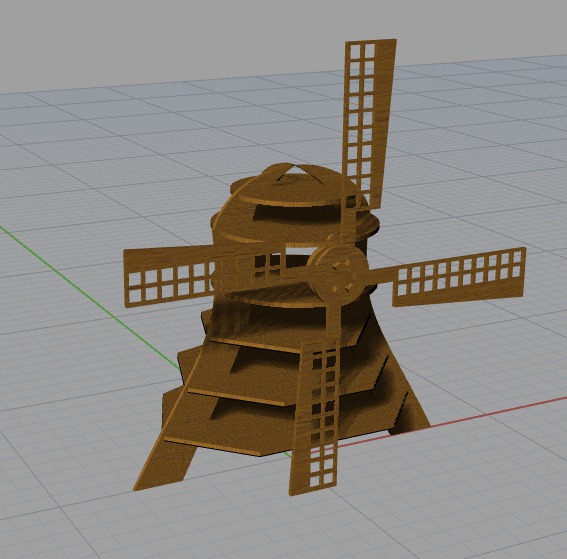

here is my preliminary drawing, modeled on rhino:

i later rotated the two windmill "walls" on the left and right side each 25 degrees toward each other for aesthetics and stability. as a note for next time using rhino, i should keep the curves even after extruding the surface in order to edit later. i realized that Duplicate Face Border gives me a curve with more points than my original vertices, which makes it difficult to maintain straight edges.

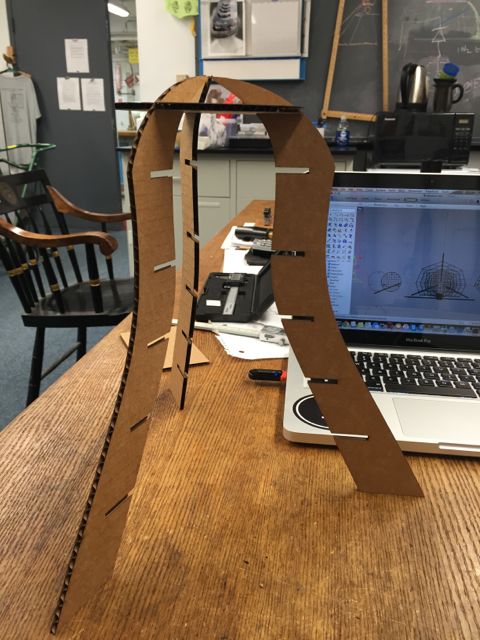

i started by laser cutting a few pieces to test the grip:

i made the notches .150 inches thick, which resulted in a good tightness. i should, however, chamfer the slots next time because the tightness made assembly much more difficult later on as more pieces were introduced. i ended up marking some irreparable creases in my pieces because i was too impatiently forceful.

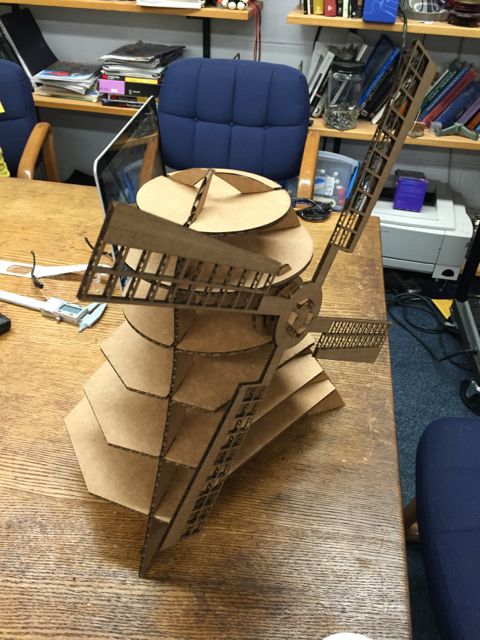

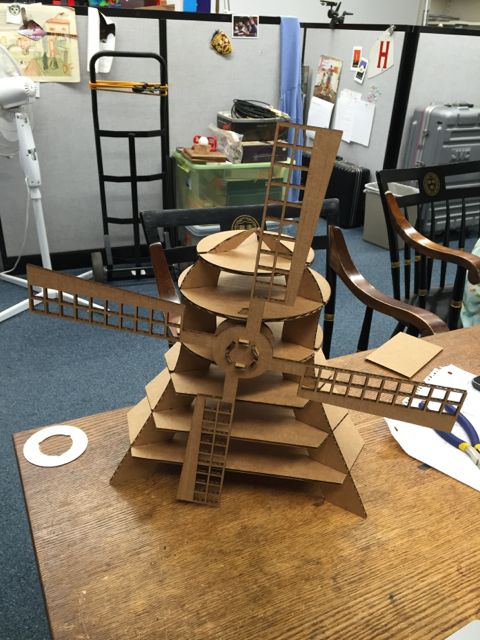

the finished product:

i liked the way the blades turned out--especially from the side where you can see the holes between the corrugated paper innards in addition to the cutout square pattern. but otherwise, it's a derpy, dorky, dalek-resembling dutch windmill!

but it does spin!

note:

i had intended to make the body of the windmill hollow, which i think would make it more elegant. but i just completely forgot.