FINAL PROJECT: OMNI

OMNI tries to answer the following question:

What if we could bring the vision of the

ultimate interactive apartment to the conventional homes of today?

The answer is “yes”, if we could design a

device that was so cheap and simple that it could, not only bring that

experience, but also make it scalable to thousands, millions of homes.

This is how it all started: http://fab.cba.mit.edu/classes/863.13/people/Hasier/Week1.html

And this is how it evolved, subsystem by

susbsystem:

Inspiration

I was inspired by slot car technology, that

is both simple and cheap. I bought an analog scalextric start track ($150) to

understand better how the system works. I decided to keep the standard track

for my project (with the 15V power supply) and focus on the carriage system.

Even the car chassis had to be redesigned because slot cars can only go in one

direction, and of course, they are not thought to accommodate a pan/tilt moving

head either. At least, I salvaged the drive wheels, gears and motors to use in

my system.

Even though I was keeping the track, I

decided to cut it in half, in order to make it more aesthetically pleasing. I

used the vertical saw for that.

Carriage

= 3D design + 3D printing

First iterations were based on using the

caliper and making sense of the key dimensions. I used the Makerbot for quick

iterations (orange and blue in the photos) and the Dimension for the last

version (white). I used solidworks for the 3D design.

Some technical problems with the makerbot

(at least I got to learn the innards of the machine):

I mounted in the chassis the parts I

salvaged from the original car:

- Wheels

- Drivetrain

- Guidance

connector. I used two (the two that come with the two slot cars in the set), so

that the car could go in both directions

As it can be seen in the picture, Ięm using

standard Neodymium magnets to fake gravity.

Pan/Tilt

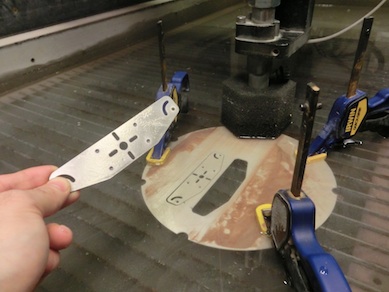

Bracket = 2D design + Waterjet +

Bending

For the pan/tilt bracket I was inspired by

an old pan/tilt bracket I found in my lab space.

Process:

- 2D design in

solidworks

- Cutting in the

waterjet

- Bending

Hasiduino

= Electronics Design + Fabrication

The electronics has been an ongoing project

during the whole semester. Check:

http://fab.cba.mit.edu/classes/863.13/people/Hasier/Week11.html

http://fab.cba.mit.edu/classes/863.13/people/Hasier/Week12.html

The summary:

The design is based on Neilęs fabduino, but

I added the h bridge, dc motor connector, servo connectors, regulator and

headers for the pins. Ięm getting decent with eagle and I managed to create a

pretty small board.

My debugging skills are also improving:

check the h bridge bottom pad touching one of the pins and shorting one of the

control pins to ground.

DC

motor + Servos = Output Devices

The DC motor came with the original car and

the servos are from Spakfun: https://www.sparkfun.com/products/9065

The Hasiduino controls both the DC motor and

the two servos (Ięm attaching the code to see how they are controlled at the

end). I mounted them to the chassis. Time constraints led me to use Velcro tape

(probably too much), which I call “magic tape”. You can use it for “almost

“anything.

I had to make some adjustments to the

connectors of the hasiduino, so that the pan/tilt bracket would not hit it.

Quick hack using ftdi pins.

Mounting motors. I used a lego block as a

hack to adjust to the chassis width.

Input

devices = RFID reader / Reed Switch

https://www.sparkfun.com/products/11827

I bought an rfid for specifying the location of the car.

Unfortunately, even though I had the rfid reader working, the car was too fast

to recognize the tags when moving.

So, due to time constraints I decided to use

some Reed switches temporarily to stop the car in specific locations:

https://www.sparkfun.com/products/8642

They seem faster than the rfid. I had to

adjust the code though (attached at the end), as sometimes the car was still

too fast to see it and go to the subroutine that stops the motor.

This is something I would like to rethink

for the next version, as it is extremely important to have a good location

system for the application.

Communications

= Bluetooth Terminal

I found a Sparkfun Bluetooth terminal that

was extremely easy to interface using the arduino serial.

https://www.sparkfun.com/products/10269

More details in week 12:

http://fab.cba.mit.edu/classes/863.13/people/Hasier/Week12.html

Integration

Adding all subsystems

Trying to minimize consequences of possible

accidents under the table (car falling from track):

Accidents

Fatal accidents (the worst so far):

Testing new system after fatal crash:

Final tests before open house:

http://www.youtube.com/watch?v=P7liMzWv3YE

I had a very few accidents so far, but when

there is one it is a tragedy, as this “toy” falls from 3 meters high.

Code

Using Arduin:o

#include <Servo.h>

int servo = 5;

int servo2=6;

//#define rxPin 1

//#define txPin 0

// Pins for H-bridge

int h1 = 9;

int h2 = 10;

Servo ser;

Servo ser2;

int magnet1=8;

int magnet2=7;

int led=13;

int magnet1enable;

int magnet2enable;

void setup() {

Serial.begin(115200); //

Start bluetooth serial at 9600

ser.attach(servo);

ser2.attach(servo2);

// initialize the digital pin as an output.

pinMode(magnet1, INPUT);

digitalWrite(magnet1, HIGH);

pinMode(magnet2, INPUT);

digitalWrite(magnet2, HIGH);

pinMode(led,OUTPUT);

digitalWrite(led, LOW);

magnet1enable=0;

magnet2enable=0;

pinMode(h1, OUTPUT);

pinMode(h2, OUTPUT);

Serial.println("Enter -1 to move the car backwards, 1 to move the

car forwards, 0 to stop it");

}

// the loop routine runs over and over again

forever:

void loop() {

if (Serial.available() > 0) {

int input =

Serial.parseInt();

if (input == 0) { // stop

stop();

} else if (input == 1) { //

forwards

setDir(true);

delay(1000);

while(digitalRead(magnet1)==HIGH){

}

stop();

digitalWrite(led, HIGH);

delay(500);

digitalWrite(led, LOW);

ser.write(160);

delay(500);

ser2.write(110);

}

else if (input == 2){

ser.write(130);

}

else if (input == 3){

ser.write(160);

}

else if (input == 4){

ser2.write(170);

}

else if (input == 5){

ser2.write(100);

}

else if (input == 6){

ser2.write(50);

}

else if (input == 7){

setDir(true);

delay (1000);

stop();

}

else if (input == 8){

setDir(false);

delay (1000);

stop();

}

else{

setDir(false);

delay(1000);

while(digitalRead(magnet2)==HIGH){

}

stop();

digitalWrite(led, HIGH);

delay(500);

digitalWrite(led, LOW);

ser.write(120);

delay(500);

ser2.write(170);

}

}

}

// Sets the motor direction to be forward if

forward is true,

// backwards otherwise

void setDir(boolean forward) {

digitalWrite(h1, !forward);

digitalWrite(h2, forward);

}

void stop(){

digitalWrite(h1, true);

digitalWrite(h2, true);

}