Week 8: Molding and Casting

02 Nov 2016 · 4 min readThe assignment for this week was to design a 3D mold, machine it, and cast parts from it.

Because this was my first time molding and casting, I decided to keep it simple and do a one part mold. I followed a three step process — I machined a positive out of machineable wax, made a mold using OOMOO 25, and cast a part out of Hydro-Stone.

Designing the Part

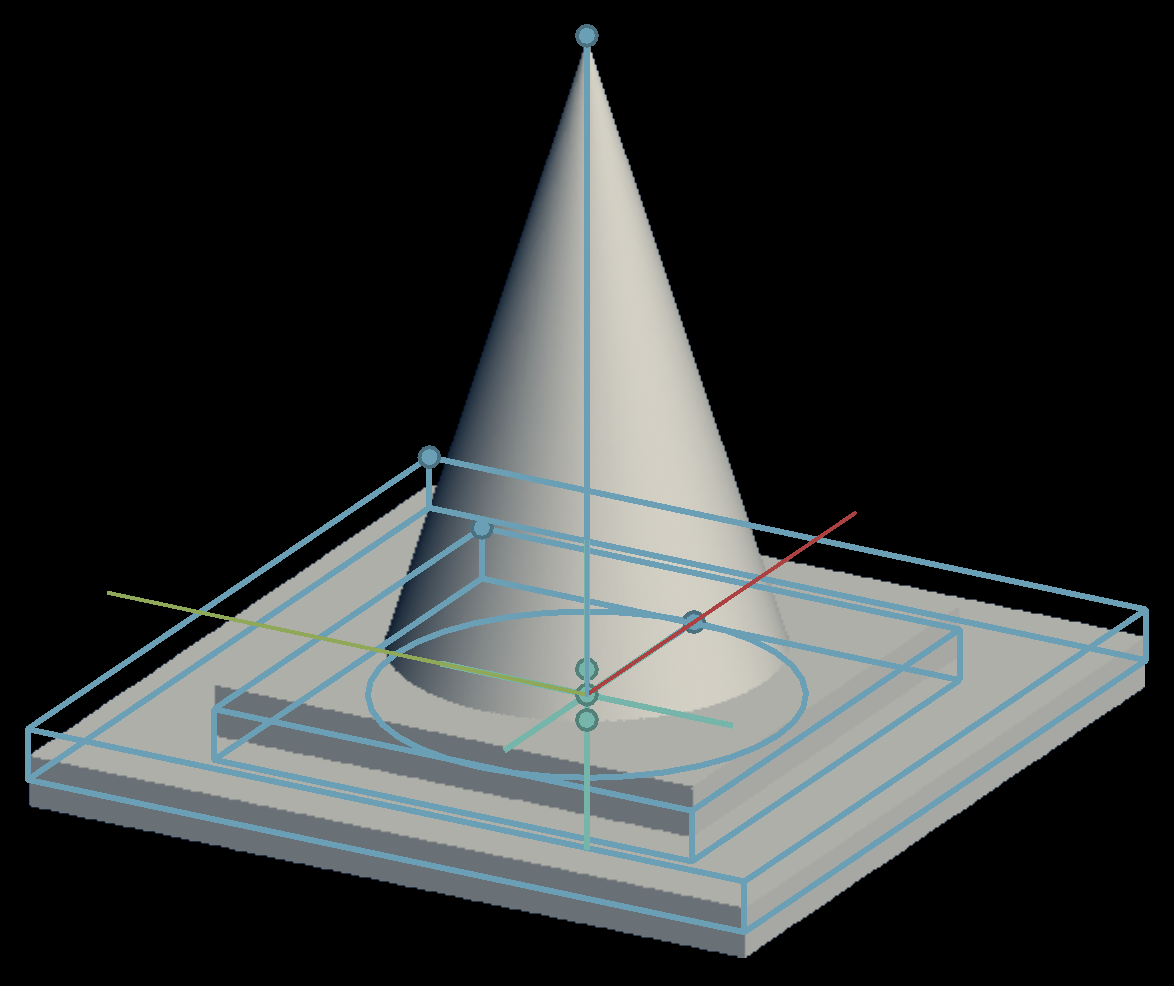

I decided to make a miniature traffic cone. I designed the part using Antimony, and the process took about 5 minutes:

