Week 2: Computer Controlled Cutting

21 Sep 2016 · 3 min readI used the laser cutter to build a press fit construction kit.

I’ve only used a laser cutter once before, and I didn’t really know what I was doing back then, so in my design, I ended up with loose joints because I didn’t understand what a laser kerf was. Back then, I compensated with epoxy glue, so I didn’t end up with a nice friction fit design. This time, I wanted to make sure I got it right, using a parametric modeling tool and making sure it was really easy to tune the parameters until everything fit perfectly.

Design

I took the “press fit construction kit” part literally — I designed a part that was designed to fit together with other copies of the same part, forming a construction kit that could be used to make all sorts of (mostly very boxy) shapes.

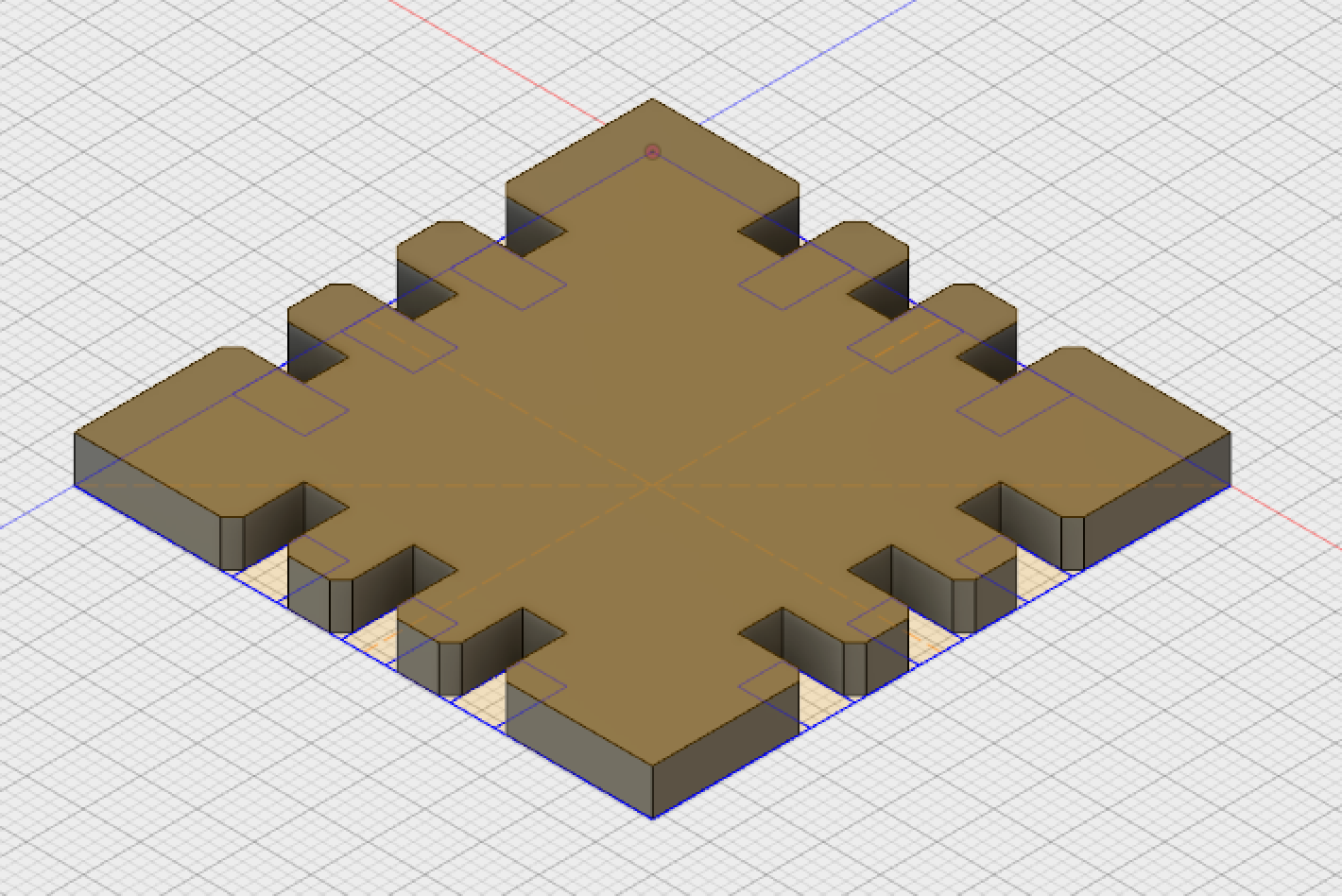

