HAOHENG TANG'S PROJECT

HTMAA23

Week 8: Computer-Controlled Cutting

Let's make something big!

Idea

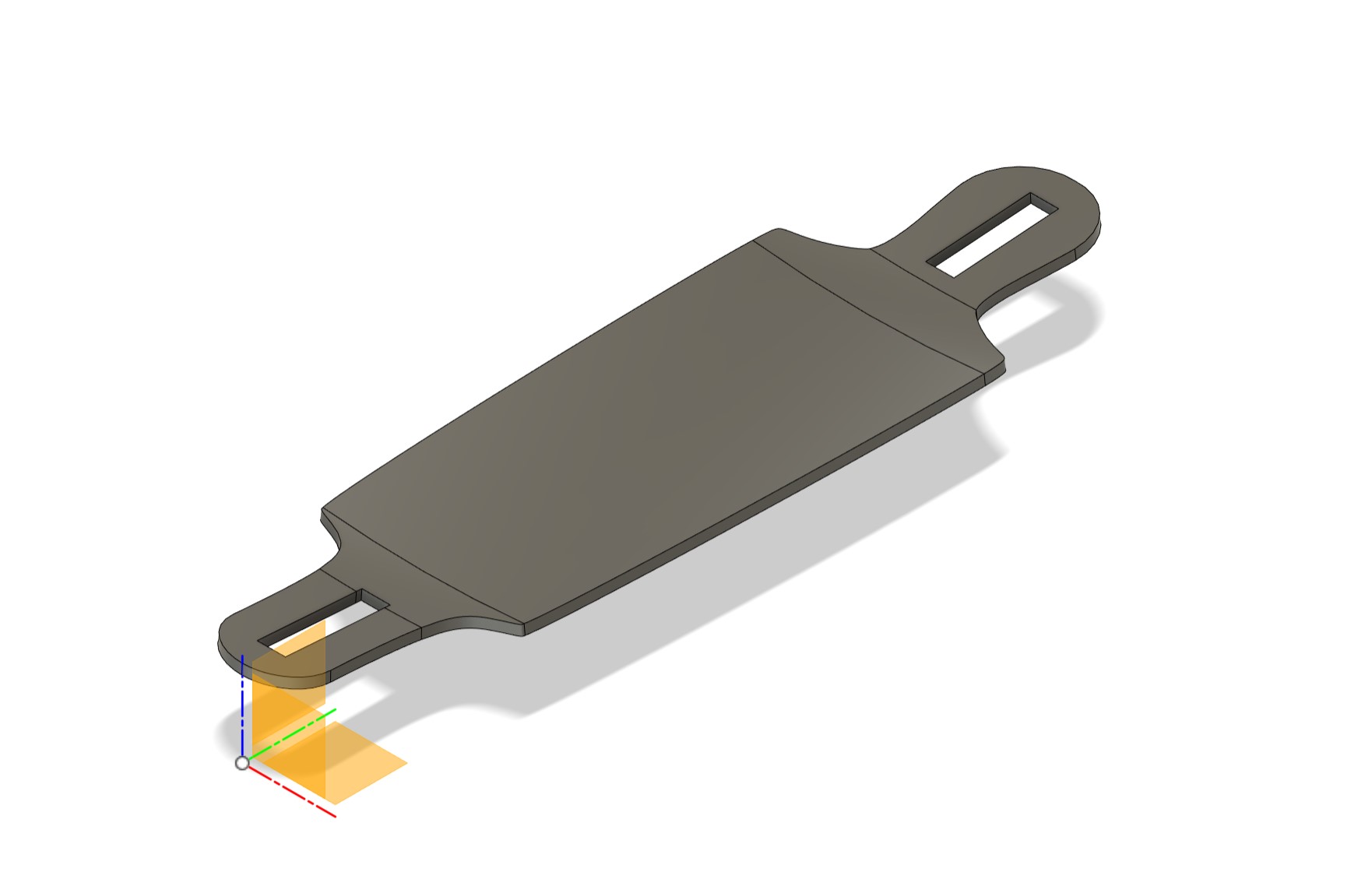

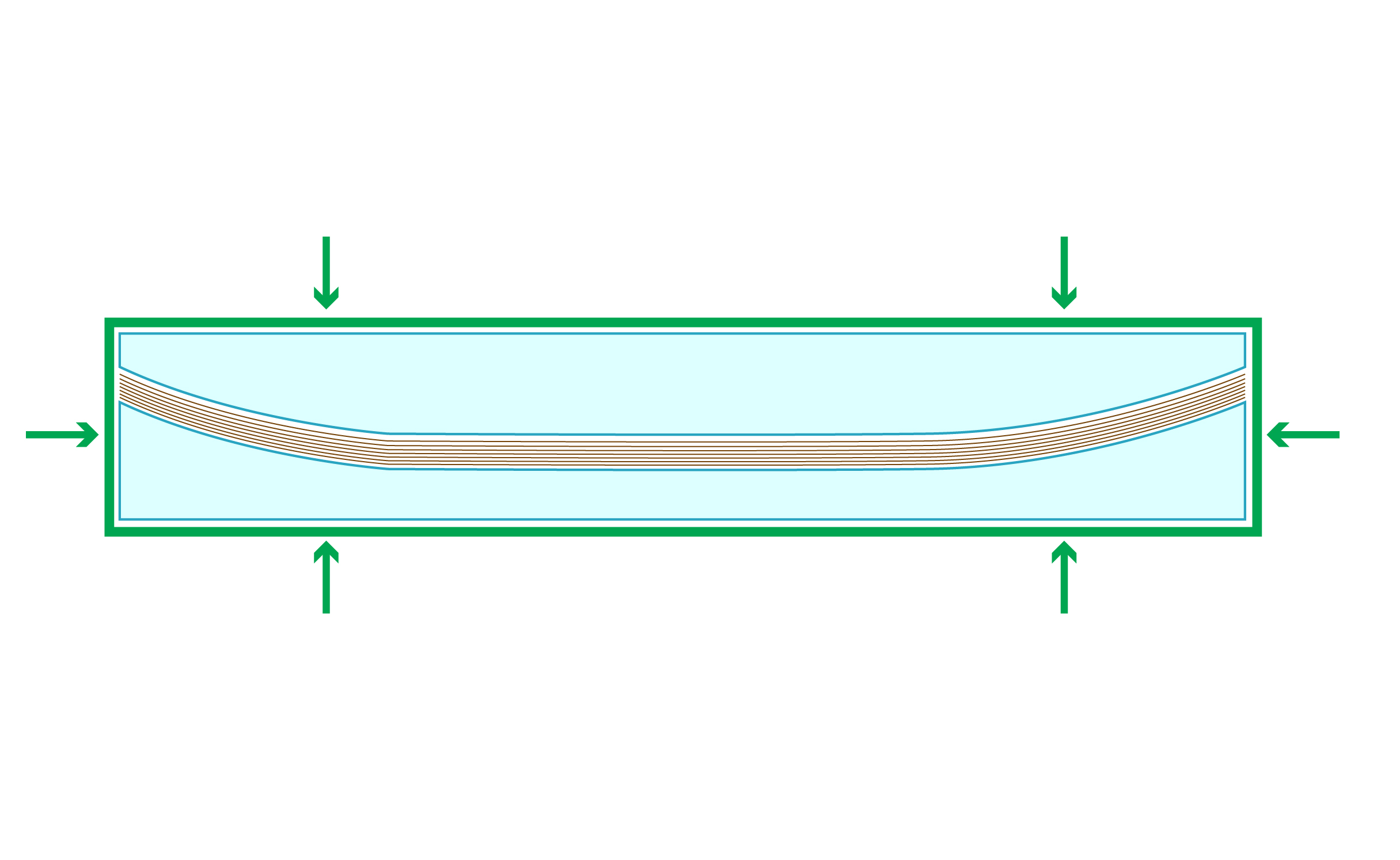

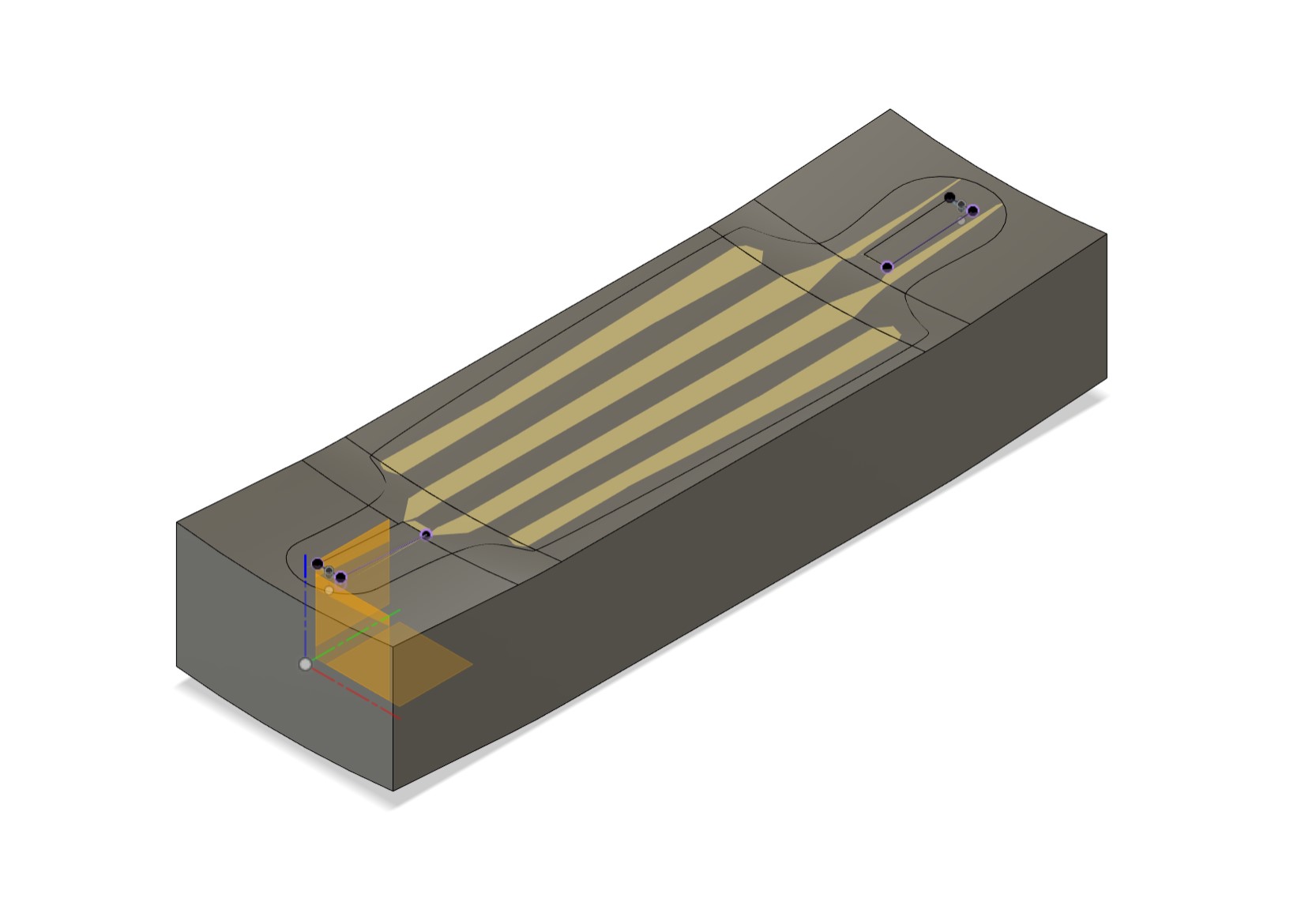

Recall that I would like to make a longboard for my final project. To do so, I need to make a mold to laminate wood veneers.