Machining the Positive

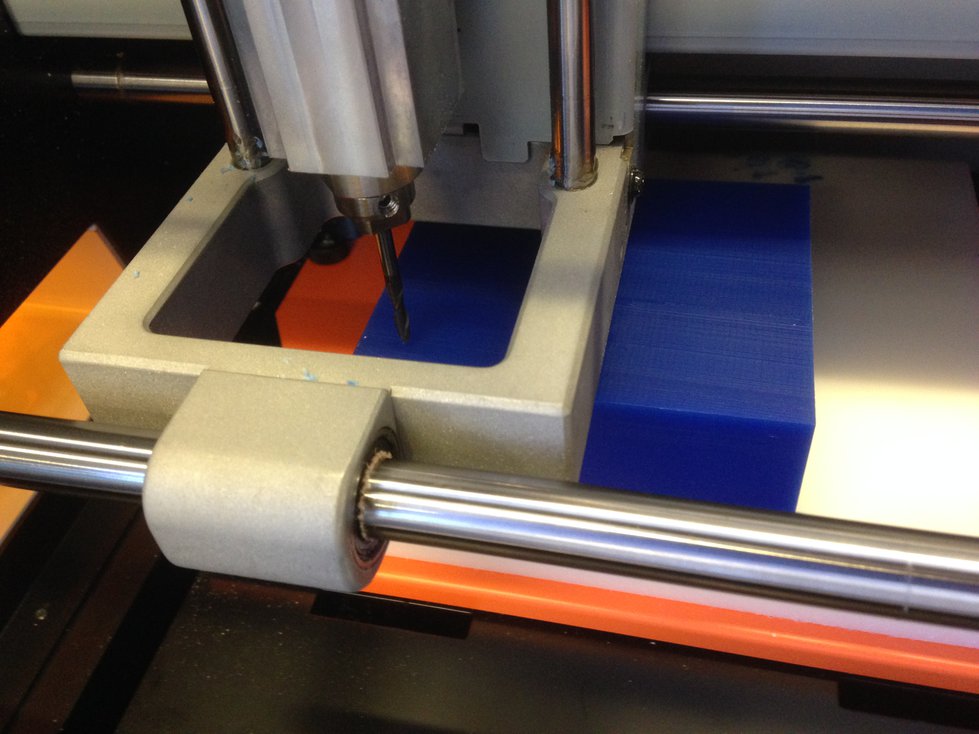

I used fab modules to drive a Roland SRM-20 to machine my piece, using a two phase process, first doing a rough cut and then doing a finish cut. For both phases, I used a 1/8” flat end mill.

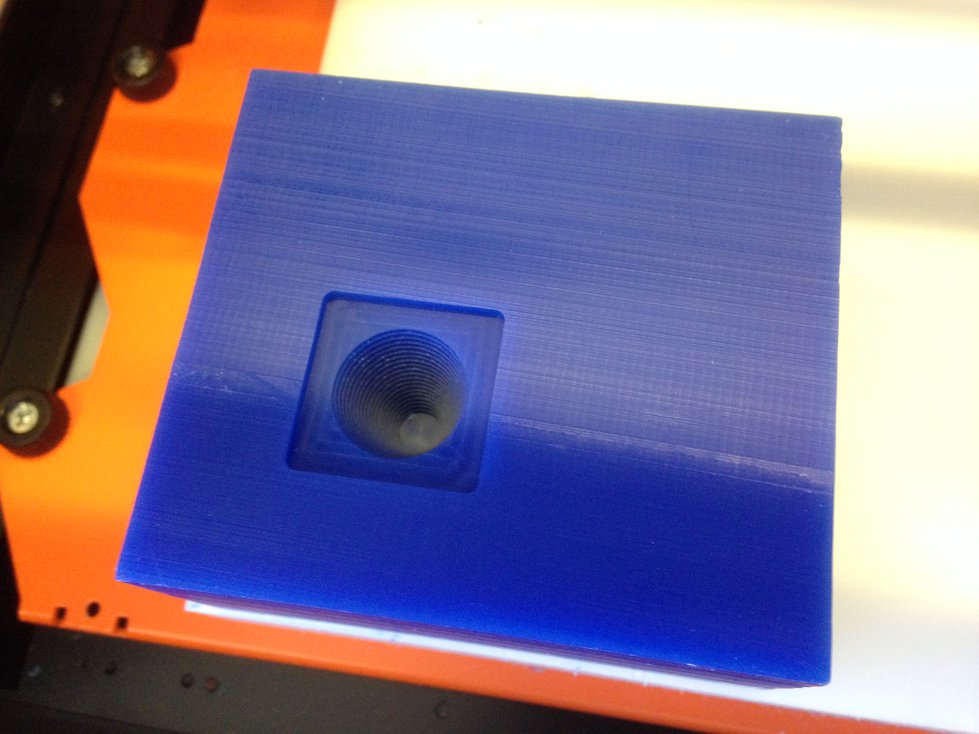

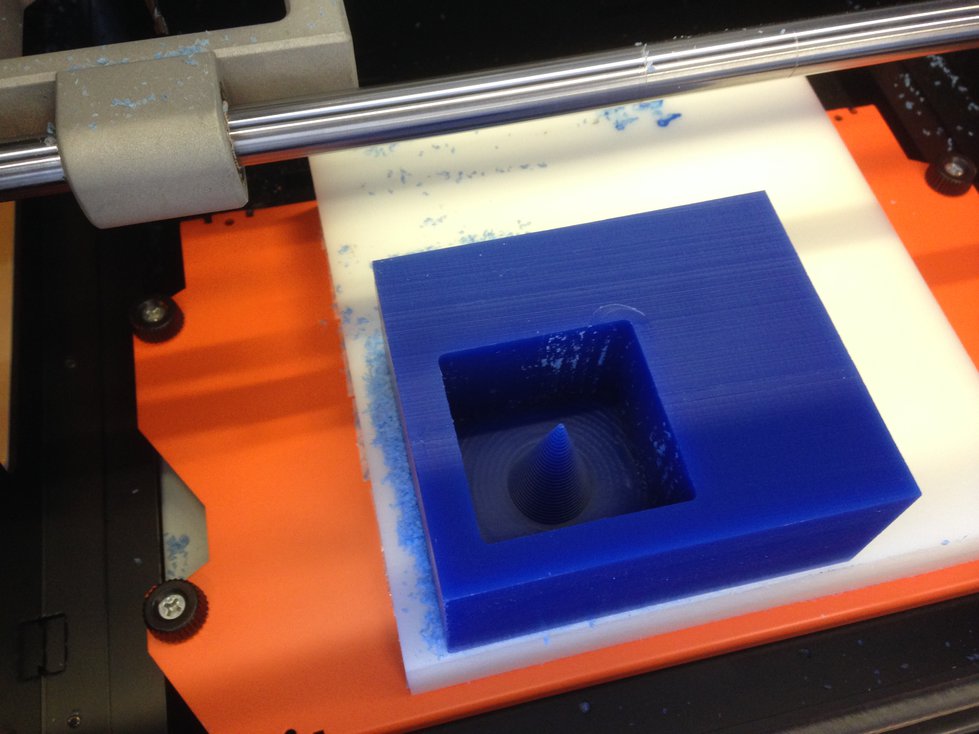

Without a good understanding of how the software worked, I accidentally ended up machining a negative instead of a positive. Here are the results after the rough cut, which took about five minutes:

With a better understanding of the software, I started another job to machine a positive. I tried to reuse my material, but the piece didn’t fit, so I cancelled the job:

I got a fresh piece of machinable wax and started another job:

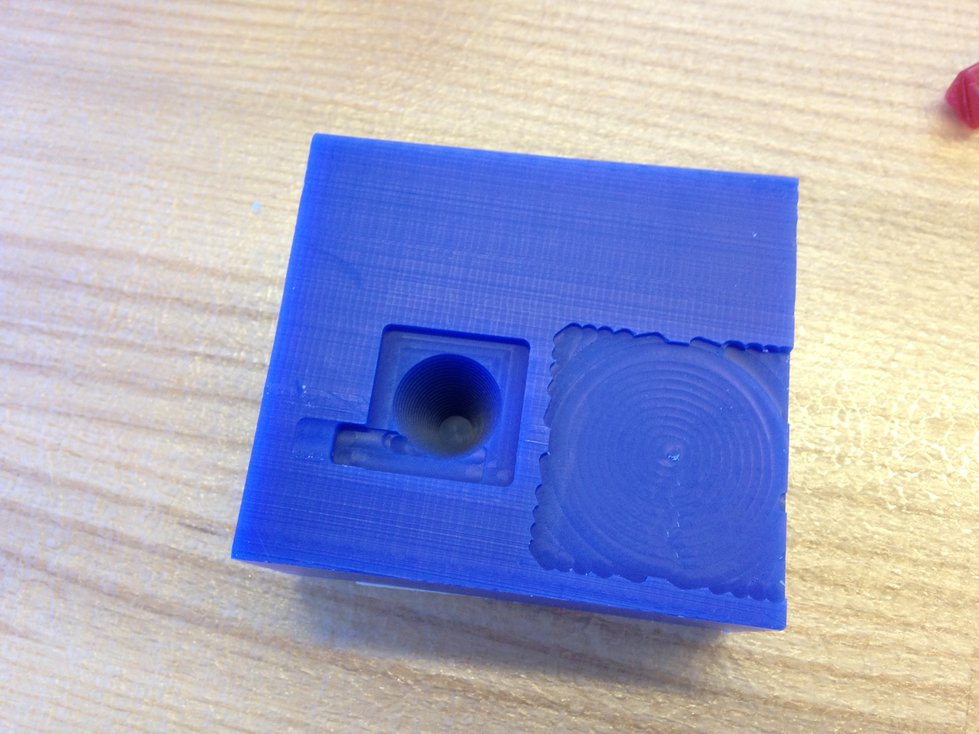

This time, I had another problem. My piece was very deep, and the end mill was not quite long enough to reach the bottom of the piece without the collet coming into contact with the surface of the material. It was only a millimeter or so, but still, it caused problems. It seems that the SRM-20 has some way of detecting this kind of condition, perhaps reacting to a suddenly increased torque at the motor. After waiting for about 40 minutes, my job was 98% complete, and the machine automatically stopped and terminated my job. The collet came into contact with the material at the top right:

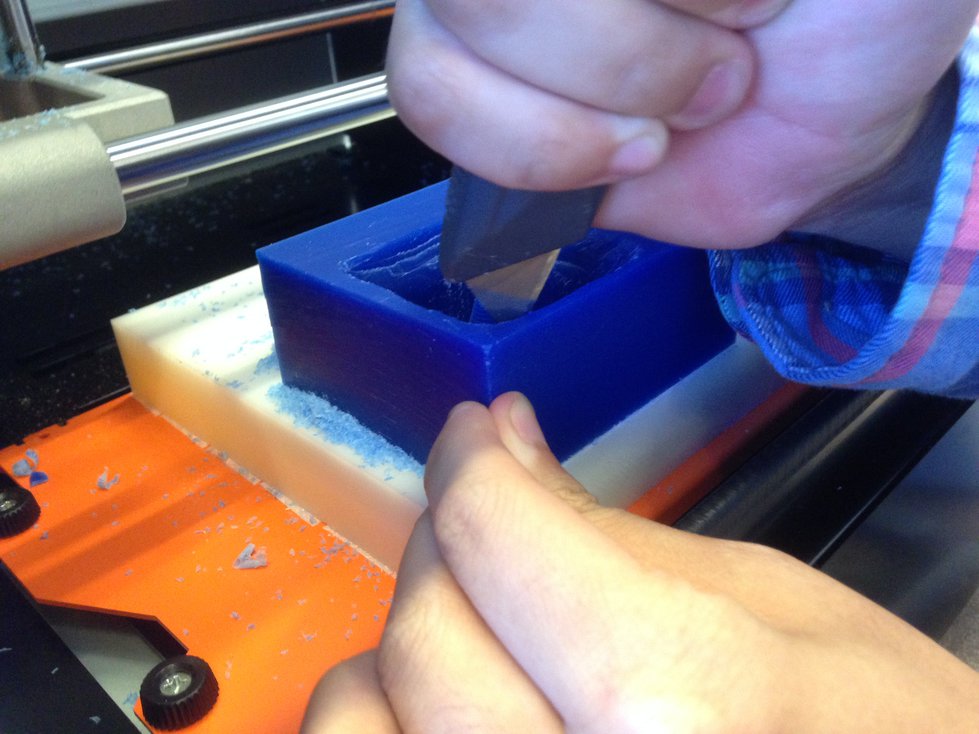

I considered starting another job to mill out material to make space for the collet. My friend Kevin Kwok had an even simpler idea — manually carve out a small amount of material using a utility knife:

The process took about 5 minutes. Next, I had to deal with another problem: my job had been terminated 98% of the way through, and I needed to redo the last 2% of the job. I downloaded the G-code for the full job, manually removed the first 98% of cutting instructions while leaving the configuration code in place, and sent the modified code to the printer. It worked.

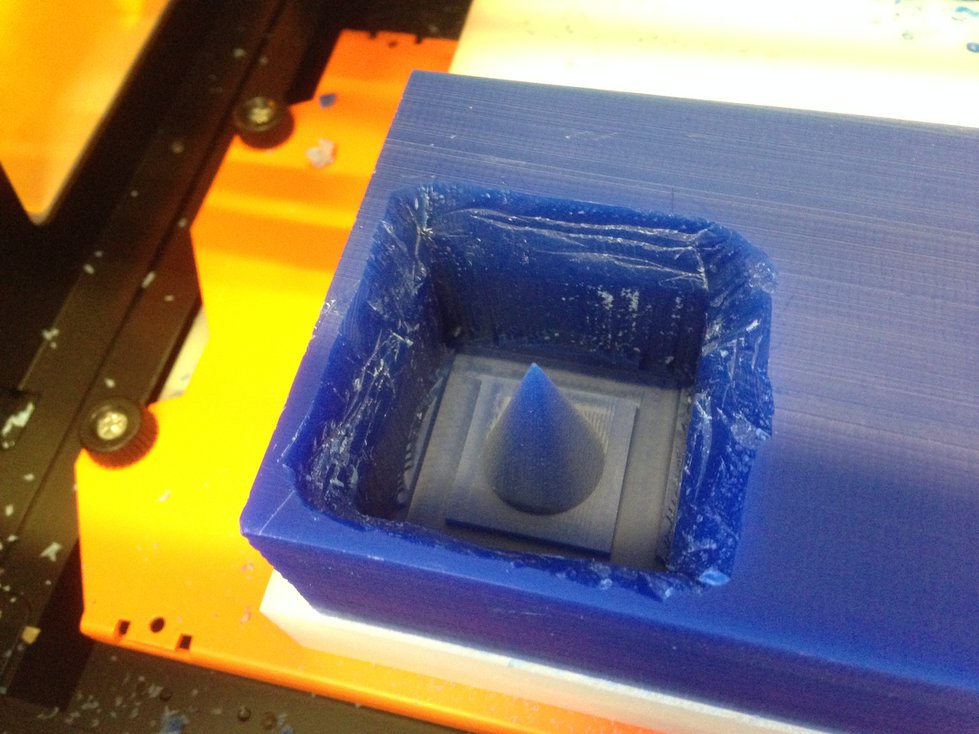

Next, I did a finish cut of the material. This process took about 30 minutes, and everything went smoothly. The finish quality looked really good:

Making the Mold

I made a mold using OOMOO. I mixed the two-part silicone rubber following the instructions on the packaging and poured it into my milled wax. Afterwards, I spent 5 minutes trying to release air bubbles by manually tapping the piece:

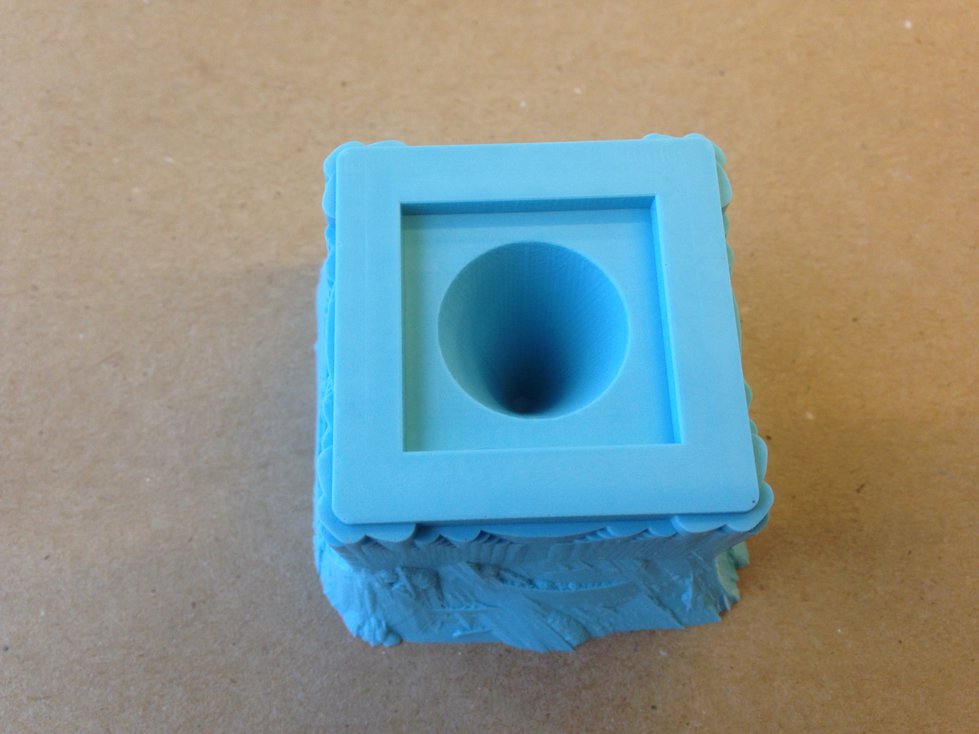

After letting the OOMOO set overnight, I released the newly created mold from the machinable wax:

