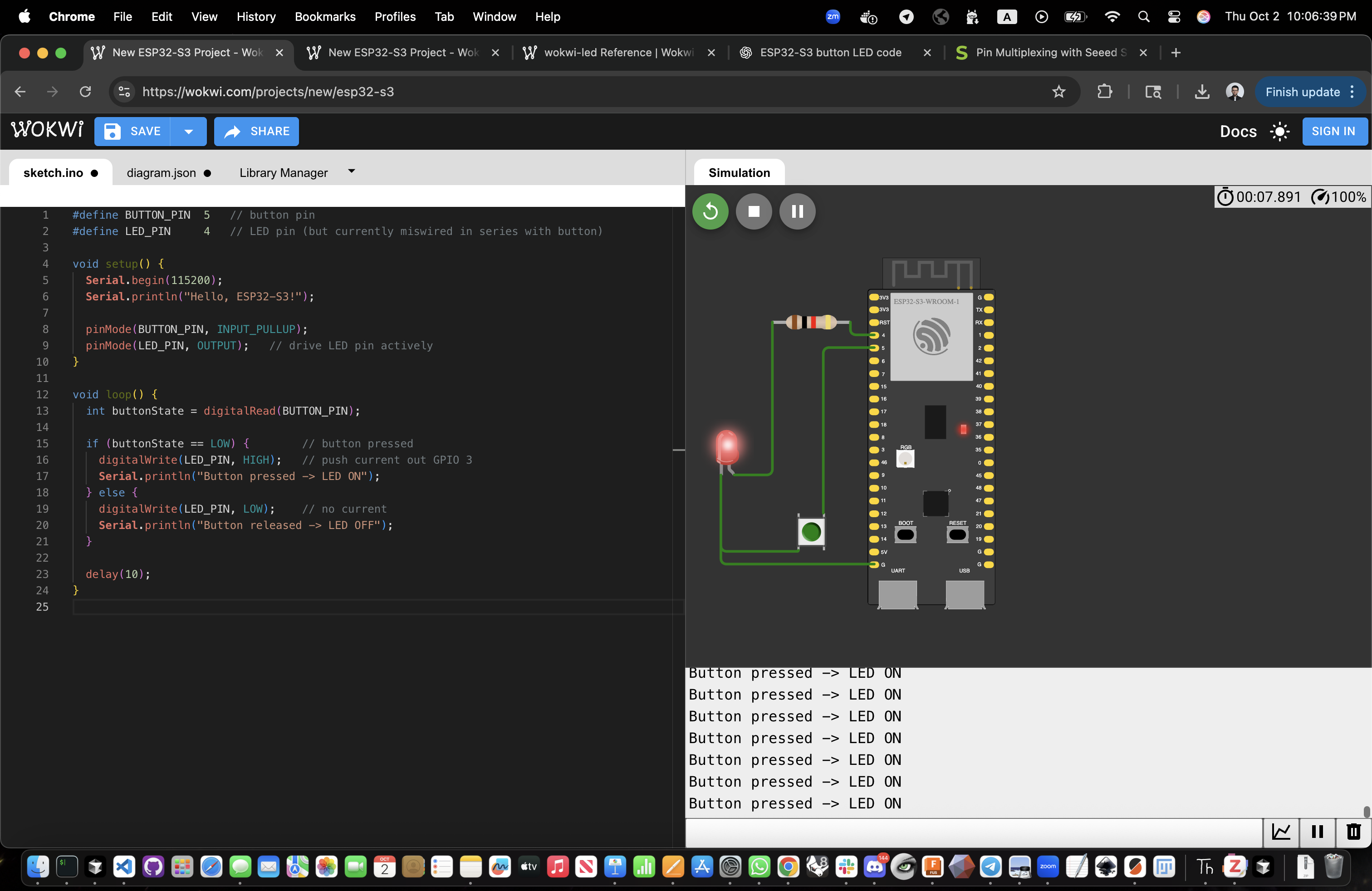

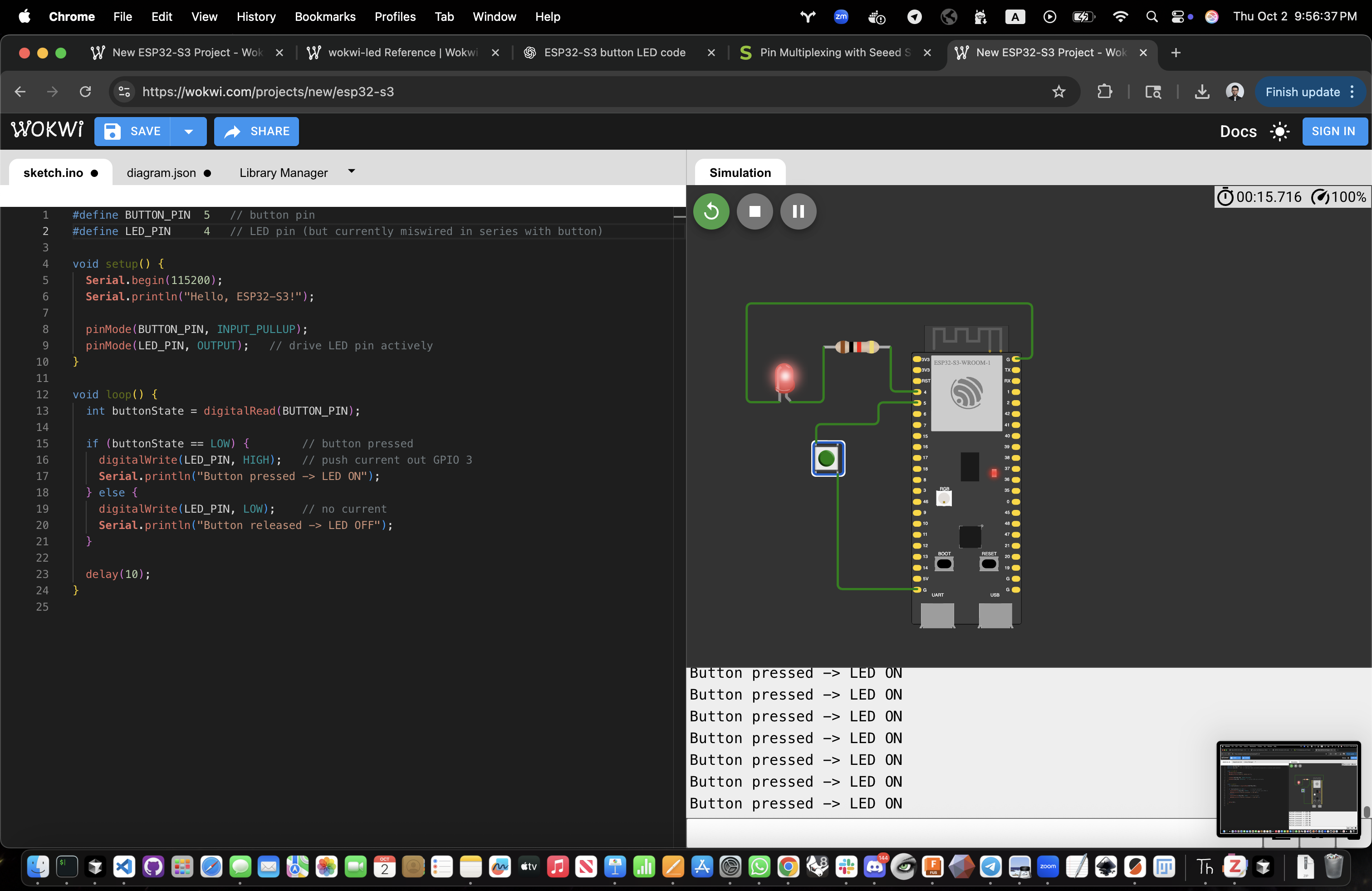

Circuit Simulation & Verification

Interactive circuit simulations created using Wokwi to verify the ESP32S3 LED circuit designs before fabrication. These simulations demonstrate the button-controlled LED functionality and help validate the circuit operation.

ESP32S3 LED Circuit Simulation 1

Primary simulation showing button-controlled LED circuit with ESP32S3 microcontroller.

Interactive Simulation: Button-controlled LED circuit with ESP32S3

Simulation Links

Code Files

ESP32S3 LED Circuit Simulation 2

Alternative simulation configuration with the same circuit functionality.

Alternative Configuration: Same circuit with different simulation setup

Simulation Links

Code Files

Arduino Code Explanation

The same Arduino code is used for both simulations, implementing a simple button-controlled LED circuit.

#define BUTTON_PIN 5 // button pin

#define LED_PIN 4 // LED pin (but currently miswired in series with button)

void setup() {

Serial.begin(115200);

Serial.println("Hello, ESP32-S3!");

pinMode(BUTTON_PIN, INPUT_PULLUP);

pinMode(LED_PIN, OUTPUT); // drive LED pin actively

}

void loop() {

int buttonState = digitalRead(BUTTON_PIN);

if (buttonState == LOW) { // button pressed

digitalWrite(LED_PIN, HIGH); // push current out GPIO 3

Serial.println("Button pressed -> LED ON");

} else {

digitalWrite(LED_PIN, LOW); // no current

Serial.println("Button released -> LED OFF");

}

delay(10);

}Code Functionality

- Button Input: GPIO 5 with internal pullup resistor

- LED Output: GPIO 4 drives LED directly

- Serial Monitor: Debug output at 115200 baud

- State Detection: LOW = pressed, HIGH = released

Circuit Behavior

- Press Button: LED turns ON, serial message

- Release Button: LED turns OFF, serial message

- Real-time: 10ms loop delay for responsiveness

- Debugging: Serial output for troubleshooting

EDA Tools & Workflow

Overview of Electronic Design Automation tools and the complete design workflow from schematic to fabrication.

Schematic Design

- Component library management

- Symbol creation and editing

- Netlist generation

- Electrical rule checking

PCB Layout

- Component placement

- Routing and trace optimization

- Design rule checking (DRC)

- Gerber file generation

Recommended EDA Tools

KiCad

Open-source, full-featured EDA suite with excellent community support

Eagle

Professional PCB design tool with extensive component libraries

Altium

Advanced PCB design with integrated simulation capabilities

Design Files

All design files, schematics, PCB layouts, and simulation files for the electronics design assignments.

Schematic Files

- schematic.kicad_sch — KiCad schematic

- schematic.pdf — PDF schematic

- bom.csv — Bill of materials

PCB & Simulation

- pcb.kicad_pcb — KiCad PCB layout

- gerber.zip — Gerber files for fabrication

- simulation.asc — LTspice simulation

Reflections & Learnings

Key insights and learnings from the electronics design week, including challenges faced and skills developed.

Key Points

- EDA tool workflow mastery is essential—understanding schematic capture, PCB layout, and design rule checking

- Simulation before fabrication saves time and materials—verify designs before committing to board production

- Component selection requires balancing functionality, availability, and cost constraints

- PCB layout best practices (signal integrity, power distribution) directly impact board performance

- Understanding fabrication constraints (minimum trace width, via size) is critical for manufacturable designs

Technical Learnings

- EDA tool workflow mastery

- Design rule checking importance

- Simulation before fabrication

- Test equipment proficiency

Design Insights

- Component selection strategies

- PCB layout best practices

- Signal integrity considerations

- Fabrication constraints

Contributions

Acknowledgements and team contributions for the electronics design week assignments.

Group Assignment

- Collaborative test equipment setup

- Shared measurement techniques

- Documentation of procedures

Individual Work

- Complete EDA design workflow

- Simulation and verification

- Design file documentation

Ethical AI Use

AI tools used to assist with electronics design, EDA tool learning, and circuit simulation guidance.

📋 General Guidelines: See General Commands for Cursor on the homepage for standard guidelines and commands used consistently throughout documentation development.

AI-Assisted Tasks

- EDA tool workflow guidance and troubleshooting

- Circuit simulation setup and parameter optimization

- Design rule checking interpretation and fixes

- Component selection and datasheet analysis

Week 4 HTML Template Creation

Cursor AI assistance for creating the week4.html template with comprehensive electronics design content, including EDA tools, assignments, and documentation resources.

Focus: HTML template creation, electronics design content population, assignment structure, and documentation integration

Individual Assignment Enhancement

Cursor AI assistance for updating the individual assignment section with detailed Fusion360 design process, board design images, and improved visual presentation.

Focus: Fusion360 design process documentation, board design image integration, visual alignment improvements, and highlights section updates

Week 4 Group Assignment Update

Cursor AI assistance for updating the Week 4 group assignment section with comprehensive test equipment details, image link updates, and group page integration.

Focus: Group assignment content integration, test equipment documentation, image path updates, and group page link addition

This work is licensed under a

Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

This work is licensed under a

Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License