contact // irina chernyakova

1

[0912]

FINAL

PROJECT PROPOSAL

2

[0919]

COMPUTER

CONTROLLED CUTTING

3

[0926] ELECTRONICS

PRODUCTION

4

[1003]

COMPUTER

CONTROLLED MACHINING

5

[1010]

FINAL

PROJECT UPDATE

6

[1017]

MOLDING

/ CASTING / COMPOSITES

7

[1024]

EMBEDDED

PROGRAMMING

8

[1031]

3D

SCANNING + PRINTING 9

[1107]

INPUT

DEVICES 10[1114]

INTERFACE

+ APPLICATION PROGRAMMING 11[1121]

OUTPUT

DEVICES 12[1128]

MECHANICAL

+ MACHINE DESIGN 13[1205]

NETWORKING

+ COMMUNICATIONS 14[1212]

FINAL

PROJECT DEVELOPMENT 15[1219]

FINAL

PRESENTATIONS

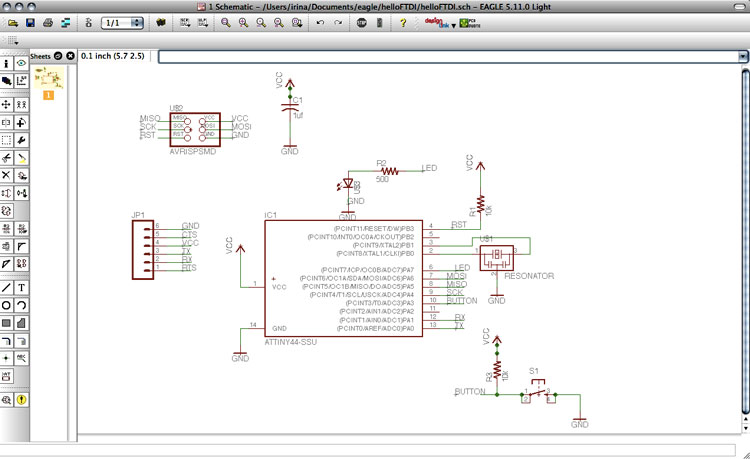

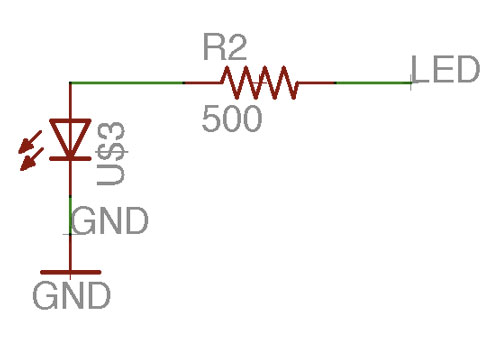

1 schematic design using Eagle (CAD for electronics!)

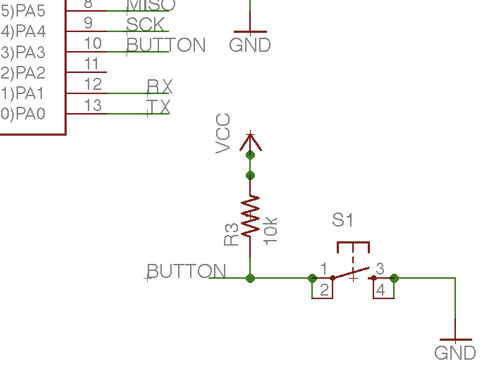

This

week we're designing a board and have added an LED and a button.

Eagle

is

CAD-like program for electronics. We downloaded Neil's fab library,

which includes basic components that can be added to the drawing. The

Eagle tutorial was extremely helpful, and Eagle is easy to learn.

First, open the file in SCHEMATIC. When Eagle asks if you'd like to

open the .brd (BOARD) window, say yes. Always have the two windows

open. This allows the Board to update its components and connections

as you draw them in the schematic. In this window, you can drop in

components and establish all the relationships between parts. I

modified the original drawing by adding an LED at pin 6 and a button

at pin 10. In order for the LED to receive the right amount of power,

we've added a 1K Resistor (R2_500). Below is the schematic window

with the resultant board. You can use the ERC command in the

schematic window and the DRC in the board window to check electronic

and design rules; it seems that Eagle spots errors but would not

necessarily detect if your board is actually drawn correctly and will

work.

added

components:

[LED

and resistor]

[LED

and resistor]

[button]

[button]

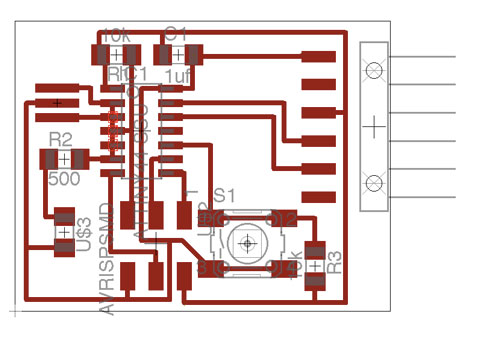

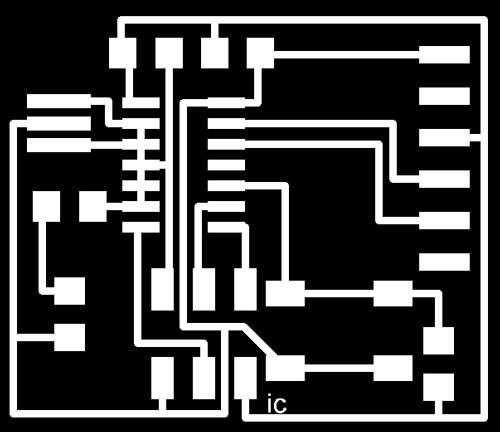

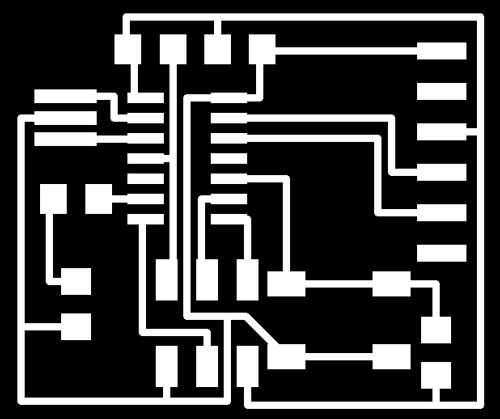

board

design png:

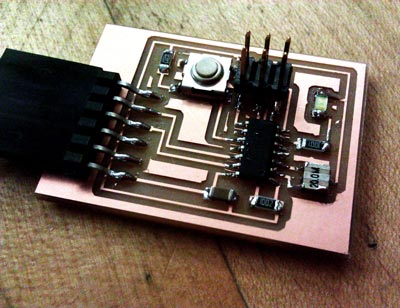

[After

soldering, and programming errors for several hours, we spotted the

error in the board. I accidentally connected the pins with a route,

which caused the entire board to short circuit..] Below is the first

wrong board, then the right one.

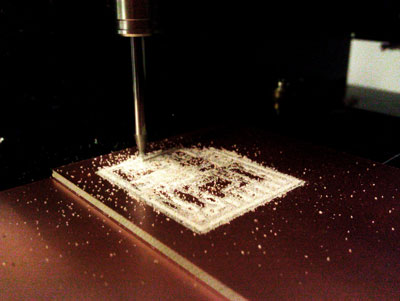

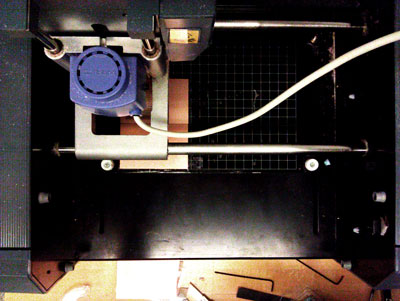

2 milling the board on the Roland Modela

Milling

was much faster this time. I changed the speed from 4 mm/s to 3.7 mm,

and the cut was much smoother and cleaner. There was an issue with

fabmodules, as the path generator was not compiling multiple cuts.

Shahar showed me that checking the XY paths under 3D settings solved

that problem.

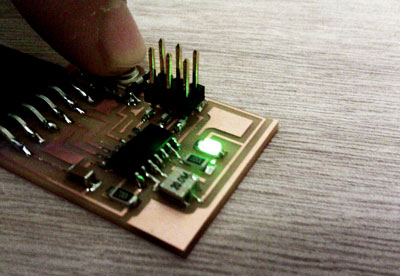

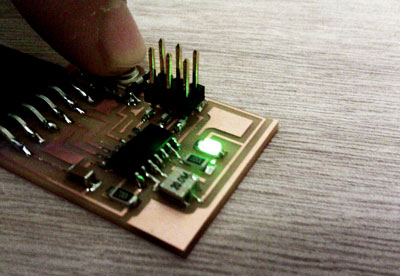

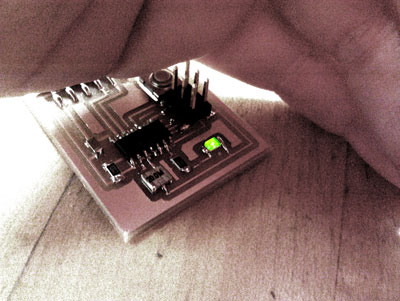

3 stuffing the board

Overall,

stuffing was smooth. Too many small parts. Be very careful while

soldering the LED, the crystal, and the ATTiny. After soldering, I

connected the board with an FTDI cable to my computer, and the LED

turned on! I don't actually think it was supposed to, given my board

was actually wrong and probably had a short-circuit...

3 “programming...”

A

big thank you to Filip, Theodora, Moritz, and Brian Mayton for all

the help! Lesson learned – attend the debugging session.

All my

knowledge below.

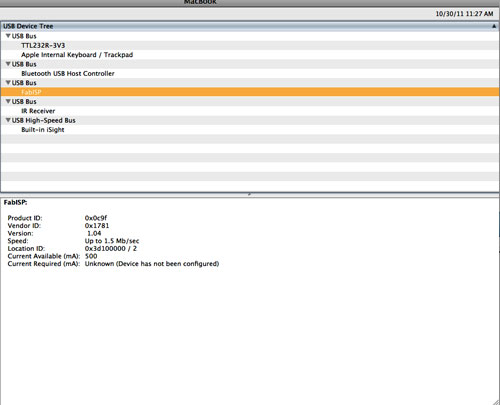

First, check that the FabISP we made in week

[3] is actually programmed and recognized by the computer.

About

my MAC > More info > USB

If

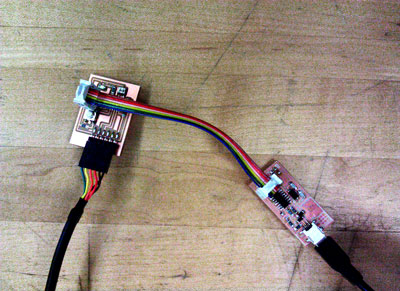

it is, great. Next, connect the FabISP to the computer using a

tinyUSB cable, connect the FabISP board to your new board with a

6-pin wire, and finally connect back the computer using an FTDI

cable.

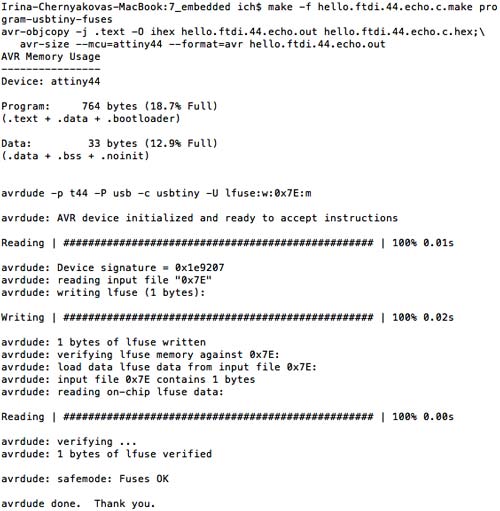

Download the hello.ftdi.44.echo.c and the hello.ftdi.44.echo.c.make files from the website. The C file is a text file that contains the code necessary to instruct how to execute the given program. Each .c files has to have a .make counterpart. You can edit Neil's .make file for new projects. Place this files into designated directory on your computer.

Also

download CrossPack,

which installs the AVR code; as well as an FTDI

serial server.

(Download MAC 64 bit)

Both of these are necessary to run through

terminal.

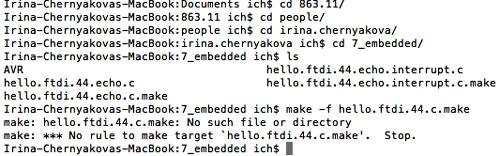

Open

Terminal. [Thanks Moritz for the commands!]

Open the directory in

which the files are located. [cd

Documents/, press

Enter; ls

to list all files within the directory] For example, my sequence

below. Listing all the file within the directory helps spell file

names correctly...

First

step is to create a .hex file. This transfers the .c instructions

into bit information [0 0 0 0 0 1 0, for example].

The command

for this is make

-f hello.ftdi.echo.c.make.

My problem at first was simply that I misspelled the file name..

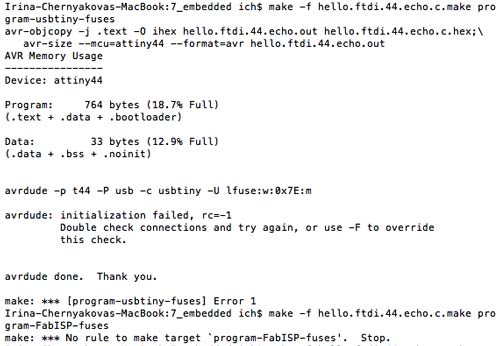

Once

you have a .hex file, you need to program the FabISP fuses.

The

command for this is make

-f hello.ftdi.44.echo.c.make program-usbtiny-fuses.

If something is wrong with your board, it will give you the message

below- most likely Double check connections and try again. Try

switching the pin cable, make sure Pin 1 corresponds to Pin 1 on

both boards.

Run

make

-f hello.ftdi.44.echo.c.make program-usbtiny-fuses again.

If your board is working, connections are right, avr will accept and

execute the insructions.

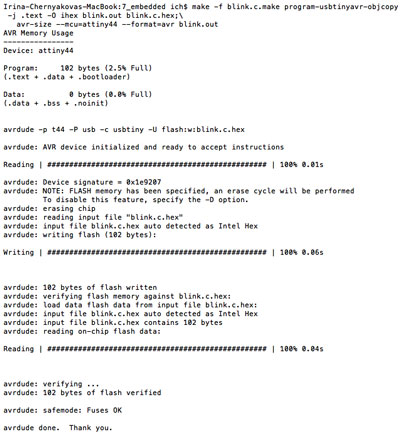

Finally,

run make

-f hello.ftdi.44.echo.c.make program-usbtiny to

program the .c instructions onto the board.

I

was having a issues with programming the fuses. After an e-mail

exchange with Brian, I thought the 20 mhz crystal may be the issue,

so I replaced the crystal, replaced the LED, re-flowed the

connections on the board and still no luck. Turns out the issue was a

route connecting the the traces of the ATTiny microprocessor...

Thanks to Theodora for letting me use her board to practice

programming!

4

“programming...

part two..”

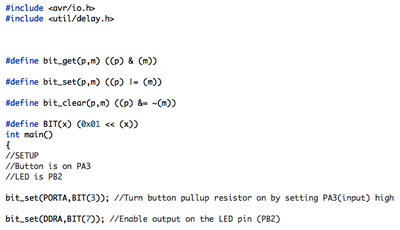

C

+ Terminal

Moritz

suggested I download TextWrangler

to edit text for C, as Text Editor tends to damage the code. I tried

to adapt a blink code from Yeon Wha's website, as it looked somewhat

understandable. Moritz suggested I try this code that he wrote - I

first used the blink code, then modified the blink code to blink in

sync with certain beats and time variations. This is the blink.c

file

and the blink.makefile.

To run this terminal, use the same commands as above, but replace the

file name.

-

make -f blink.c.make

- make -f blink.make program-usbtiny-fuses

-

make -f blink.make program-usbtiny

Images of the code; you can download the files by clicking on file names above.

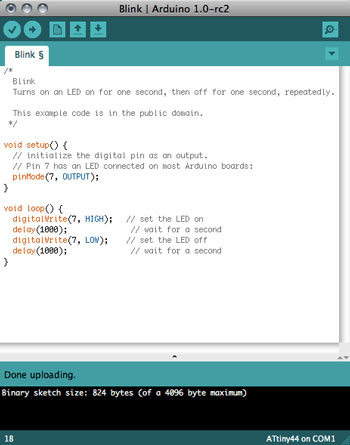

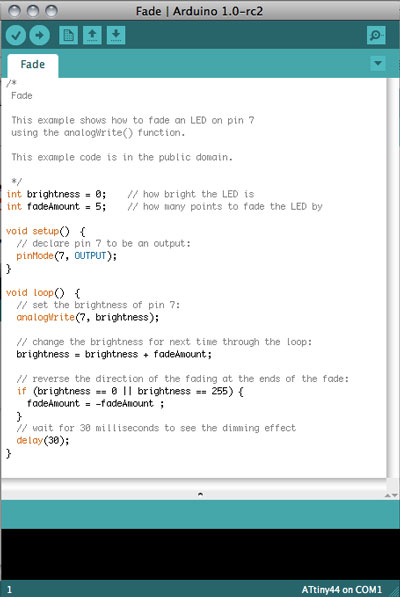

Arduino

David

Mellis gave us a tutorial on using Arduino, which

you can download here. To use Arduino, make sure your board is

connected.

First, select the correct board: Tools

> Boards > ATTiny 44

Then,

slecect the correct programmer: Tools

> Programmer > FabISP

Finally,

Burn

Bootloader.

This

completes the set-up. Afterwards, you can run several of the example

scripts in File

> Examples > Basic > Blink or Fade, etc. Make

sure to change the LED pin number to match your board. BLINK

VIDEO

BLINK

VIDEO FADE

VIDEO

FADE

VIDEO