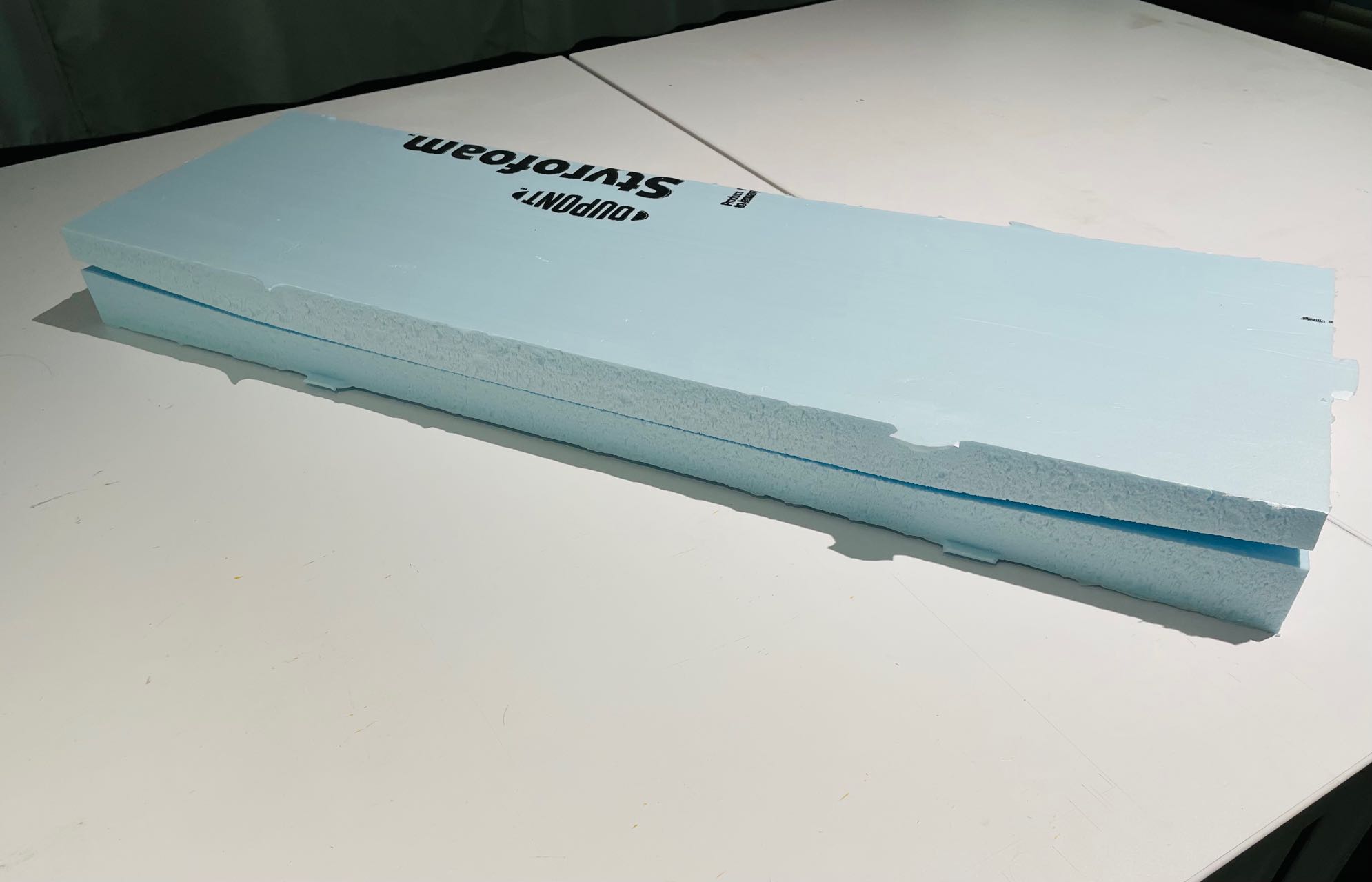

I would like to use foam as the material of the mold and laminate wood veneers in a sandwidch way in week14.

To make a foam mold with smooth Hyperboloid surface, CNC is the best choice.

CAD

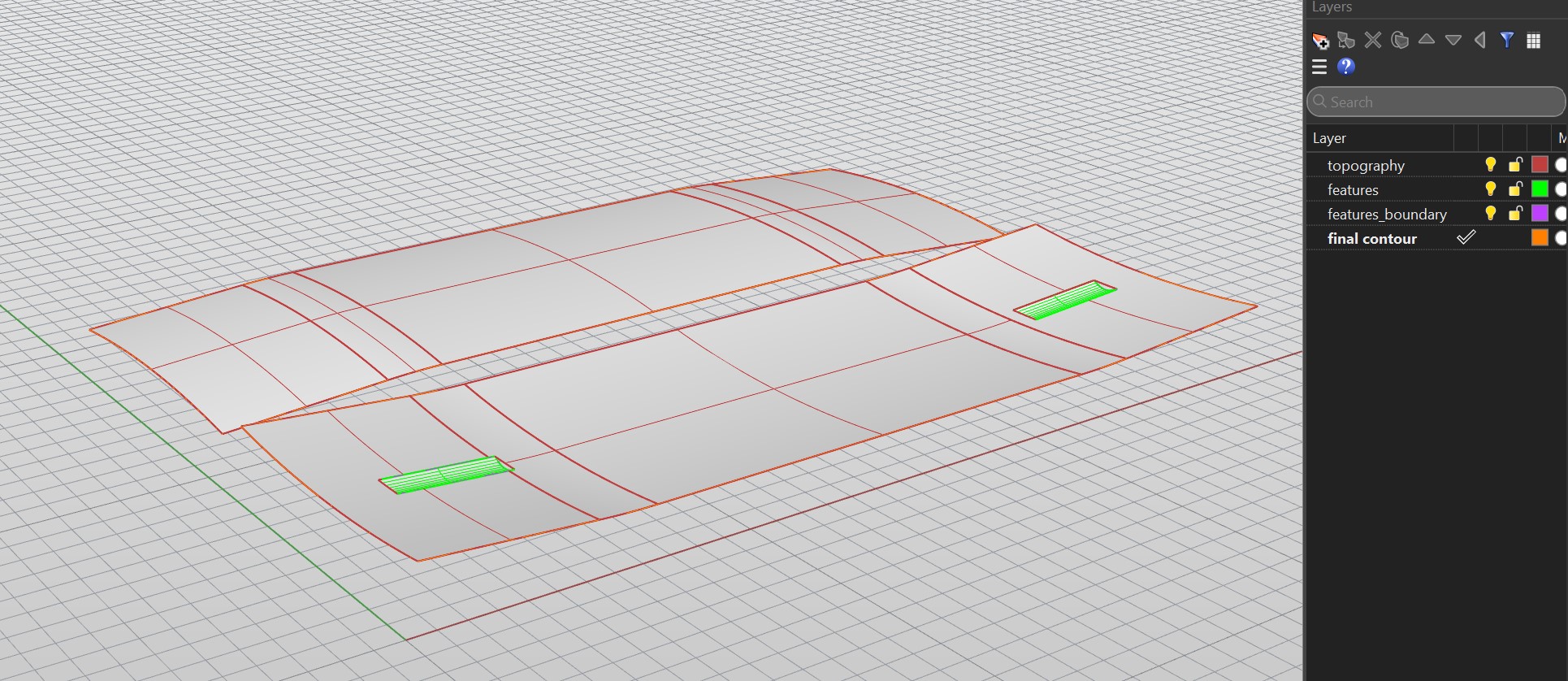

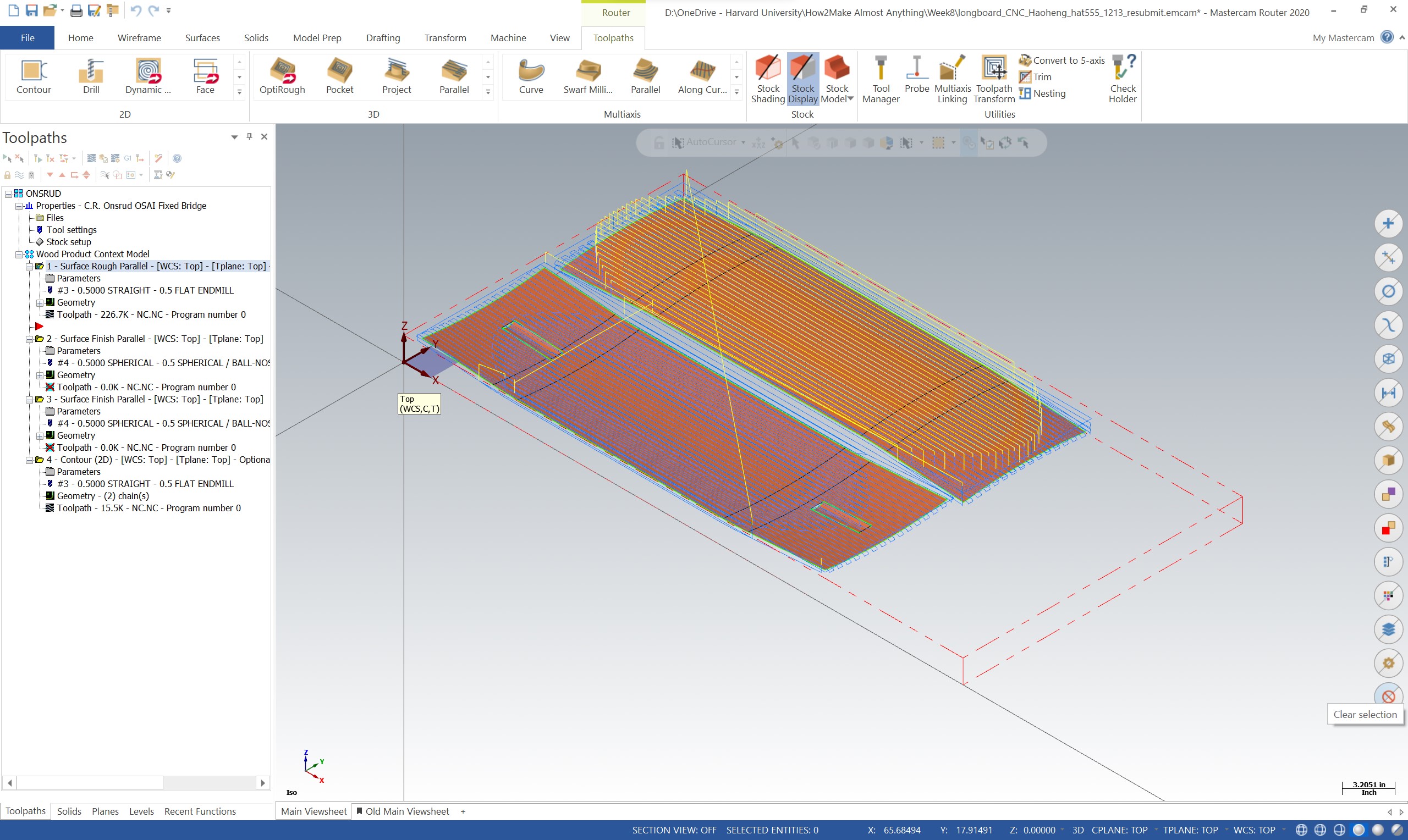

CAM

Merge rhino file into MasterCAM2020. Use GSD Fab lab template file. Set the stock size. Set the toolpath.

Once setting up the parameter and geometry, we can check the CNC process with the help of MasterCAM simulator.

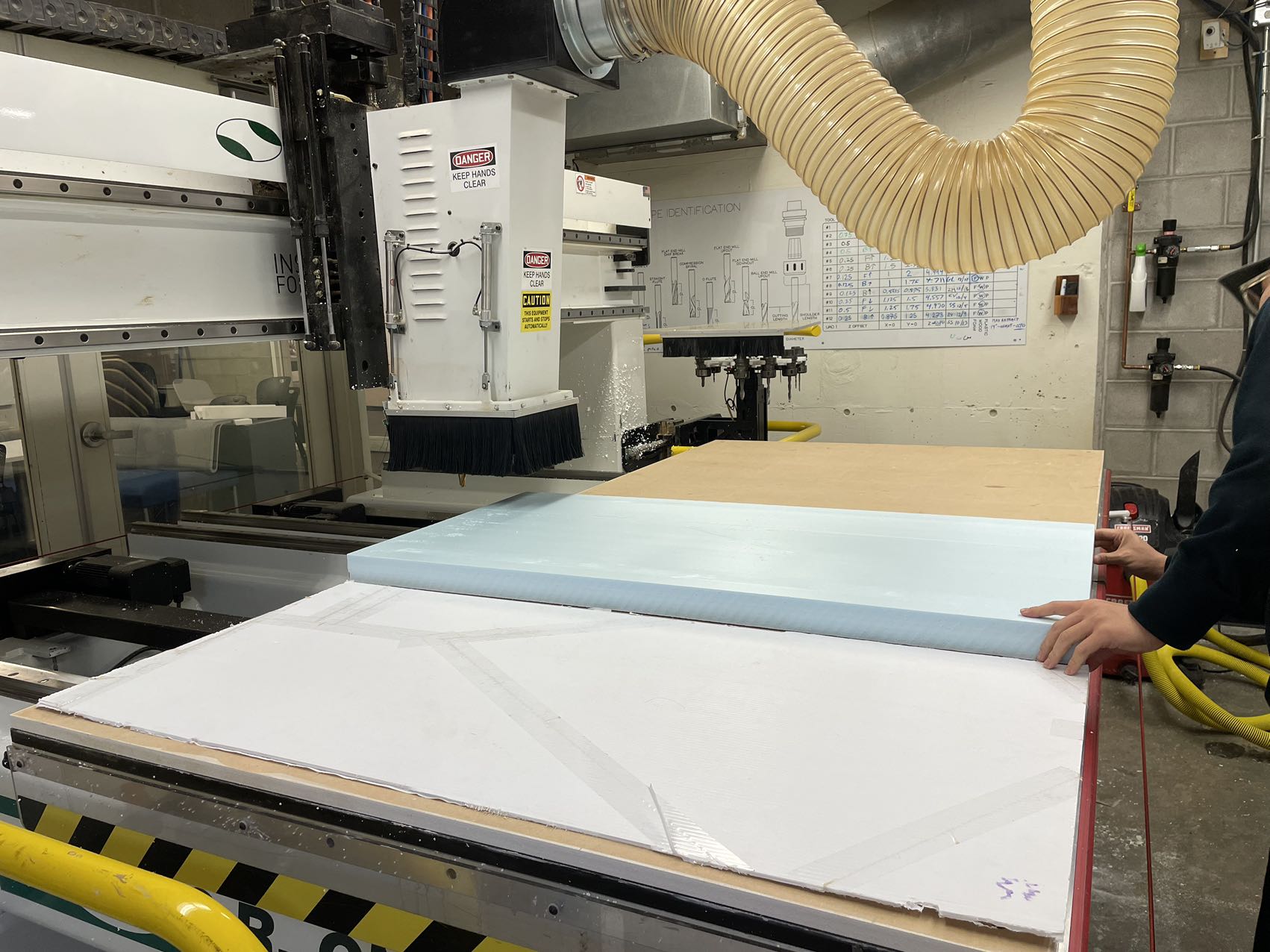

Milling

Woodshop staffs checked the masterCAM file and helped me set up the CNC milling machine.

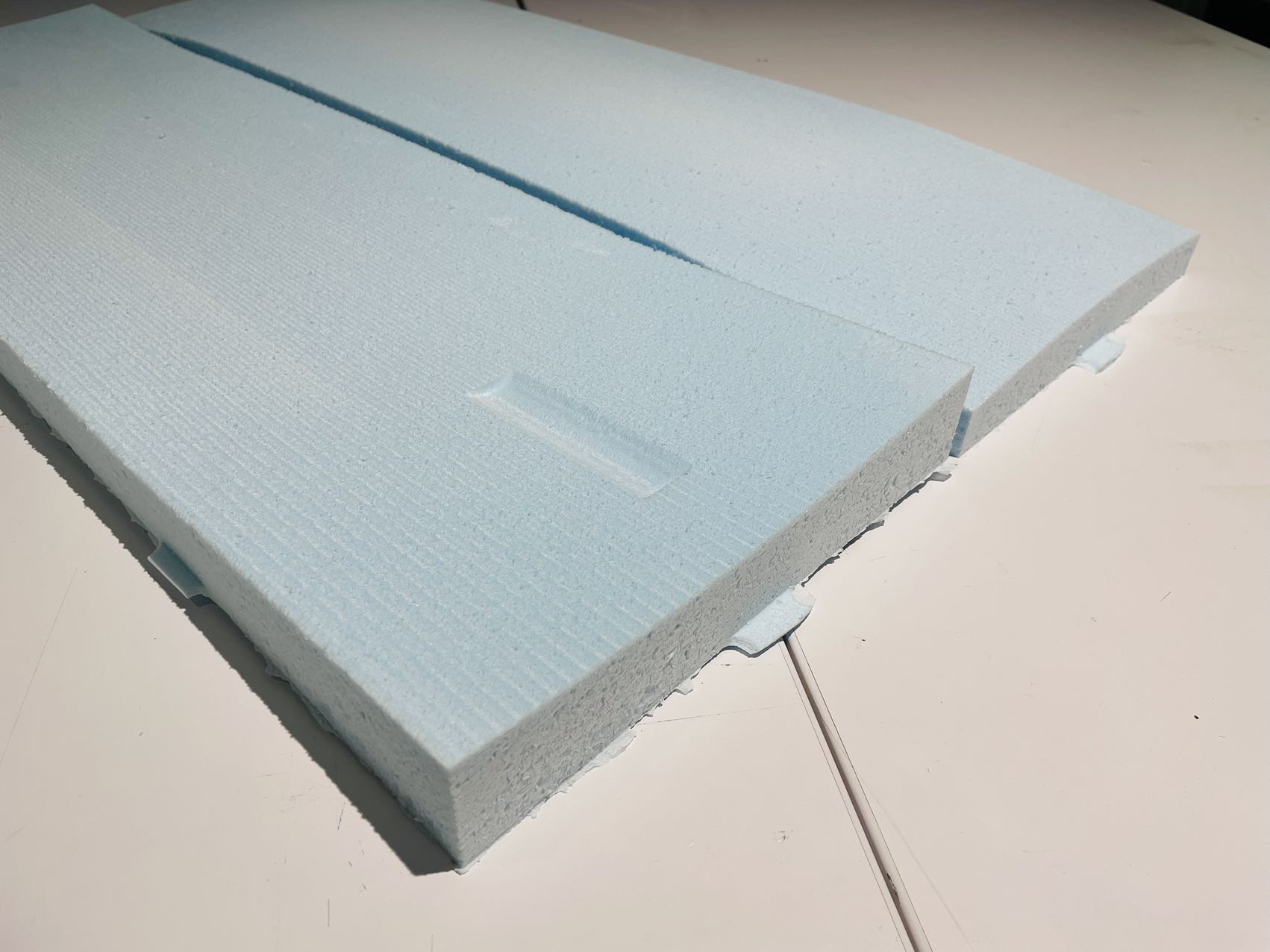

Step 1: Surface rough parallel

In the first step, the machine uses a 0.5 flat endmill to create a rough curved shape, running in a straight way. This step doesn't take much time.

Step 2: Surface finish parallel

In the second step, the machine uses a 0.5 ball-nose endmill to create a smooth shape, running in a spherical way. This step lasts much longer than the previous one.

Step 3: Contour 2D

In the third step, the machine uses a 0.5 flat endmill to cut through the stock but leave some tabs on it.

Finished!