Week 3: Electronics Production

28 Sep 2016 · 2 min readThis week, I made a FabISP, an in-system programmer for AVR microcontrollers.

Milling the PCB

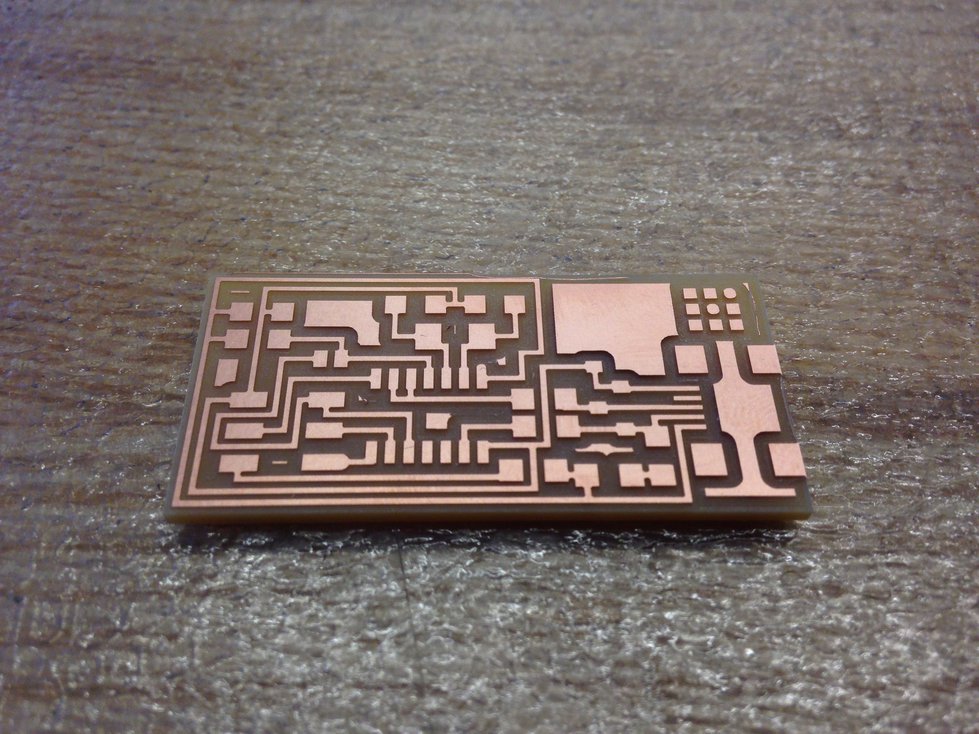

I milled a PCB (using these traces and outline).

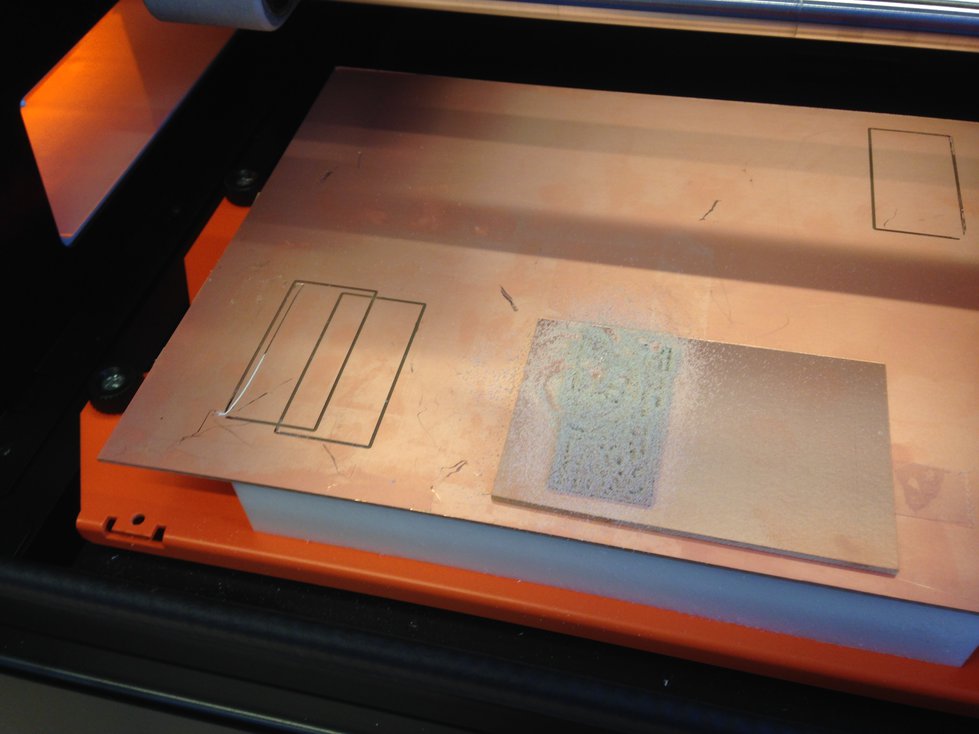

I used fab modules to calculate toolpaths for the Roland SRM-20 milling machine, using all the default settings. I used a 1/64 end mill for cutting PCB traces and a 1/32 end mill for cutting the outline:

After working through it carefully, everything worked on the first try, and I ended up with a nice finished PCB with pretty clean traces:

Soldering Components

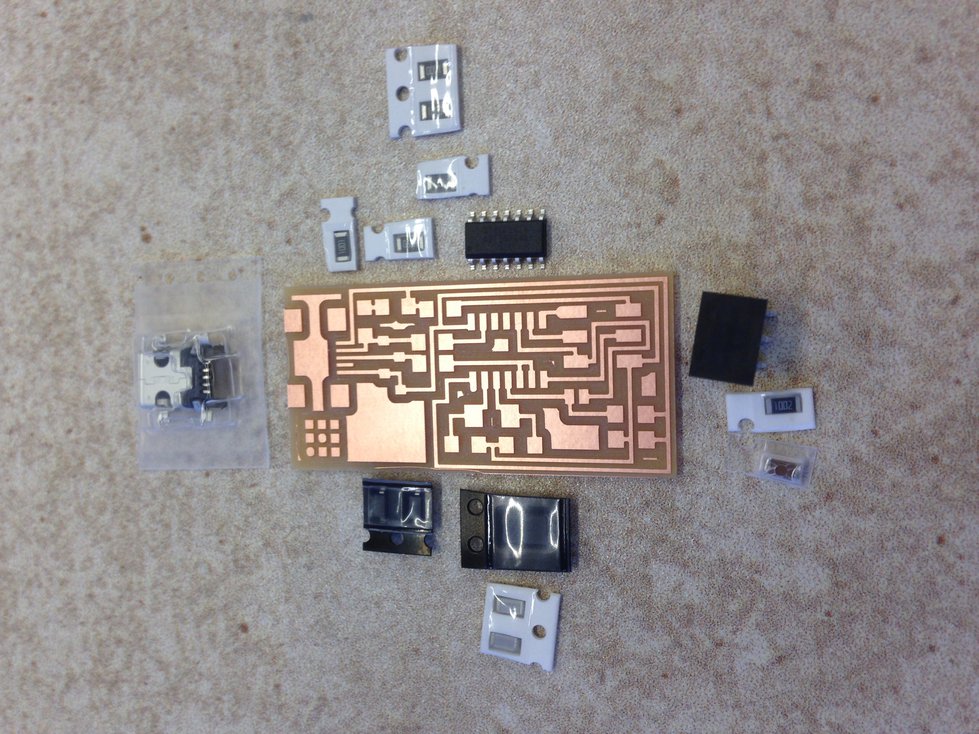

Next, I soldered the components. Before starting, I picked out all the parts and made sure I knew what was going where:

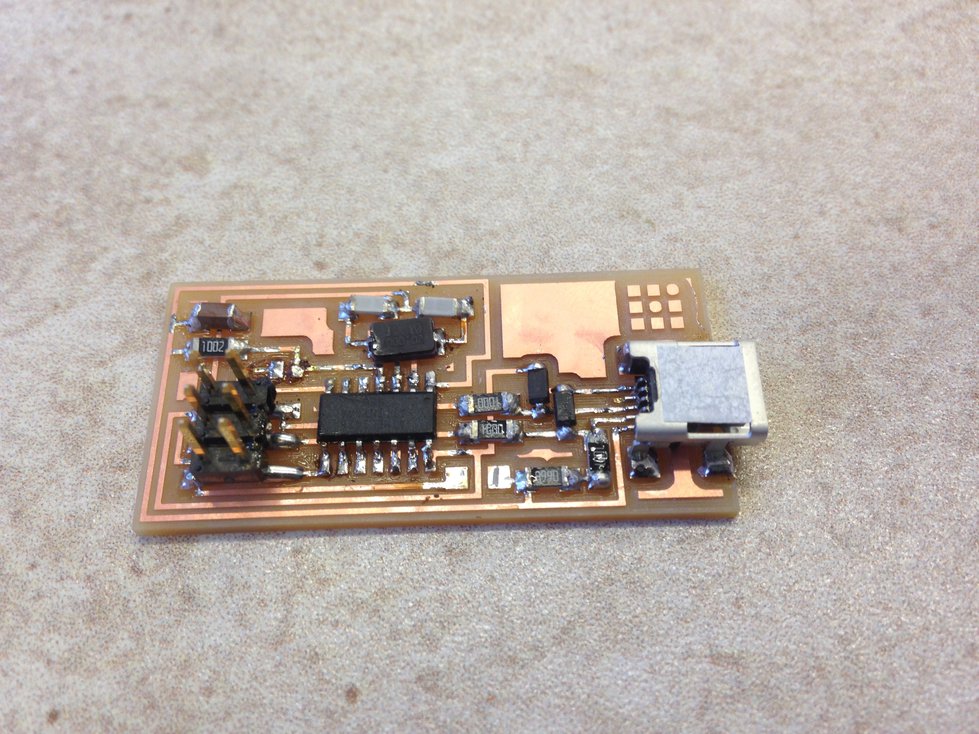

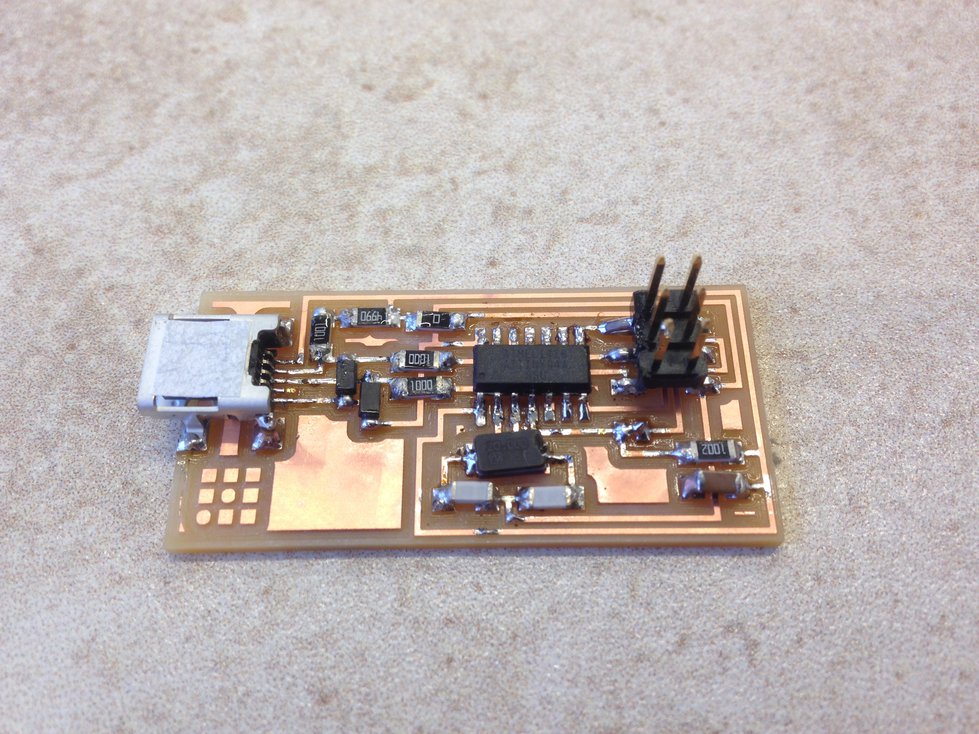

As I soldered components, I tested for continuity to reduce the amount of time I would have to spend debugging later. After about half an hour of soldering, I had a board that was ready to be programmed:

Programming

I used Debian 8 (Jessie) and followed the

instructions

for using Ubuntu (Ubuntu is based on Debian). I needed to use sudo when

running some of the commands that talked to USB devices, but besides that, the

instructions worked perfectly.

After programming, I removed the zero-ohm resistor and solder joint to finish my programmer: