This week’s assignment was to make a cardboard press-fit construction kit using computer-controlled cutting. I’ve designed a kit made up of similar blocks which can snap into one another in different configurations to make a bigger structure.

The design is not entirely original. It was inspired from a sample design presented in lecture. I took the idea of a single repeated block that can interlock with itself at right angles and designed the connection joint to be a buckle. The design was modeled in KeyCreator, and the blocks cut out with a laser cutter.

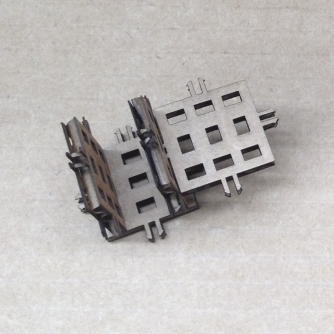

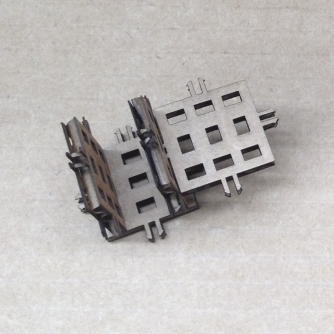

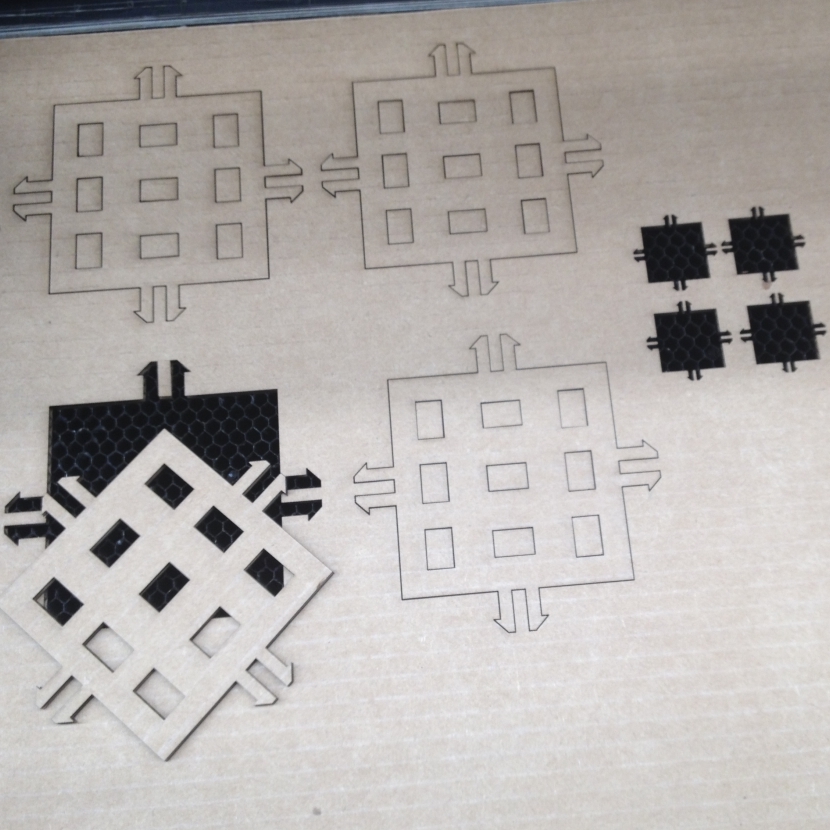

My original design had blocks one square inch big (1" by 1") with tiny little protruding buckles a little under 3/16" long (the thickness of the corrugated cardboard) and 1/16" wide. I laser cut samples of this design and found that while the blocks are cute and little, the slenderness of the buckles made them very weak. So I decided to scale up the blocks in rhino at the laser cutter and re-cut them.

Bad idea.

It turns out that certain dimensions (specifically the length of the buckle) are static values - Duh! The buckle length is dictated by the thickness of the cardboard onto which it buckles, so scaling the entire block rendered the buckles completely useless. So, after my failed attempt at scaling, I had blocks that weren't good for anything. Well, except for show and tell.

Actually, I don't take credit for the scaling idea. Here's Robert, scaling my block before laser-cutting.  And there's Ye documenting her project.

