I started off with a 3D printer test file I found on Thingiverse (I couldn't initially get the .stl files from HTMAA website working). In any case, this also suggested that I shouldn't be going below 0.2mm when it comes to the resoluttion of walls or gaps. I decided to use that on my next mould print.

The first print came out quite bad. I didn't notice that someone changed the default settings for the speed and amount of material extruded. I was noticing that my surfaces were patchy and would leak the silicone if I used them. I decided to print it all again.

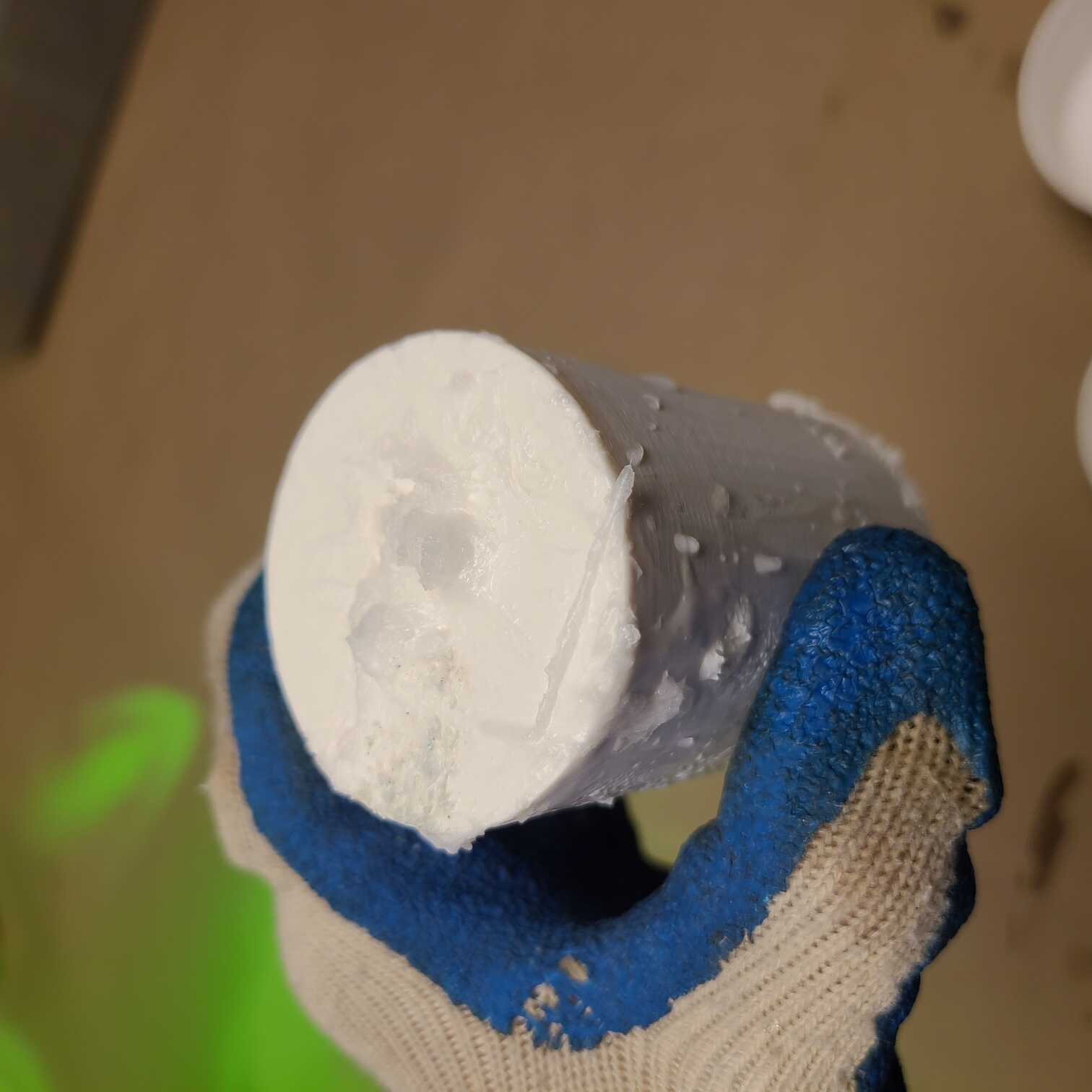

The next print came out much better and I could start assembling the mould...