This week's assignment is to model and print something that can't be made subtractively, and to 3D scan (and optionally print) something that couldn't be made subtractively.

Because I have access to the print farms at Formlabs, where I work part time, I decided to print many things. First, inspired by the math-inspired models printed by George Hart, I decided to model the Seifert surface formed by three interlocking rings. I have zero idea what the underlying math here is about, I just think it looks cool. To create the model, I used SeifertView, a free program made specifically for these surfaces that allows you to export a mesh. I printed it using Flexible 80A resin on a Form 3.

One of the main downsides of SLA printing is the postprocessing that is required. Prints need to be washed in isopropanol, and then post-cured to achieve the right mechanical properties. By far the most time consuming step is support removal. This is especially pronounced for a material like Flexible 80A, which has low stiffness, and thus needs a lot of supports. I spent 30 minutes carefully trimming off the supports with a flush cutter, and I didn't even bother completely removing the support marks.

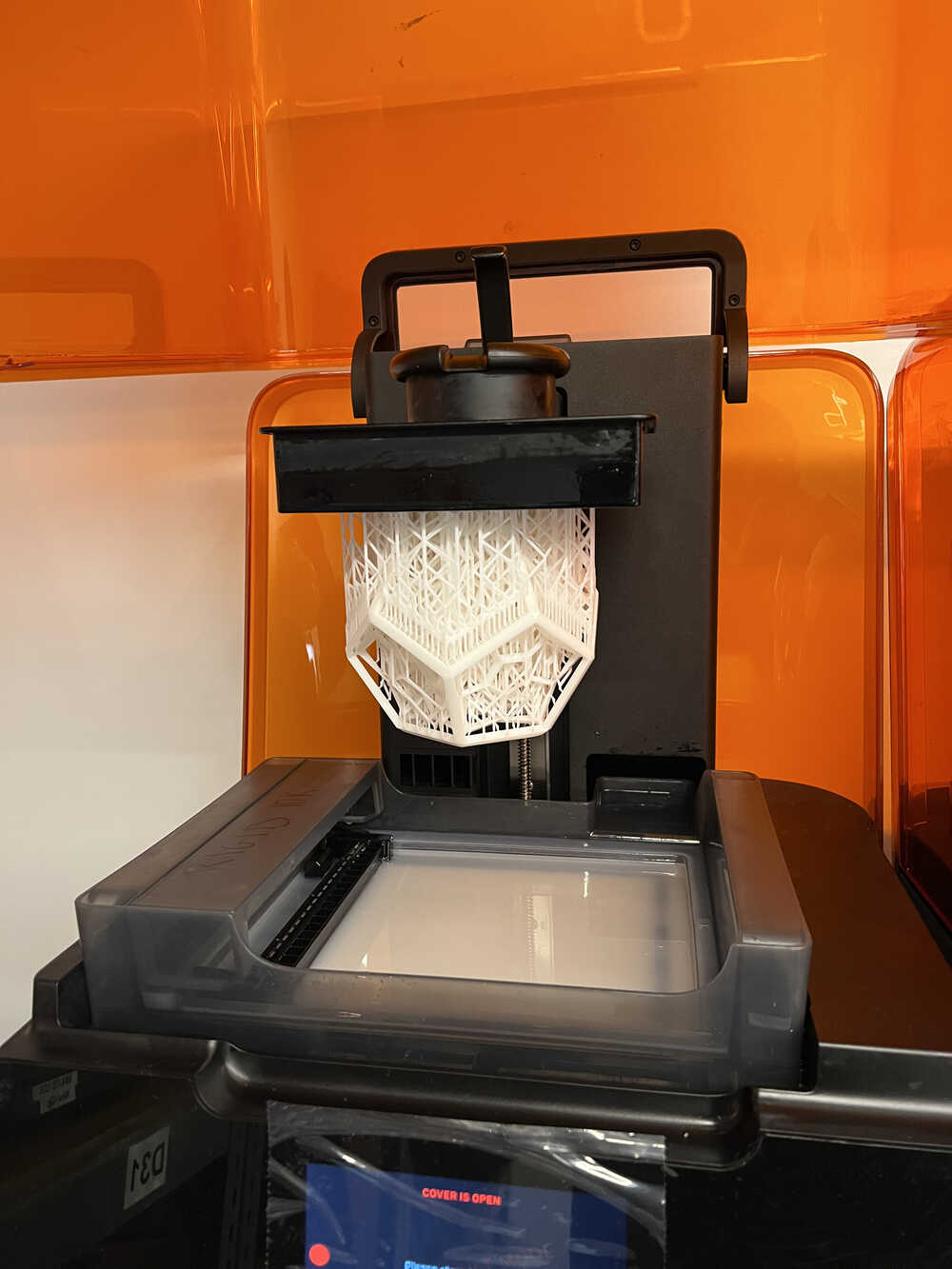

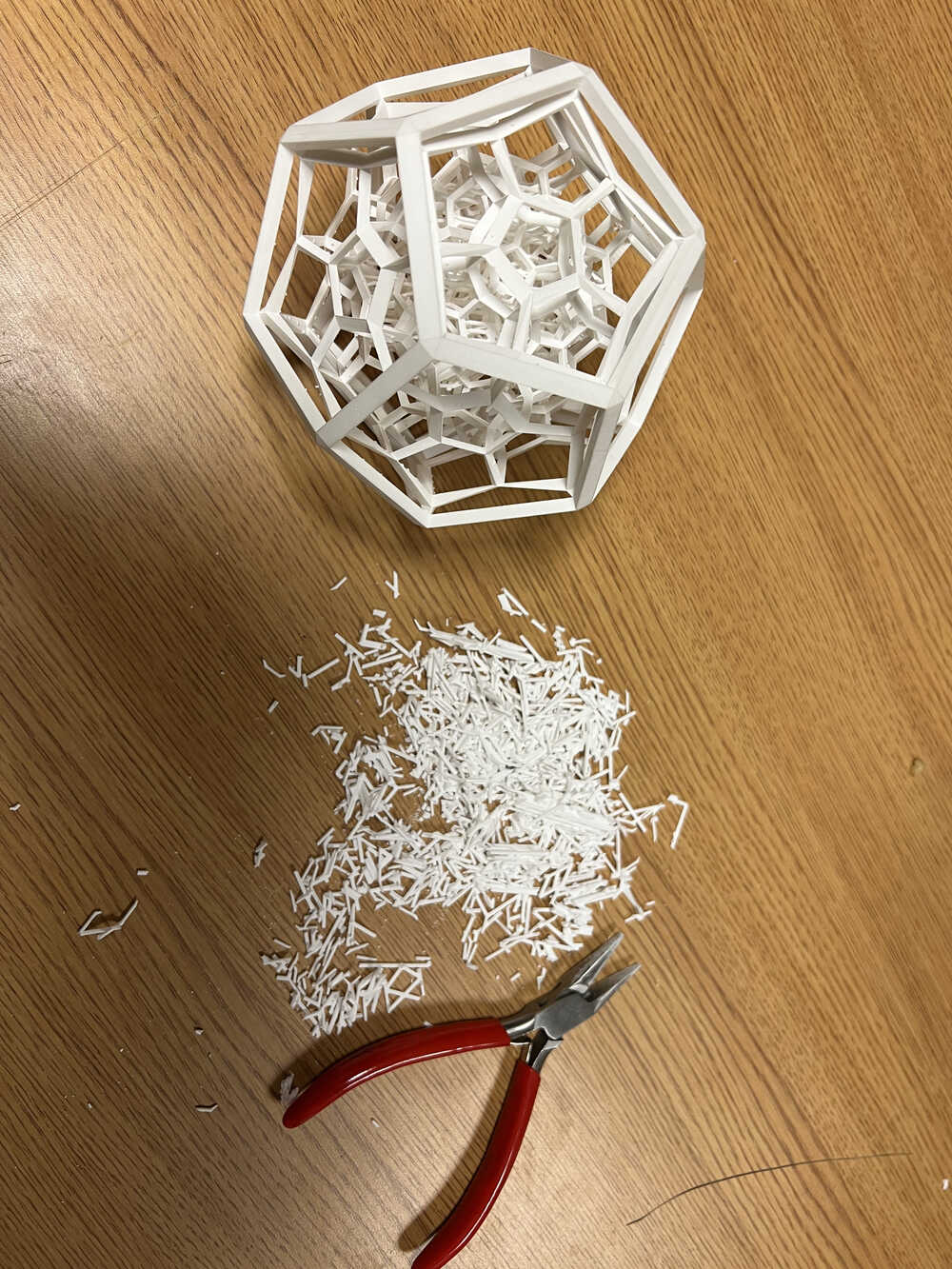

I downloaded some STL files from George Hart's page to showcase more of Formlabs' materials library. My favorite material to print with is by far Rigid 10K. The resin is filled with glass microbeads that gives the printed part extremely high stiffness, and a finish similar to porcelain. These properties come at a steep cost of $300 per liter, but thankfully I don't have to worry about that. I decided to print a model of the 120-cell, a four-dimensional analogue of the dodecahedron.

The part had to be washed in a separate unit to prevent the glass filler from contaminating the surface of parts made from other materials. Support removal with this material is usually quite easy, as the supports are quite brittle and shatter easily. However, the geometry of this model made the process a nightmare and I spent over an hour knocking out every little internal support with a pair of needlenose pliers

Now that I think about it, this kind of model would be ideal for printing with SLS. The end product still came out looking great, though!

I also printed some surfaces of constant width out of the grey resin. These could easily be made on a lathe, but I decided to print them anyway because I think they are cool.

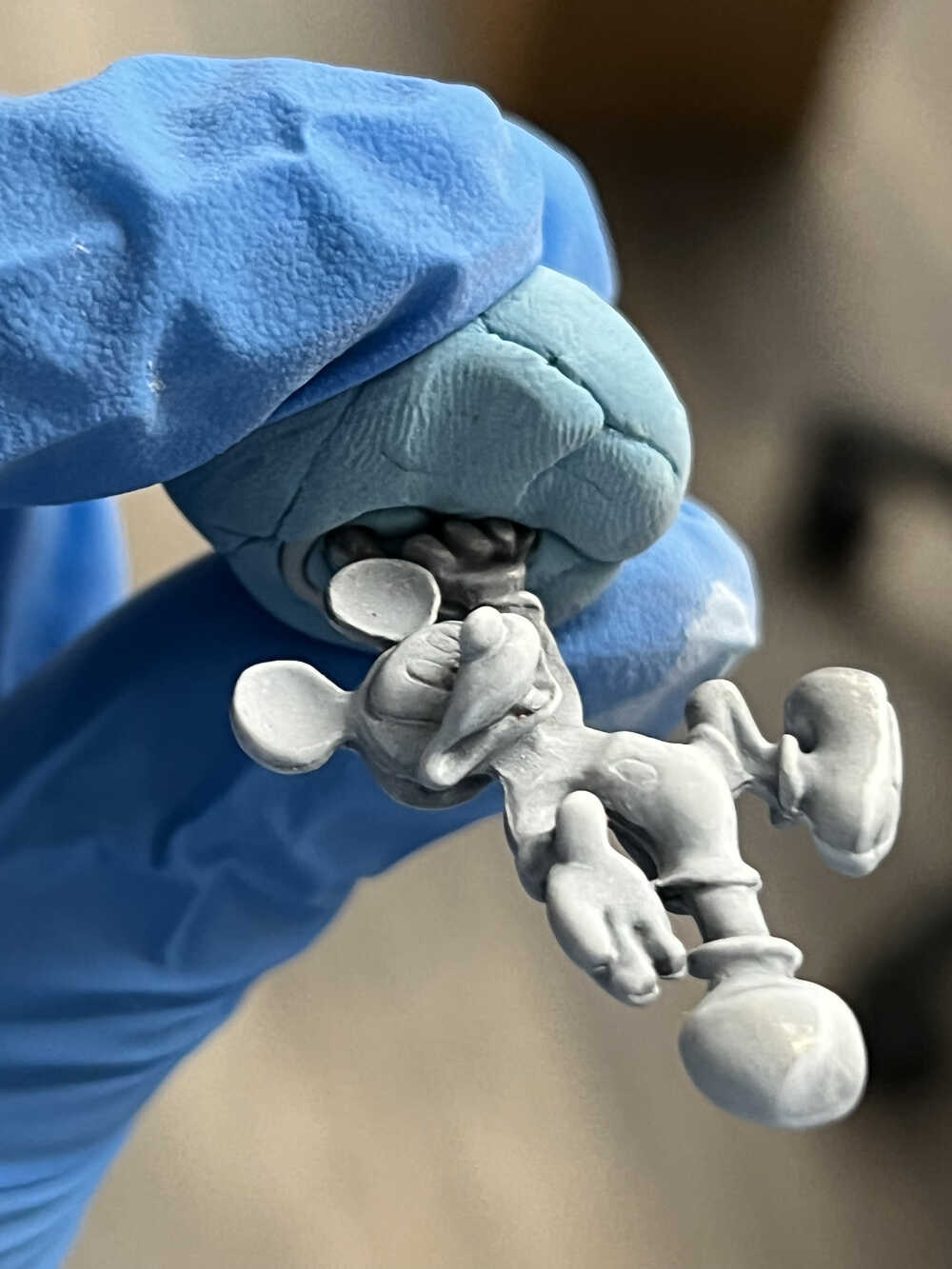

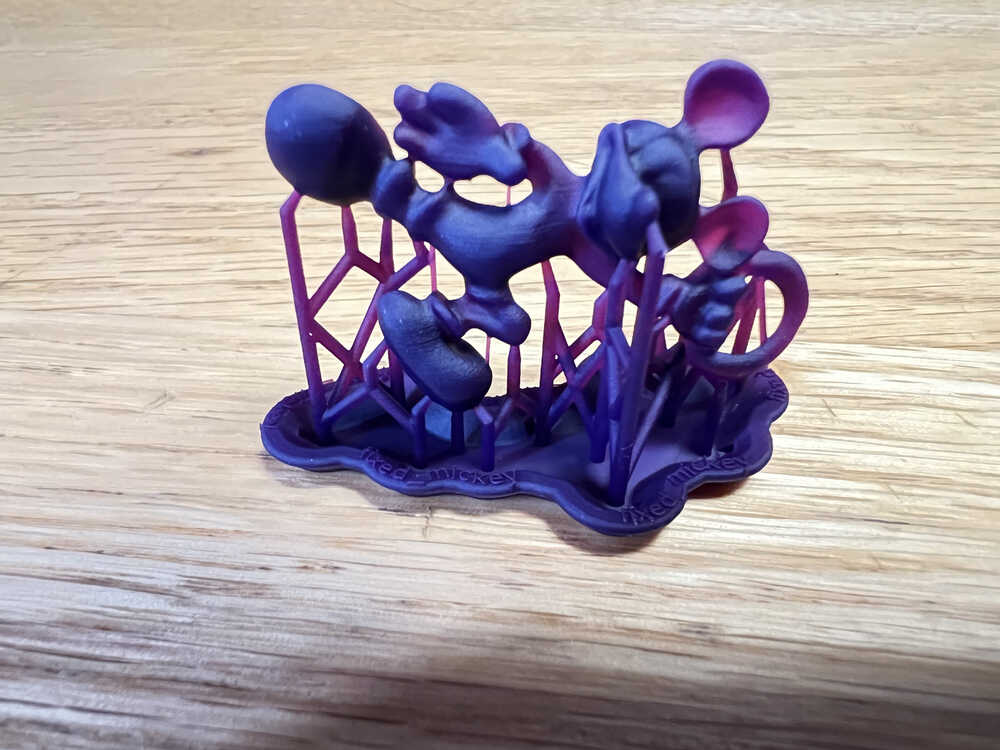

For the scanning portion of the assignment, I used the Medit T300 scanner in the Formlabs dental lab to scan my Mickey Mouse keychain ornament.

Since my object is metallic, I had to hit it with some 3D scan spray to make the surface matte.

Finally, I'm ready to scan!

I had to take two scans from different orientations, since the object gets partially buried in the modelling clay, which prevents the scan from capturing the full geometry. I took two scans and used meshmixer to splice them together and repair any small holes in the mesh. I then printed a replica out of castable wax resin.

If I wanted to, I could take the castable wax model and use it to recreate the ornament out of aluminum or bronze, but I think I'll just be keeping this one around for decoration purposes.