Machines Week

Toilet Paper Launcher, Marble Trapping Mechanisms, and overall speaking - machine mayhem

Machines week. We knew this week would come, but could we have been prepared what was yet to happen? No.

Ideation

We met as a group on Thursday morning to brainstorm machine concepts. Here’s the blue-sky list we ended up with:We then gave everyone in attendance three votes for their favorites. Top candidates after this were:

- Gingerbread-house-maker

- Toilet-paper-launcher

- Makeup-applier

- Handshaker/stabber

- Forger (not related to Jessica's extracurricular activities)

Then, we talked through logistics for each finalist before voting again on our favorite. The toilet-paper-launcher won by a significant majority, and we resolved to add some additional boobytraps inspired by Home Alone if spirals allowed.

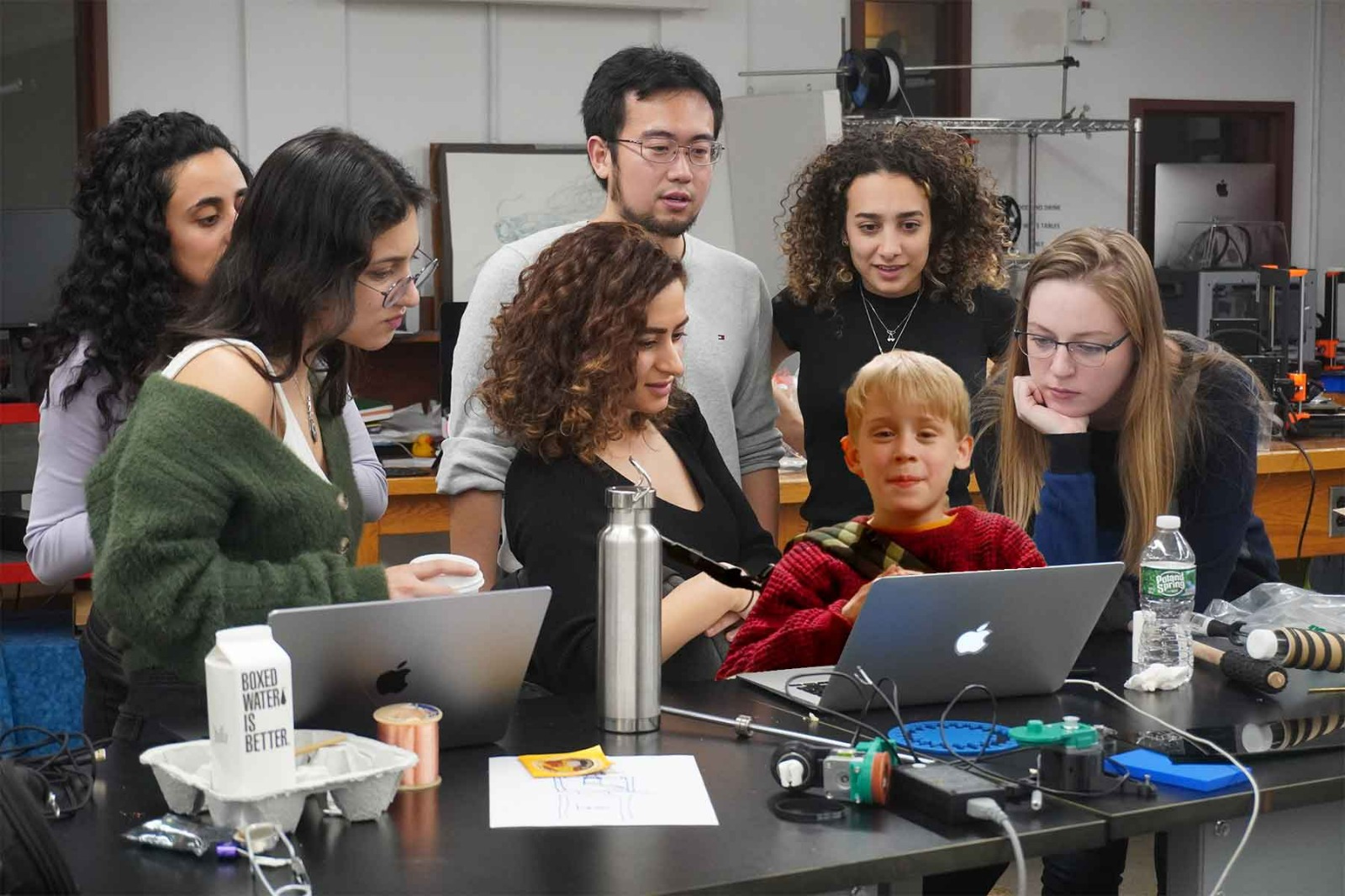

Dividing to Conquer

Next, we split up into teams to tackle each sub-component of our larger system, plus logistical support.- Photographer / videographer: Nix

- Video editing: Alexia

- Software: Caine, etc. etc.

- Dispenser/unspooler: Claire, Noy, Rehana, Selin, Sondos

- Aimer: Danny >

Dispensing Team

Engineering a dispensing mechanism

Day 1

We started out by comparing several different options for launching mechanisms:- air

- motorized feeder wheels, and

- combination of the two.

Noy and Selin found videos of leaf blower systems that sent toilet paper soaring a considerable height and distance solely with air.

Claire suggested a motorized feeder wheel and follower to unspool the paper and hopefully throw it forward at the same time.

Selin found a video of a toilet paper unspooler (and folder!) where the toilet paper roll itself was motorized to spin. Nathan was an advocate for this last idea.

First, we decided to experiment with an air-powered system where we would build our own fan using a motor from the shop, 3D printing our blades, and creating our casing. For proof of concept, we hooked up one of the soldering airguns to test its airflow… and quickly discovered it was nowhere near powerful enough.

Some googling revealed that leaf blowers typically move air at 90-250mph. There was no way we were going to achieve comparable speeds with the motor we had.

