This week's assignment is to create a parametric laser cut construction kit that accounts for the laser's kerf, so I decided to make a little charging station for the iPhone 13 Pro and Magsafe wireless charger that I recently ordered.

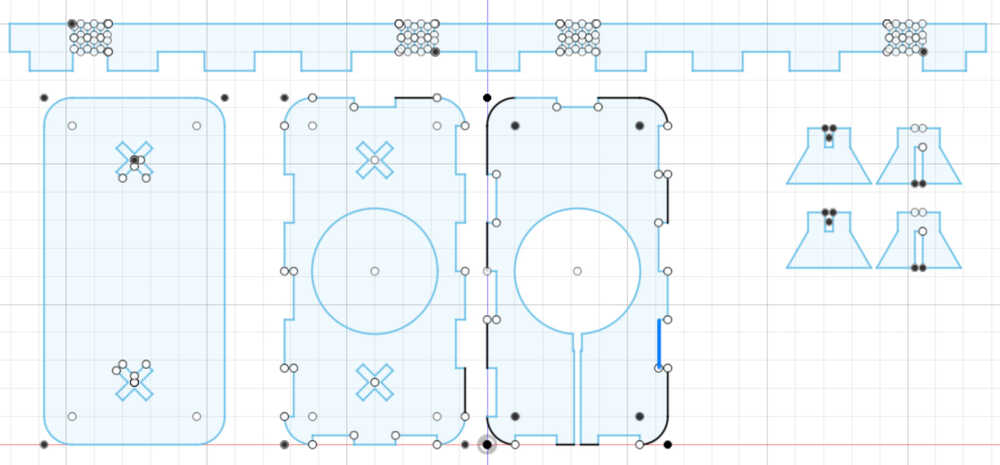

I created the sketch using Fusion 360. The design features five components: the top layer, middle layer, bottom layer, walls, and feet. The top layer has a cutout for the magsafe charger body and wire. The middle layer has a cutout for the magsafe charger body and feet. The bottom layer just has a cutout for the feet.

The two feet are each composed of two slotted pieces that slide into each other. The entrances of the slots are chamfered to allow for easier assembly. Once the two pieces are put together, they are inserted into the cutouts in the bottom and middle layer.

The walls rise above the top layer to keeep the phone in place, and also have press fit notches that slide into the top and middle layers. When fully assembled, all three layers are constrained together by the feet and walls.

In making the sketch, I made the overall phone dimensions, cardboard thickness, and kerf parametric. After determining the kerf of the EECS shop laser cutter to be 0.5mm, I was easily able to apply a correction to the whole sketch.

With the sketch all done, all I have to do is export the DXF, load the file into the Universal Laser Systems laser cutter, and get to cutting. Through my section's group assignment, we determined that the appropriate settings for cutting our cardboard are 100% power and 10% speed.

