Basic Questions

Answered:

What does it do?

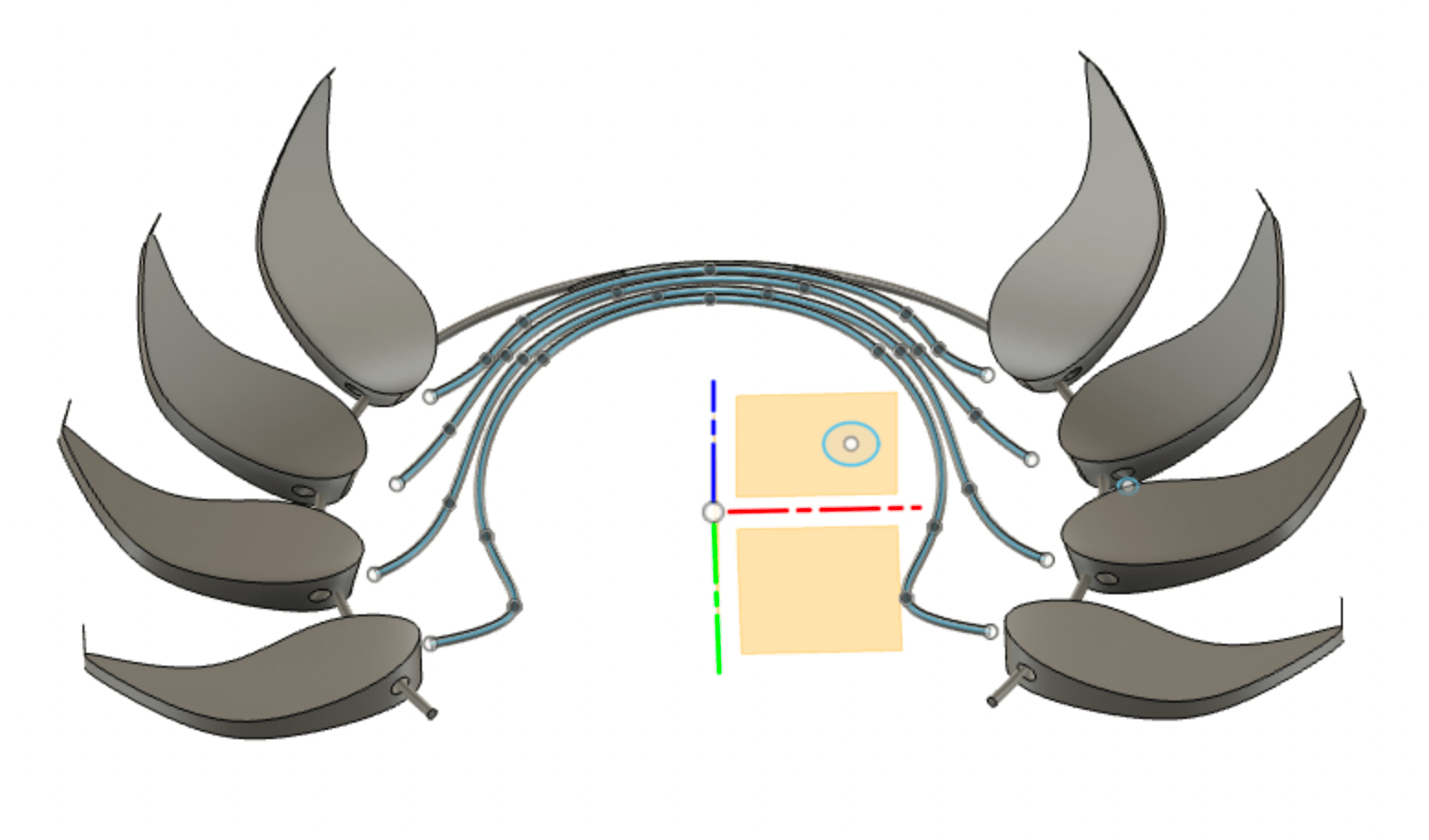

The project is a wearable piece of kinetic art that is custom made to my body. It is a series of “feathers” that move in a wave motion up and down on my chest, and uses strings and motors to create this effect. The project is modular in a sense that every single of the “feathers” that create the wave can be replaced with other objects, such as flowers, animal features, or other designed pieces, as the bendable joint will have a press fit hole that objects can insert into.

Who's done what beforehand?

This project is based on the kinetic crown artist Casey Curran created for the Iris Van Herpen show on July 1st, 2019, titled ‘Hypnosis’, at Élysée Montmartre in Paris. My design will adapt this crown into a chest piece that has interchangeable components that don’t have to be featherlike.

