Week 2 - Computer-controlled cutting

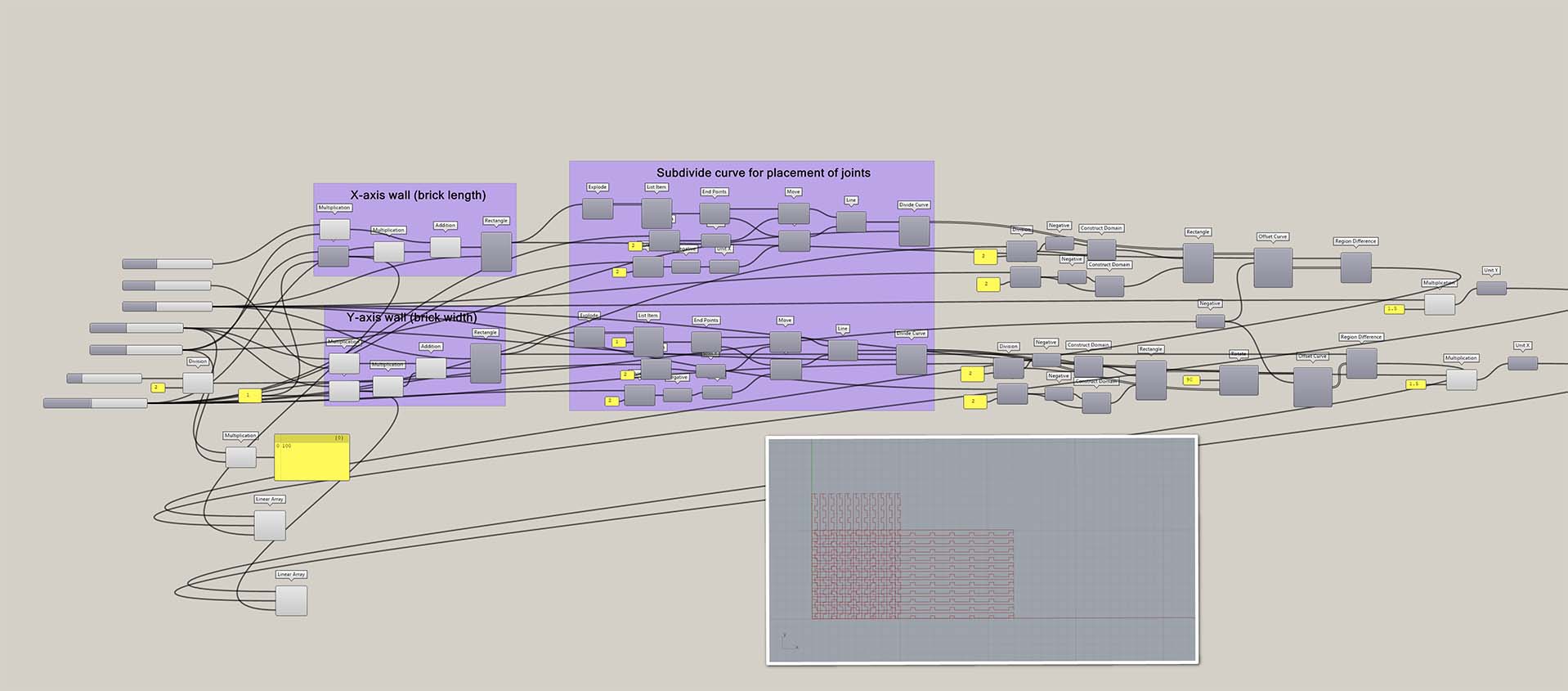

This week's exercise was to develop a parametric design of an object to be cut on a laser cutter. It just so happened that I had to produce a mold for my studio assignment and, instead of doing it by hand I decided to produce it strictly in Grasshopper. The mold would be used to cast 1:25 CMU bricks for a physical model.

