process diary: 05/16/12

status

safety

laser

electronics

motors motor control

body

build tips

questions

status

laser: see prashant's update. we safely fired both diode and CO2 lasers: paper,cardboard and acrylic perforated.'

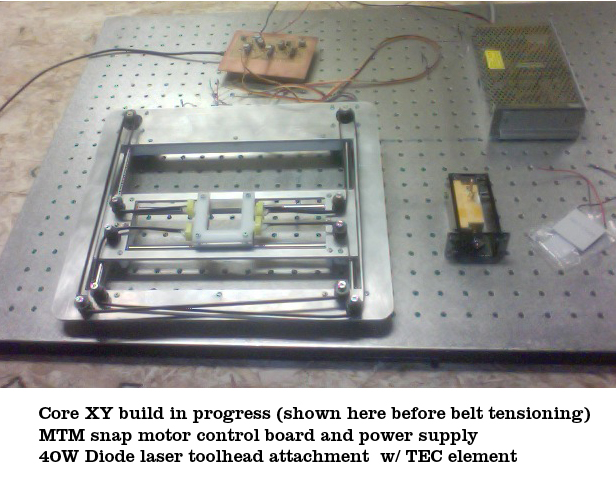

electronics: MTM snap motor control board milled, stuffed, tested with motors on power supply. Prashant has both laser options powered.

motors: working, need to modify motor control software pipeline for H-bot CoreXY kinematics.

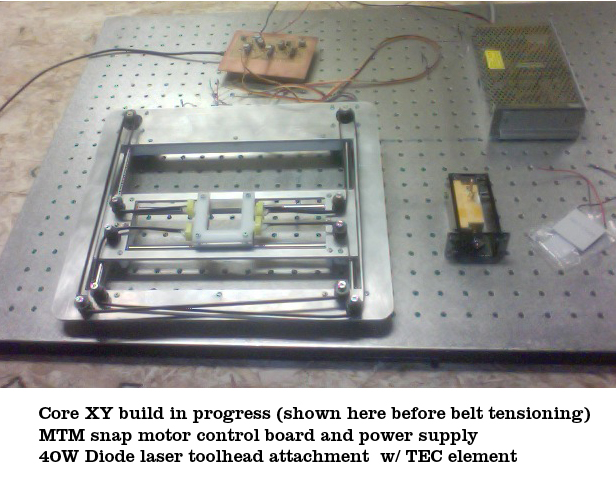

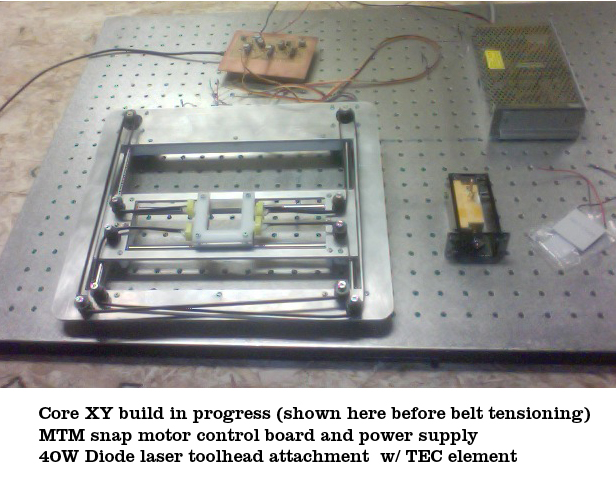

body: using CoreXY for the XY table, team is working on enclosure

class 4 to class 1 conversion process

:O.D.-appropriate eyewear for 803nm laser

:material selection

:enclosure kill switch (exterior?)

exhaust system

:air filter

:motorized fan

:exhaust plan

easy clean tray for byproducts

diode 40W

fiber optic delivery to tool-head via actuated carriage

psu for laser

integration with control logic board, enclosure safety switch, exhaust fan

motors

:motor selection principles

use Jonathan Ward’s spreadsheet

account for friction, OVERengineer

based on torque curve, NEMA 17 screw pattern to match CoreXY and power we chose an inexpensive OSM stepper for $14 and spoke with supply chain to arrange volume discounts (alltronics.com)

Fab it (status: board milled, stuffed and tested)

software pipeline in place, can jog the motors but need to explore code to ensure compliance with CORExy's kinematics.

microstep it (board doubles steps, i.e. 200 actual steps = 400 microsteps)- more?

body

we have completed the CORE xy in aluminum. See Ariadne's page for more on experiments in pouring cement into molds for the frame

rigidity not so important in comparison to MTM snap CNC

HDPE or cheaper plastic possibly wrapped in aluminum foil or Lithco laser-safe film

desired laser work area = 30x18

strive for high (>80%) working area/machine area ratio

See: Fab in a box

ultimaker 3d printer (super fast)

clothesline design: smallest pulley possible in a capstan drive

direct drive: attach ea. motor to *smallest* pulley that mates the shaft

note: increasing diameter increases speed but lowers the resolution and torque. Resolution is lowered by the motor missing steps.

complete the clothesline by attaching a timing belt from the motor’s pulley to an

idling pulley on the opposite side.

actuate the moving carriage by securing it to the belt with a u-bolt.

tension the belt

-z up/down on bed

master tips:

look for slop everywhere

-feel for unwanted DOFs while assembling/holding parts

-When building the CoreXY, when you are ready to affix the carriage with epoxy, be careful as the entire assembly will be balanced and pivoted on the carriage. Constrain the CoreXY during this phase of production. Using a level surface like an optical table if you can.

MTM site