Week 12 - Machine Building

-

DIY Nerf Gun or "Please don't dribble in"

This week EECS team built a machine that throws nerf darts when it detects a human. Here is a link to the group documentation with more detailed explanation about the functionality of each modules and system breakdown.

Overall it was a great experience, both sprinting through the project and working in a big (20+ people) team. It was my first experience of tackling a complicated system, breaking it into separate components, and collaborating with others to make it work.

Videos on the left show our system working together as a whole, during testing and in class. Thanks to the team! -

Sooo, what did I do?

As mentioned above, the project was big and was split into multiple systems. I was working on the actuator team - designing and making mechanism of pushing the bullet into the chamber, from where it can be accelerated and launched (thanks flywheel team!).

On the image on the right you can see notes from our first group meeting, where we split into teams, defined nessesary integration moments (dimensions of neighbouring sides), timeline. My team was planned to be started first, so we started the same day.

-

Linear Actuator

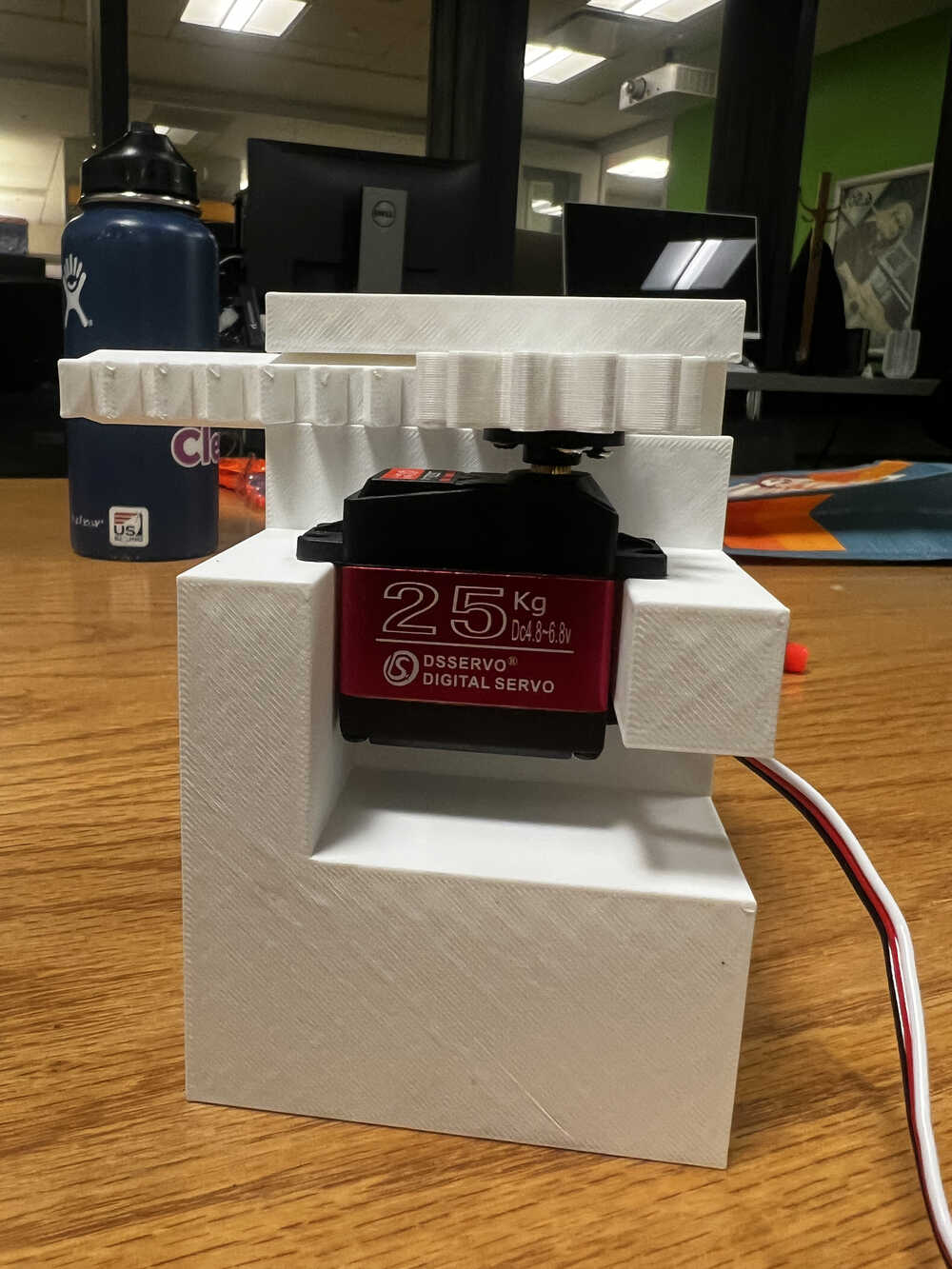

The first challenge of my team was to design and construct a linear actuator - so that we can use a servo that is spinning to give a bullet some linear momentum.

Left photo is a photo from web, that gave me some initial understanding how linear actuator can be constructed. The right image is prototype n0 - definitely way thinner than it needs to be, and it went through a lot of iterations later on, but it served as a proof of concept developed the first day (Thursday).

CAD file for this print can be found here. -

Developing the system

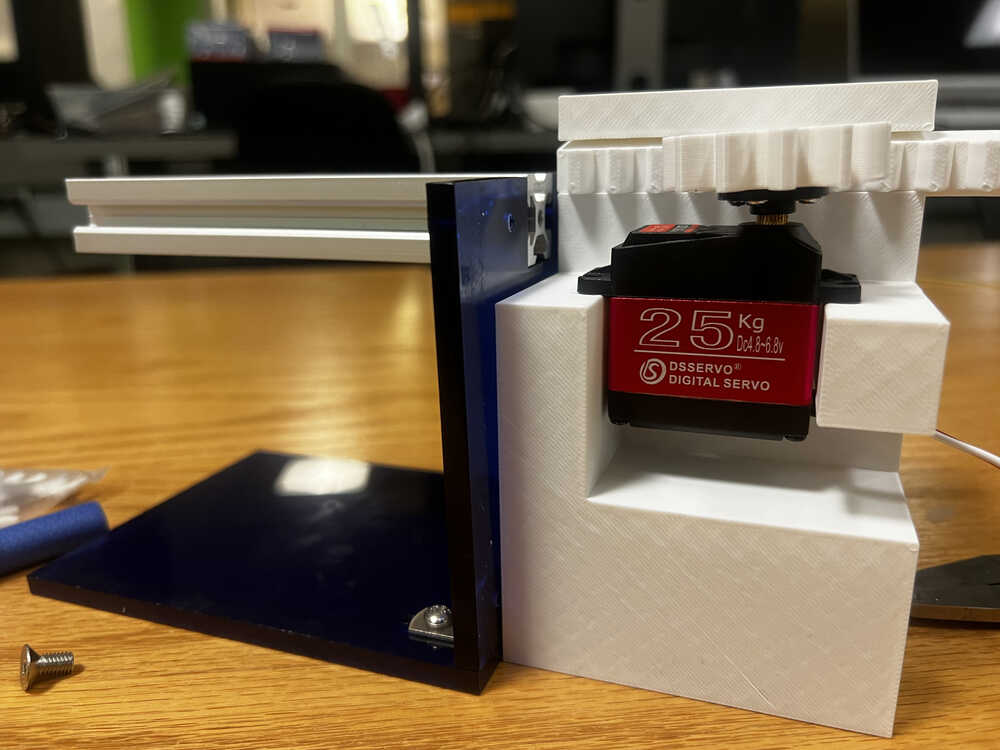

Once we confirmed that the mechanism works, and sizing is good, we went ahead to CAD our module. It was a few hours in Fusion 360, some troubleshooting, and at the end of the day we printed our part of the system. As seen on the images on the right, it was designed so that the screws fit perfectly the gear (thanks calipers), and the servo fits in the slot right under the linear actuator.

On the bottom you can see first integration with the flywheel team - it almost matches perfectly. They made their module a tiny bit taller, so worst case fix was to put our module on a sheet of acrylic to level up, but we ended up reprinting anyways, so it wasn't required.

CAD file for this iteration can be found here (Fusion file).

-

Fast Foward Final Result

As mentioned above, my role was in the beginning stafe of design and fabrication, so I was responsible for CADing the system, and designing linear actuation model.

After this, we went through one more iteration of the design, trying to optimize for its weight to be small. On the left side, you can see our final module being integrated into the system. As you can see, quite some volume was shaved, although the mechanism stayed the same. -

Thoughts?

I try to write a "future improvements" section for each of my weeks, but this week it is weird, because of a group nature of a project.

Soo, let's call it thoughts and reflections:

1. Working in a big team is a great experience, it gives a good feel of how it happens later on in life, as well as gives an excuse to share experience and collaborate. I am conflicted between "I wish this week was earlier, so that we have an inspiration to collaborate on weekly projects" and "it was at a right time to give a feel of a sprint before another sprint for final project".

2. Integration is hard, start early and be ready to readjust. Sometimes things don't work as you think, and it is important to be ready to change your design to make it work with others.

3. Have fun and don't dribble in! At the end of the day, it is just a class project, as complex and involved the project can be, there is always space for some fun and jokes. I think our team did a great job at that, and it was a pleasure to work with everyone.

4. Talk to people, they have very different strengths and weaknesses. One of the teammates in my subgroup can do CAD with his eyes closed, while my other teammate got a great understanding of circuits. Tl;dr: don't struggle alone, everyone is very supportive and willing to help..gif)