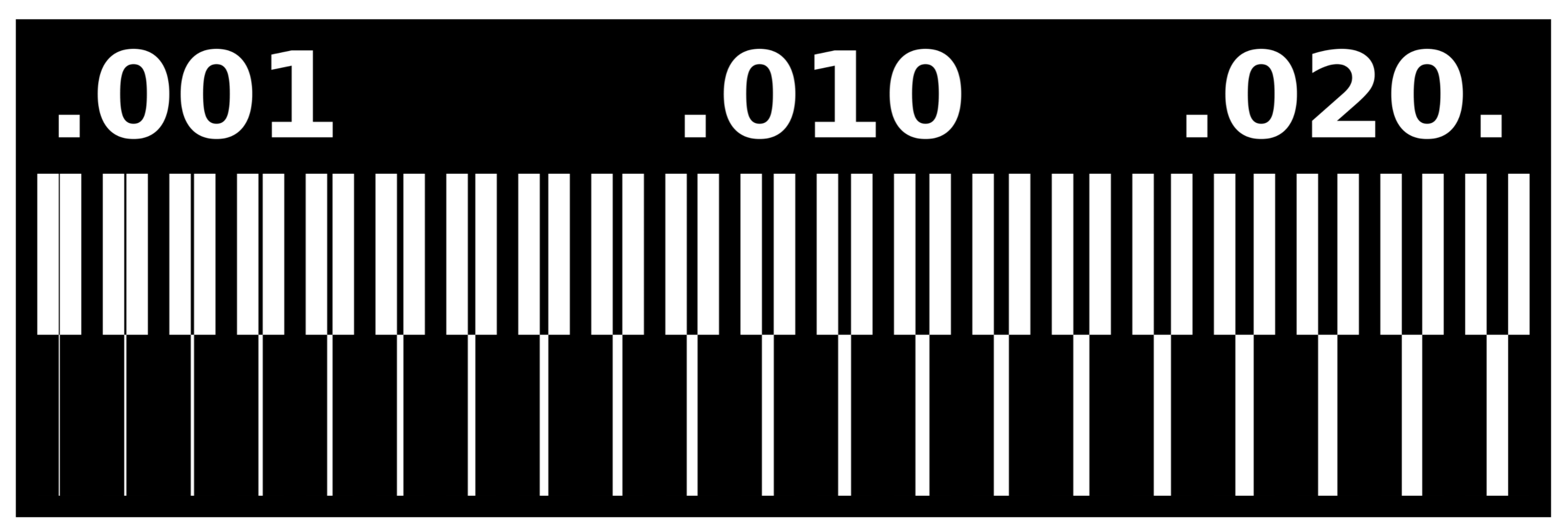

In order to characterize the design specifications for the process of producing our PCBs this week, we investigated how well the 1/64 bit would be able to mill out channels and around ridges of magnitudes between 0.001 and 0.20 inch. Using the trace shown in the image above, we were able to test these parameters.

Given that 1/64 = 0.015625, we can safely assume this bit will be unsuccessful in milling channels on the 0.001-0.015 inch range, but it will be interesting to see how successful it is at milling channels in the 0.016-0.02 inch range. As for the ridges (see bottom half of trace image file above), given that the spacing between them is significantly larger than 0.02 inches, we can assume the drill will be able to cut them out successfully with smoothness and accuraccy depending on the process and the quality/wear of the bit used.

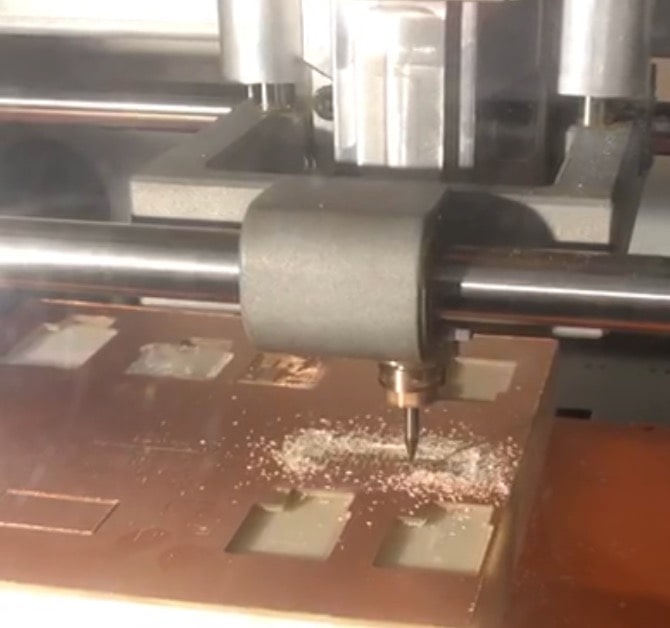

Kels, well-versed in the milling process by now, set out to obtain the smoothest results possible, taking a new 1/64 drill bit and configuring the milling machine the way that she had successfully when fabricating her circuit board. As you can see in the image above, she had no trouble achieving "white dust" on the first try.

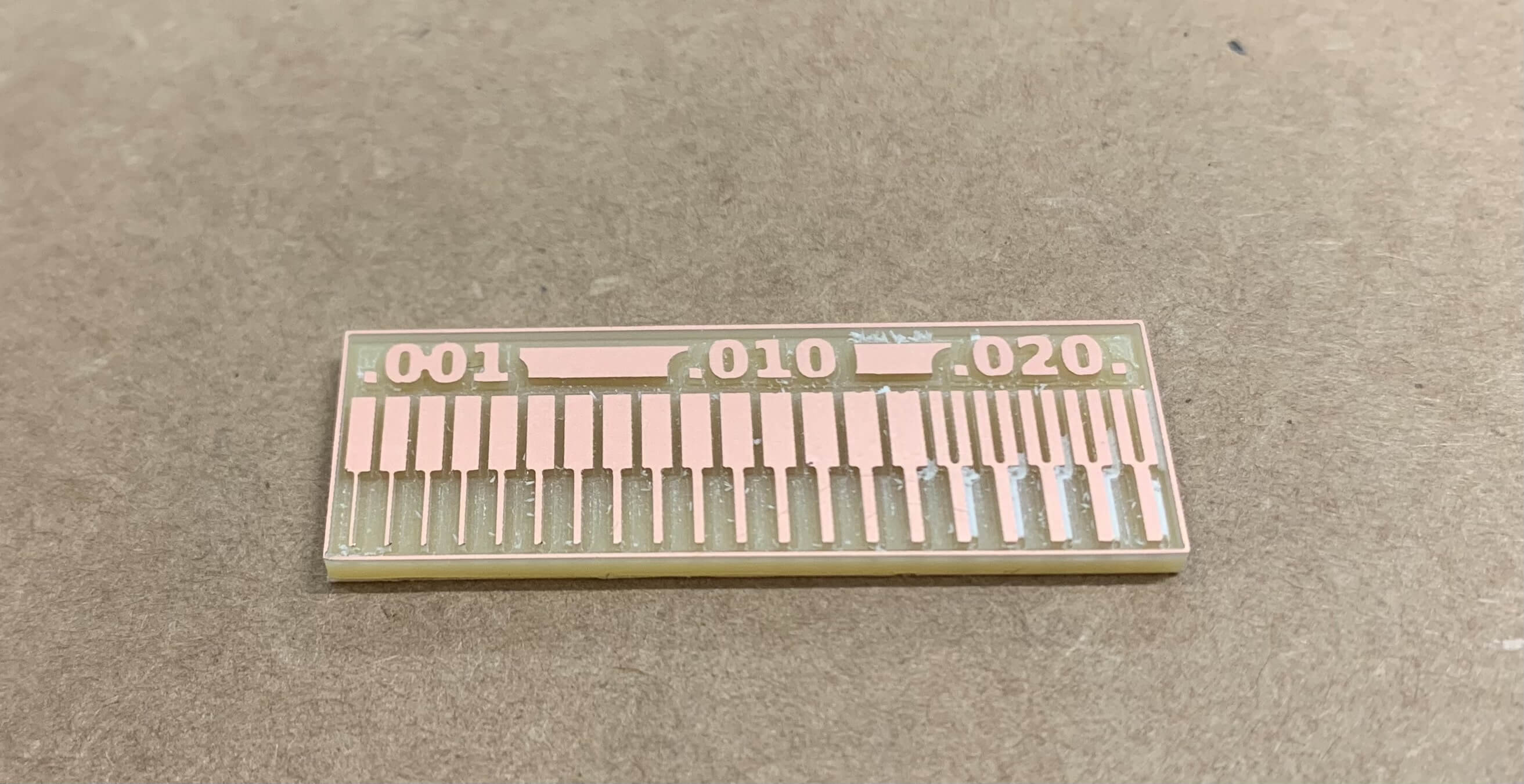

As expected, the 1/64 bit smoothly milled around all the ridges mostly successfully, with minor deformities on the end of the ridges (see image above) as a result of the thin, remaining copper ridges probably snagging on the bit.

Also as hypothesized, the bit was unable to successfully penetrate the areas where the trace image called for channels < 0.016 inches, but it is interesting to note that the machine does not even attempt to mill these widths, and is probably programmed not to do so since we input the bit size. There seems to be little issue with kerf with this new bit as smooth channels seem to appear about where we expected (halfway between 0.010 and 0.020 inch).

These results align logically with our hypothesis and give us an idea of the precision limitations of milling with 1/64 inch bits.

For further insights by our group investigating the comparison of using conical bits rather than the 1/64 millend, please refer to this link.