And there's Ye documenting her project.

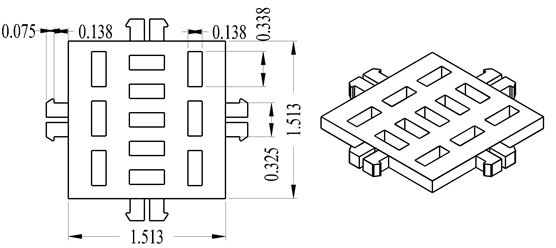

Anyway, I re-did the design in CAD and was able to scale up the size of the blocks and width of the buckles while keeping the buckle length constant. I also made a few other changes, including buckle-hole size (necessary if buckle width is changing) and number of buckle holes on each block. This is the final design with dimensions in inches.These strange-looking digits weren't chosen arbitrarily - I used sisteenths and thirty-secondths of inches. These here are my carefully-selected numbers rounded to decimals. Sigh.

I am quite pleased with the results. However, these construction blocks would have worked better in a more resilient material such as acrylic or plastic. Resilience is the ability of a material to absorb energy when it is deformed by a load and release the energy when when the load is removed. Corrugated cardboard, with its low resilience in the parallel plane (does this make sense?), doesn’t like being snapped or flexed. So it doesn't work very well as a material for buckles, which have to be able to bend on insertion and unbend to fasten when fully inserted. For this kit, the buckes fail after one or two times of insersion. Consequently, the construction kit can only be used once or twice before latches fold in and the joints become too weak to hold. Alternatively, I could have used a different joint design, such as the one shown here.

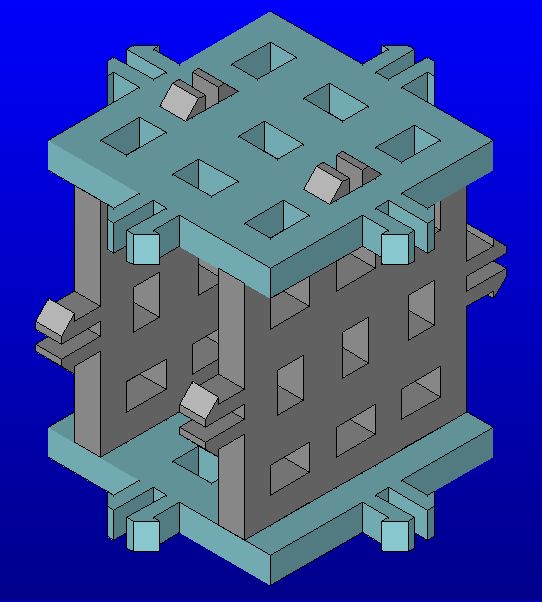

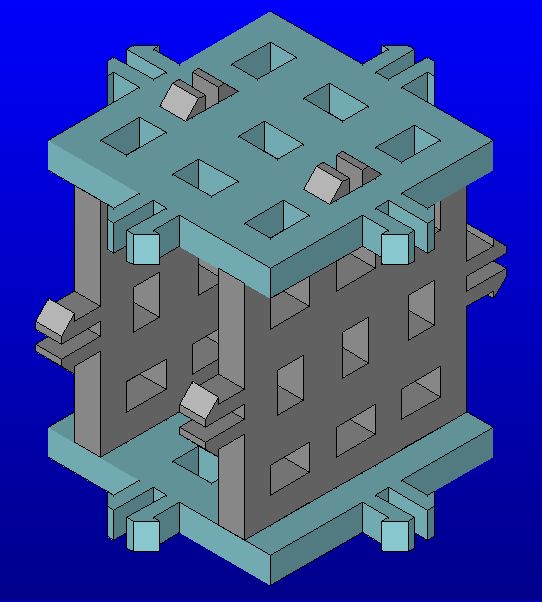

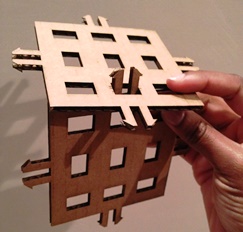

Here is an example of a structure made with these blocks. We'll call him the Watertown Tower (I live in Watertown and this structure reminds me of the Eiffel Tower). Imagine how cool this would be in acrylic or plastic! I would totally have played with this toy as a child!