Casting Parts

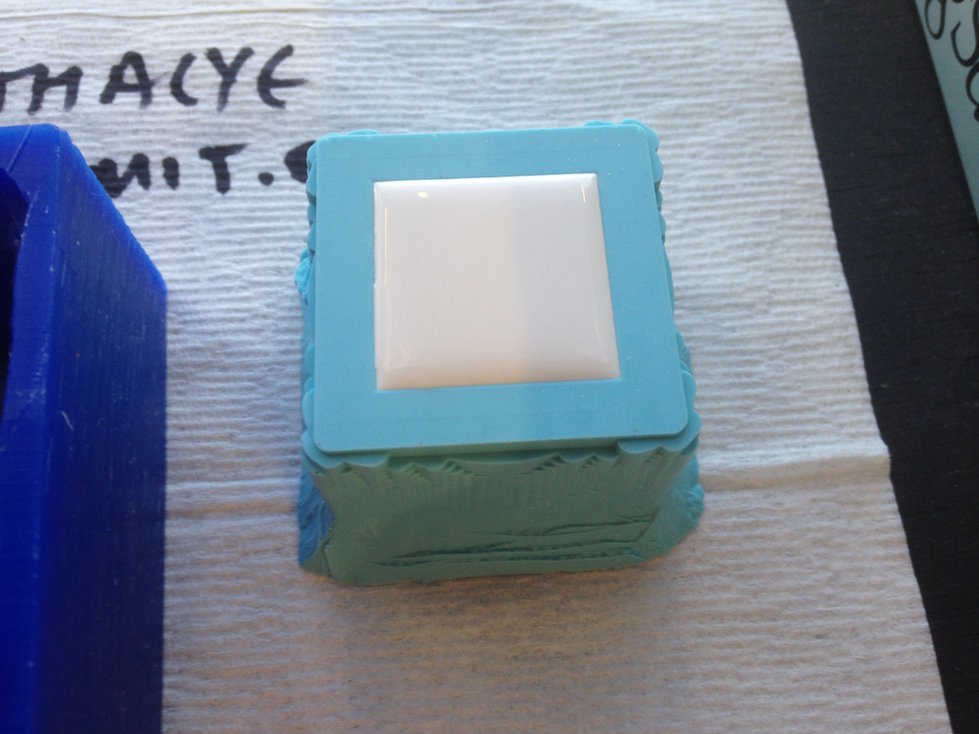

I cast a part out of Hydro-Stone. I followed the instructions on the packaging to mix the powder with the appropriate amount of water, and I poured the liquid into my mold:

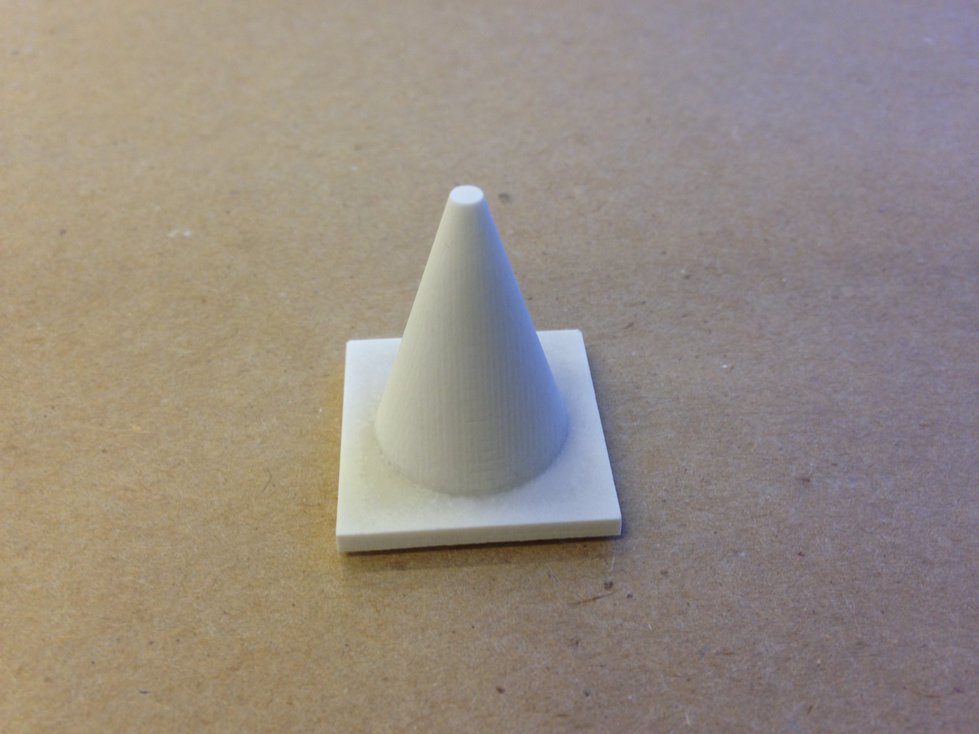

After letting the piece set for an hour and a half, I removed it from the mold. Here’s the final result: