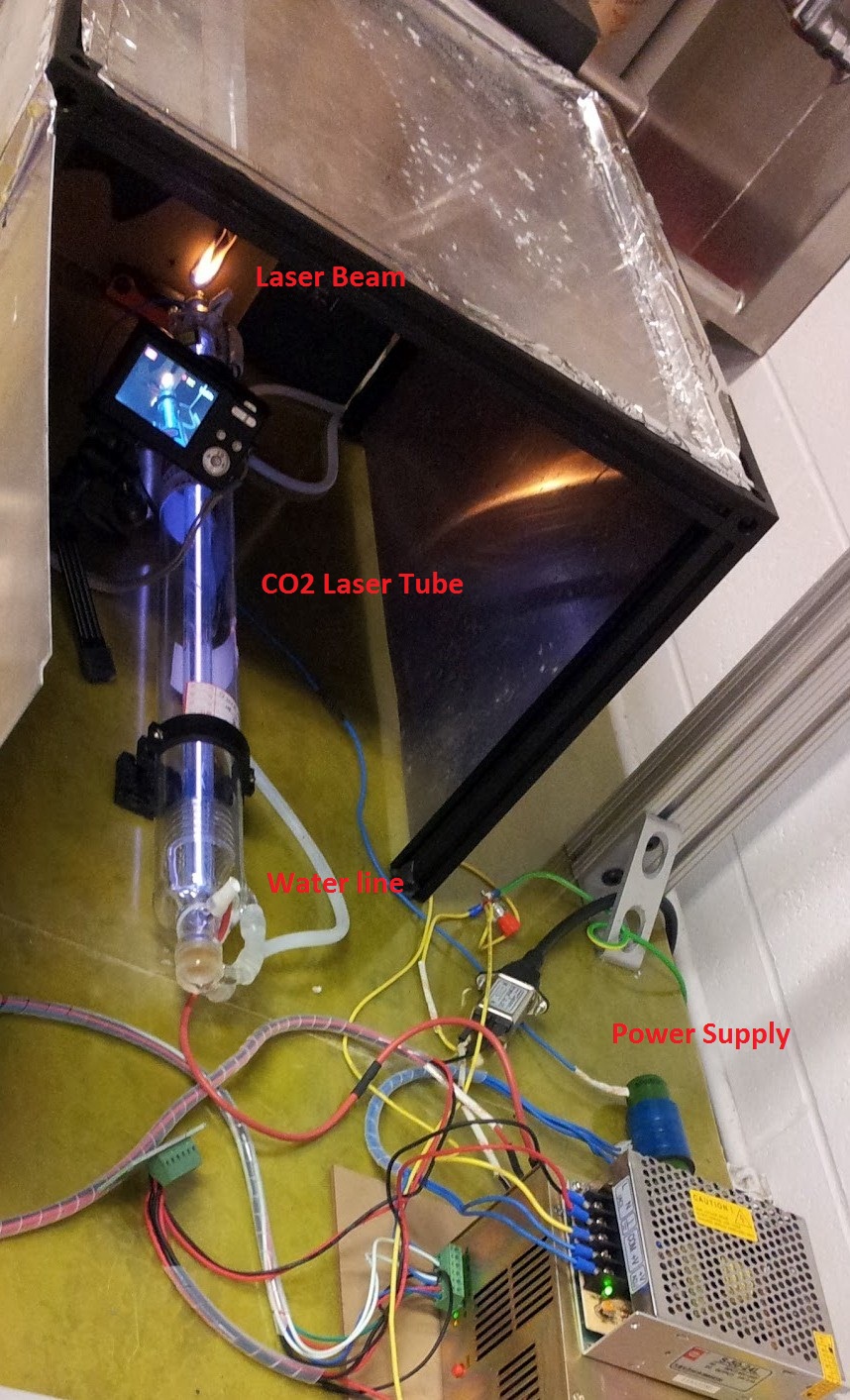

40W CO2 Laser Burning

Cooling System

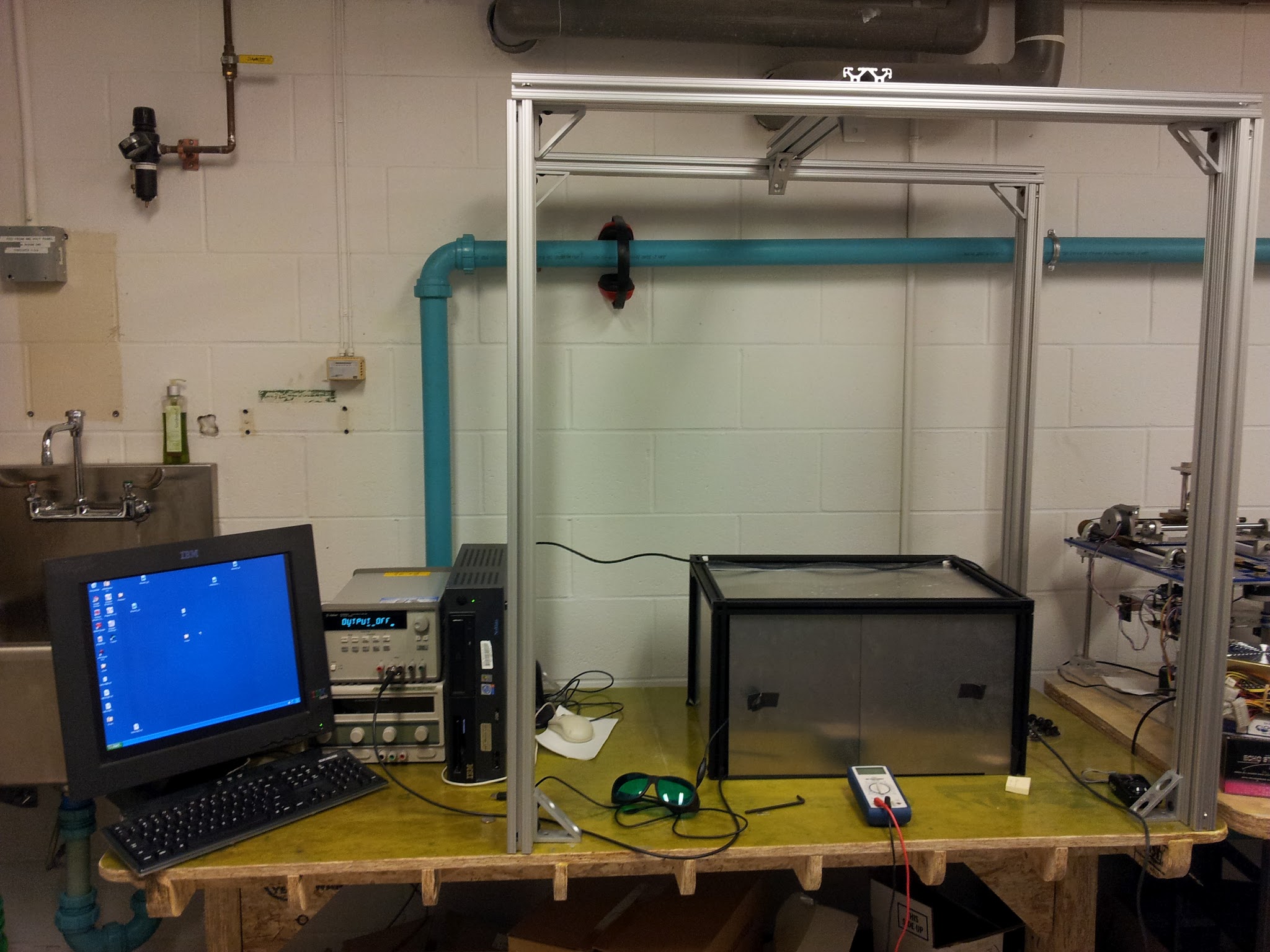

Lasercutter enclosure

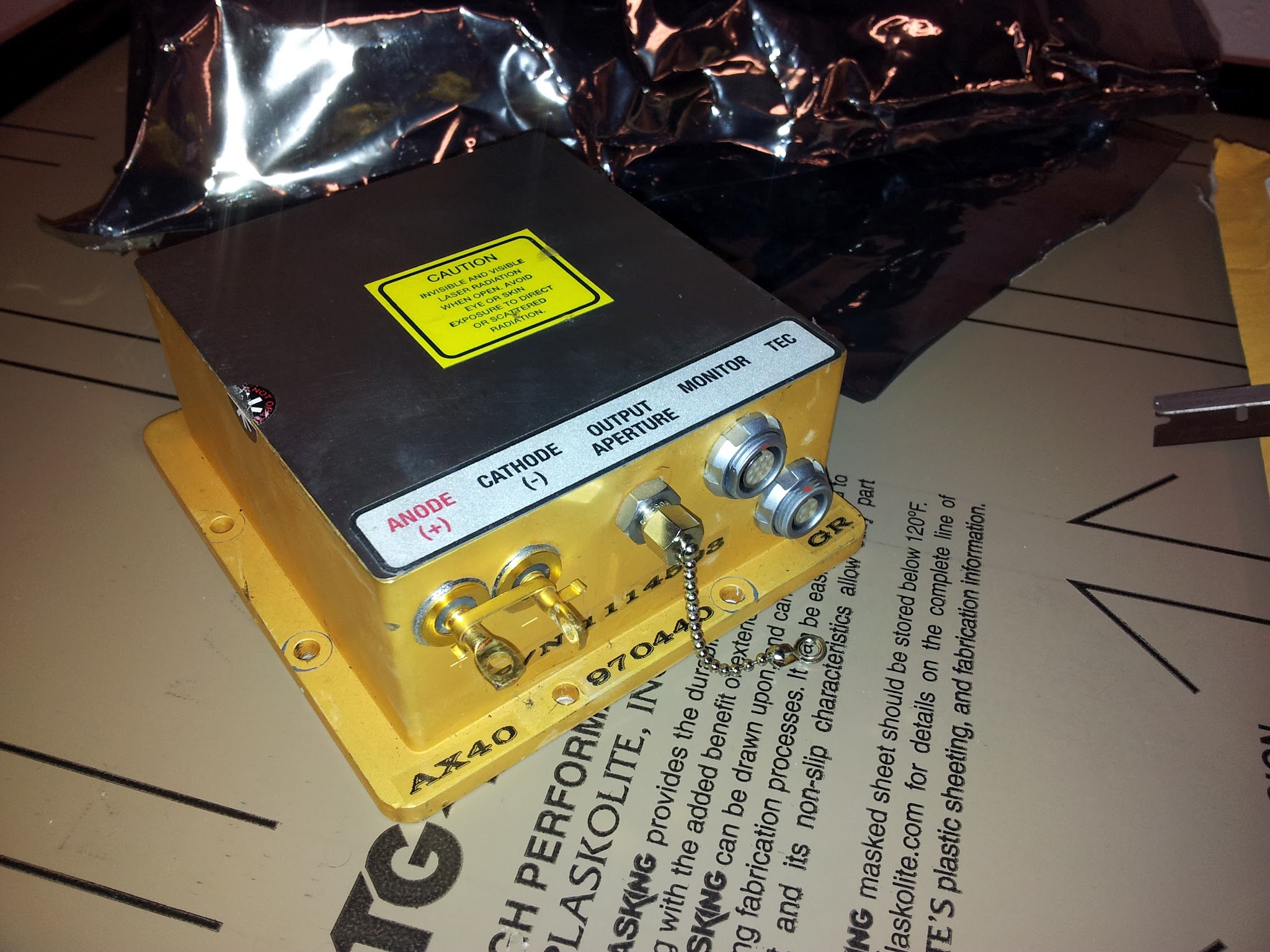

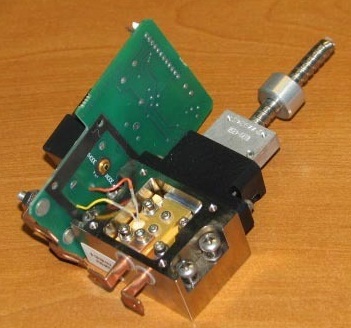

FAP800 Series laser bar

1) 40W CO2 laser tube

http://www.lightobject.com/40W-CO2-Sealed-Laser-Tube-for-Small-K40-laser-engravning-machine-Free-shipping-P208.aspx

2) KV voltage source

http://www.lightobject.com/40W-PWM-CO2-Laser-Power-Supply-P71.aspx

(The power supply has interlock system, when triggered it

switch off the laser)

3) Cooling system-

option 1 (short term) - 015 have chilled water supply

near the optical table.

option 2 (long term) - Small pump + water reservoir

http://www.amazon.com/Thermaltake-CL-W0132-P500-Water-Pump/dp/B000W3K0HS/ref=sr_1_2?ie=UTF8&qid=1329210267&sr=8-2

4) Ventilation

We already have ventilation system used for DNA synthesizer.

(I

discarded all the chemicals, only machine need to be trashed

and will

be done in a week)

Safety

1) Lit class 4 laser safety sign

http://www.lasersafetyindustries.com/Class_4_Lit_Laser_Safety_Sign_p/100-70-262.htm

(power supply has TTL output to drive

the laser safety sigh)

2) Safety glasses

http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=762

3) Laser safe curtain

Installed by EHS

Advantage of solid state lasers

1) Compact

2) Cheap (?)

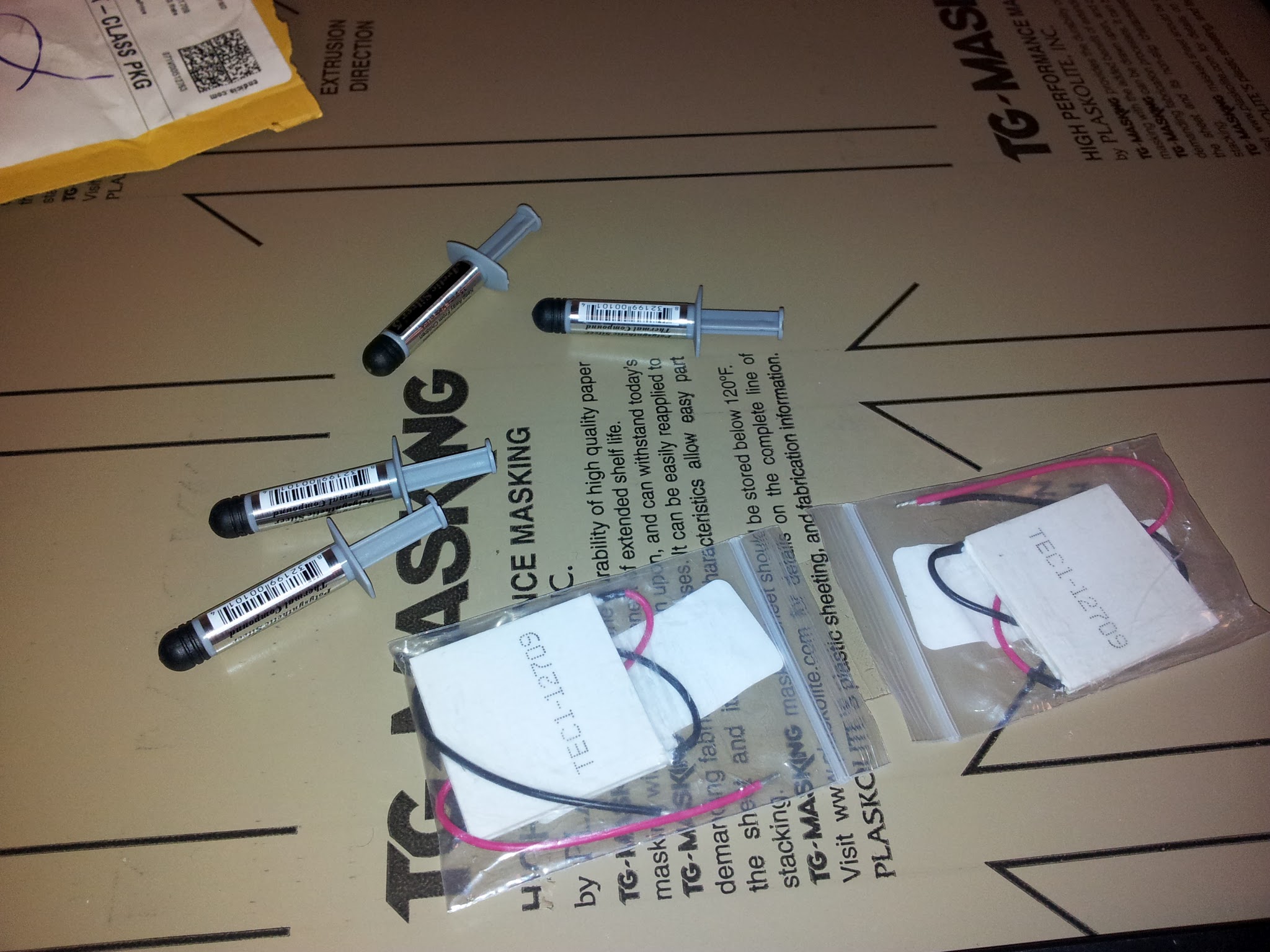

3) TEC cooling

4) Power supply ~2V, ~50A

5) Optical Fibers

Some suppliers of solid state lasers

1) Coherent laser diode - 40W FAP800 Series - TEC cooled

Price - Used one in ebay ~90$, New - Waiting for quote

Sufficient to burn wood, (see video below)

It operates at 800nm - 900nm so one has to see what

materials it can

cut and all.

2) 100W 950nm DPSS Laser diode Bar (Made in China), ~ 200$ per unit

3) 35W 808nm Opto Power Corp Fiber coupled Laser (cooling ?)

4) Spectra Physics 40W laser Diode (used - 90$), New - ?

5) JENOPTIC Laser (German company, power 30W-250W, any cooling)

Source - http://www.jenoptik.com/en-diode-laser-modules-product-overview

Minutes of the meeting

1) Reclassify Class 4 laser into Class 1 laser - enclose beam, interlocks, warning sings

2) Division of work -

1 - Laser (Prashant) - TEC cooling, fiber coupled,

interlocks

2 - Mechanical system design (Solidworks etc) (Sam, David)

3 - Fabbing - Prashant, Sam, David, Andrew

4 - Power supply (Andrew ?) - The laser require ~ 2.0V, ~50A power supply which we can buy but its a good idea if we can make one of our own.

5 - Head start laser enclouser - Optical table + water-jet

cut sheets

3) Some cool Ideas came up in meeting

1 - Using CCD camera rather then Window - Safe , cheap (?)

2 - Using laser bar as head - No optical component and alignment needed , reduce cost

3 - Use snap-together joints, fexible size of cutting bed.

Resources

1 - Open Source Laser cutter

2 - Lasercutter Project blog

3- Datasheet of FAP 800 series lasers

http://www.coherent.com/downloads/FAP800series_DSFinal.pdf

4 - JENOPTIC Laser datasheet - http://optonlaser.com/IMG/pdf/jold.pdf

5 - Some Buring with 60W IR laser diode

PART 1

PART - 2

Fiber Laser

Epilog FiberMark Series Laser cutter uses

Ytterbium Fiber Laser, Air Cooled, 1062 nm From 10 to 50 watts

http://www.epiloglaser.com/fibermark_series.htm

http://www.hypertherm.com/en/Products/Laser/Fiber_Laser/

Vendors

J K Lasers

http://www.jklasers.com/fiber-lasers

http://www.ipgphotonics.com/Collateral/Documents/English-US/YLM_Series_SM_IPG.pdf

2)

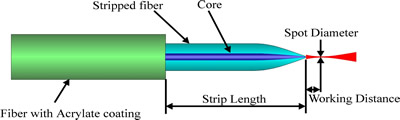

Fiber Lens

http://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1341

Lensed Fibers

http://www.laseoptics.com/lensed-fibers.html

http://www.laseoptics.com/Lensed-Tapered-Fibers-Description.pdf

http://www.ozoptics.com/ALLNEW_PDF/DTS0080.pdf

Lensed Diode Array

http://www.indiamart.com/newage/laser-diode-arrays.html

Some resources

1) http://www.princetel.com/tutorial_collimator.asp