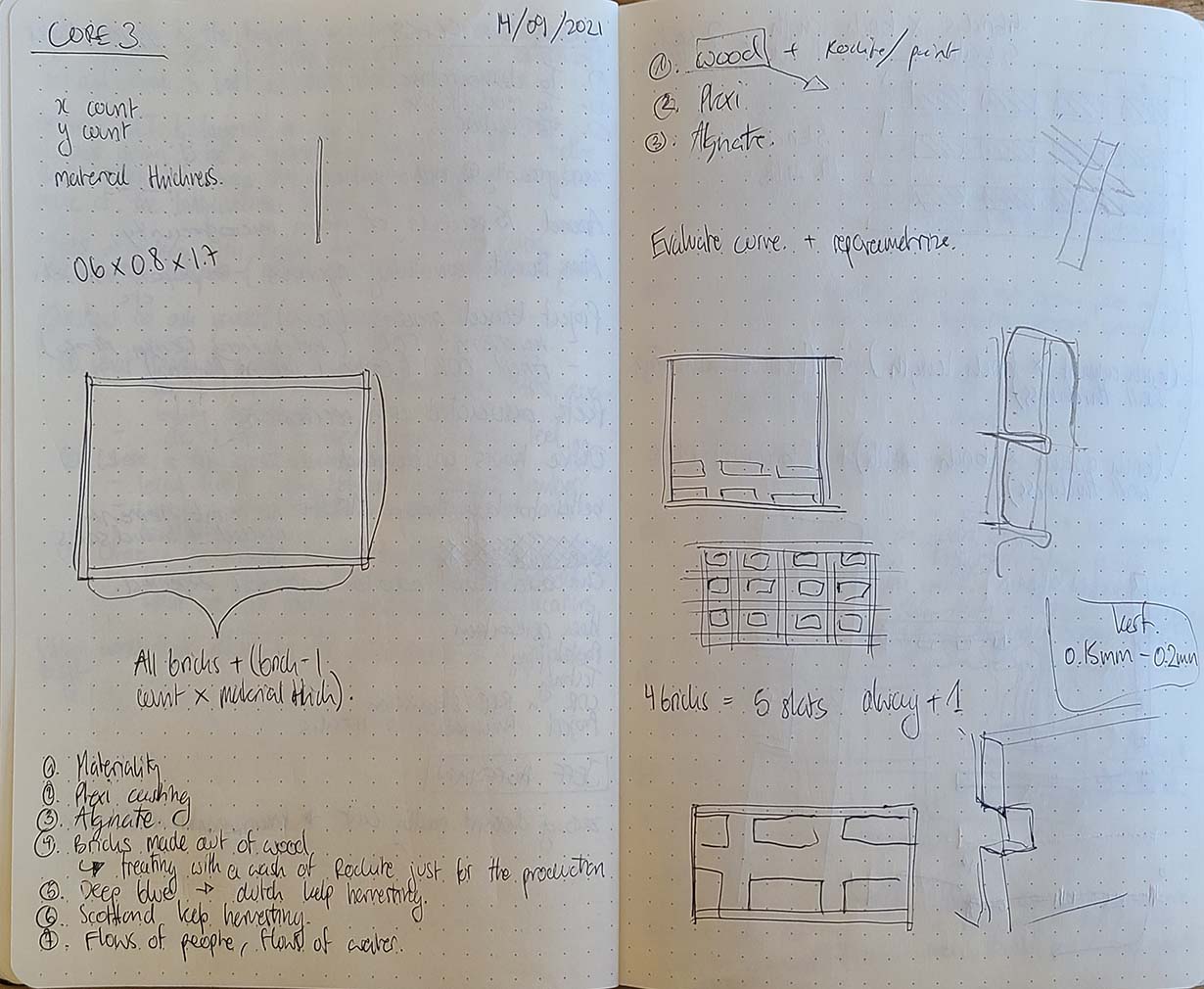

Some initial sketches of my thought process. It took me some time to work out how many walls my mold would need for a given number of bricks I wanted to produce. I even had to start by creating a script that just arrayed the bricks into a grid to help myself visualise what the pure laser-cutting script will have to do.