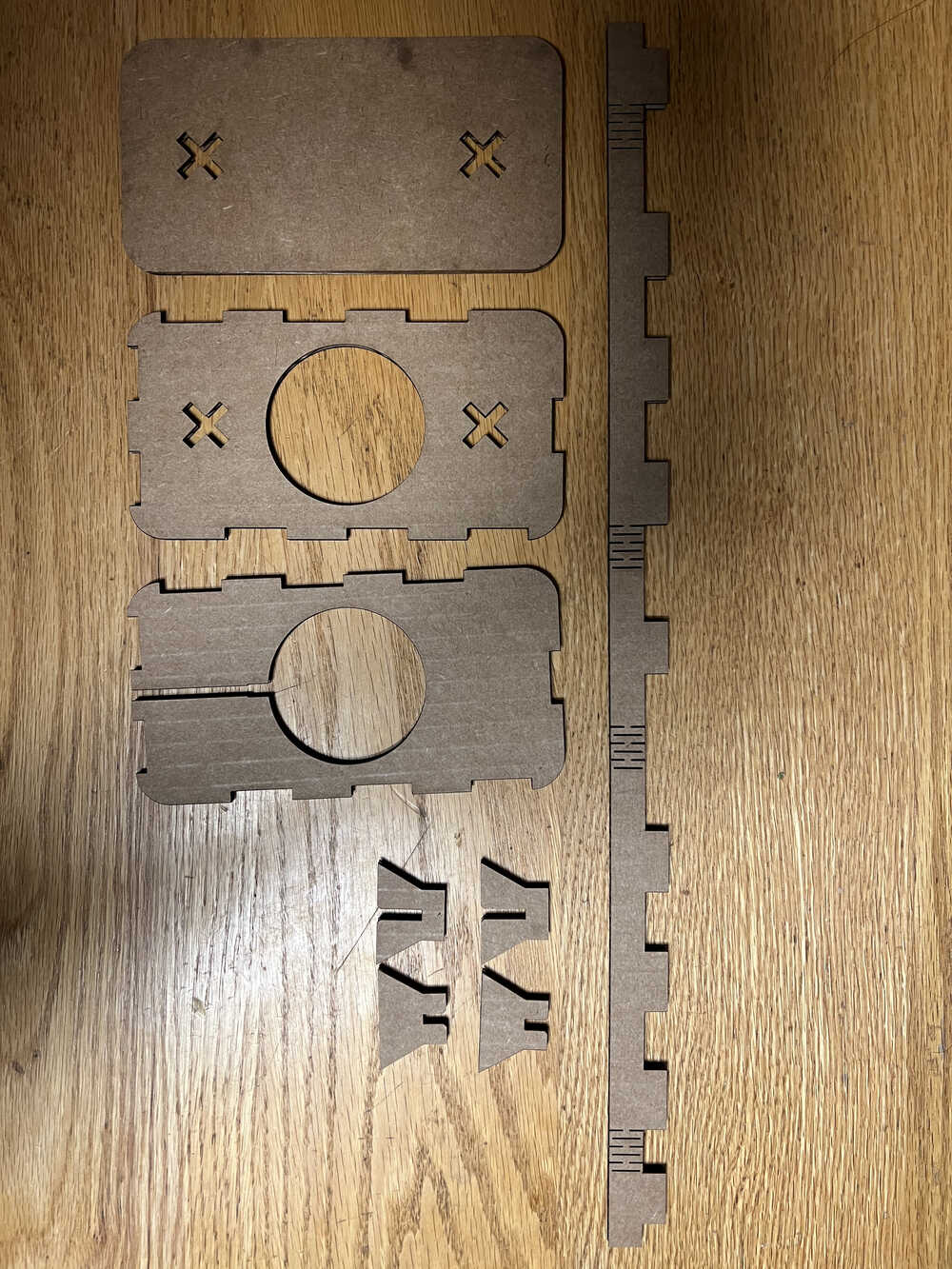

Success! This is what it looks like before assembly...

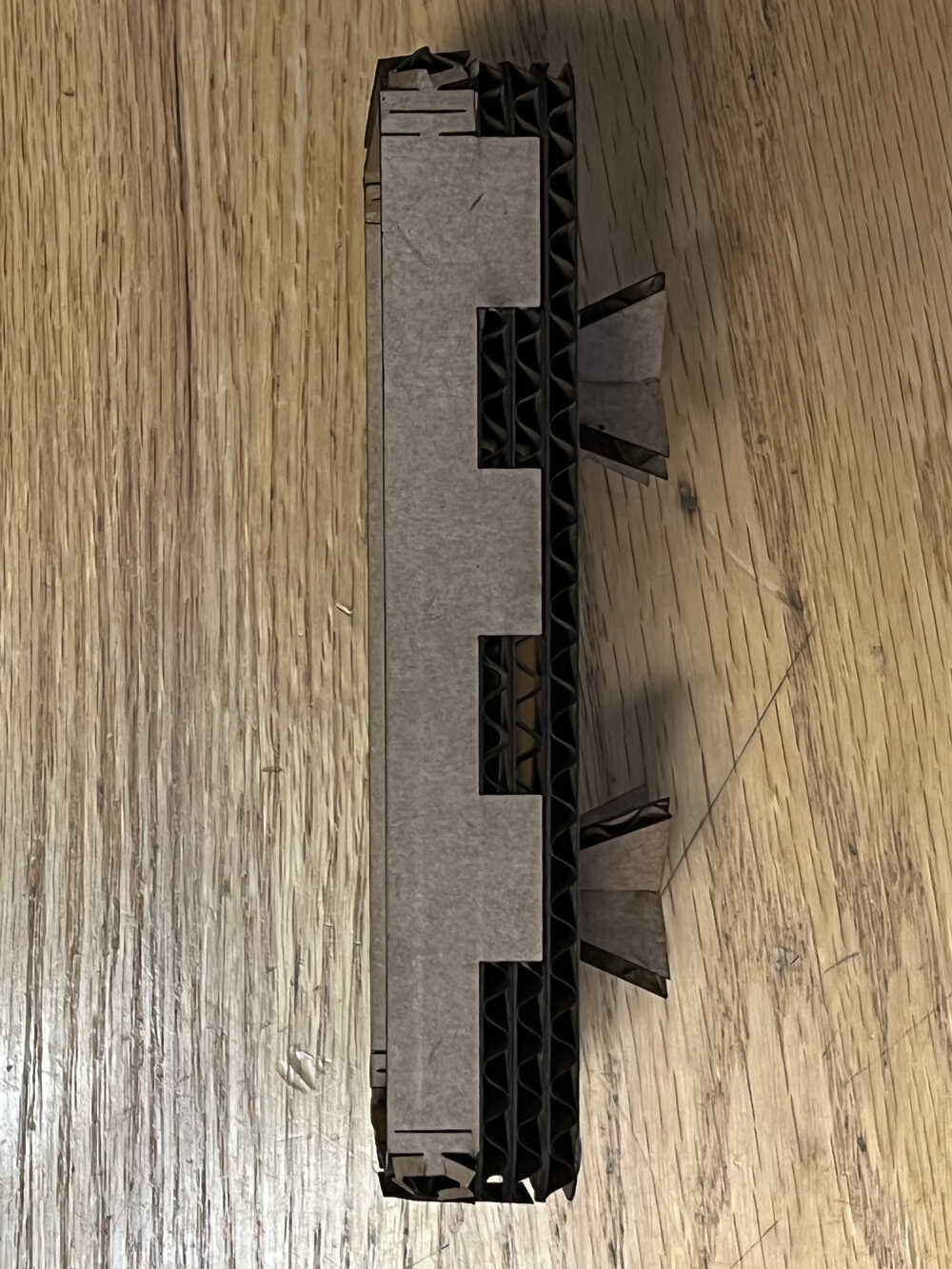

... and after

My living hinge corners (I was going for the bonus curved element) kinked after assembly. I realized that the bend was perpendicular to the corrugations in the cardboard, instead of being in line with them. This goes against the way that the material naturally wants to bend, resulting in the kinks. To alleviate this, I cut the kit all over again, but turned the cardboard by 90 degrees. This somewhat helped the kinking, but it still doesn't look perfect. It seems bends in cardboard need to have a radius much larger than the wavelength of the corrugations in order to fully prevent kinking and folding.