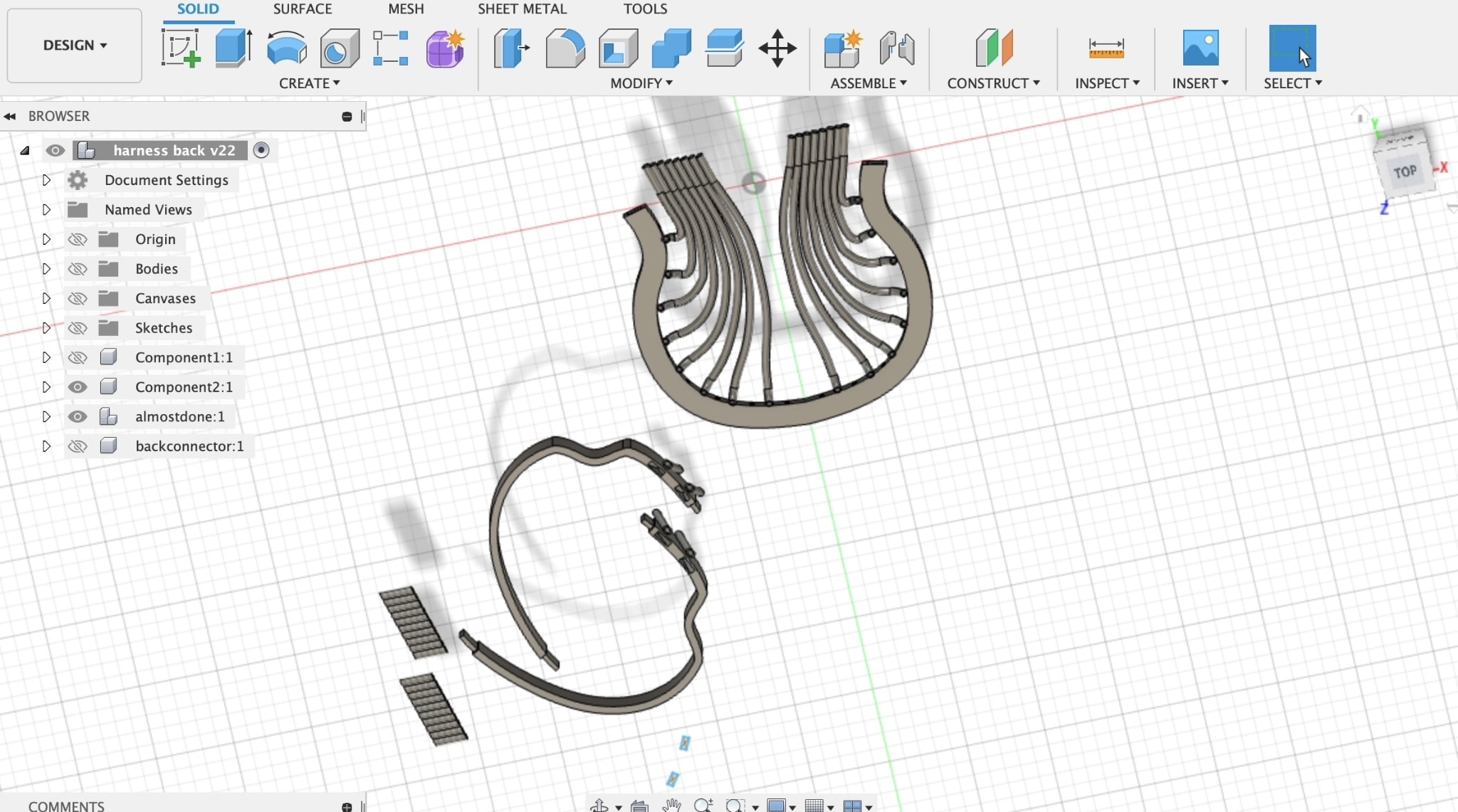

What did you design?

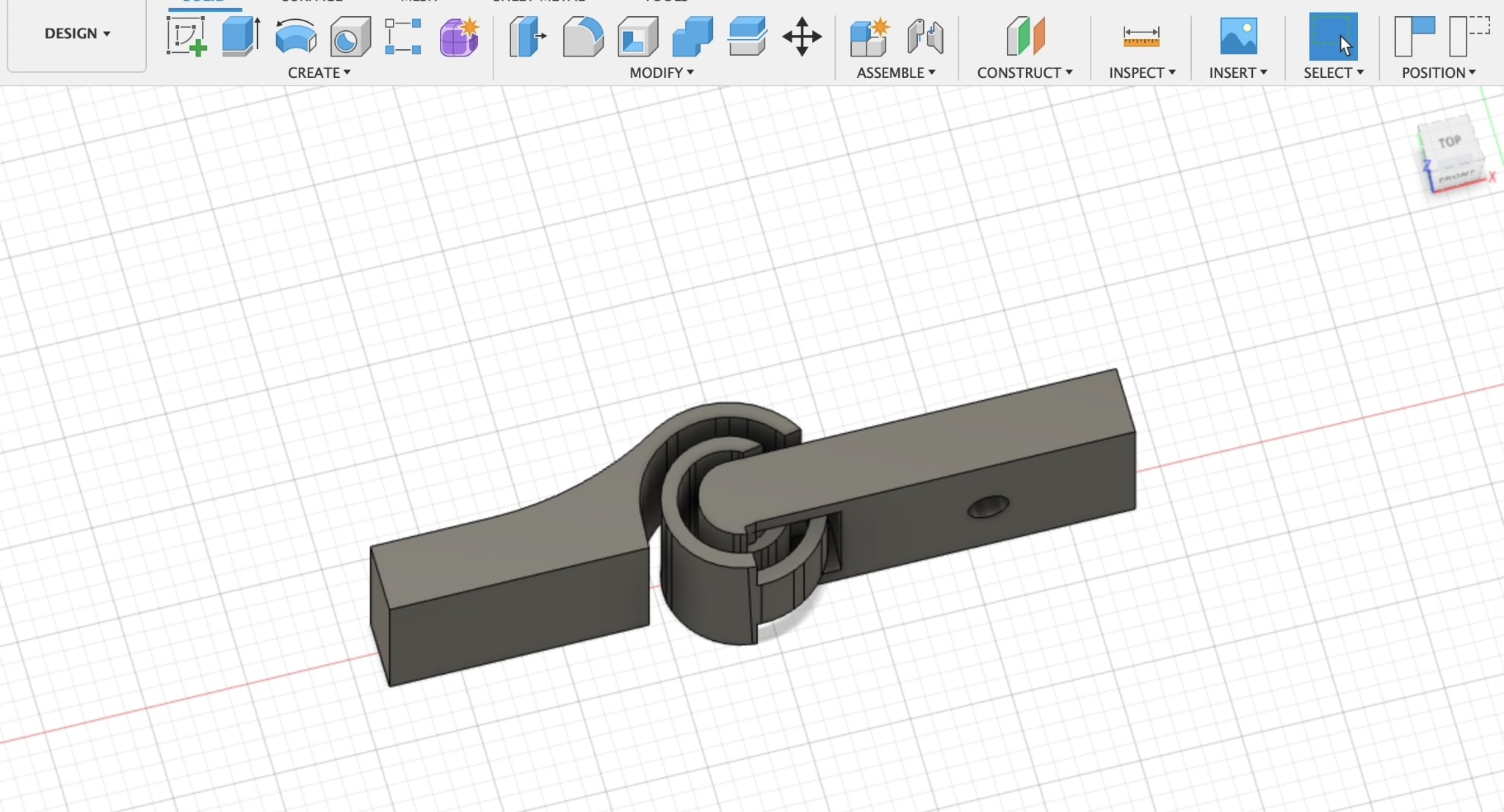

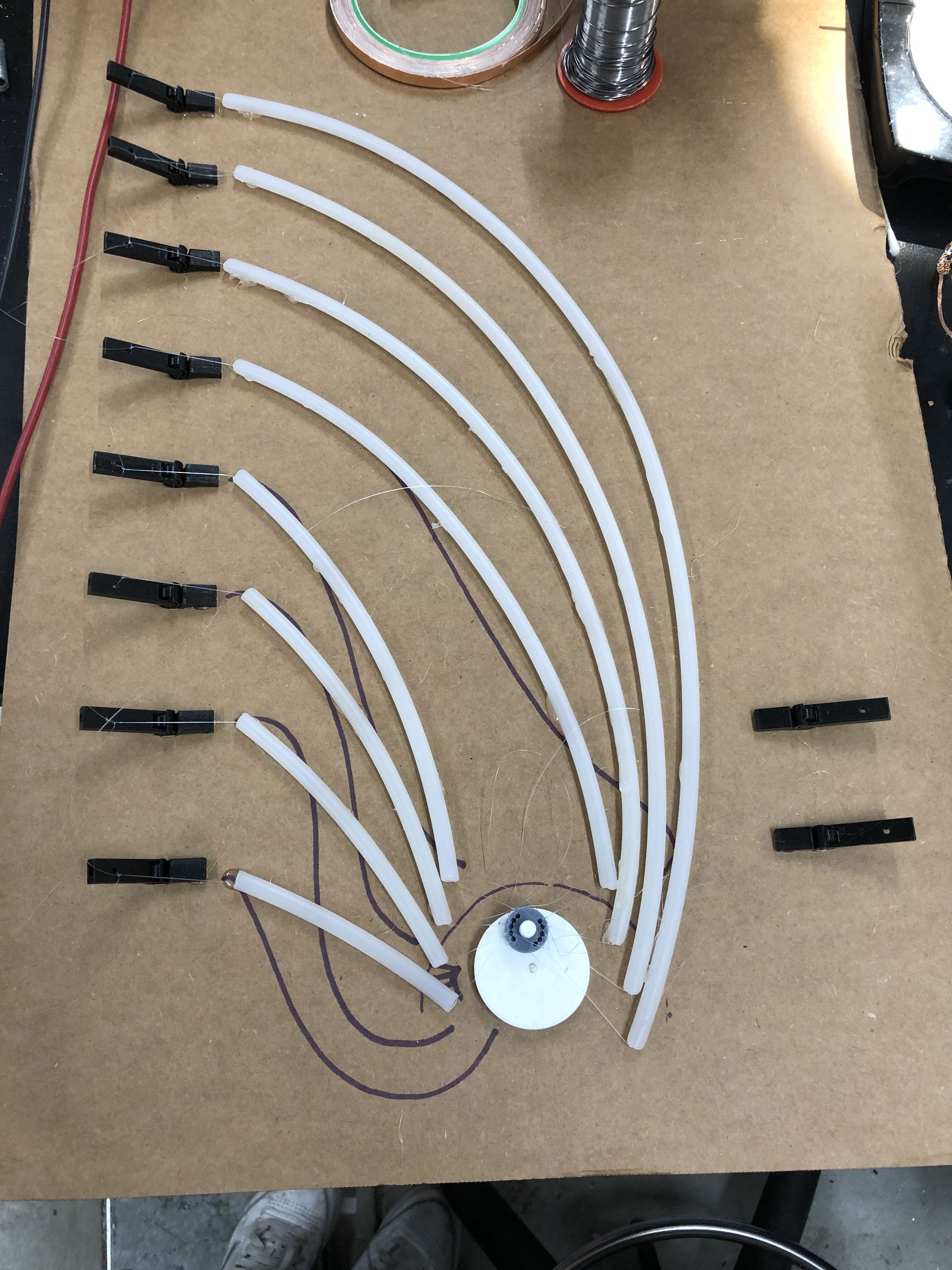

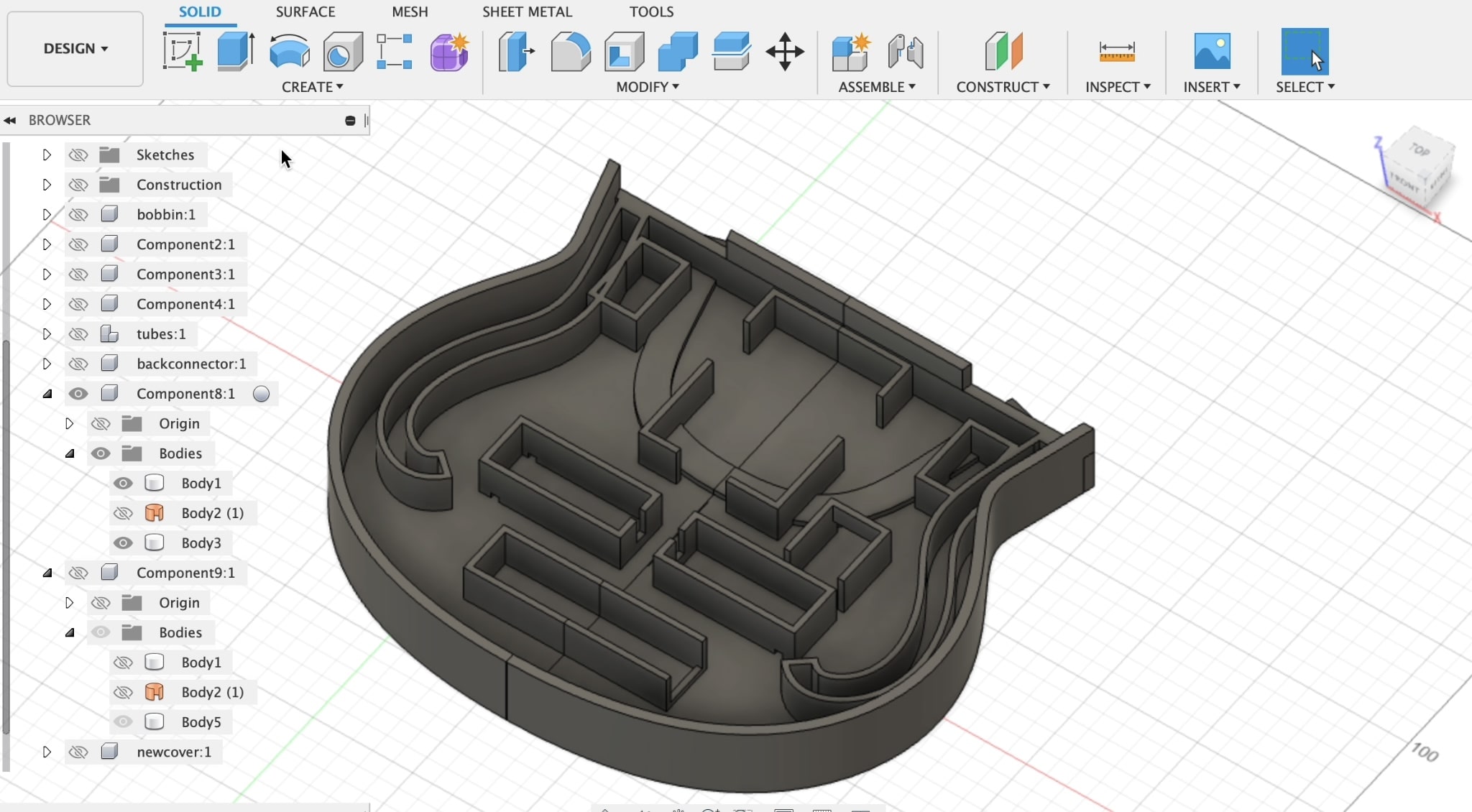

I designed the entire project, but referenced photos and behind the scenes footage of Casey Curran’s original piece. Specifically, I modified torsion joints I found on Thingiverse after designing several springs of my own, and designed the feathers, schematic, packaging, tubing, electronics, and harness. I found ways to differentiate and deviate from the initial sculpture by changing the spring loaded joints and designing a custom body harness for myself to make the project couture clothing, rather than an intricate accessory. The overall movement is pretty similar to the initial design, but I was only using visual references and had to plan all the nitty-gritty components myself.

What materials and components were used?

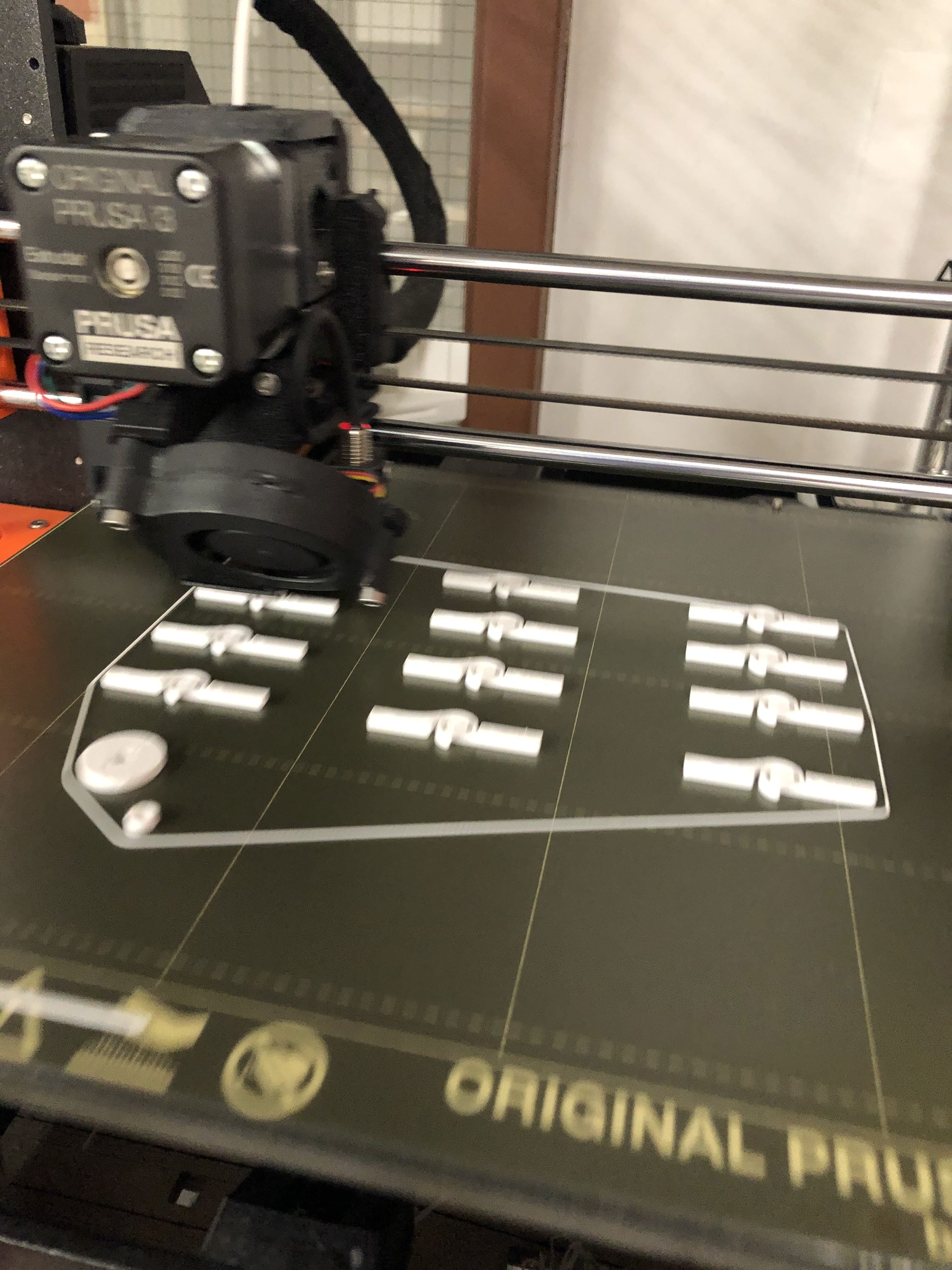

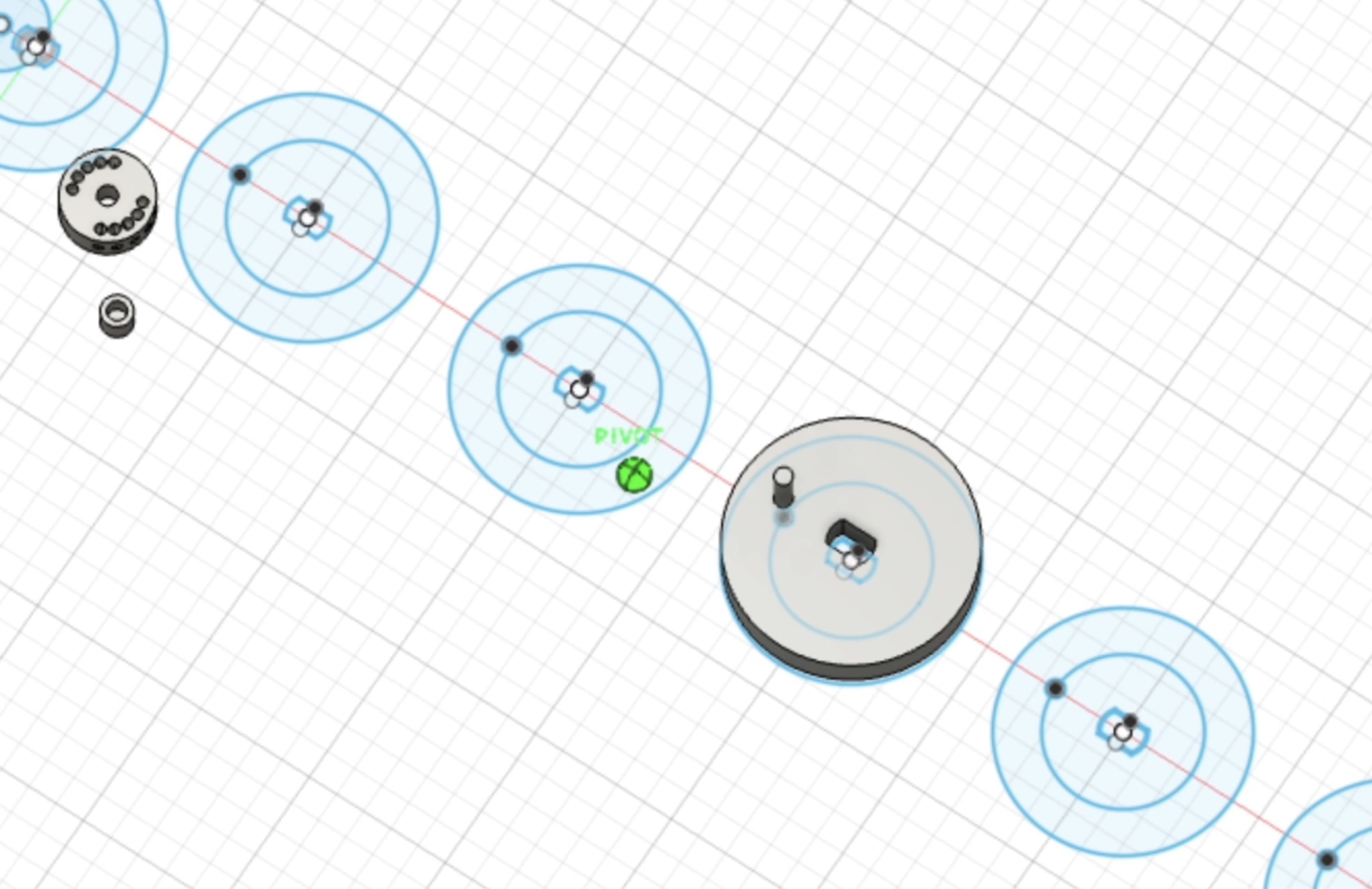

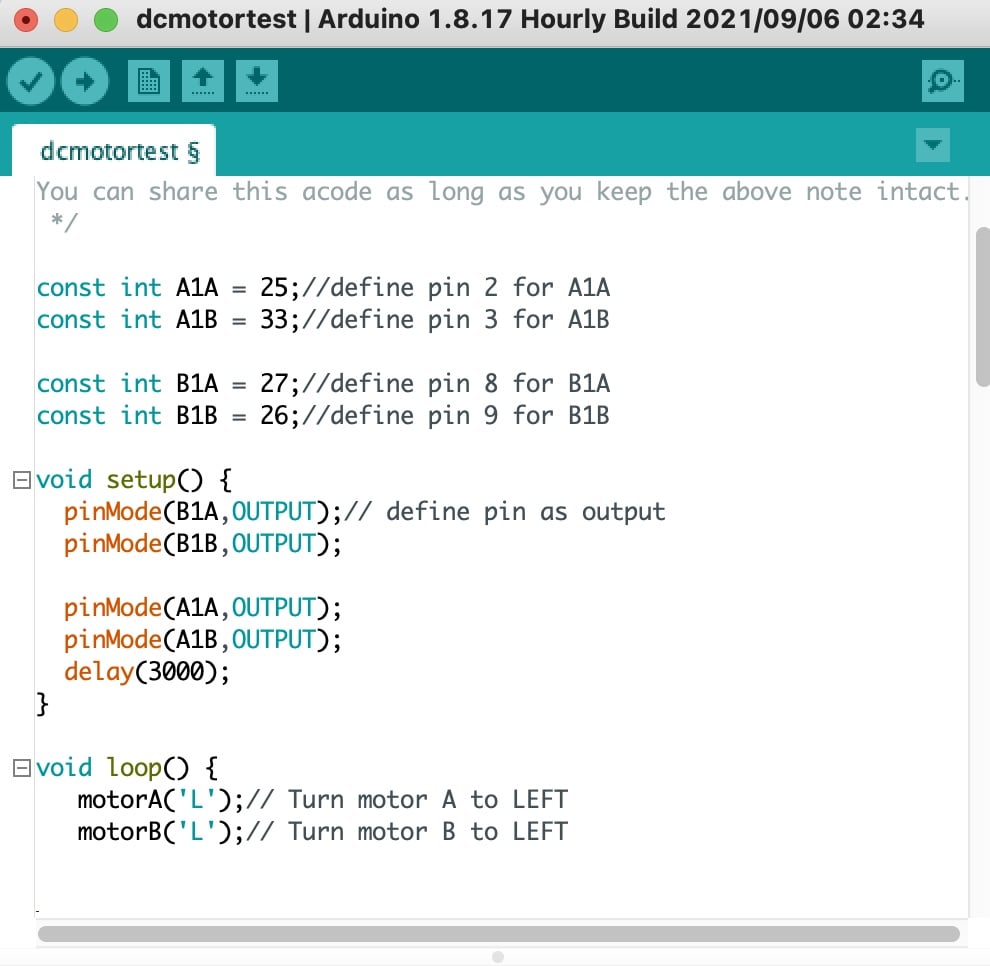

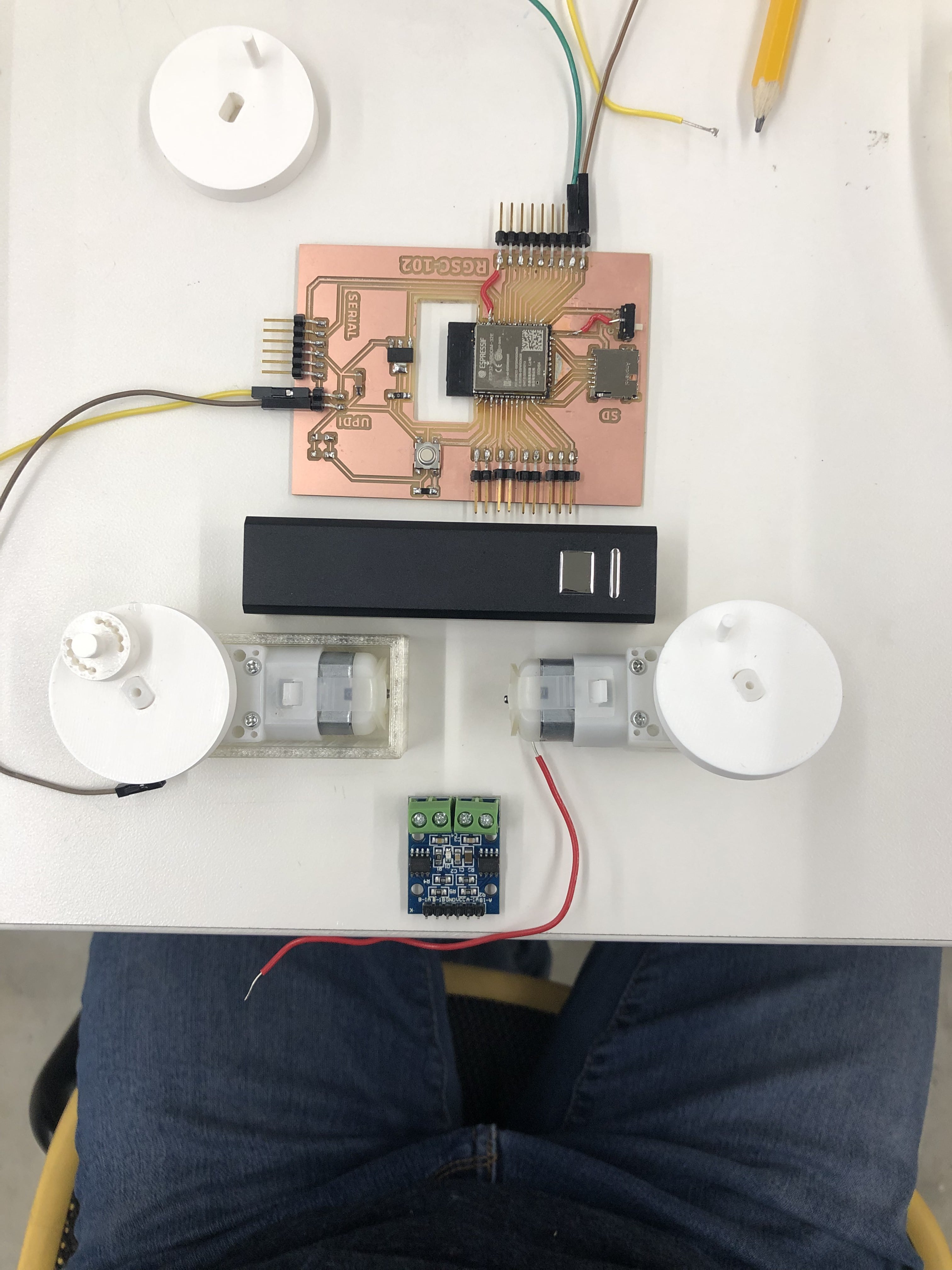

Most of the materials in my project are D printed using PLA filament, but I also used transparent acrylic, copper tubing, DC motors, L9110 motor driver, monofilament string, and electronic components like PCB board, wires, motor drivers, and a rechargeable phone battery.

Where did they come from?

Most of the materials were already in the lab, but I ordered transparent filament(which I ended up not using but lent to the rest of the class), extra superglue, and 32 ft of ⅛” copper tubing from Amazon.

How much did they cost?

The 32 ft of ⅛” copper tubing cost $40, and the PLA transparent filament cost $25. The motors from the lab cost around $6 each(I used 2), phone battery ~$10, and the amount of PLA I used totalled to around 1/2 of a roll of white filament($7.50). I used scrap acrylic and monofilament, and the electronic components were recycled from earlier projects from the class($6 for an ESP32+$3 Motor Driver L9110), so I’m estimating that the total cost of materials was around $80.

What parts and systems were made?

I made joints, a harness, tubing, feathers, packaging, and the mechanical movement with 3D printing. Some electronic components were made by milling an ESP32 board.

What processes were used?

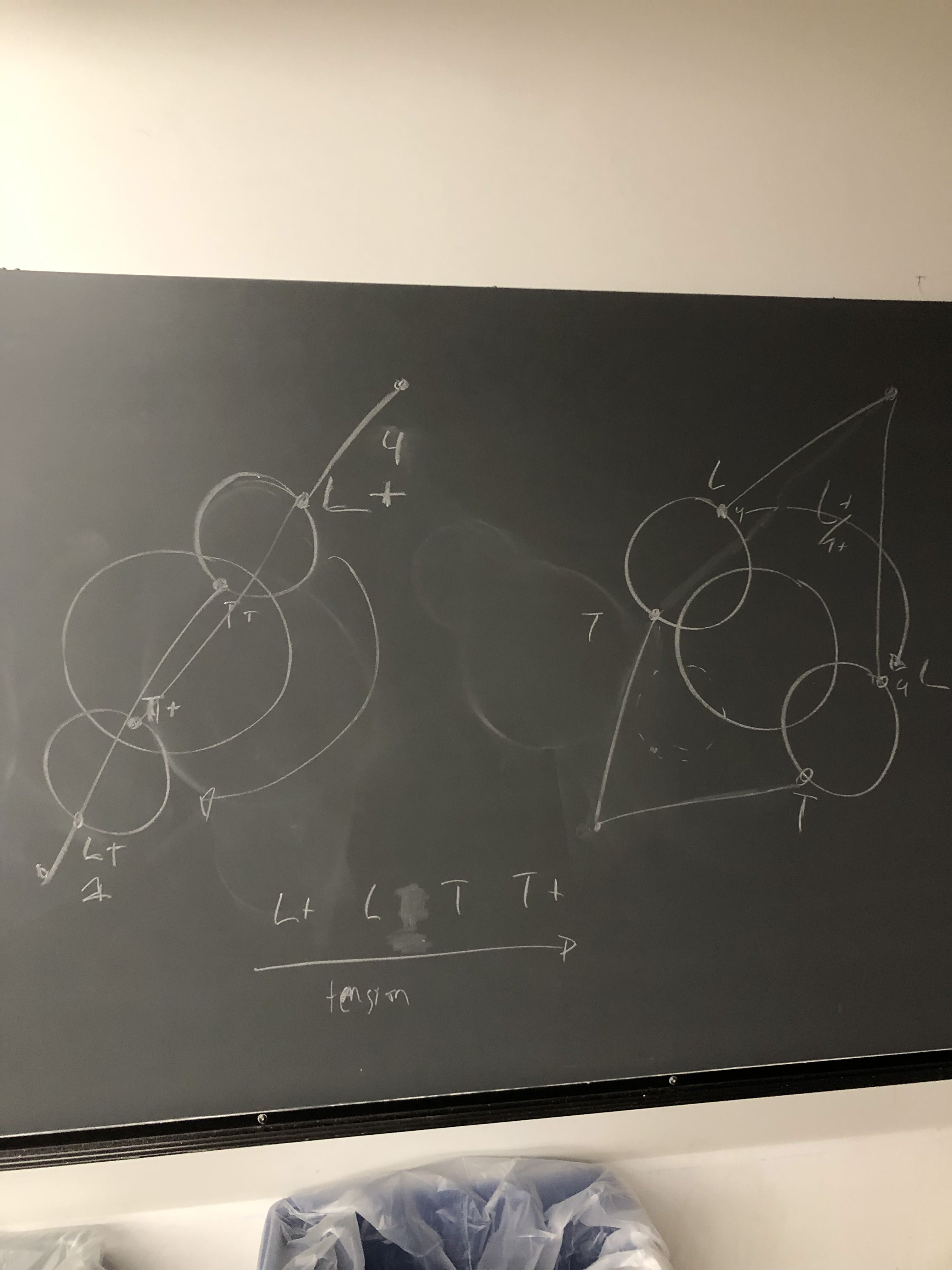

2D and 3D design was used to design this entire project with either CAD software like Fusion360 or chalkboard ideation to plan the schematics of the extremely complicated mechanical movement. I used subtractive fabrication processes to laser cut transparent acrylic and mill a PCB board. Electronics design and production was used to create the ESP32 board, and embedded microcontroller programming was used to program the 2 DC motor rotations. System integration and packing were used to create the arrangement of the electronics on a back piece, as well as fitting the whole project custom to my body.

What questions were answered?

Can I create haute couture using modern fabrication techniques? Yes!

What worked? What didn't?

The wave motion stayed pretty consistent throughout the presentation day, but one of the strings eventually snapped. This is ok since I could easily replace it, but I plan on replacing it with a stronger filament. Other than that, everything seemed to work!

How was it evaluated?

Since my project had a simple premise but complicated design, I evaluated it based on its functionality(whether or not the motion worked, quality of motion, number of features), and aesthetics(symmetry, detailed appearance, neatness). I think I succeeded overall, but the wave motion could be calibrated in closer detail, as some of the feathers have larger ranges of motion than others, and some fell prey to too much friction within the copper tubing. In the future, I would also add more capabilities if given more time, such as the ability to adjust the speed of the wave, and also make it easier to put on/take off. Aesthetically, I thought it looked amazing, but I would still like to add some stationary feathers to decorate it further, and also make the feathers more symmetric within the motion. I also think that if given more time the assembly should be done in a neater and cleaner way.

What are the implications?

The implications of my project prove that high couture involving electronics and mechanical parts are possible to fabricate by oneself. Haute couture, specifically involving electronic components, is currently seen as a process that is very far out of reach for normal individuals to produce or even procure, so I was very proud of myself for being able to produce something that was not only functional but aesthetically beautiful. I also learned that creating things and testing them out tangibly was a lot more productive than diving deep into a hole of math and precise measurements to fabricate complicated machines. I wasted a lot of time ideating and worrying about the nitty gritty details of the mechanics that were very hypothetical, but ended up realizing that some things could be planned better and quicker simply by making them physically and adjusting them to a final result. I learned so much more by creating a 2D physical mockup of the kinetic aspects of my project than staring at a chalkboard all day. Another application of this lesson was learned by making many different versions of my designs physically to prove their functionality, such as the press fit joints, packaging, and tubing. Rather than making detailed CAD models of each of these aspects in the hopes that they can be printed accurately and precisely to function, keeping my expectations low and just printing things and toying around with them sped up the process of design and fabrication.