Meanwhile, Nathan sent a message in the Slack suggesting a feeder wheel and follower similar to Claire’s but in reverse (with the feeder wheel on the bottom and the follower on top).

We decided to try a version of this motorized feeder, switching the follower back to the bottom so that the feeder wheel would be less likely to get tangled. To create prototype feeder and follower wheels, Rehana and Selin wrapped a rubberized belt material around two stiff cardboard tubes and glued the ends in place.

To test the motor’s capabilities, we hooked it up to a benchtop power. Wanting to be able to see the output, we wrapped a rubber band around the rotational shaft, and looped a zip tie around this. Then, when we cranked up the voltage, we could see the movement of the zip tie.

This worked, so we graduated to trying to attached our feeder roller to the motor shaft. Claire wrapped the shaft with a few rubber bands for grip, and then wedged a rubberized LEGO tire over these. This was almost wide enough to friction-fit into the center of our feeder wheel but not quite, so Claire added some blue tape and medical vinyl for grip. This did the trick, and we were able to squeeze the homemade system onto the motor shaft and into the hollow roller. Now we could spin the feeder wheel with the motor!

We tested out our system, which worked well... until we cranked the voltage high enough that the centrifugal force ripped the belt off of its glue and flung it around at us. This is why we wear safety glasses!

We replaced the belt with strong double-sided tape and tried again. This time, we got a little functionality but not much. We also had trouble maintaining even contact between the feeder roll and follower. Because the follower was cantilevered off its connection point to the motor, one end wanted to droop slightly lower than the other. This resulted in more downward force at one particular spot, which was enough to friction-burn a hole through the toilet paper there.

Eventually, through pure trial and error, we landed on a configuration that worked! Instead of the feeder wheel being stacked directly on top of the follower, we discovered that it needed to be stacked diagonally to it, set slightly back, in order to achieve the throw we were hoping for.

It was an exciting end to the evening, as we finally had proof of concept! We decided to add a fan back into the equation as well, hoping to supply some additional lift.