Week 4:

3D-Printing Week: Homework was to create something you couldn’t make subtractively.

This week I was traveling the first few days, so I got a late start on my project. I also spent a decent amount of time doing research for my final project, since it’s a big idea and I need to get started on it ASAP. So, I kept this week’s assignment fairly simple. The idea was to print something inside of something else, where the outer “shell” was a single piece that allowed you to see the other shape freely rolling around inside. On its own, this would be hard, if not impossible to do subtractively. But I also wanted the geometry of the outer shell to be something that itself could not be produced subtractively.

I chose to make the outer shape an icosahedron, since I had little experience making this sort of unextrudable geometry in Fusion before. I found this neat video that walked-me through producing the icosahedron using only the 3D sketch tool and equals constraints, and I was business.

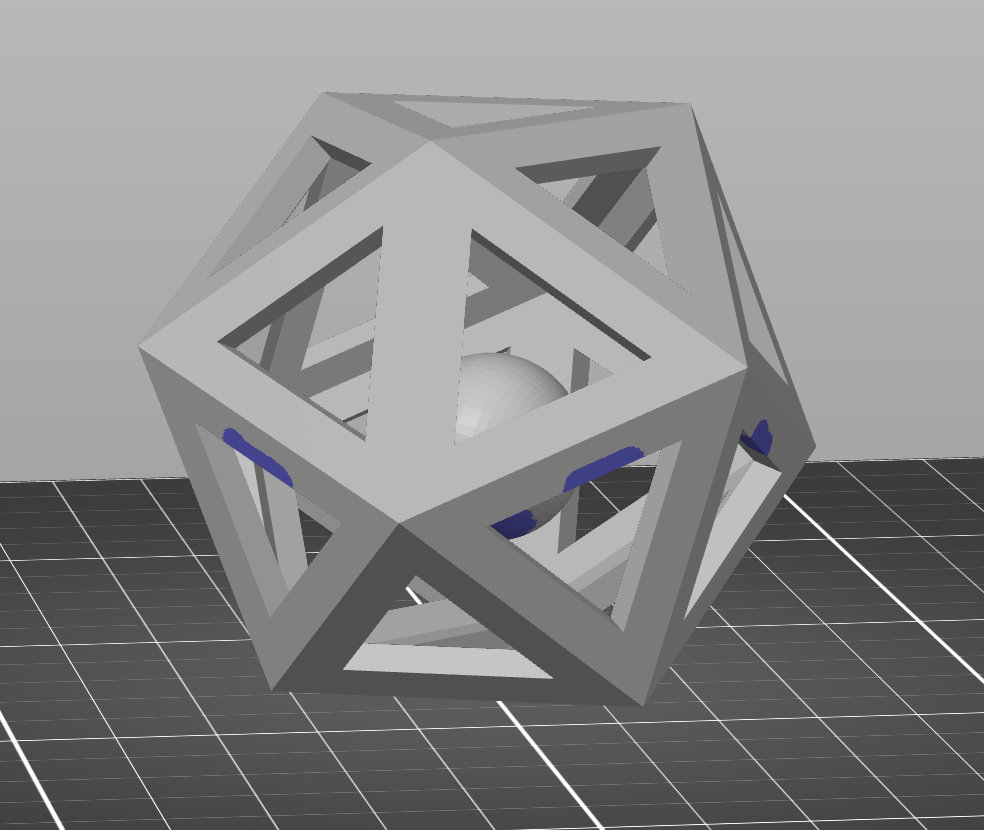

Once I got an icosahedron shell, I sketched triangular cutouts on a few faces and used a rotational pattern to apply them to the entire body. Now I had this sort of skeletal polygon, which I could put something inside. For a first test, I just dropped a small sphere in there, then hopped into PrusaSlicer to prepare the print. I had to support the ball inside with some support material, since I couldn’t have it adhering to the outer shell.

Once I got an icosahedron shell, I sketched triangular cutouts on a few faces and used a rotational pattern to apply them to the entire body. Now I had this sort of skeletal polygon, which I could put something inside. For a first test, I just dropped a small sphere in there, then hopped into PrusaSlicer to prepare the print. I had to support the ball inside with some support material, since I couldn’t have it adhering to the outer shell.

My first print failed, miserably. The skeletal beams of the icosahedron were simply too small, and the print layer lost adhesion halfway through, leading to a messy tangle of filament. I made my second attempt about two and half times bigger dimensionally so that this wouldn’t happen again. I also added some support material beneath a few of the more horizontal beams of the icosahedron, which I hoped would help ease the printing of such shallow (near horizontal) inclines.

To be honest, I actually thought this one would fail as well due to the unsupported shallow-angle beams at the top that I couldn’t add support material under. But to my surprise, besides a few stray strands of filament floating underneath the top beams, everything else turned out fine. After some clawing and tearing at support material with some tweezers and and a pair of pliers, I freed the sphere inside, and verified that my shape-inside-shape printing method did in fact work.

The print made a kinda Christmas-y ringing noise, so I figured that with a few tweaks to the CAD design, the end-product could make a nice tree ornament. I replaced the sphere with another, filled, icosahedron of half the shell’s size, and added a loop on top for an ornament hanger. For printing, I added the same support structures as in my previous attempt, making sure to point the side with the hanger loop up, then let ‘er rip.

The print made a kinda Christmas-y ringing noise, so I figured that with a few tweaks to the CAD design, the end-product could make a nice tree ornament. I replaced the sphere with another, filled, icosahedron of half the shell’s size, and added a loop on top for an ornament hanger. For printing, I added the same support structures as in my previous attempt, making sure to point the side with the hanger loop up, then let ‘er rip.

The final print turned out quite nicely, and makes a light, slightly plastic-y jingle when you shake it. Freeing the inner shape from its support material was a bit of a pain, but nothing some good old -ashioned brute force couldn’t solve. The black PLA might be a bit hard to see on Christmas tree, but the filament actually has some sparkles in it, so near string lights I think it’ll look decent.

My mom’s a fan, at the very least.