I used Fusion 360 to parametrically model a square shape with 3 cutouts on each side for slotting into other copies of the same shape. Parameters included things like piece size, slot spacing, and most importantly, material thickness and laser kerf width.

Cutting

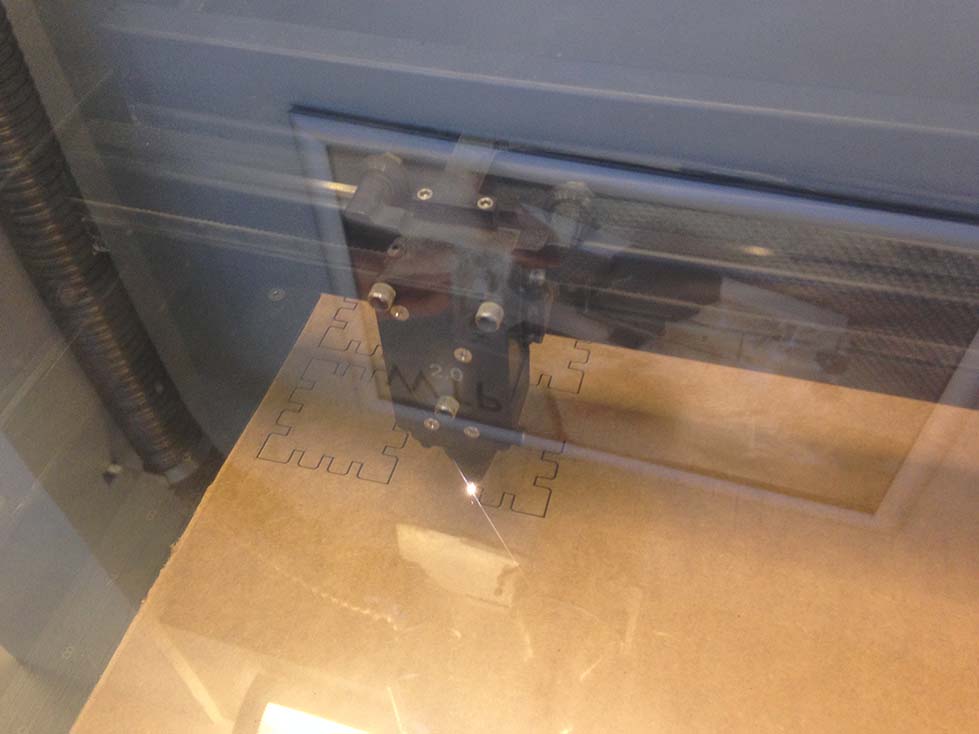

I was cutting this on a Universal PLS 6.75. When cutting, I had to experiment with laser settings to get good results. Initially, I was using the materials database, setting the material to balsa wood (it was actually cardboard), 0.160” thickness, with a +50% modifier for vector cutting.

That didn’t make clean cuts through the material, so I switched over to manual control. I tried using 70% power, 8% speed, 300 ppi, and setting the thickness to 0.160”. That worked a little bit better, but it wasn’t quite perfect — I still didn’t get clean edges on some of the pieces I was printing. I tried boosting the power to 75%, and I consistently started getting nice pieces.

