The sixth project was an exercise in 3d scanning and printing.

Objective: 3d scan an object, make a composite, print the object

Materials: Konica Minolta 3d digitizer, Zcorp 3d printer, FDM Stratasys 3d printer, geomagic software

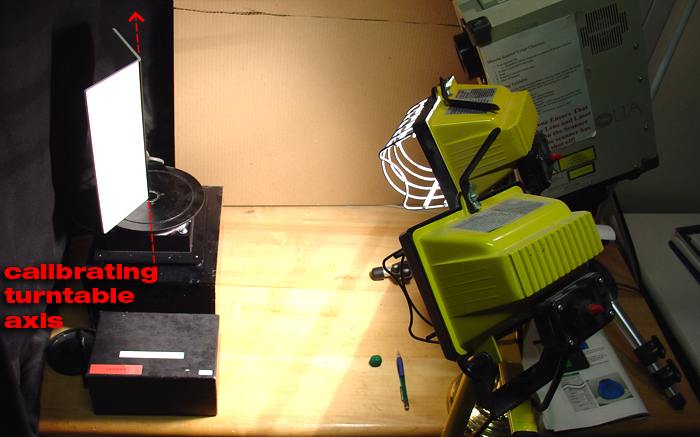

Procedure 1: 3d scan an object

- Open Geomagic

- Click blue sphere icon to begin calibration

- Don't calibrate turntable axis!

- Set white axis board (black spine) on turntable with pins in the table's groove

- Check "Show image window" and "enable streaming video" to watch calibration

- set rotation steps to 90 degrees (goal: minimum number of scans possible)

- update range and color

- if the preview looks good, close window and click "scan" (scanmode = multishot)

- for each successive scan, hit "next." hitting scan again will restart the scanning process

- highlight and click "alt + 1" to look at a particular scan

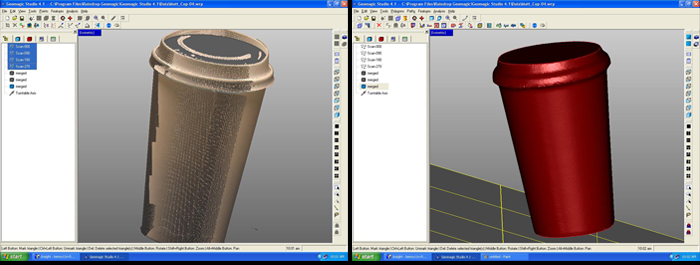

- select all the scans you want to composite, right click and go to "merge"

- make as many "merged" objects as you need, and delete those you don't

- save regularly...

Procedure 2: Clean the merged 3d scans

- Go into the Polygons menu and click "reduce noise" to clean the merged scans

- also go to Polygons menu and click "clean"

- to fix holes go to Polygons menu and click "fill holes" or "decimate"

- right click on the screen and click "clear all" to deselect everything

- go to Polygon menu and click "section by plane" to cut off geometry. align plane with X, Y, or Z to change rotation of cutting plane. intersect plane, delete intersection, and close

- right click on desired "merged" icon, save as .stl and .vrml

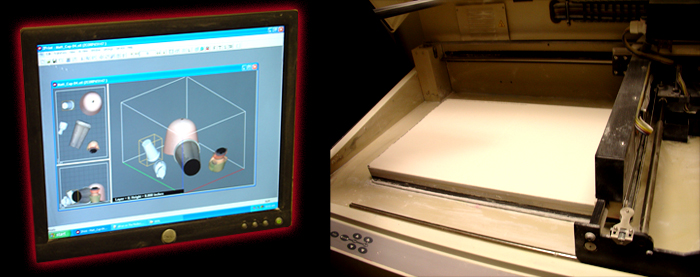

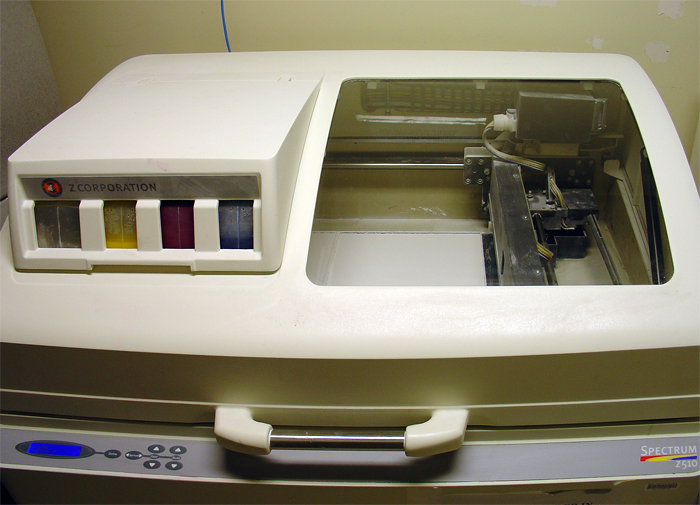

Procedure 3: 3d print the object (Zcorp)

- Prepare/fill the "build" and "feed" troughs using "spread" to flatten the powder

- clean area of print heads w/ deonized water and wipe down with paper towel

- Open Zcorp software

- Import .vrml (use default settings)

- fast render - NO

- click transform > justify to force a piece to a certain position in the trough

- hit "3D" icon to print

- go through the preparation steps (with reference images)

- the machine will warm up, then begin to print

NOTE: manually select excess geometry with the mouse, then type "delete" |