Experimentation

After getting the laser cutter parameters tuned, I did my first real cut:

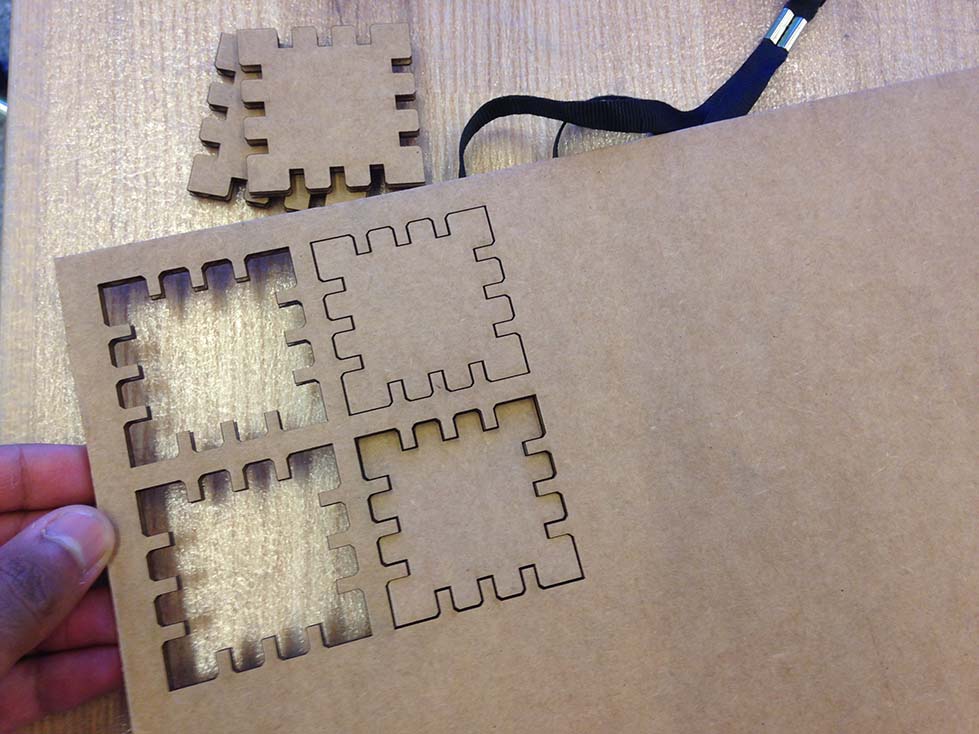

After playing around with the physical pieces, I felt that the notches were too close together, so I tweaked the design and cut some new pieces. I was happy with the new results, so I cut 60 copies:

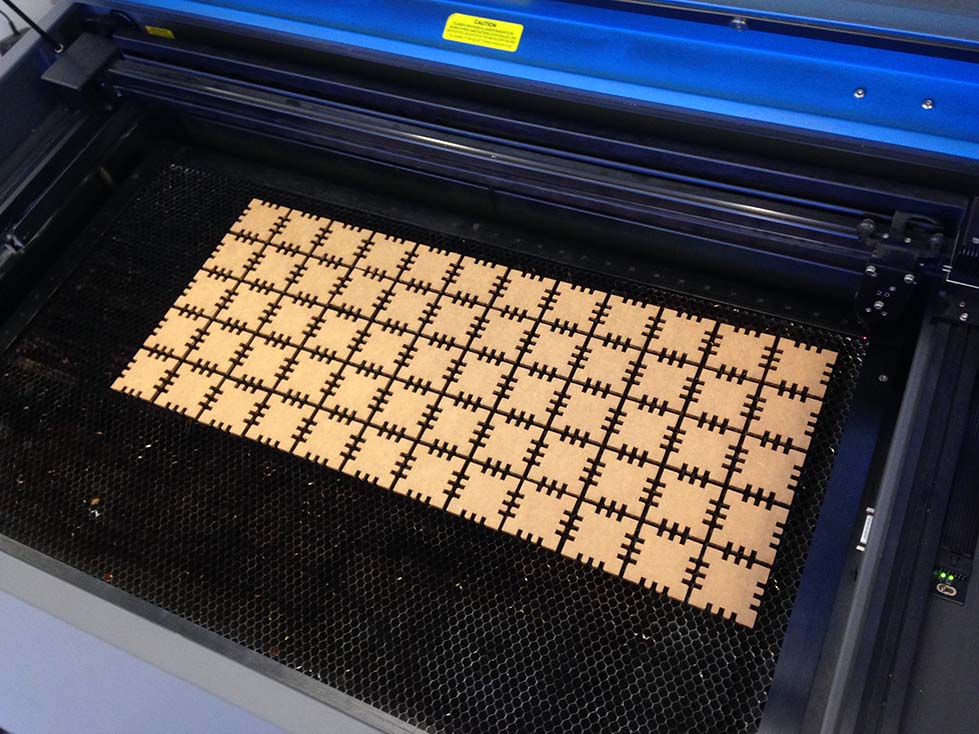

The pieces looked quite nice when neatly laid out on the laser cutter bed:

Final Result

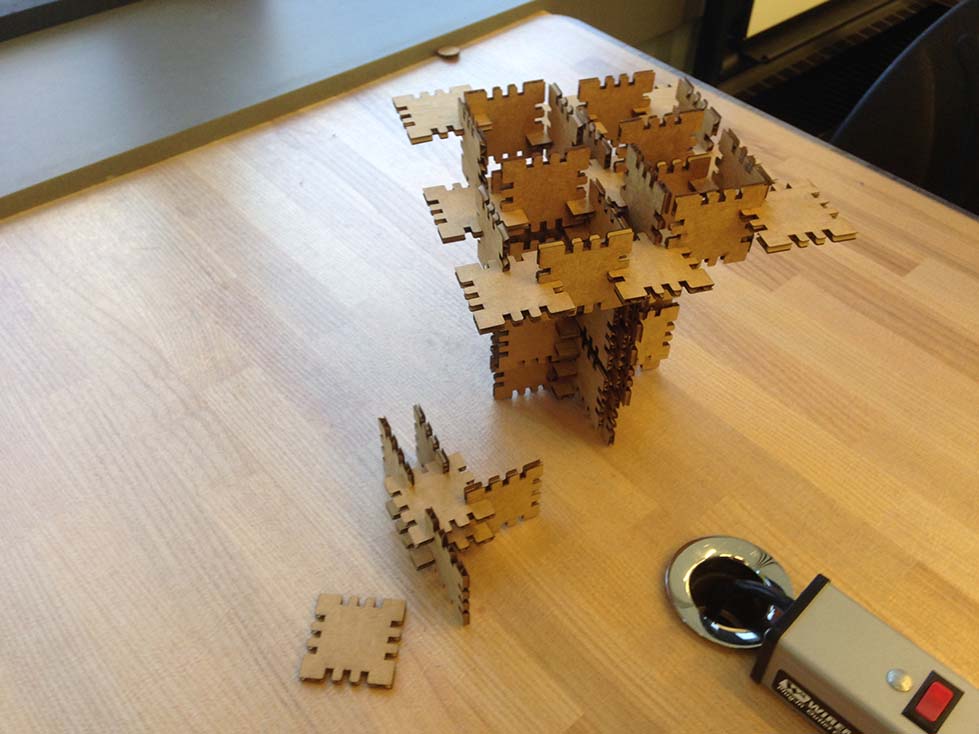

After printing, I ended up playing with the pieces for some time, and I ended up with this art:

Bonus: Laser Cut Laptop Stand

After getting some experience with the laser cutter, I was interested in making something useful for myself using the tool. I decided to make myself a laptop stand, designed parametrically in Fusion 360: